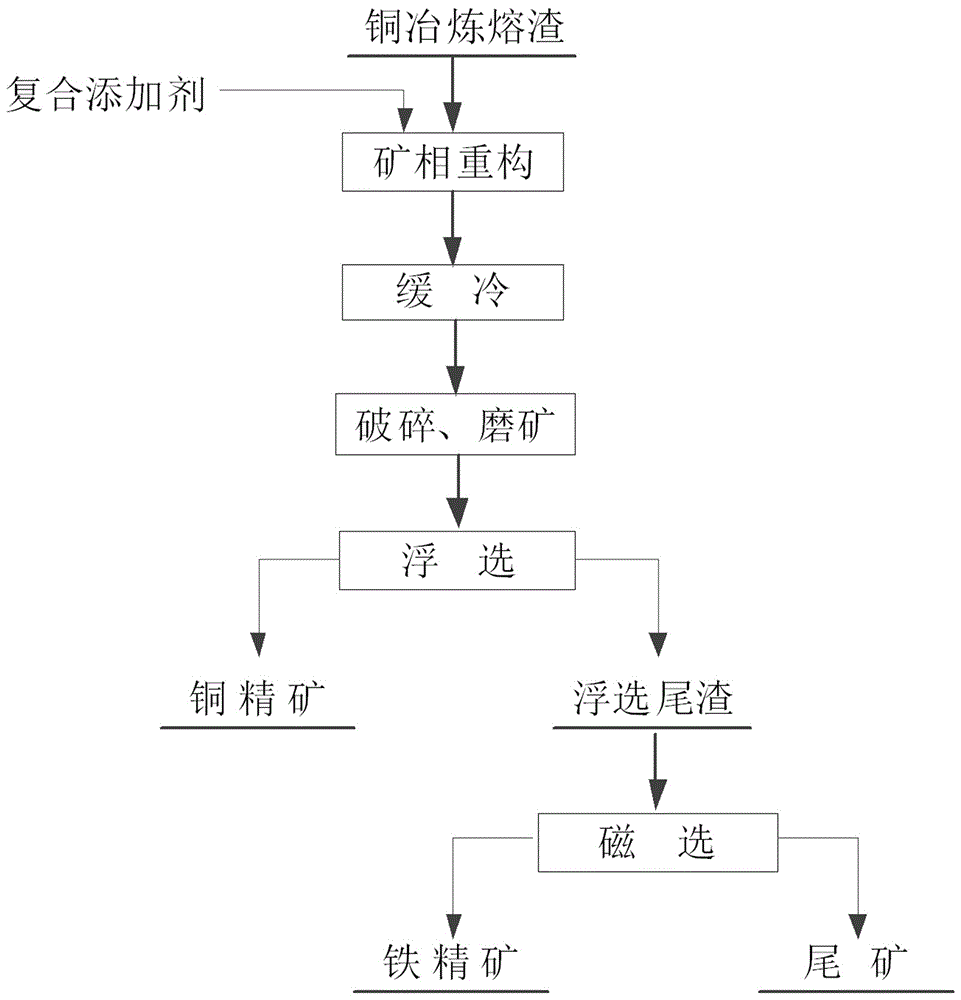

Process for comprehensively recycling copper and iron through ore phase restructuring of copper smelting molten slag

A technology for copper smelting slag and molten slag, applied in the field of industrial waste slag resource utilization, can solve the problems of large fluctuation of flotation index, iron utilization rate of less than 1%, poor adaptability of copper smelting slag, etc., to achieve effective separation and recovery, The effect of reducing fayalite formation and tailings stockpile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The composite additive of the present invention adopts the following preparation method: after drying quicklime, manganese monoxide, pyrite, chalcopyrite and iron oxide, then weigh and mix according to the mass ratio, to obtain Composite additives.

[0025] In the following examples, crushing and grinding are performed by coarsely crushing the modified slag to -5 mm, then crushing to -1 mm by high-pressure roller mill, and then grinding to fineness in a ball mill.

Embodiment 1

[0029] The iron grade in the copper smelting slag depleted by the electric furnace is 39.10%, the copper grade is 0.83%, and the compound additives are added according to 20% of the mass of the copper smelting slag (45% of quicklime, 15% of manganese monoxide, 20% of ferric oxide, yellow iron 10% ore, 10% chalcopyrite) for slag modification, modified slag after slow cooling, crushing, grinding, flotation to obtain copper coarse concentrate and flotation tailings, flotation tailings after wet magnetic separation , to obtain iron concentrate and magnetic separation tailings. Modification is carried out at a temperature of 1250°C, a cooling rate of 1.5°C / min, and a cooling end temperature of 900°C. Conditions for the modified slag in copper flotation: grinding fineness -0.045mm90.2%; butyl xanthate 200g / t The dosage of inhibitor is 3.6kg / t; under the condition of magnetic separation intensity of 0.17T, the crude concentrate grade of copper is 11.04%, the recovery rate of copper i...

Embodiment 2

[0031] The iron grade in the copper smelting slag depleted by the electric furnace is 39.10%, the copper grade is 0.83%, and the compound additives are added according to 18% of the mass of the copper smelting slag (50% of quicklime, 10% of manganese monoxide, 15% of ferric oxide, yellow iron 15% ore, 10% chalcopyrite) for slag modification, modified slag after slow cooling, crushing, grinding, flotation to obtain copper coarse concentrate and flotation tailings, flotation tailings after wet magnetic separation , to obtain iron concentrate and magnetic separation tailings. The modification is carried out under the conditions of melting temperature 1250°C, cooling rate 1.5°C / min, and cooling end temperature 900°C. Conditions of modified slag in copper flotation: grinding fineness -0.045mm90%; butyl xanthate 200g / t; The dosage of inhibitor is 3.0kg / t; under the condition of magnetic separation intensity of 0.17T, the copper rough concentrate grade is 10.01%, the copper recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com