High-aluminum slag system for smelting of nickel flash furnace and application of high-aluminum slag system

A flash furnace and high-alumina slag technology is applied in the field of high-alumina slag to achieve the effect of reducing the viscosity of the slag and reducing the melting temperature of the slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

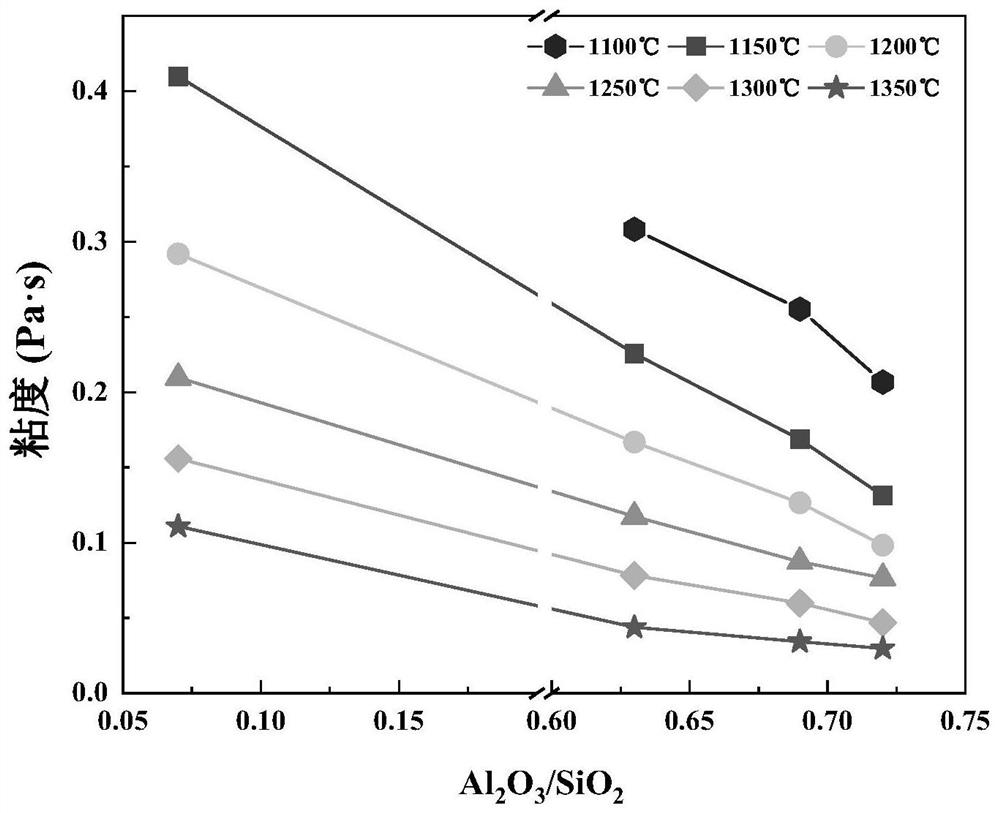

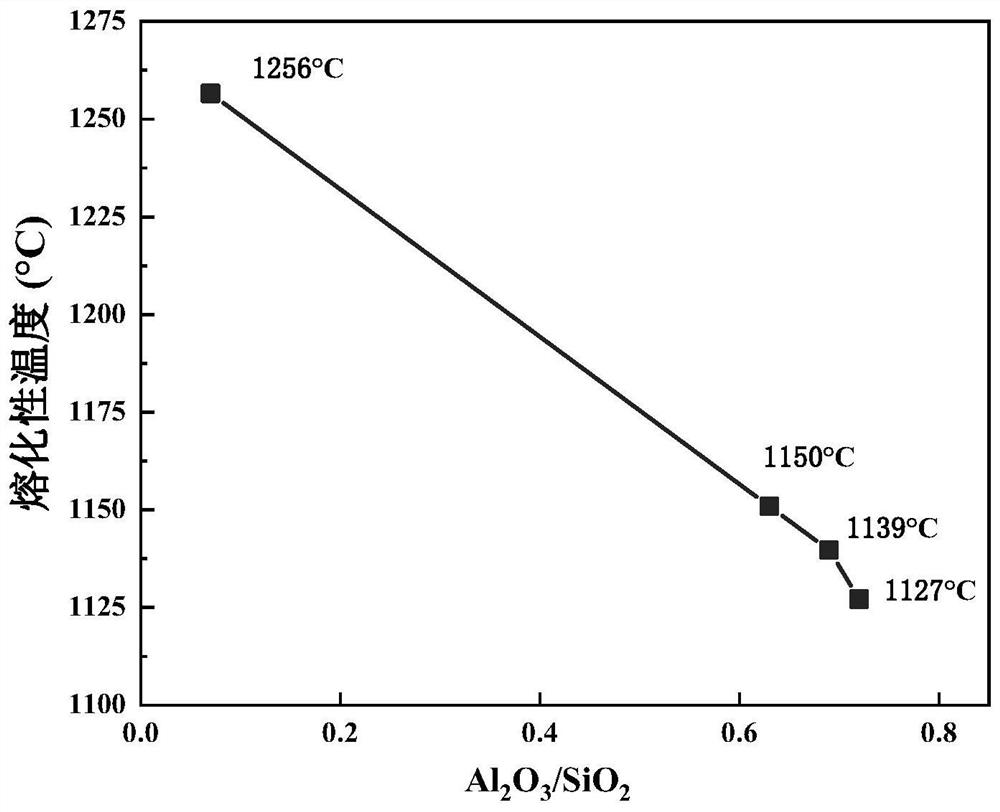

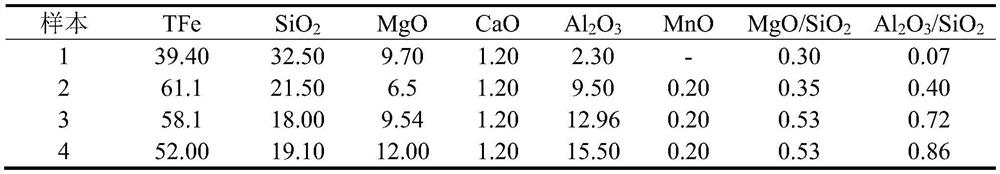

[0023] Table 1 is the composition table of the main components of the nickel flash furnace smelting slag system. The substances in the table are expressed in mass percentages. Sample No. 1 in the table is the composition of the existing nickel flash furnace smelting slag system. Examples 1 to 3 of the present invention are composed of high-alumina slag.

[0024] Table 1

[0025]

[0026] Use chemically pure reagents to mix slag according to Table 1, use the Brookfield DV-II+ high temperature melt physical property tester, and use the rotation method to conduct viscosity-melting temperature test experiments on the slag system in Table 1. The results are as follows figure 1 and figure 2 shown. During the viscosity measurement, about 150 g of the sample was placed in the Pt crucible. The sample was heated to 1500°C at a speed of 5°C / min, and kept at a temperature of about 240min to fully react. The spindle is slowly injected into the fluid slag at a low rotational speed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com