Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

433results about How to "To achieve the purpose of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for coal tar suspension bed of heterogeneous catalyst

ActiveCN101885982ATo achieve the purpose of recyclingImprove utilization efficiencyTreatment with hydrotreatment processesFuel oilBULK ACTIVE INGREDIENT

The invention relates to a hydrogenation method for a coal tar suspension bed of a heterogeneous catalyst. The method comprises processes of coal tar raw material pretreatment and distillatory separation, coal tar heavy fraction suspension bed hydrogenation cracking and conventional light fraction oil extraction, wherein the suspension bed hydrogenation reaction temperature is between 320 and 480DEG C, the reaction pressure is 8 to 19MPa, the volume air speed is 0.3 to 3.0h<-1>, the hydrogen oil volume ratio is 500 to 2,000, the catalyst is a powdery granular coal tar suspension bed hydrogenation catalyst of a single metal active ingredient containing molybdenum, nickel, cobalt, tungsten or iron or a composite multi-metal active ingredient, the adding amount of the catalyst is based on the ratio of the metal quantity of the active ingredient to the weight of the coal tar raw materials of 0.1: 100-4: 100, most of tail oil containing the catalyst after lightweight oil is separated froma hydrogenation reaction product is directly circulated to a hydrogenation bed reactor, a small part of tail oil is subjected to catalyst removal treatment and then circulated to the hydrogenation bed reactor to be subjected to further lightweight treatment, and the heavy oil is totally or furthest circulated. The method fulfills the purposes of maximum production of the lightweight oil in the coal tar and cyclic utilization of the catalyst, and greatly improves the utilization efficiency of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

Separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption

ActiveCN101559320AIncrease concentrationEasy to separateSolidificationLiquefactionHydrogenHydrocarbon mixtures

The invention relates to a separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption. The separation method comprises the following steps: Fischer-Tropsch synthesis gas pretreated is conveyed to a demethanizer after being cooled; the top of the demethanizer separates hydrogen and other light gas, methane, part of C2 fraction and little amount of C3; the mixed gas enters an absorption tower and uses C3, C4 or C5 or hydrocarbon mixture as an absorbing agent to absorb C2 and heavier components; the products of the top of the absorption tower comprise hydrogen and other light gas, methane, the little balanced amount of C2 and the absorbing agent; the products of the bottom of the tower are components above C2 and little amount of hydrogen and methane; the materials are conveyed to the demethanizer for further absorbing C2 and heavier fraction and removing the methane and lighter components therein. The light hydrocarbon mixture of the bottom of the demethanizer can adopt conventional light hydrocarbon separation method to separate out various light hydrocarbon products with needed purity and recycling rate. Compared with the prior art, the invention has the advantages of simple process, low energy consumption and high recycling rate of various components and the like.

Owner:WISON ENG

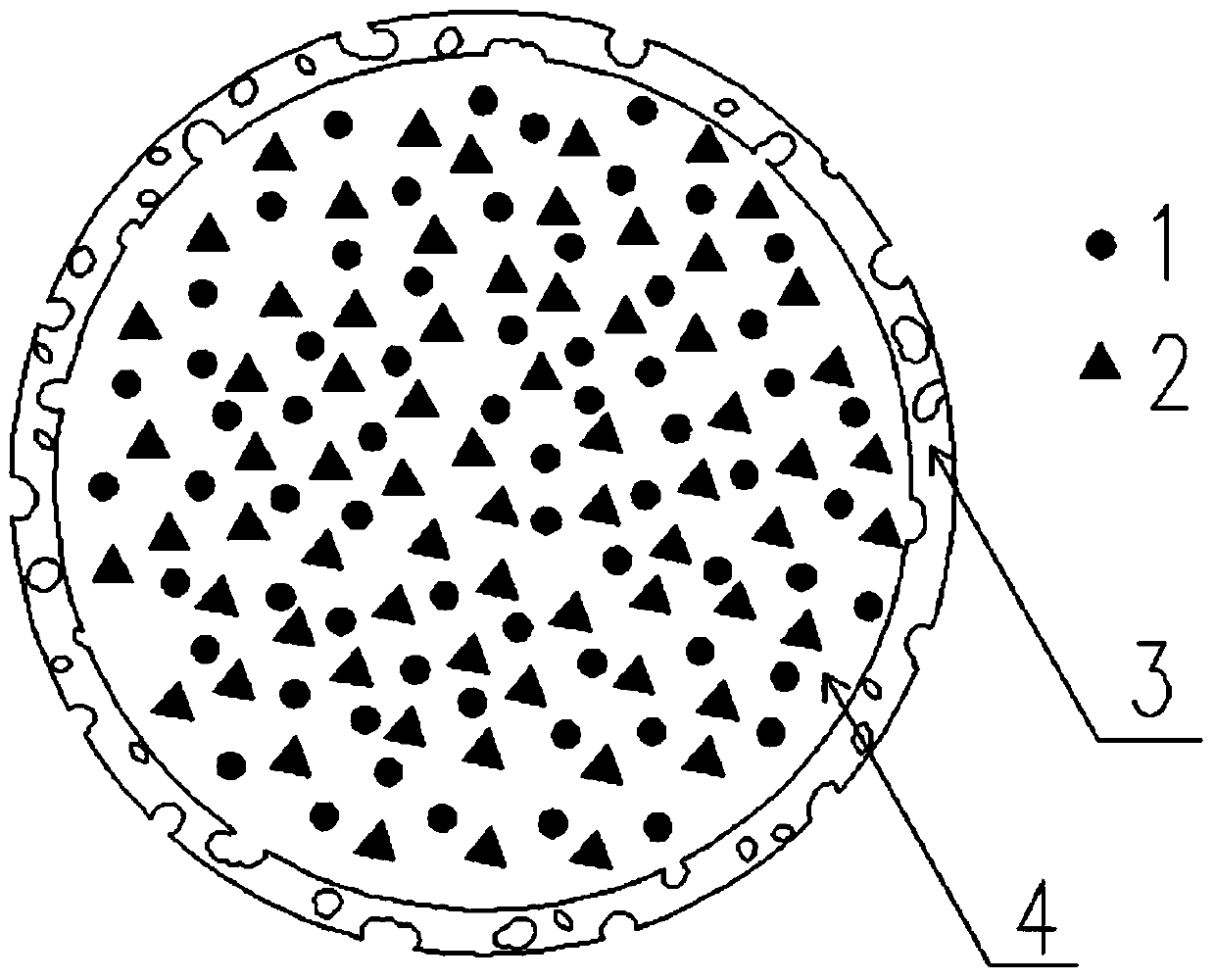

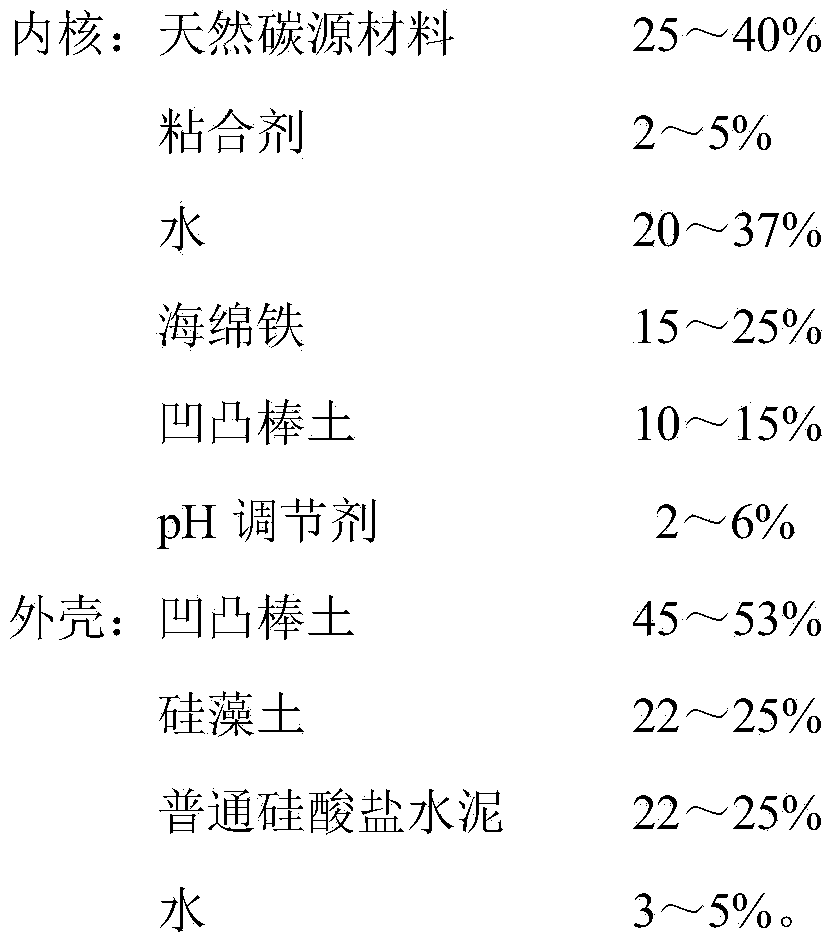

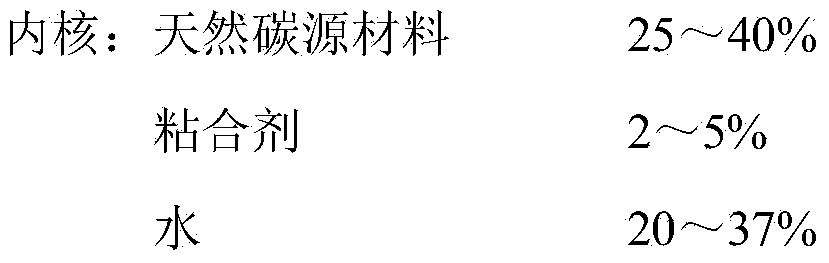

Carbon-iron microbattery slow-release carbon source filler and preparation method thereof

InactiveCN103723824AEliminate ChromaImprove biodegradabilityTreatment with anaerobic digestion processesAdhesivePortland cement

The invention discloses a carbon-iron microbattery slow-release carbon source filler and a preparation method thereof, belonging to the field of restoration of underground water pollution. The carbon-iron microbattery slow-release carbon source filler is composed of an inner core and an outer shell, wherein the inner core is made from organic carbon source mixed materials, and the outer shell is prepared from cement and high-permeability raw materials. The inner core is prepared from the following components in percentage by mass: 25-40% of natural carbon source material, 2-5% of adhesive, 20-37% of water, 15-25% of spongy iron, 10-15% of attapulgite and 2-6% of pH regulator; and the outer shell is prepared from the following components in percentage by mass: 45-53% of attapulgite, 22-25% of kieselguhr, 22-25% of ordinary Portland cement and 3-5% of water. By using the filler and method, the particle strength of the inner core can be enhanced to 70-105N / particle, and the thickness of the slow-release outer shell is lowered to 1-1.5 mm, so that the carbon-iron can be uniformly distributed in the material.

Owner:NANJING UNIV

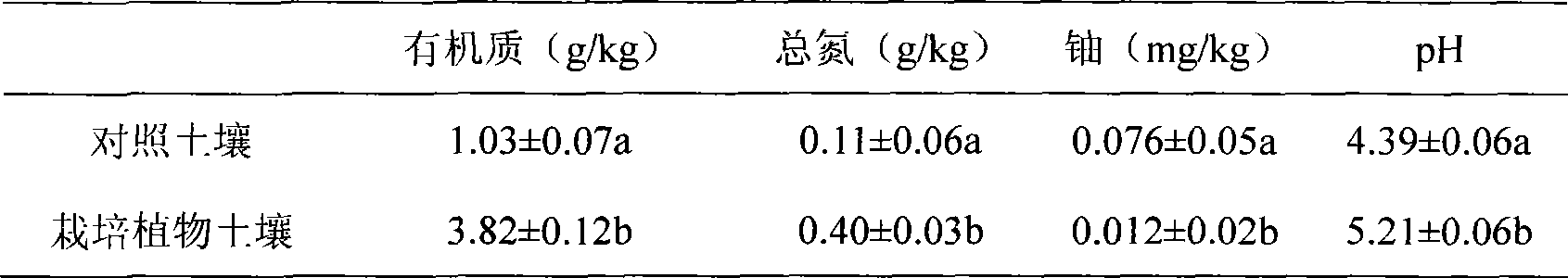

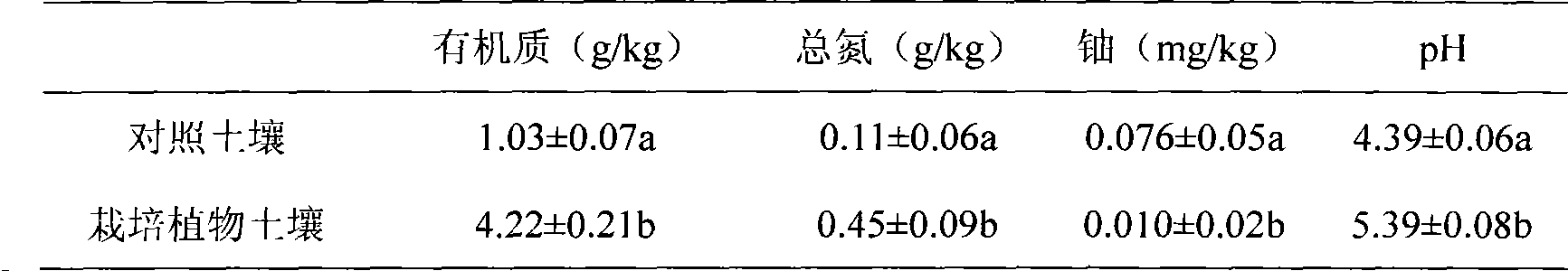

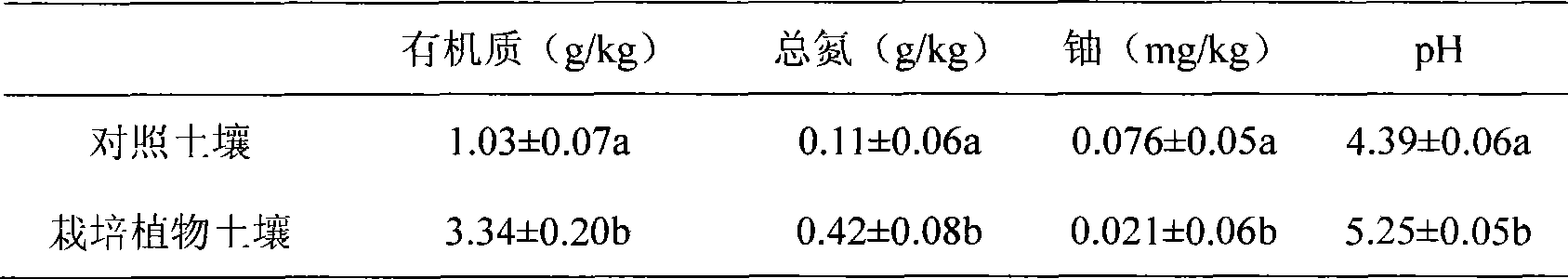

Method for repairing and improving soil polluted by uranium mine tailings

InactiveCN101502843AEnhanced efficiency of fixing uraniumInhibit migrationContaminated soil reclamationAeschynomene indicaVegetation

The invention discloses a method for restoring and improving uranium tailing residues-contaminated soil, the employed materials comprise Aeschynomene indica, Miscanthus floridulus and Imperatacylindrica, plant ash and cow dropping, the plant ash is made by burning the Miscanthus floridulus and the Imperatacylindrica. The plant ash and the cow dropping is formulated into a mixed fertilizer in accordance with a proportion to be fertilized in a plant ditch that is built in uranium tailing residues-contaminated region, the three plants of the Aeschynomene indica, the Miscanthus floridulus and the Imperatacylindrica are planted in groups in the plant ditch. By using the method, dense vegetation can be constructed in a very short time to prominently increase soil nitrogen, organic matters and pH value, and meanwhile, the soil root density is increased and the content of soil water-soluble uranium is reduced obviously. The method has the advantages of simple operation, low cost, good efficiency of preventing the uranium from transfer and diffusion, and beautifying the environment. The technique can be used in reconstructing vegetation in a degraded ecosystem of mines and greening expressways.

Owner:HUNAN UNIV OF SCI & TECH

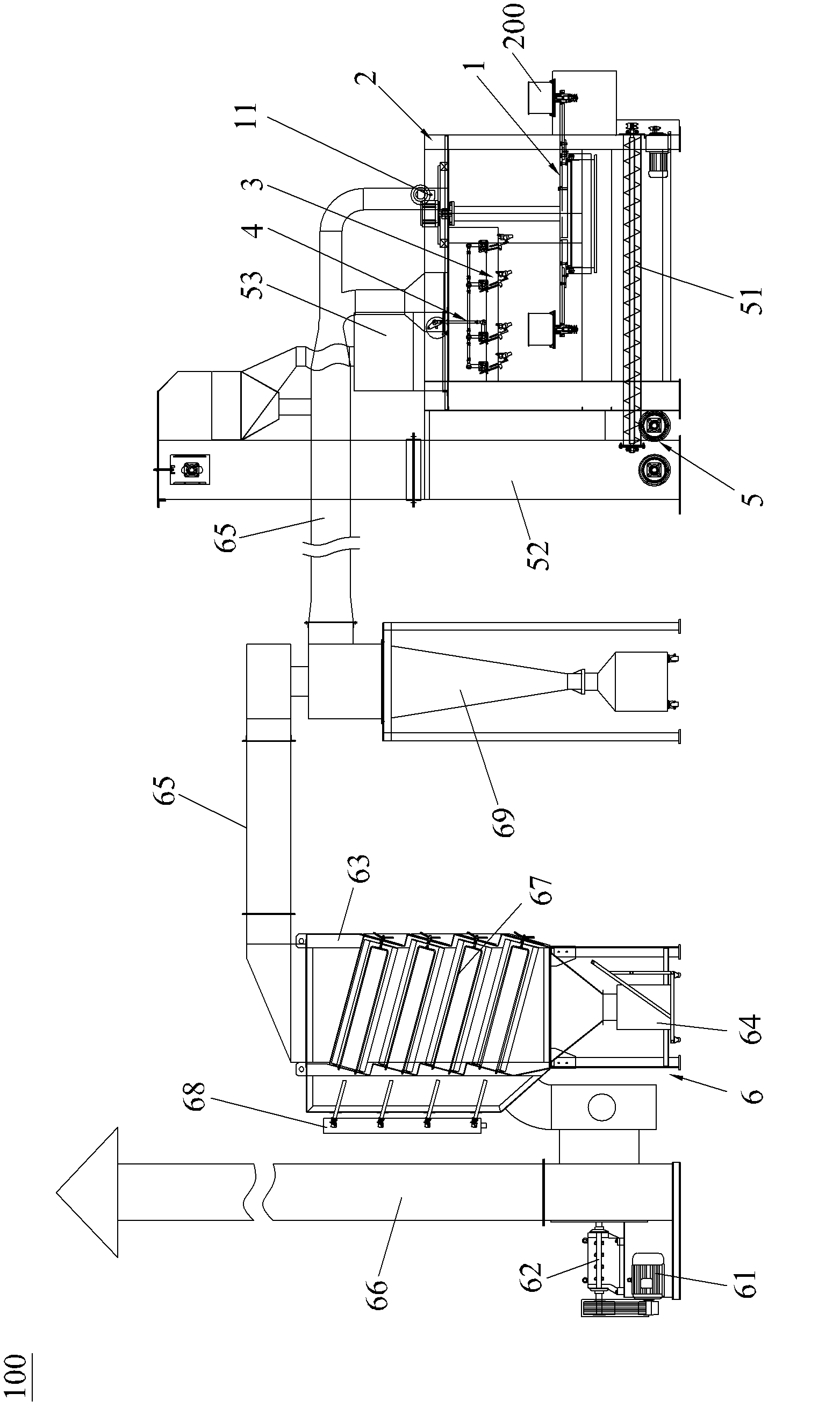

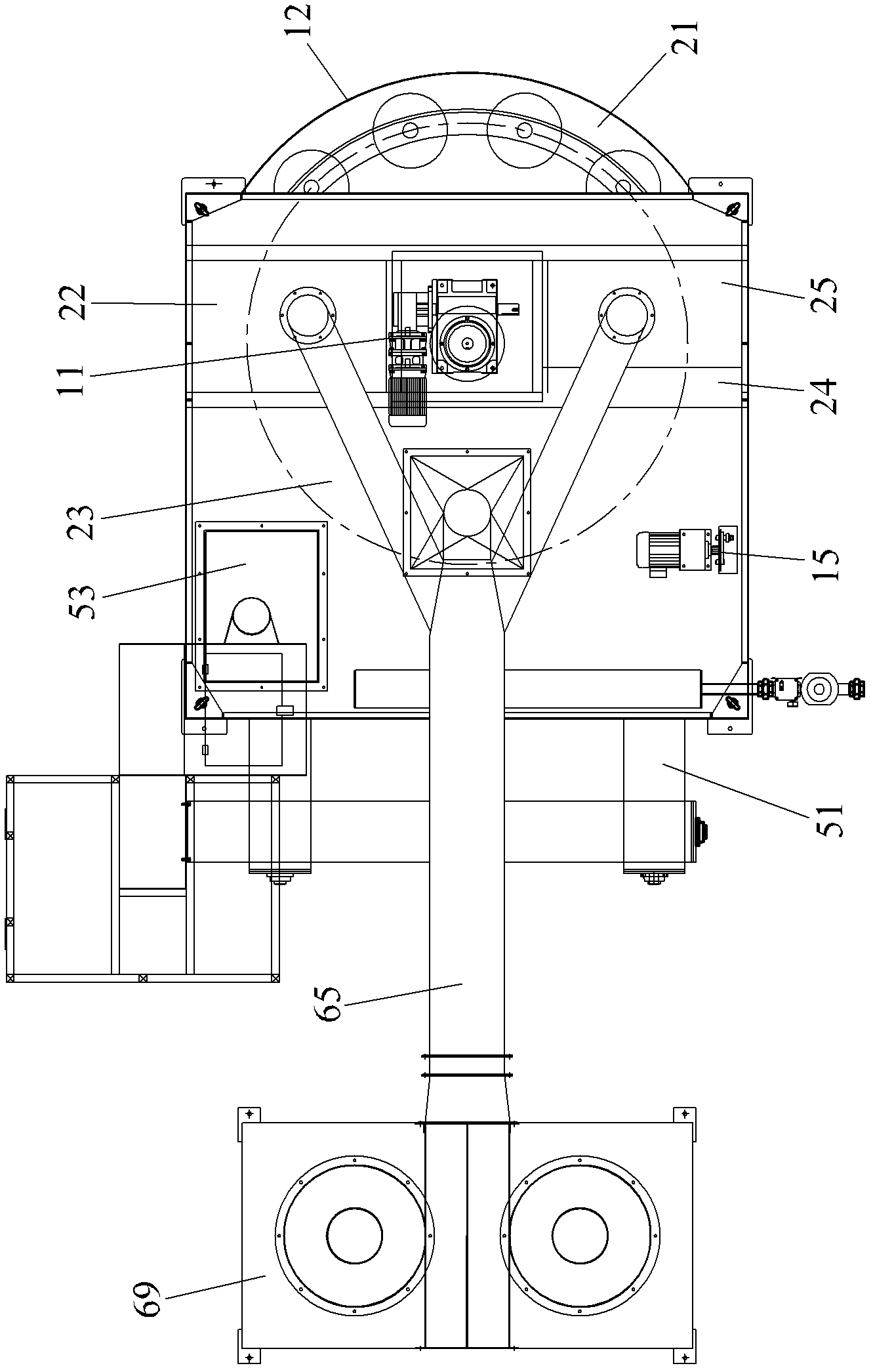

Rotating table type sandblasting machine

InactiveCN102528673ARealize automatic sandblastingAvoid pollutionBlast gunsAbrasive machine appurtenancesEngineeringElectric control

The invention discloses a rotating table type sandblasting machine, which comprises a rotating table conveying system, a working bin, a spray gun, an abrasive material recovering and circulating system, a dust removing system and an electric control system, wherein a sandblasting workpiece rotates along with the rotating table conveying system; the working bin comprises a workpiece loading and unloading region, a first isolating chamber, a sandblasting chamber, a blowing-off chamber and a second isolating chamber; the spray gun is arranged in the sandblasting chamber; the abrasive material recovering and circulating system comprises a horizontal conveying device, a vertical elevating device and a separating device; the dust removing system is communicated with the first isolating chamber, the sandblasting chamber, the second isolating chamber and the separating device; and the electric control system is electrically connected with the rotating table conveying system, the spray gun, the abrasive material recovering and circulating system and the dust removing system respectively, and is used for controlling operation thereof. The rotating table type sandblasting machine has high automatic degree and high processing efficiency, and is capable of effectively reducing the production cost and environmentally-friendly.

Owner:广东创捷机械设备有限公司

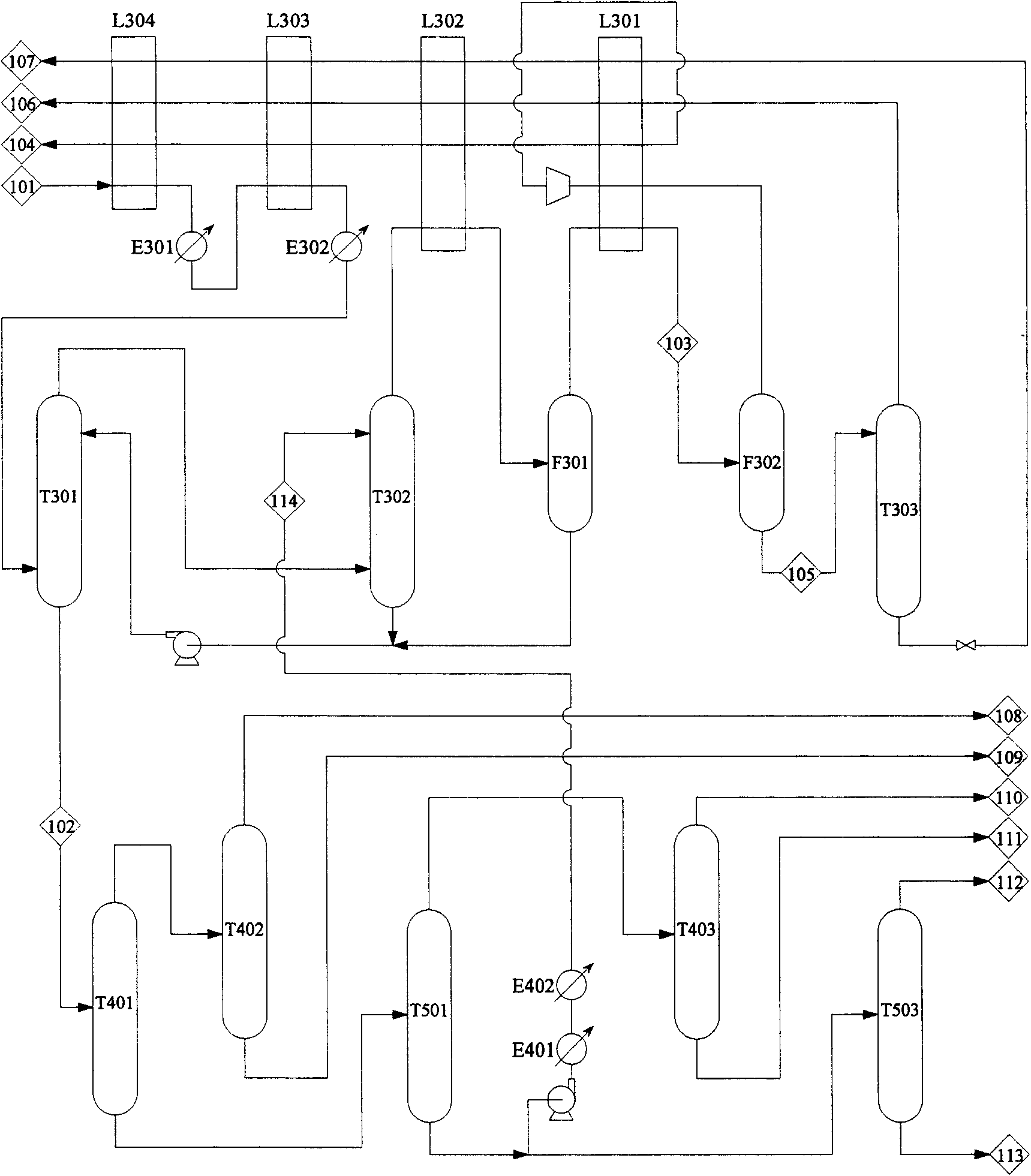

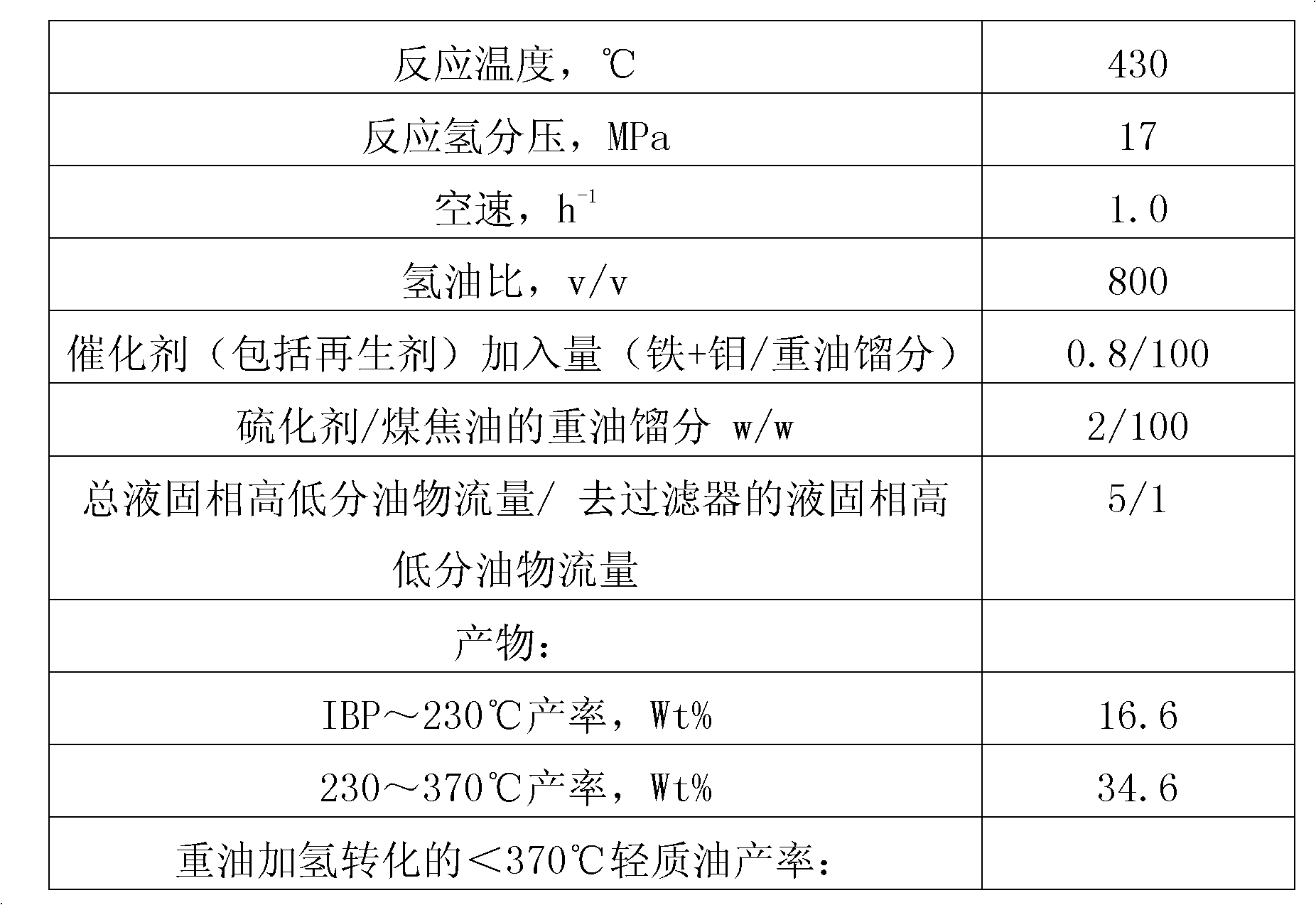

Catalytic hydrogenation method and catalytic hydrogenation apparatus for coal tar

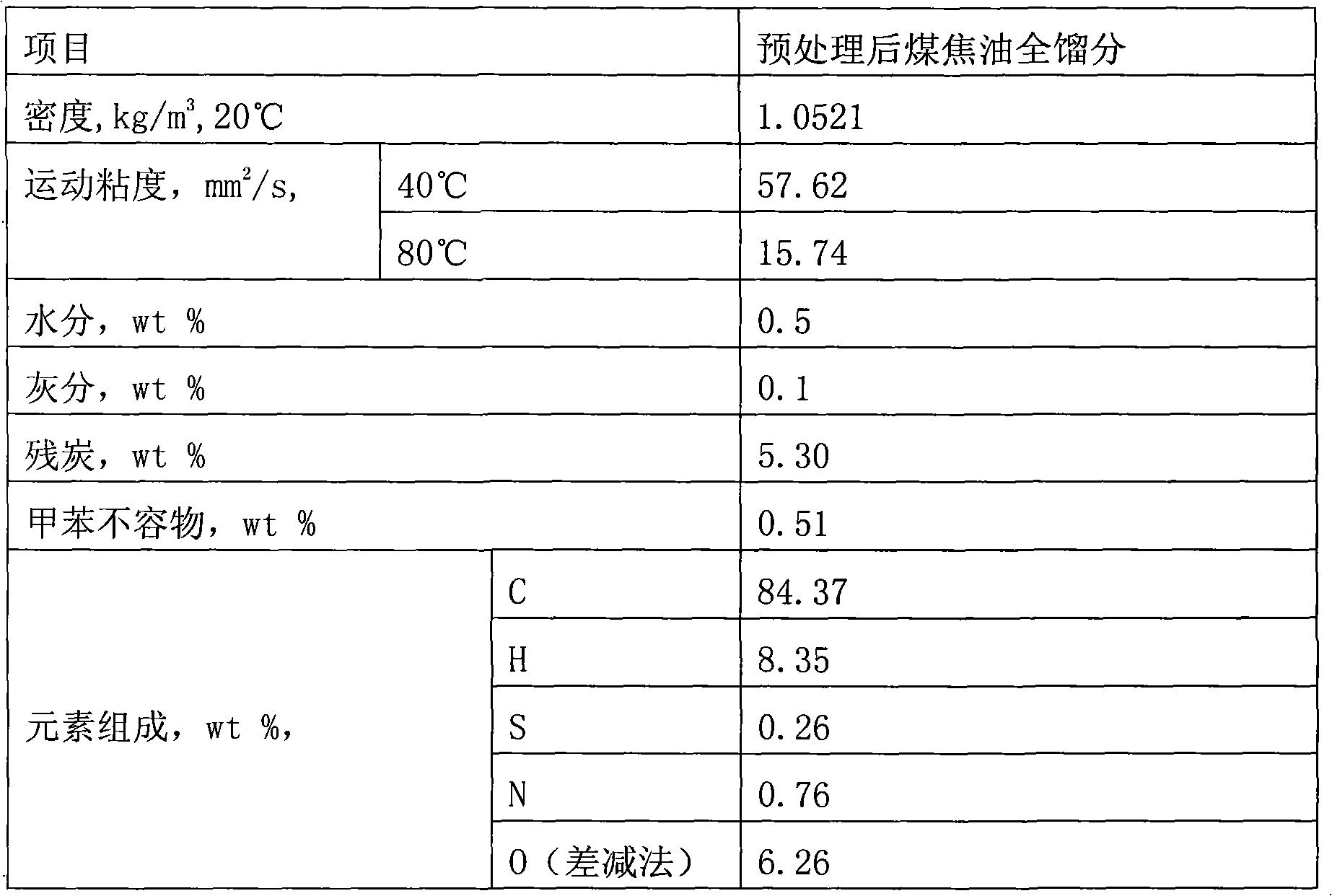

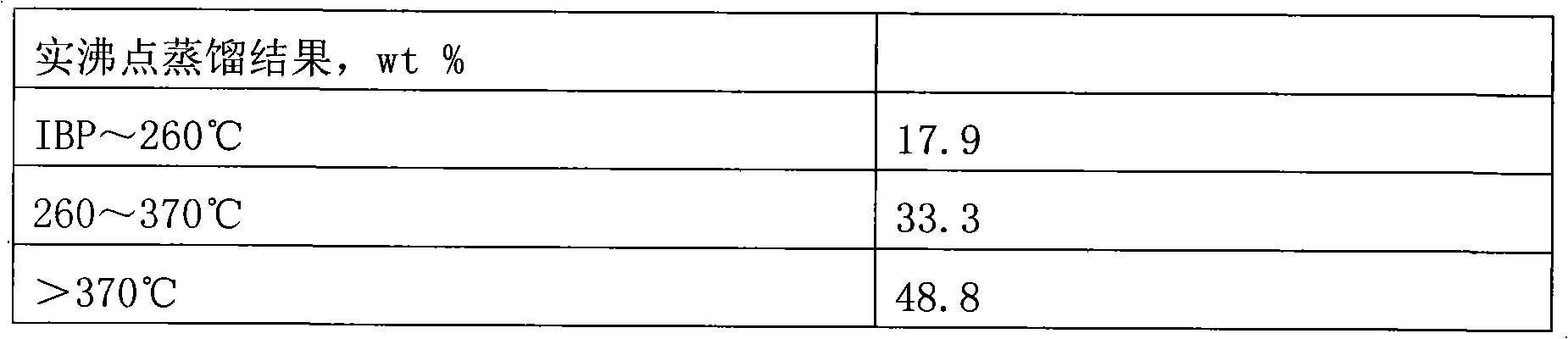

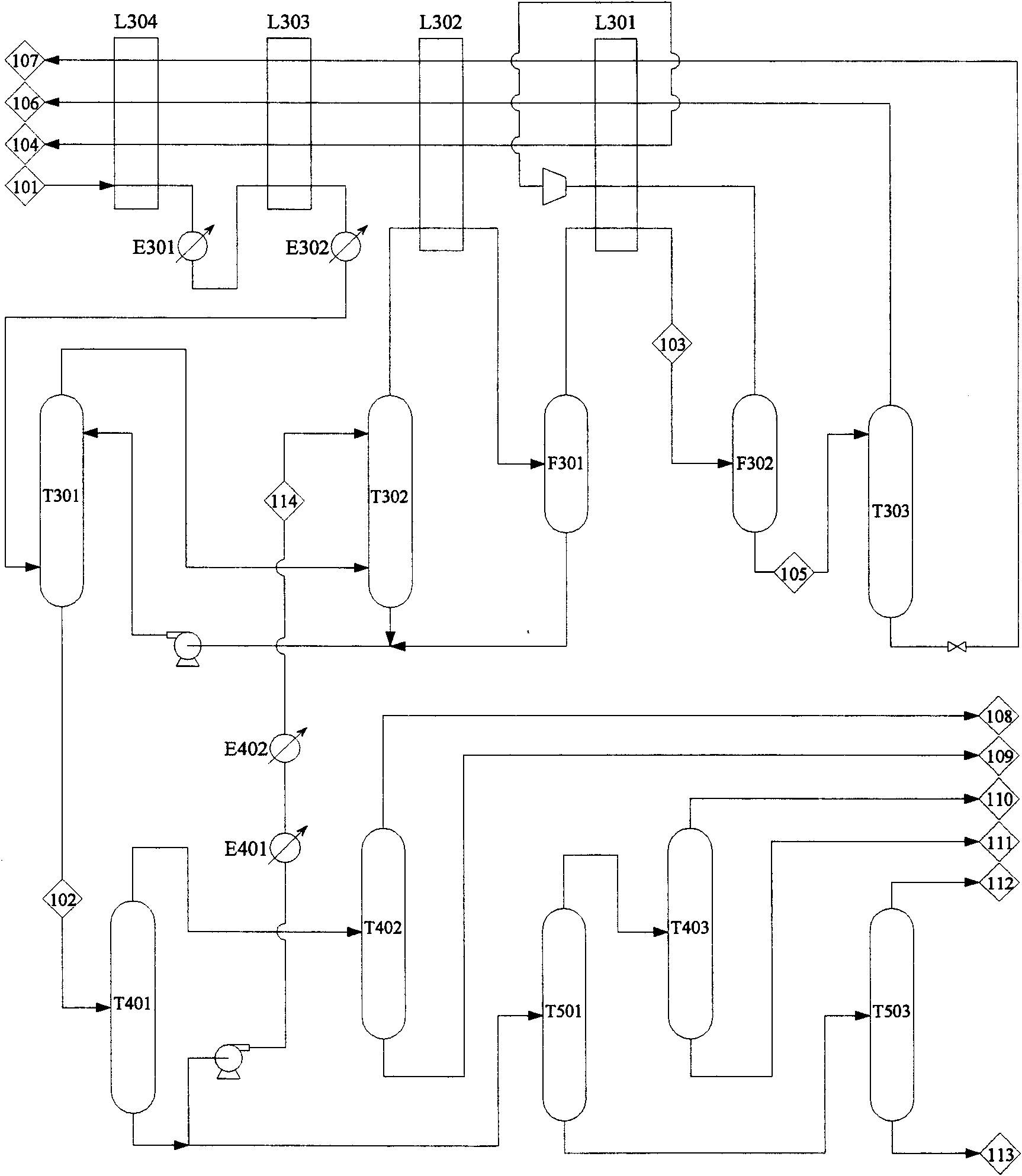

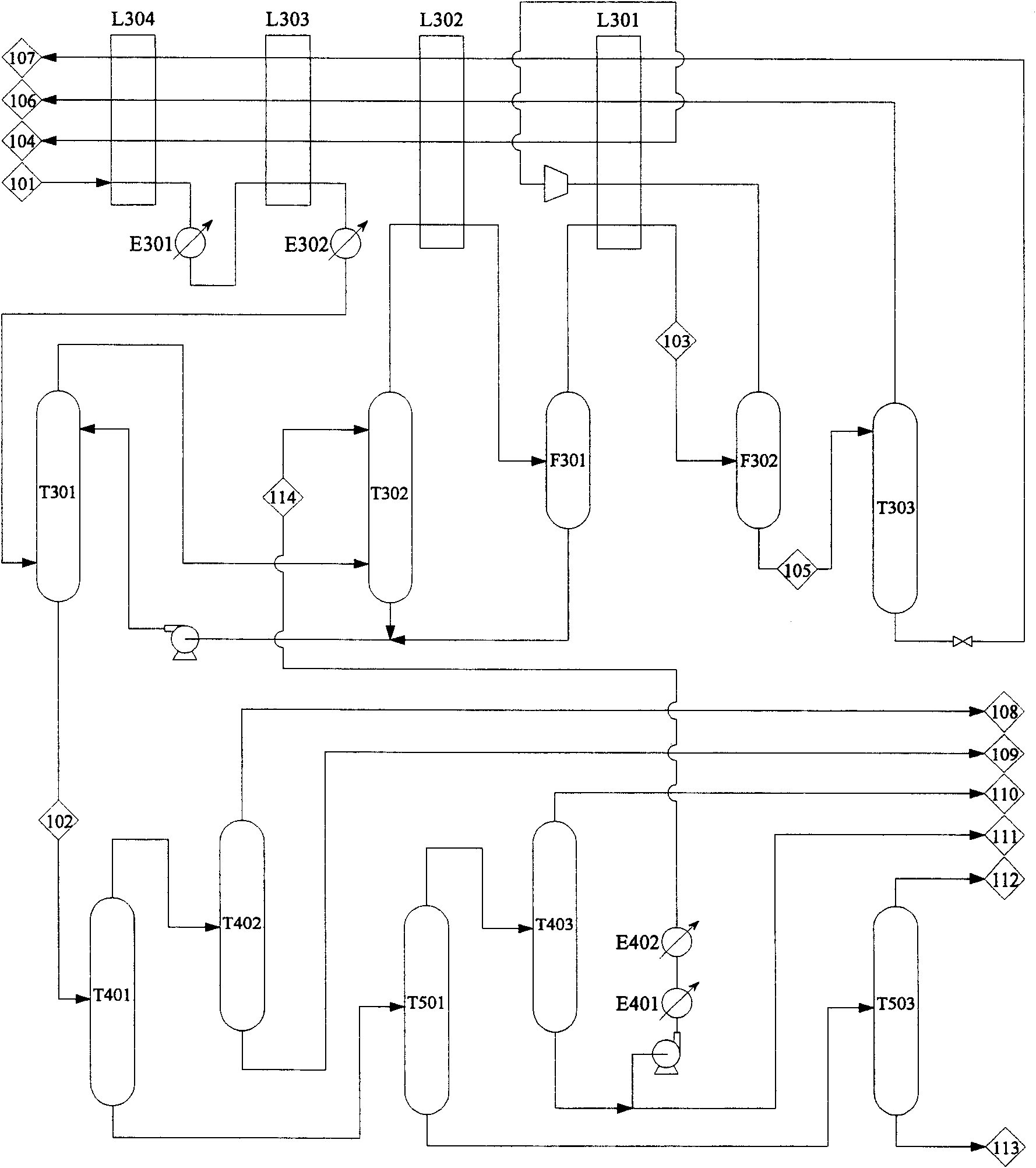

ActiveCN102977916ALow viscosityLow densityTreatment with hydrotreatment processesSolid phasesChemistry

The invention relates to a catalytic hydrogenation method and a catalytic hydrogenation apparatus for coal tar. The catalytic hydrogenation method comprises the following steps of performing atmospheric distillation on raw materials of the coal tar to obtain at least a carbolic oil fraction, a diesel fraction and a heavy oil fraction; performing slurry-bed hydrocracking on the heavy oil fraction to obtain a slurry-bed hydrocracking product; separating the slurry-bed hydrocracking product to obtain a liquid phase and solid phase mixed flow of high pressure separated oil and low pressure separated oil and a hydrogen-rich gas; filtering a part of the liquid phase and solid phase mixed flow of the high pressure separated oil and the low pressure separated oil to obtain a catalyst residue and a filter solution; performing atmospheric distillation separation on the filter solution and the residual liquid phase and solid phase mixed flow of the high pressure separated oil and the low pressure separated oil to obtain a light fraction and a catalyst-containing tail oil at the bottom of a tower; and recycling the catalyst-containing tail oil at the bottom of the tower to the slurry-bed hydrocracking reaction for reprocess. The method decreases the difficulty of catalyst residue separation and reduces the content of organic materials in the catalyst residue, so that the utilization rate of the raw materials and the efficiency of the catalyst can be increased.

Owner:CCTEG CHINA COAL RES INST

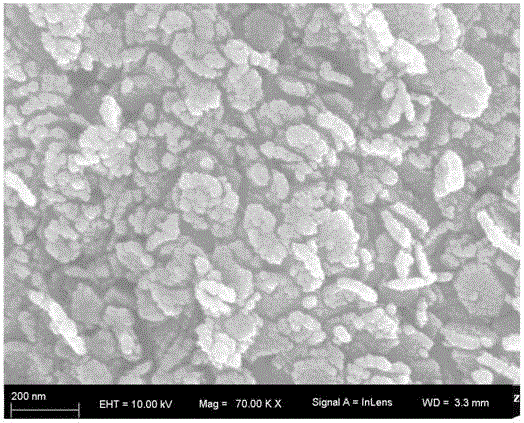

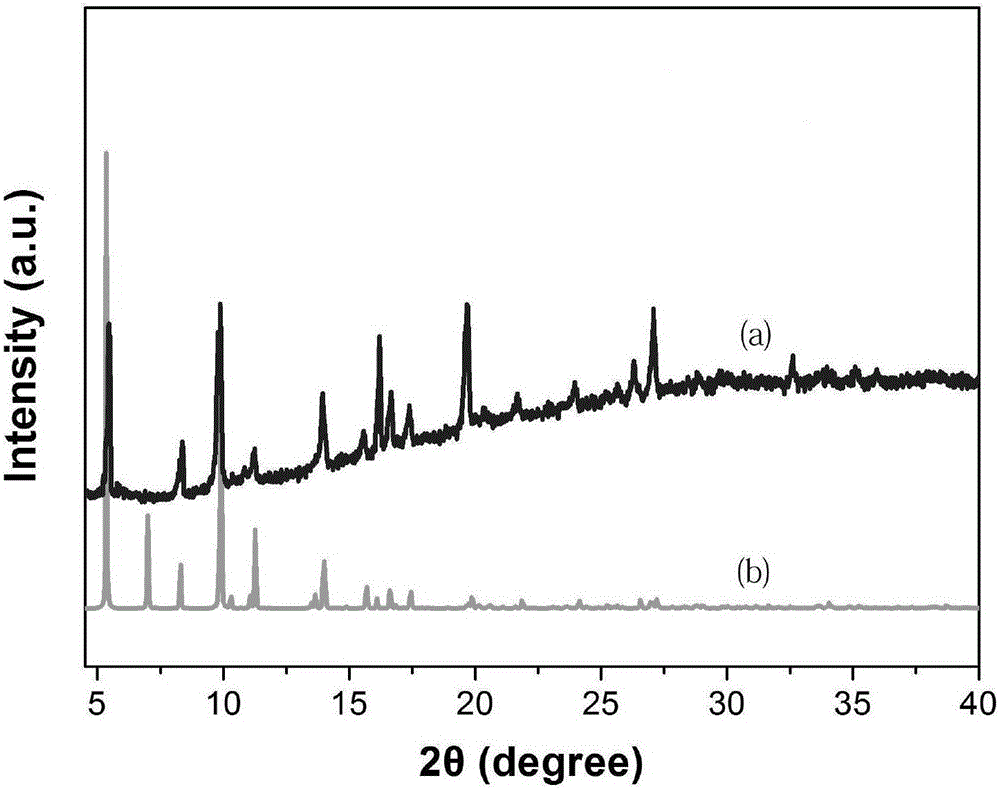

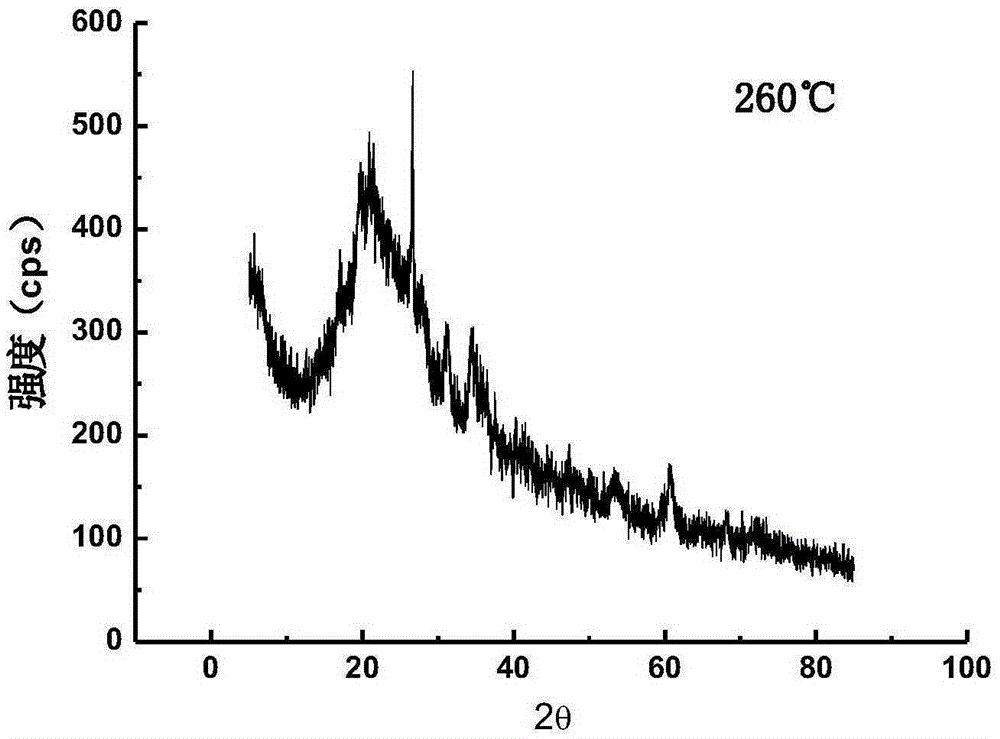

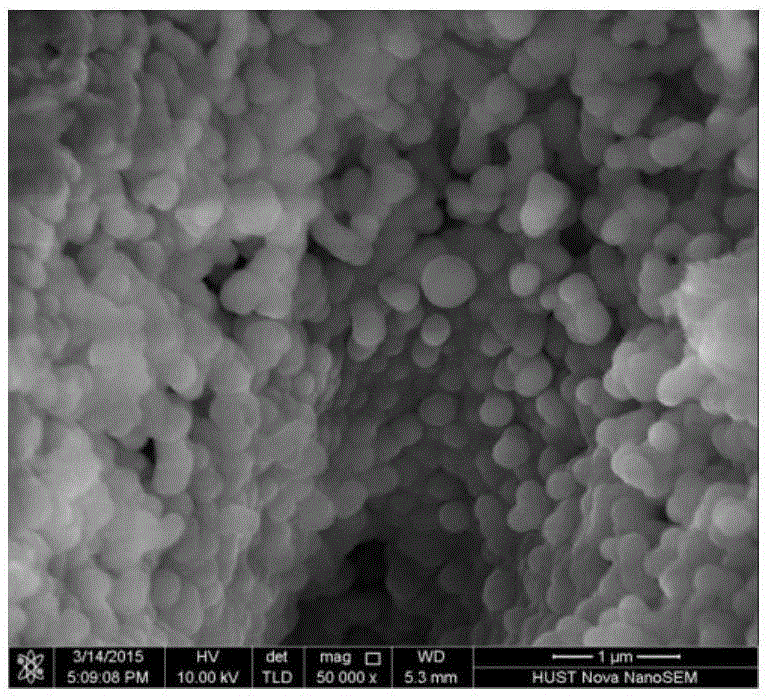

Nano oxide based on metal-organic frameworks (MOFs) and preparation method thereof

InactiveCN106057490ALarge specific surface areaThe appearance is basically maintainedHybrid capacitor electrodesNanotechnologyCapacitanceMetal-organic framework

The invention provides a nano oxide based on metal-organic frameworks (MOFs) and a preparation method thereof, which belong to the technical field of new materials. Metal nitrate is used for reaction to obtain a metal-organic framework, an alkaline solution is used for treatment, a precursor obtained after treatment is further subjected to pyrolysis to obtain a target product. The method succeeds in getting rid of multiple restrictions on the material itself when the traditional metal-organic framework pyrolysis method is used for preparing a metallic oxide. According to the alkaline hydrolysis process provided by the method, the morphology of the nano material of the synthetic material can be controlled more effectively to enhance the capacity of the capacitor, an organic carboxylate ligand used in the case of synthesis of a crystalline material can be effectively recovered, and the cost for material synthesis is greatly reduced. A new through is provided when the conventional MOFs material is used for synthesizing a metallic oxide with a specific nano morphology and a nano size, and an important role is played in expansion of industrial production of a synthesized material with excellent capacitance performance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

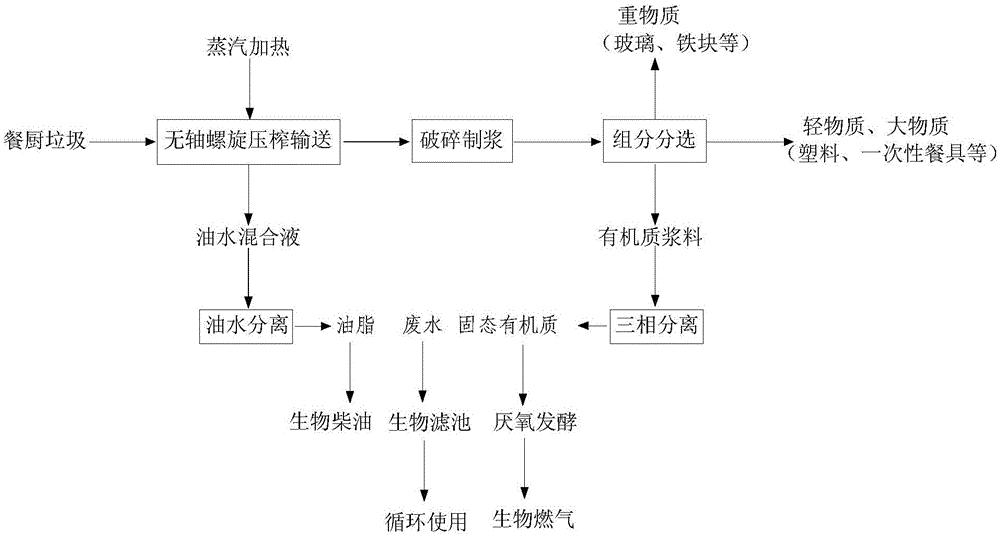

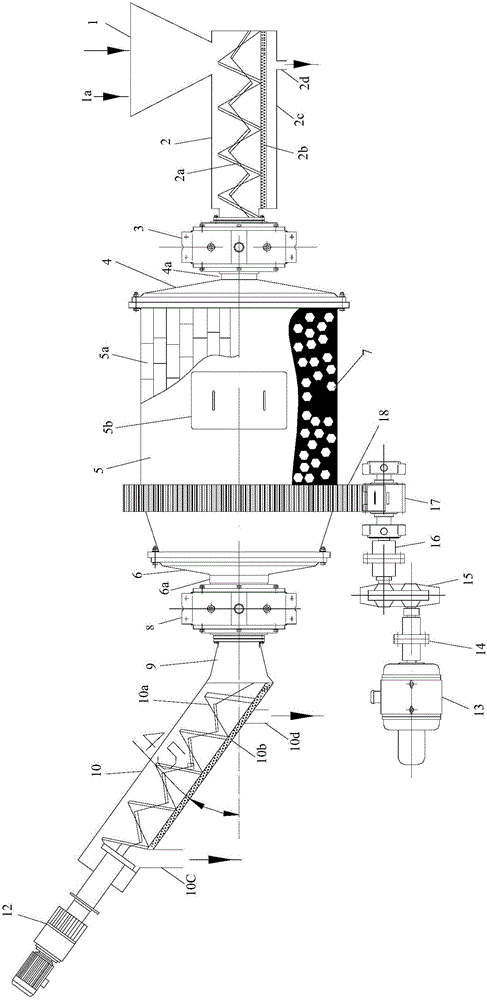

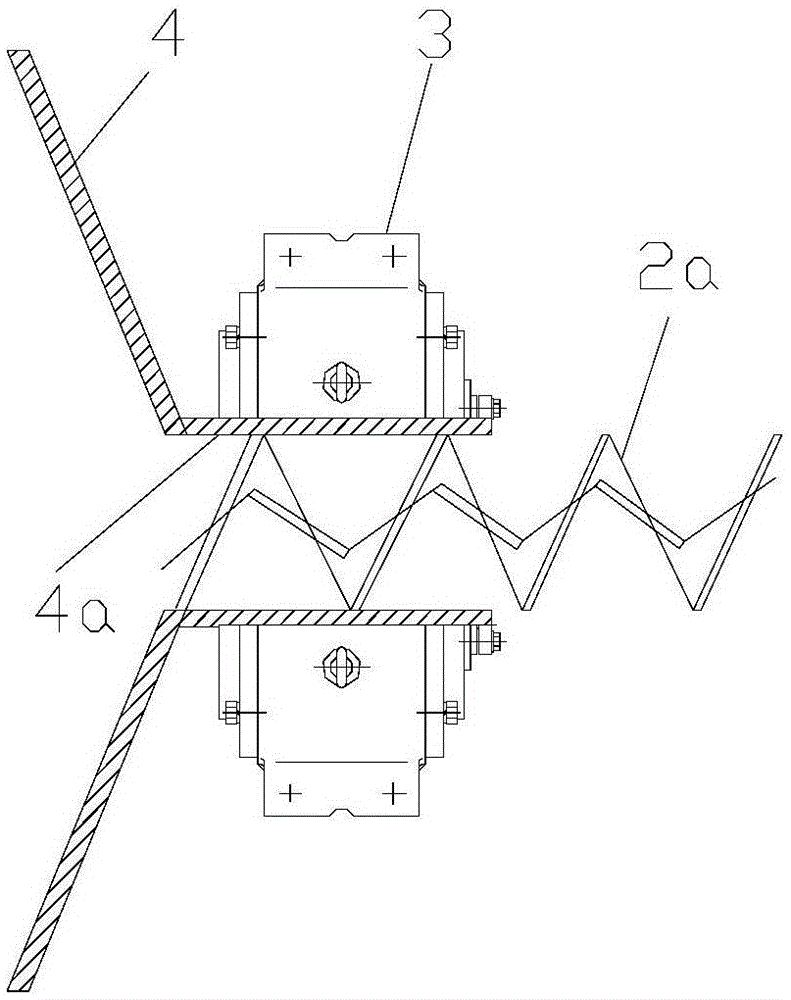

Integrated device for kitchen waste continuous crushing pulping and component sorting

ActiveCN105057305AAchieve brokenAchieve grindingSolid waste disposalDodecahedronContinuous operation

The invention discloses an integrated device for kitchen waste continuous crushing pulping and component sorting. The integrated device comprises a main driving device, and a feed oil extraction device, a feed end main bearing, a crushing cavity, a discharging end main bearing and a discharging sorting device which are sequentially connected, and the main driving device provides motive power required by operation of the crushing cavity. The integrated device has the advantages that a treatment mode of primary oil extraction, crushing and then sorting is applied, the process is simple, and the treatment efficiency is high; kitchen waste conveying and primary oil extraction can be achieved through the feed oil extraction device; a dodecahedron special for kitchen waste is used as a crushing body and performs casting motion in the crushing cavity which rotates in a decelerating mode to crush and grind raw materials, crushing effects are good, the pulping efficiency is high, and intertwining is not prone to occurrence; impurities and organic material pulps can be effectively separated by means of the discharging sorting device. The whole integrated device is reasonable in design, high in integration level and capable of performing continuous operation of kitchen waste crushing pulping and component sorting.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

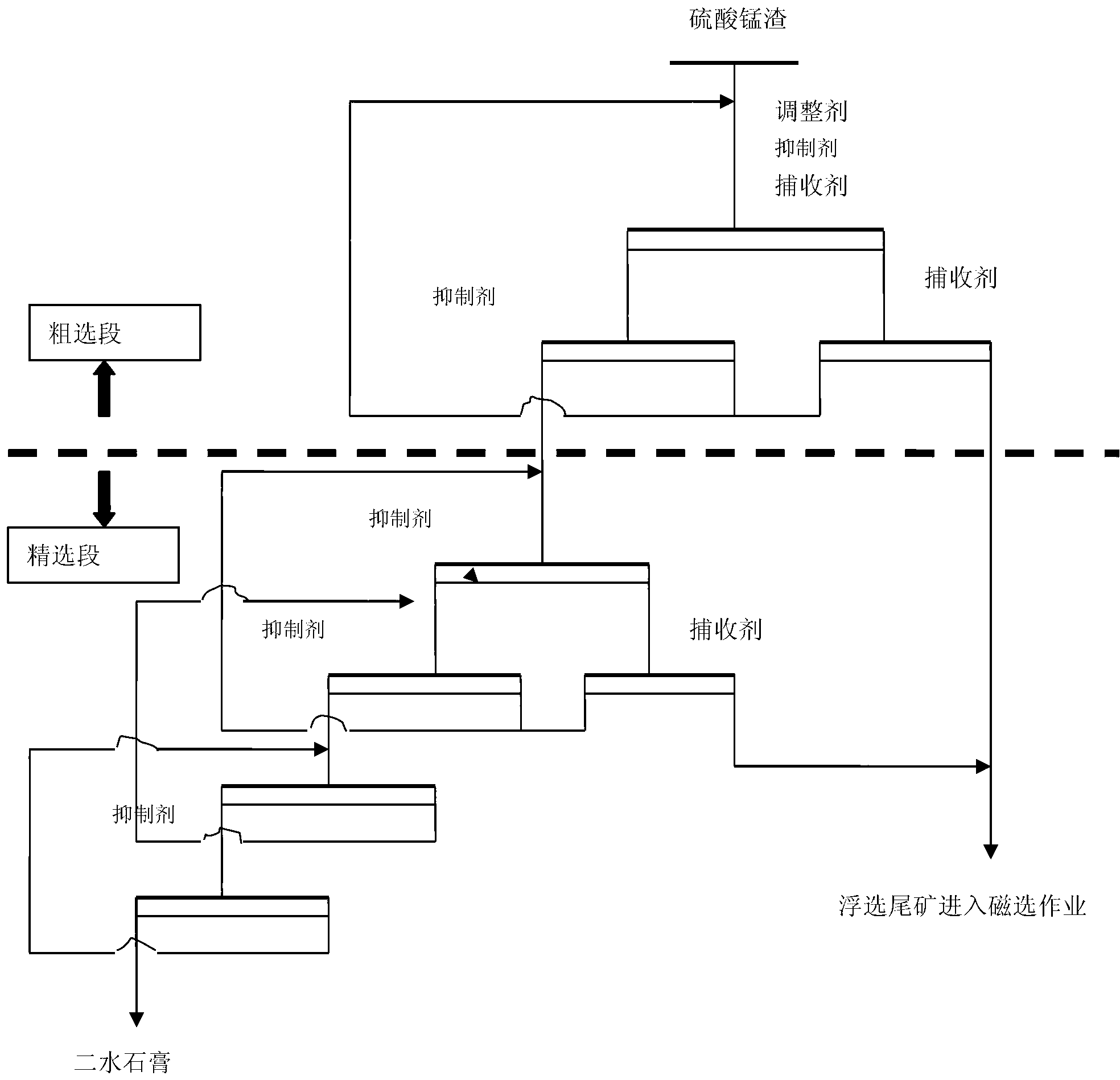

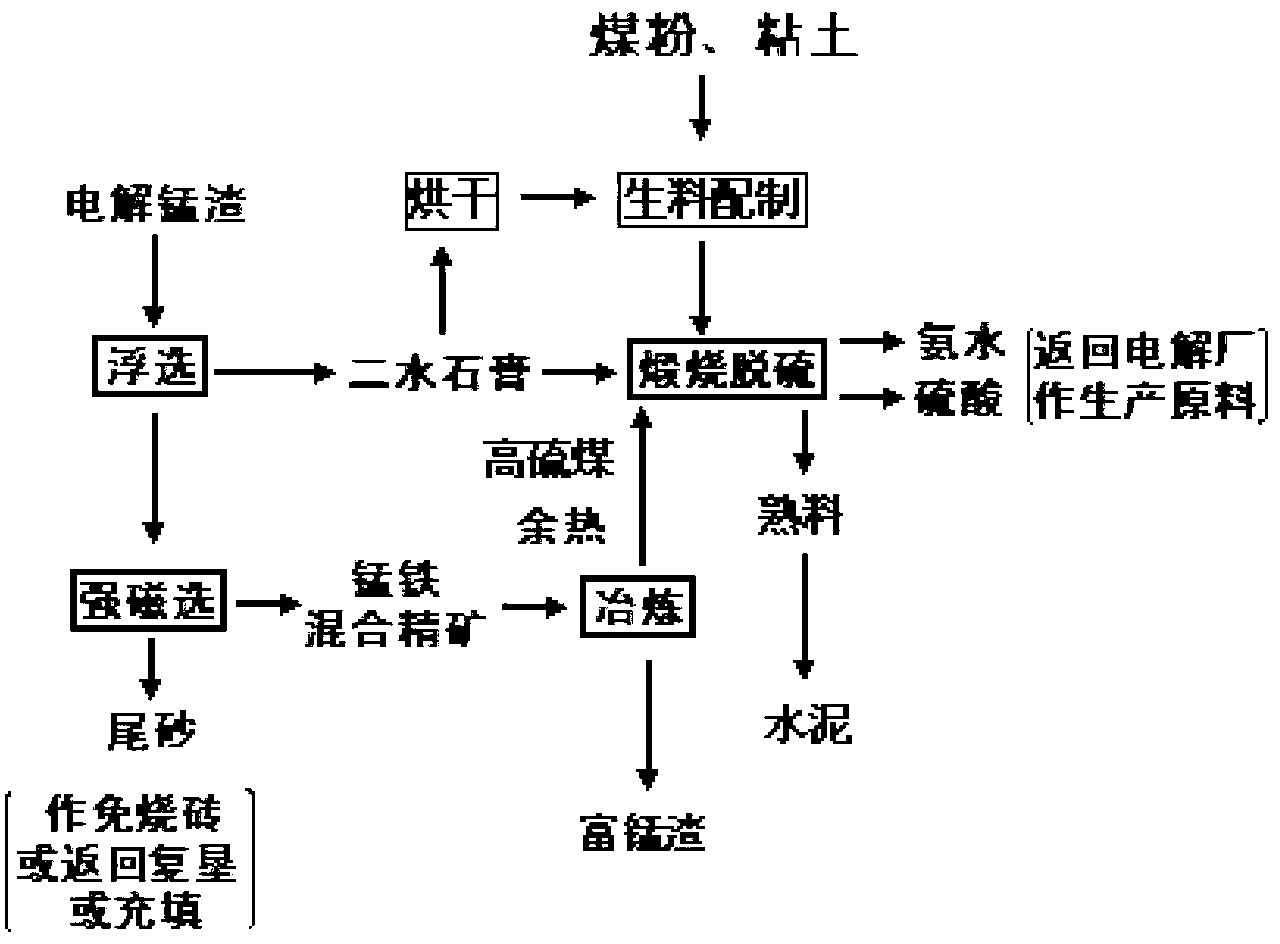

Method for comprehensively utilizing electrolytic manganese residues

ActiveCN103214201ASolve environmental problemsFix security issuesSulfur compoundsEnergy inputBrickElectrolysis

The invention discloses a method for comprehensively utilizing electrolytic manganese residues. The method comprises the following steps of: firstly carrying out flotation on electrolytic manganese residues in a flotation machine, and screening out dihydrate gypsum; carrying out strong magnetic separation on tailings subjected to flotation, and singling out ferromanganese bulk concentrate and tailings; smelting the ferromanganese bulk concentrate to obtain rich-manganese slag; and burning the dihydrate gypsum obtained through floatation with smelting waste heat so as to remove ammonia and sulfur for production of ammonia water and sulfuric acid and co-production of cement. The tailings discharged in the end are non-toxic and harmless and can be used for producing baking-free bricks, land rehabilitation or underground filling. According to the method, lots of manganese residues can be consumed, multiple related products are obtained while the environmental problem and the safety problem are solved, and thus the purposes of turning waste into wealth and cyclical utilization are achieved.

Owner:广西天工冶金科技有限公司

Wet-process comprehensive recovery and utilization method for zinc replacement residues

InactiveCN106834693AImprove leaching rateEnhanced leaching processProcess efficiency improvementLiquid wasteCopper

The invention discloses a wet-process comprehensive recovery and utilization method for zinc replacement residues. The wet-process comprehensive recovery and utilization method can efficiently recover zinc, germanium, gallium, copper, iron and silicon dioxide in the zinc replacement residues, and the leaching rates of all the metals are all higher than 94%. The wet-process comprehensive recovery and utilization method is conductive to improving the metal comprehensive recovery rate, meanwhile, the energy consumption in the whole technological process is reduced, generated waste liquid is returned for leaching to achieve the purpose of cyclic utilization, the problem of environmental pollution is solved, and the wet-process comprehensive recovery and utilization method is environment-friendly.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

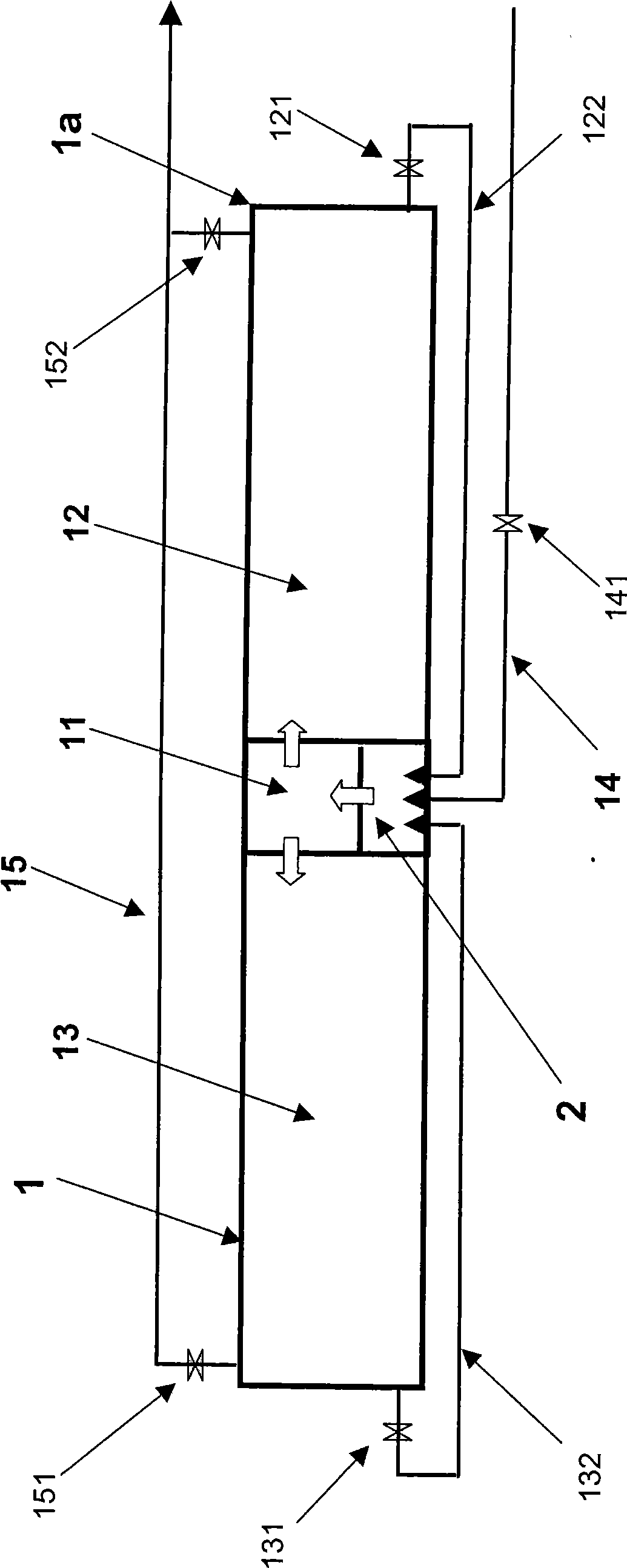

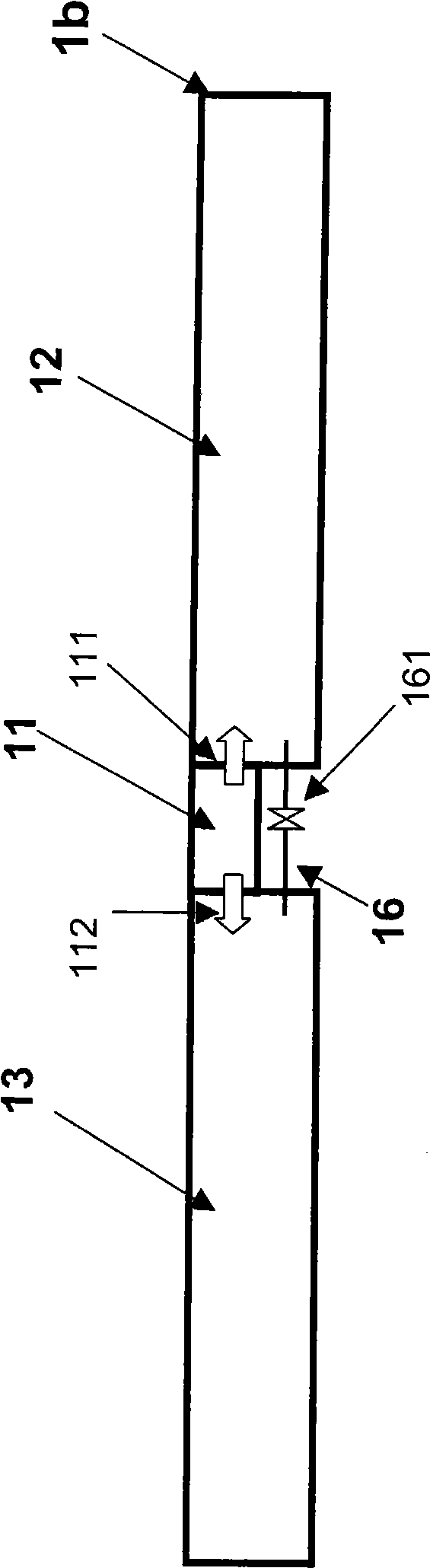

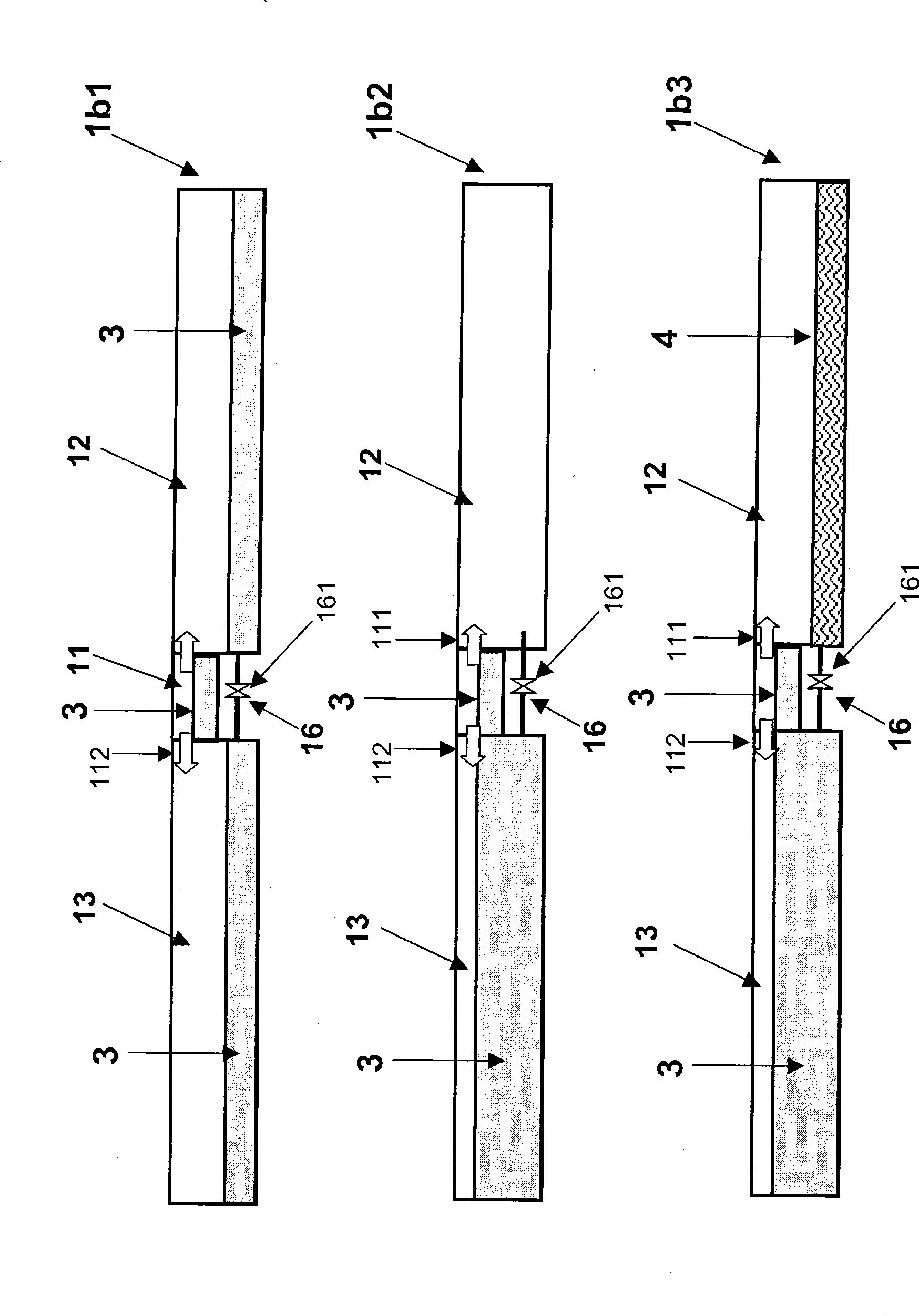

Planting system and planting method for controlling temperature of vegetable root

InactiveCN101530057AReduce nitrate levelsTo achieve the purpose of recyclingAgriculture gas emission reductionGreenhouse cultivationTemperature controlCold weather

The invention provides a planting system and a planting method for controlling the temperature of vegetable roots; wherein the system comprises a hydroponic planting nutrient solution pool and a nutrient solution sterilization temperature-control trough; the nutrient solution sterilization temperature-control trough is arranged beside the growing period hydroponic pool, is internally provided with a precise filter, a nutrient solution cooling group, a temperature sensor group and an electric heater heating group and is externally provided with a condensation compression unit that is connectedwith the nutrient solution cooling group; and a ultraviolet sterilization device is arranged above the nutrient solution sterilization temperature-control trough. The method comprises the following steps of: planting the hydroponic vegetable in the planting system for controlling the temperature of the vegetable roots; opening the nutrient solution valves arranged at two sides of the planting pool by the temperature-control planting system; pouring the nutrient solution into the nutrient solution sterilization temperature-control trough; filtering the solution by a precise filter; reducing the temperature when the solution flows by the nutrient solution cooling group subsequently or increasing the temperature by the electric heater heating group so as to lead the temperature of the nutrient solution to be kept at about 18 DEG C in summer and at about 22 DEG C in winter and lead the temperature of the vegetable plant to be reduced or increased, thus leading the vegetables to have the capability of resisting hot or cold weather.

Owner:康泉农业科技(惠州)有限公司

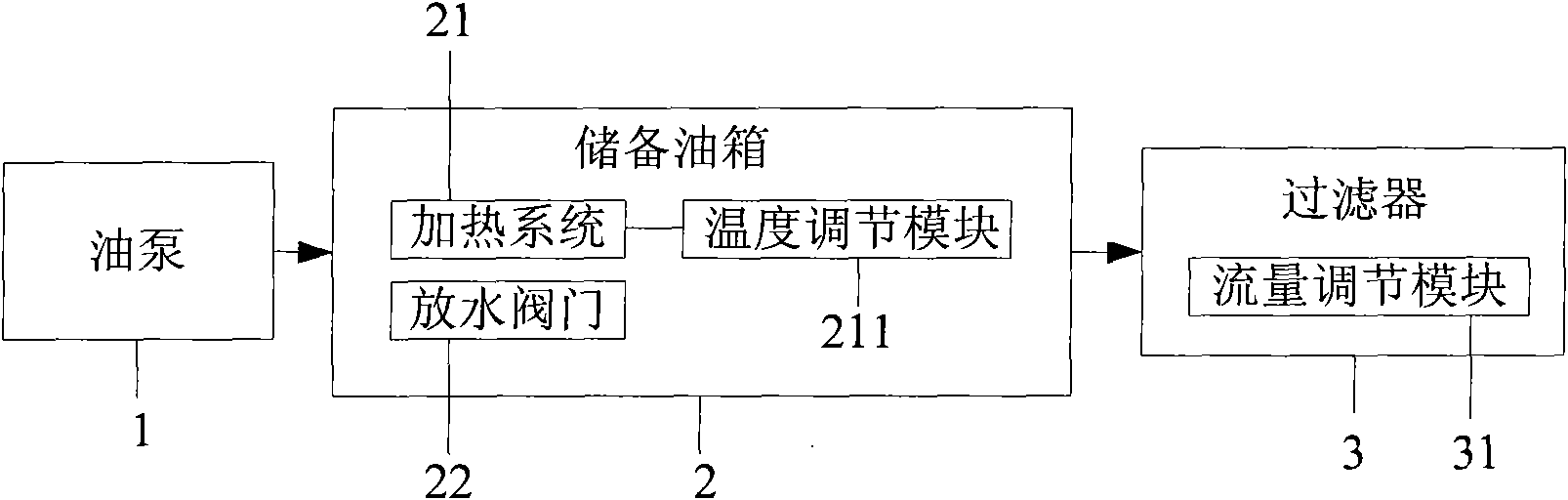

Oil filter device and method

InactiveCN101991986ADoes not change performanceTo achieve the purpose of recyclingFiltration circuitsLubricant compositionHeating systemFuel tank

The invention discloses an oil filter device, which comprises an oil pump, a reserve oil tank and a filter that are connected in sequence, wherein the reserve oil tank is provided with a heating system, and the bottom of the reserve oil tank is provided with a drainage valve. The invention further discloses an oil filter method. The invention can be used for carrying out on-site off-line hyperfine filter purification on waste oil to achieve the purpose of oil recycling, and thus, the oil consumption cost of enterprises is greatly reduced and an environmental-protection energy-saving effect is achieved.

Owner:项铎

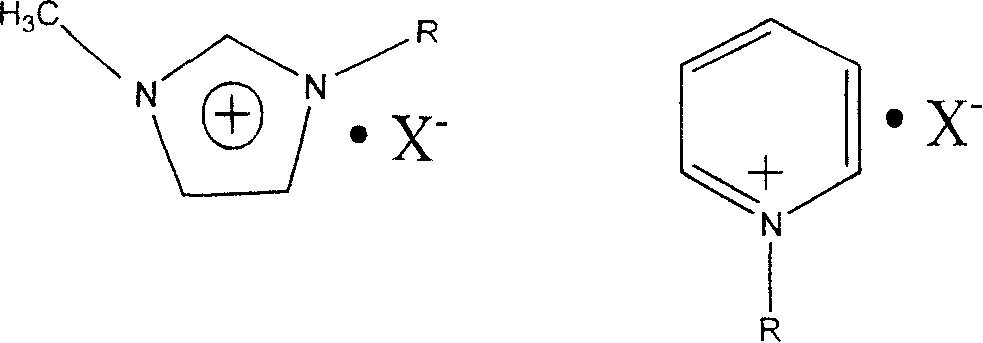

Microwave synthesis for producing polyketone ionic liquid

Micro-wave synthesis of putting N-methyl imidazole or pyridine and bromic ether, bromo-n-butane, bromo-n-hexane, bromo-n-octane or bromo-cetane into reactor, reacting at 20-150 degree and 100W-500W for 2-30mins, washing by acetic ether, drying to obtain bromo-alkyl-imidazolium or bromo-alkyl-pyridinium, microwave reacting bromo-alkyl-imidazolium or bromo-alkyl-pyridinium with tetrafluoroborate salt or toluene-p-sulfonic acid or amido-sulfonic acid in deionized water or acetone, dripping into tetrafluoroborate salt, filtering while removing water to obtain the ionic liquid, or micro-wave reacting bromo-alkyl-imidazolium or bromo-alkyl-pyridinium with hexafluorophosphate in deionized water or acetone, and filtering while removing water to obtain the final product. It's simple and efficient, has short reactive time and gentle reactive environment.

Owner:TIANJIN UNIV

Method for preparing high-sulfur iron-containing series desulfurizing agent

InactiveCN101126115AReduce desulfurization efficiencyTo achieve the purpose of recyclingGas emission reductionVulcanizationActive component

A preparation method of high sulfur capacity ferrous desulfurizer belongs to the field of coal chemical industry and preparation and application of desulfurizer, in particular to a preparation of a high temperature ferrous desulfrizer in the field of preparation and gas purification. The main active component of the desulfurizer is a nanometer frric oxide treated by a particularly technique process as that: the nanometer frric oxide is added with component such as vulcanization accelerator, carbon resistant promoter, strength enhancer and binder, then uniformly mixed by grinding and kneaded to shape, finally, dried or roasted to shape strip, granule or flake. The desulfurizer is characterized by high desulfurating efficiency, stable circulation and high sulfur capacity, etc. At least the desulfurizer removes H2S from 2000-5000ppm in entrance to 1ppm, and is suitable for removing H2S in surlfur gas of coal gas or natural gas under the temperature of 350-450 DEG C.

Owner:TAIYUAN UNIV OF TECH

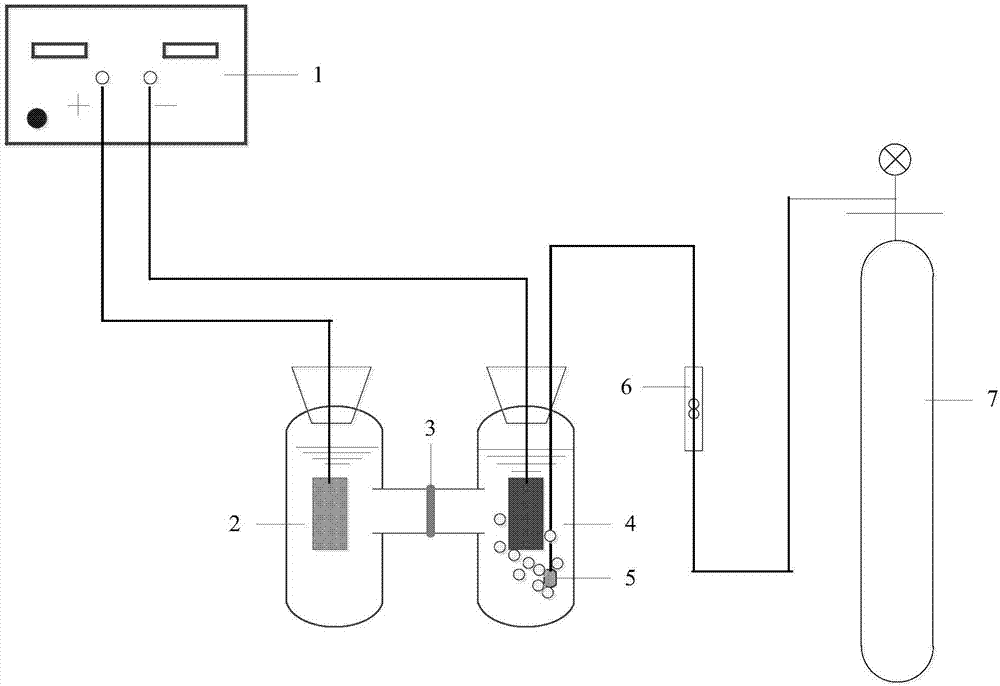

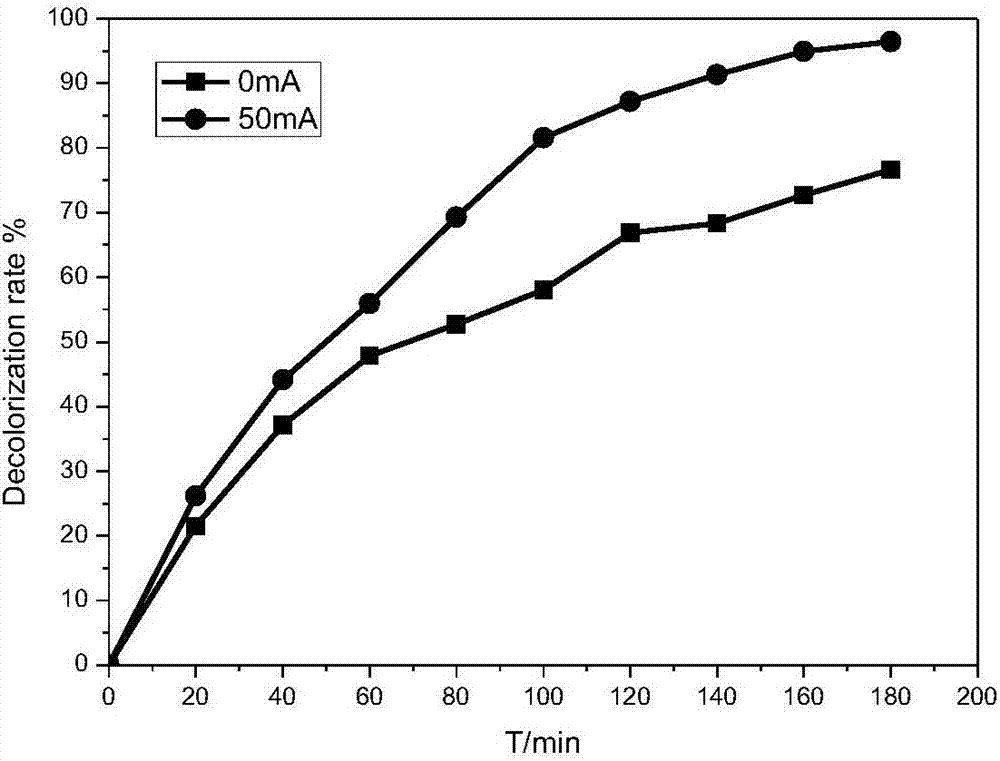

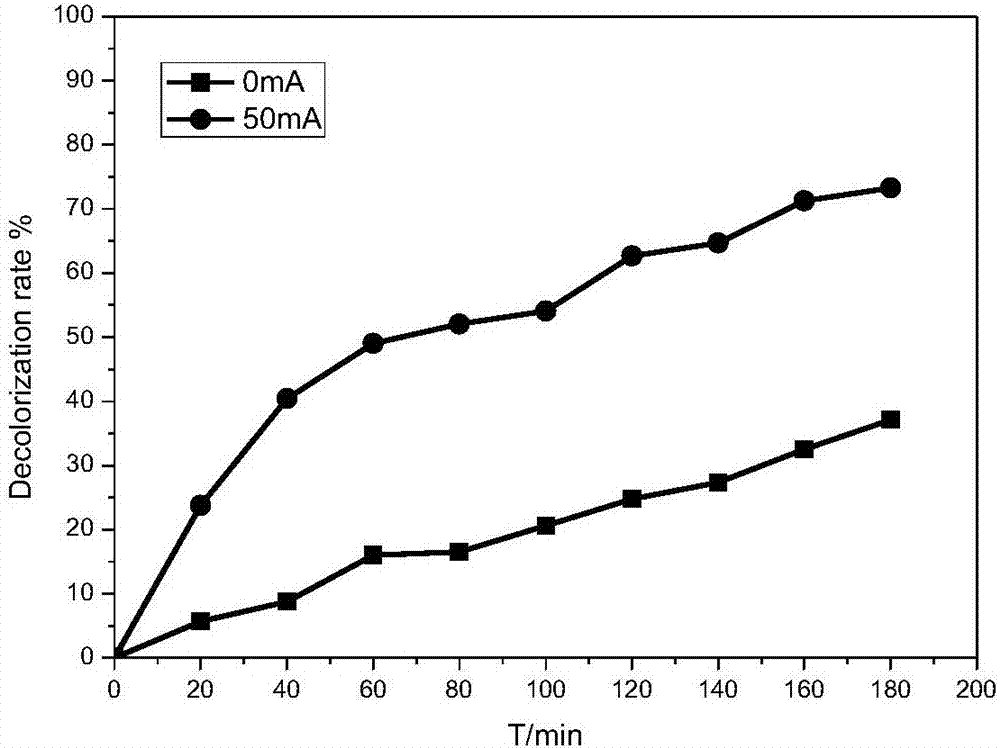

Preparation method of Fe-FeOx/carbon aerogel self-supporting cathode and heterogeneous electro-Fenton methyl orange degradation system

InactiveCN107324453AAdsorptiveWith electrochemical catalytic oxidationWater treatment compoundsWater contaminantsSynthesis methodsCatalytic oxidation

The invention provides a preparation method of a Fe-FeOx / carbon aerogel self-supporting cathode and a heterogeneous electro-Fenton methyl orange degradation system, belonging to the technical field of preparation of environmental electrochemical materials and treatment of advanced oxidation techniques. A Fe-FeOx / carbon aerogel electrode is prepared by virtue of a one-step sol-gel synthesis method and is taken as a cathode; a Ti / RuO2-IrO2 electrode is taken as an anode; and methyl orange is degraded in the precise of an additional power supply. Heterogeneous electro-Fenton has a relatively wide pH value range and is suitable for various actual wastewaters; the prepared electrode forms a block body and does not need to be subjected to complex post-processing such as tabletting; H2O2 can be produced in situ, so that the dangers during transportation and storage are avoided, and the cost is lowered; the precipitation of iron is limited, and the catalyst can be recycled; by taking electrons as a reaction agent, the process is clean and environmentally friendly; and beside an catalytic oxidation effect, an electrode material has synergistic effects such as adsorption.

Owner:DALIAN UNIV OF TECH

Re-treated cow dung recycling system

PendingCN106145587AImprove utilizationReduce pollutionSludge treatment by de-watering/drying/thickeningWaste based fuelSlagBiogas

The invention belongs to the field of livestock and poultry manure treatment and utilization, and particularly relates to a re-treated cow dung recycling system which sequentially comprises a cow house, a dung collection tank, a homogenate tank, an anaerobic fermentation tank, a dry-wet separator and a cow dung drying chamber according to cow dung treatment flow. The cow dung drying chamber is connected with a heating source biogas combustion chamber, the heating source biogas combustion chamber is connected to the anaerobic fermentation tank through a biogas transmission pipeline, a desulfurization tower is arranged between the biogas combustion chamber and the anaerobic fermentation tank, and liquid separated by the dry-wet separator flows to a biogas slurry tank. Recovery of biogas fermented by dung is separated from utilization of biogas liquor, biogas utilization is increased, pollution of the biogas liquor for irrigation is reduced, utilization of the biogas liquor is facilitated, generates a large number of biogas, solid residual slag in the cow dung recycling process is heated and dried by a large number of biogas generated by anaerobic fermentation of cow dung to prepare cow bed padding, and cyclic utilization is achieved.

Owner:ZHEJIANG YIJING ECOLOGICAL ANIMAL HUSBANDRY

Method for recycling additive lithium chloride in polyphenylene sulfide resin production process

The invention relates to a method for recycling additive lithium chloride in polyphenylene sulfide resin production process. The method includes steps of dissolving waterish sodium sulfide in NMP and removing water in the waterish sodium sulfide in inert gas shielding under the catalytic function of lithium chloride and caustic soda flakes, adding DCB and NMP solution to polymerize, and synthesizing to obtain polyphenylene sulfide resin mixture pulp; separating solid of the polyphenylene sulfide resin from liquid to obtain polyphenylene sulfide resin product containing low polymer, bi-product salt and NMP solution containing lithium chloride respectively; filtering and purifying the NMP solution containing lithium chloride to obtain NMP solution containing 75-85% of lithium chloride; inversely soaking and rinsing the polyphenylene sulfide resin product containing low polymer and the bi-product salt to obtain polyphenylene sulfide resin product containing low polymer, bi-product salt and rinsing liquid respectively; depressurizing, distilling and separating rinsing liquid to obtain NMP salt solution; desalinating the NMP salt solution to obtain NMP solution containing 10-20% of lithium chloride. The method is simple and efficient.

Owner:DUNHUANG XIYU MINING & CHEM

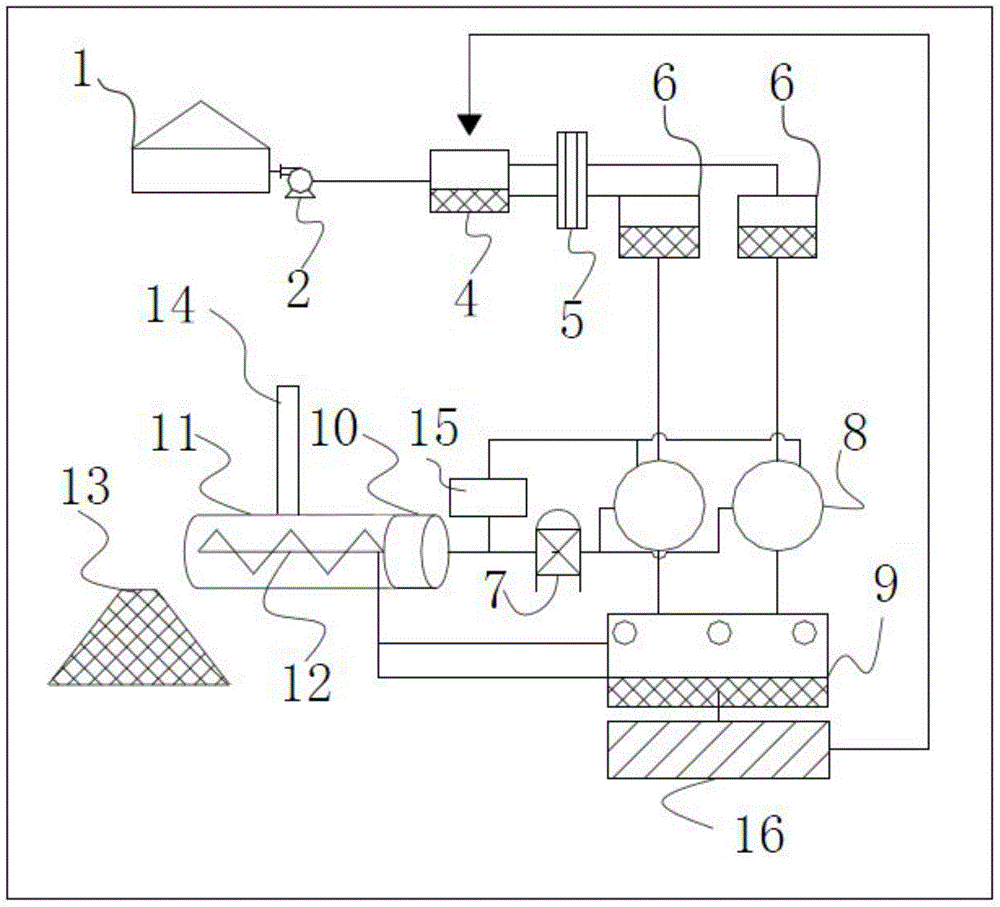

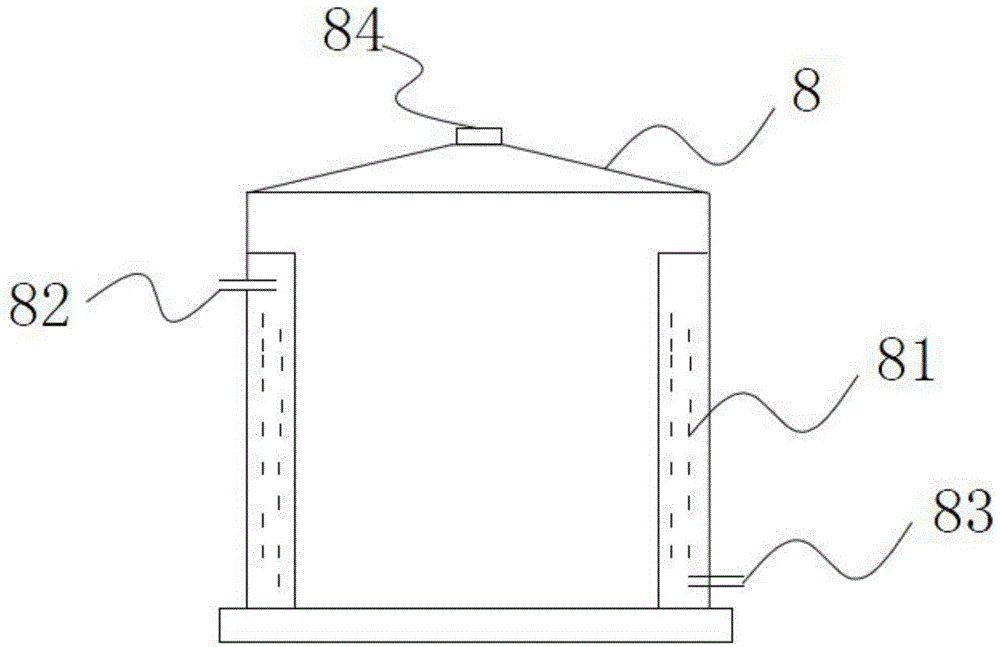

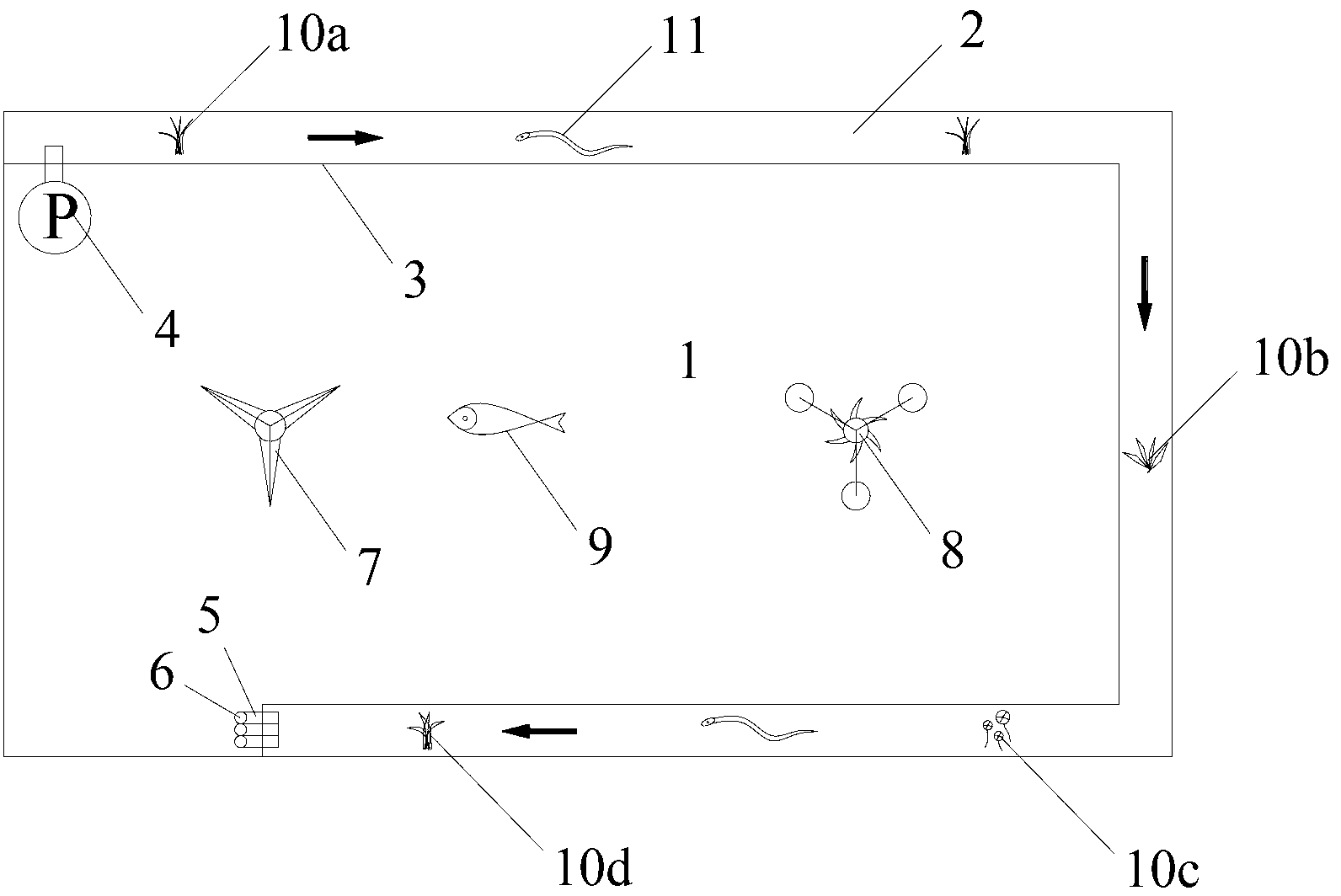

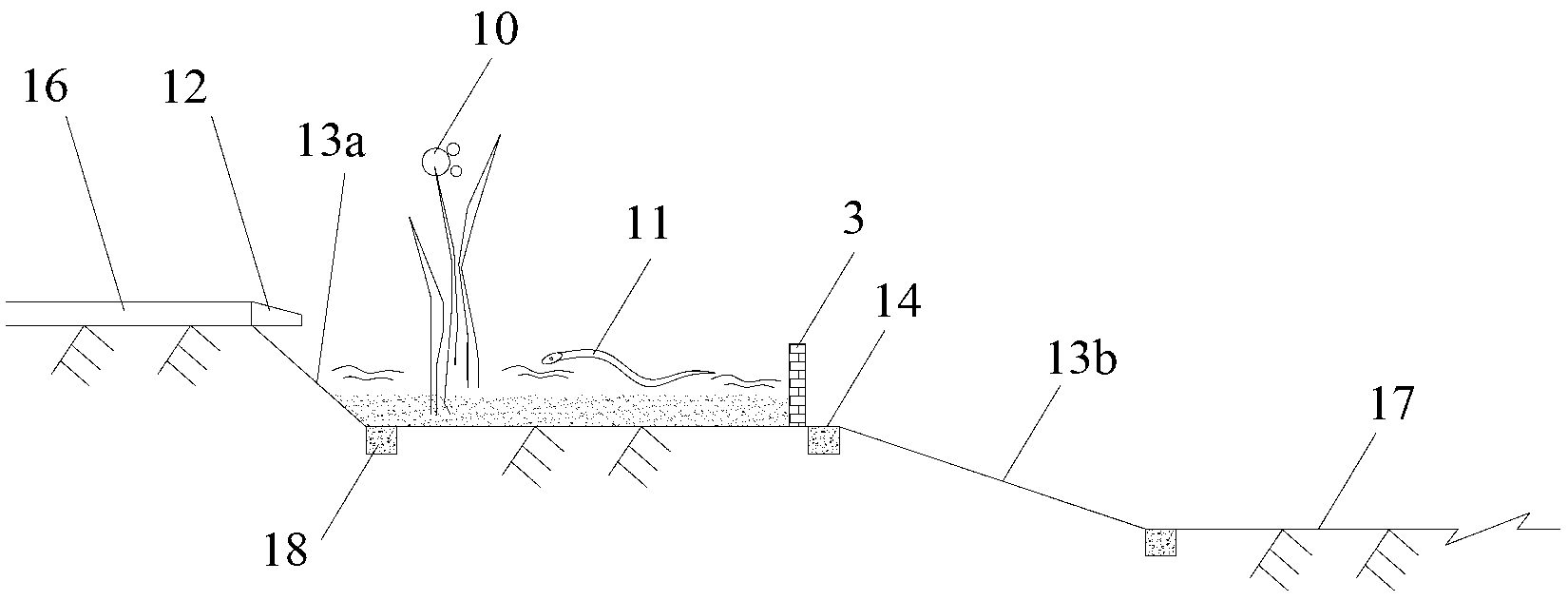

Ecological fish farming method and device based on ditch and pound compound system

InactiveCN103299935AAchieve utilizationTo achieve the purpose of recyclingClimate change adaptationAgricultural fishingBrickWater quality

The invention discloses an ecological fish farming method and device based on a ditch and pound compound system. The method comprises the steps as follows: A, source water which accords with a fishing water quality standard and acquired in a sounding area through automatic flowing is pumped into an aquaculture pond; B, an aquaculture model combing high-density stocking with multiple stocking and multiple fishing is adopted; C, the aquaculture season approaches; D, an impeller type aerator and a water cultivator are arranged in the aquaculture pond; E, different aquatic economic plants are planted in sections in an ecological ditch; and F, leakage and water evaporation occur, and water is supplemented into the aquaculture pond. The aquaculture pond is connected with the ecological ditch through a water pump, water outlet at the tail end of the ecological ditch is connected with the aquaculture pond through a water collection pipe, an escape-proof net is arranged at a water inlet end of the water collection pipe and a water level control pipe is inserted into a water outlet end; and the aquaculture pond adopts a prefabricated concrete protection slope, creasing is performed with bricks at the top of the slope, a concrete foundation beam is added at the bottom of the slope, and the ecological ditch is arranged around the aquaculture pond. The structure is simple, the aquaculture is convenient, the aquaculture yield is remarkably increased, the environment of the water area is protected, and water resources and material energy are recycled.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for reducing MnO2 in anode mud to MnO by using high-temperature reduction method

InactiveCN101264935ATo achieve the purpose of recyclingLow priceManganese oxides/hydroxidesElectrolysisResource utilization

The invention relates to a method for reducing principal component MnO2 in waste anode mud produced in electrolytic manganese production process to MnO by using high temperature direct reduction method, and belongs to the resource utilization and environmental protection fields. The method comprises the steps of mixing electrolytic manganese anode mud and a reducer in a reaction vessel, allowing reaction at 800-1,600 DEG C for 1-6 hours, naturally cooling to room temperature under the protection of nitrogen gas and reducing atmosphere to obtain a mixed product containing MnO particles, and directly recycling to electrolytic manganese production or further separating and purifying to obtain MnO product. The inventive method solves the waste pollution and resource utilization problems in electrolytic manganese industry, produces new product with high added value by using anode mud, recycles and reutilizes resources, and can bring distinct economic, environmental and social benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Preparation method of high-efficiency chromium-removing composite absorbent

InactiveCN102872797ATo achieve the purpose of recyclingNothing producedOther chemical processesWater contaminantsRed mudToxic industrial waste

The invention discloses a preparation method of a high-efficiency chromium-removing composite absorbent. The preparation method comprises the following steps of: adopting red mud and montmorillonitic clay as raw materials, adding water and soluble starch, fully and uniformly stirring, granulating, molding, and drying; and roasting for 0.5-2 hours at the temperature of 550-650 DEG C. The preparation method disclosed by the invention has the advantages that the high-efficiency water-body chromium-removing composite absorbent is prepared by adopting industrial waste red mud and montmorillonitic clay as raw materials and adopting simple granulation and roasting, the production process is simple, the production cost is low, and no harmful gas and sewage are produced in the production process. The prepared absorbent has the advantages that the affinity to water-body chromium is high, the absorbing efficiency is high, toxicity and harm can not be generated to a water body and aquatic organisms, the removal from the water body is convenient after use, the recovery is easy in the use process, and the blocking to equipment can not be caused, so that the purposes of removing the water-body chromium in a high-efficiency manner and simultaneously carrying out recycling on waste are achieved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for utilizing blast furnace dust

InactiveCN101805809ASolve the problem of high cost and difficult utilization of dezincification treatmentTo achieve the purpose of recyclingBlast furnace detailsSteelmakingTreatment costs

The invention relates to a method for utilizing blast furnace dust, which sequentially comprises the following steps: 1. material loading: loading the blast furnace dust into a spray blowing machine; 2. material addition: adding the blast furnace dust into steel slag in the steelmaking tapping process, wherein the temperature of the steel slag is between 1650 DEG C and 1750 DEG C, and the steel slag and the blast furnace dust have the mass part ratio of 12 to 25 of steel slag and 1 to 3 of blast furnace dust; 3. reduction: carrying out the reduction on the blast furnace dust in a slag pot by using the sensible heat of the steel slag with the reduction time between 60 and 90 minutes; 4. cooling: cooing the steel slag for 8 to 24 hours; and 5. magnetic separation: realizing the steel and slag separation through the magnetic separation for separating out slag steel used for steelmaking. The method for utilizing the blast furnace dust of the invention has the advantages of short technical process and low treatment cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

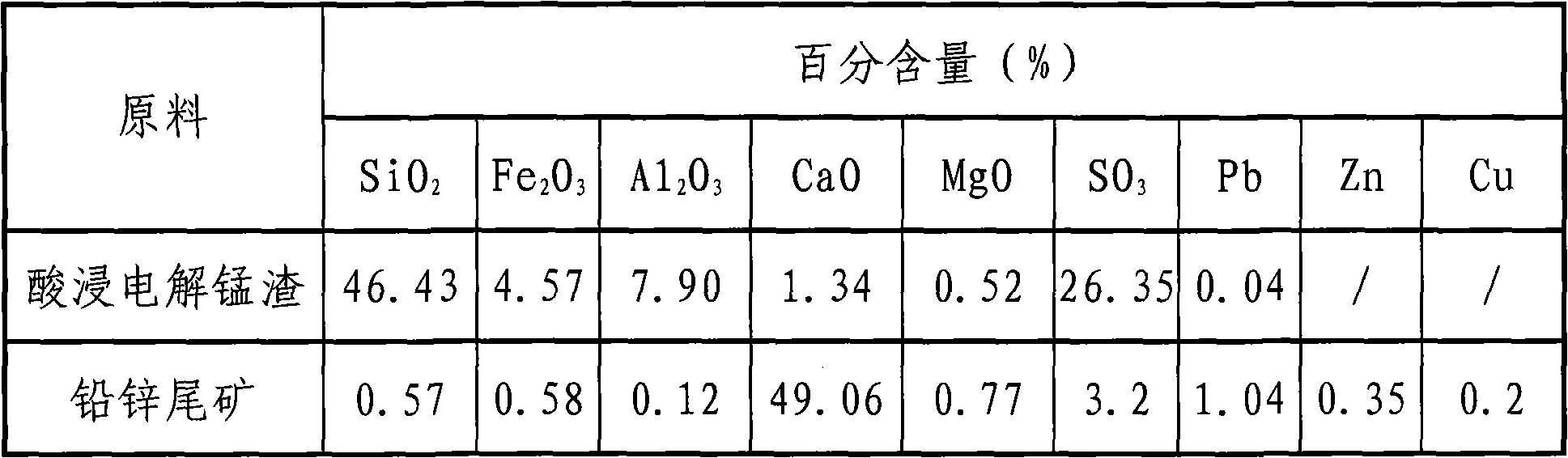

Method for co-producing cement, sulfuric acid and gypsum by using lead-zinc tailings and acid-leaching electrolytic manganese residues as main raw materials

InactiveCN101671131ASolve environmental problemsFix security issuesCalcium/strontium/barium sulfatesSulfur compoundsManganeseSlurry

The invention discloses a method for co-producing cement, sulfuric acid and gypsum by using lead-zinc tailings and acid-leaching electrolytic manganese residues as main raw materials. The method is characterized by comprising the following steps: mixing - raw materials of 67-75% of lead-zinc tailings, 16-21% of acid-leaching electrolytic manganese residues, 0-2% of aluminum raw materials and 0-2%of iron powders by weight percentage, grinding the mixture to 180 mesh, feeding the mixture into a rotary kiln and adding 9-12% of coals, taking the coals as a fuel for forging at 1,390+ / -50 DEG C toobtain cement clinkers; purifying, transforming and absorbing kiln gas SO2 generated by the cement forging to obtain sulfuric acid product in which the content of H2SO4 is no less than 98%; and transmitting the other part of purified SO2 gas to an absorbing tower to be absorbed by lead-zinc tailings slurry, and carrying out air oxidation and separation to obtain gypsum with a purity higher than 95%. In the invention, a great deal of lead-zinc tailings and acid-leaching electrolytic manganese residues are used up so as to solve the problems of environment and potential safety hazard, and threeco-products are obtained so as to realize the purpose of recycling waste materials.

Owner:湘西自治州兴湘科技开发有限责任公司 +1

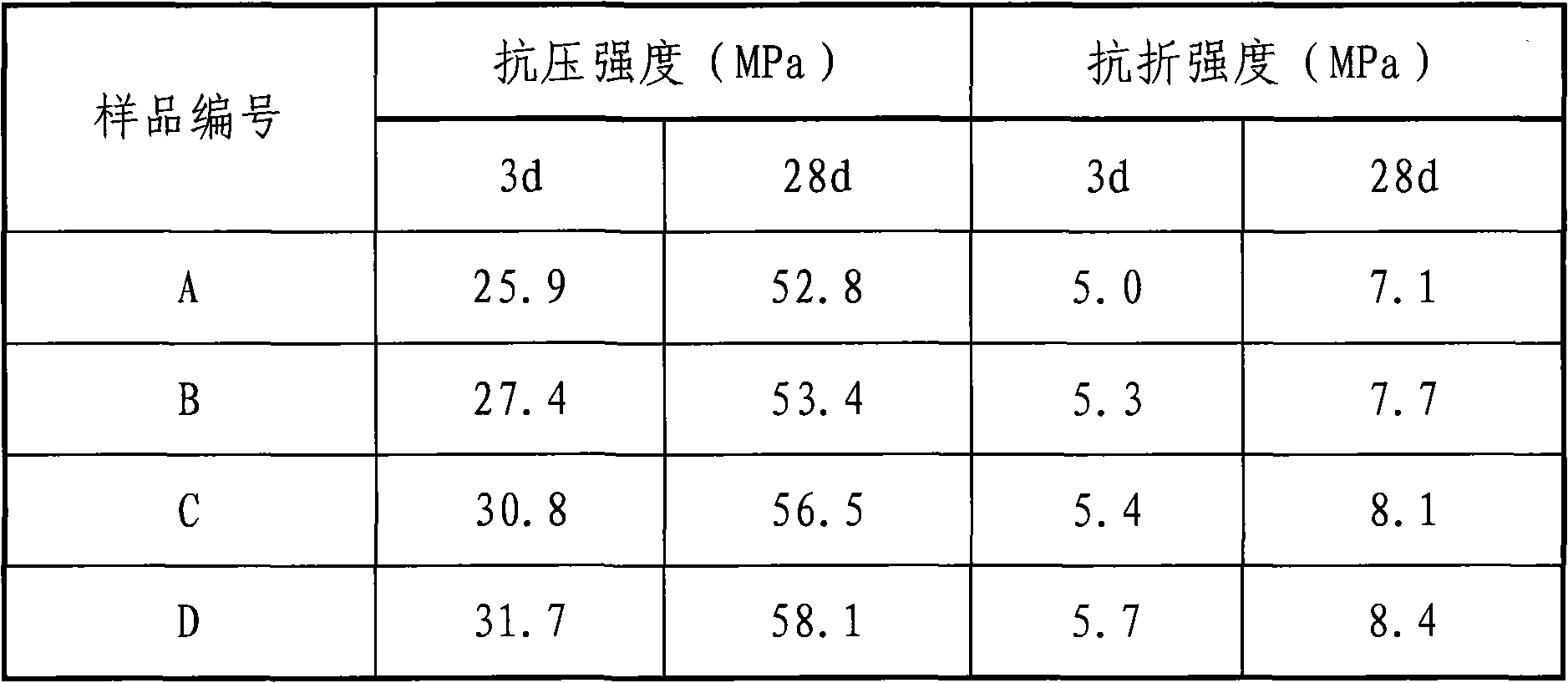

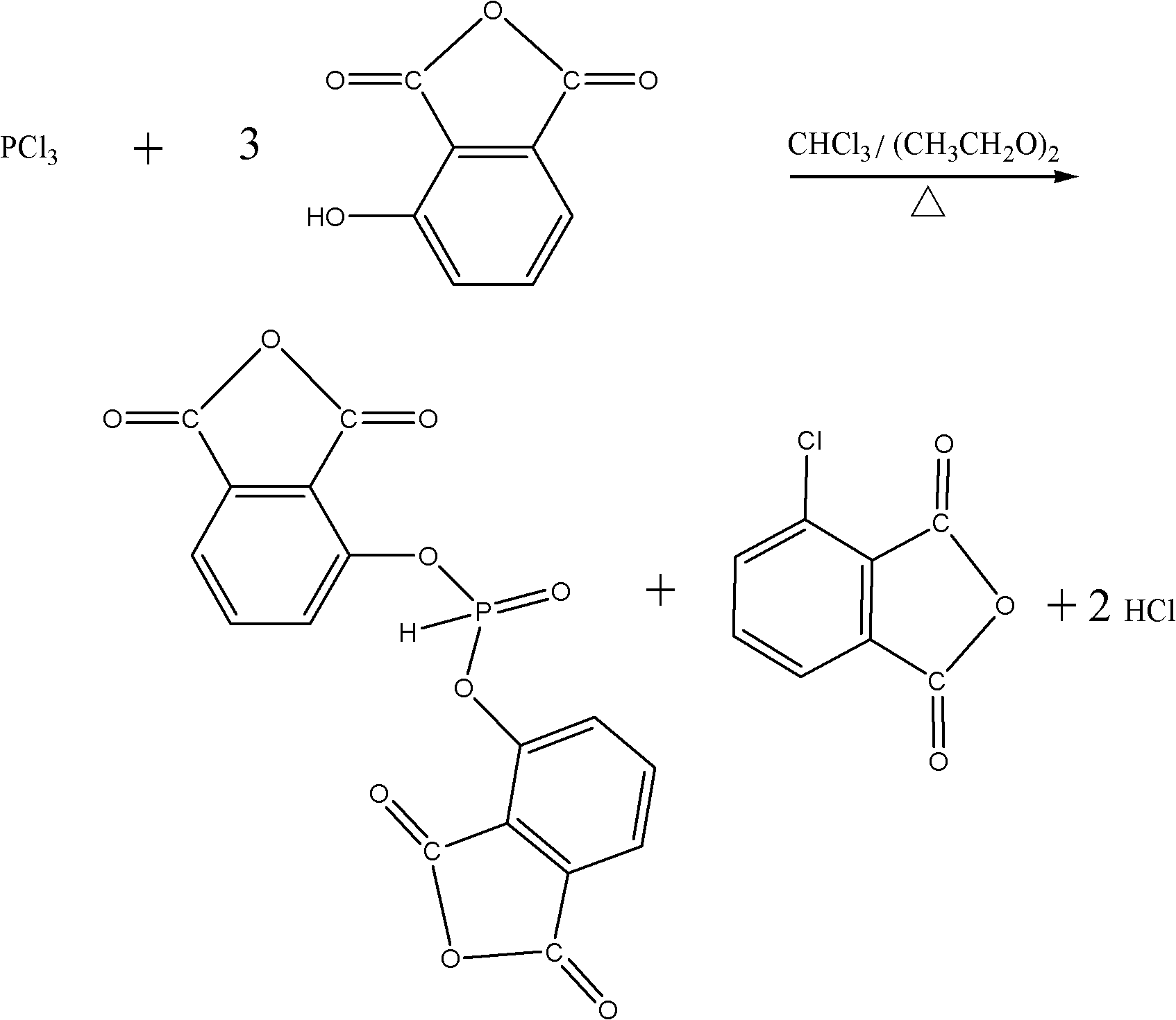

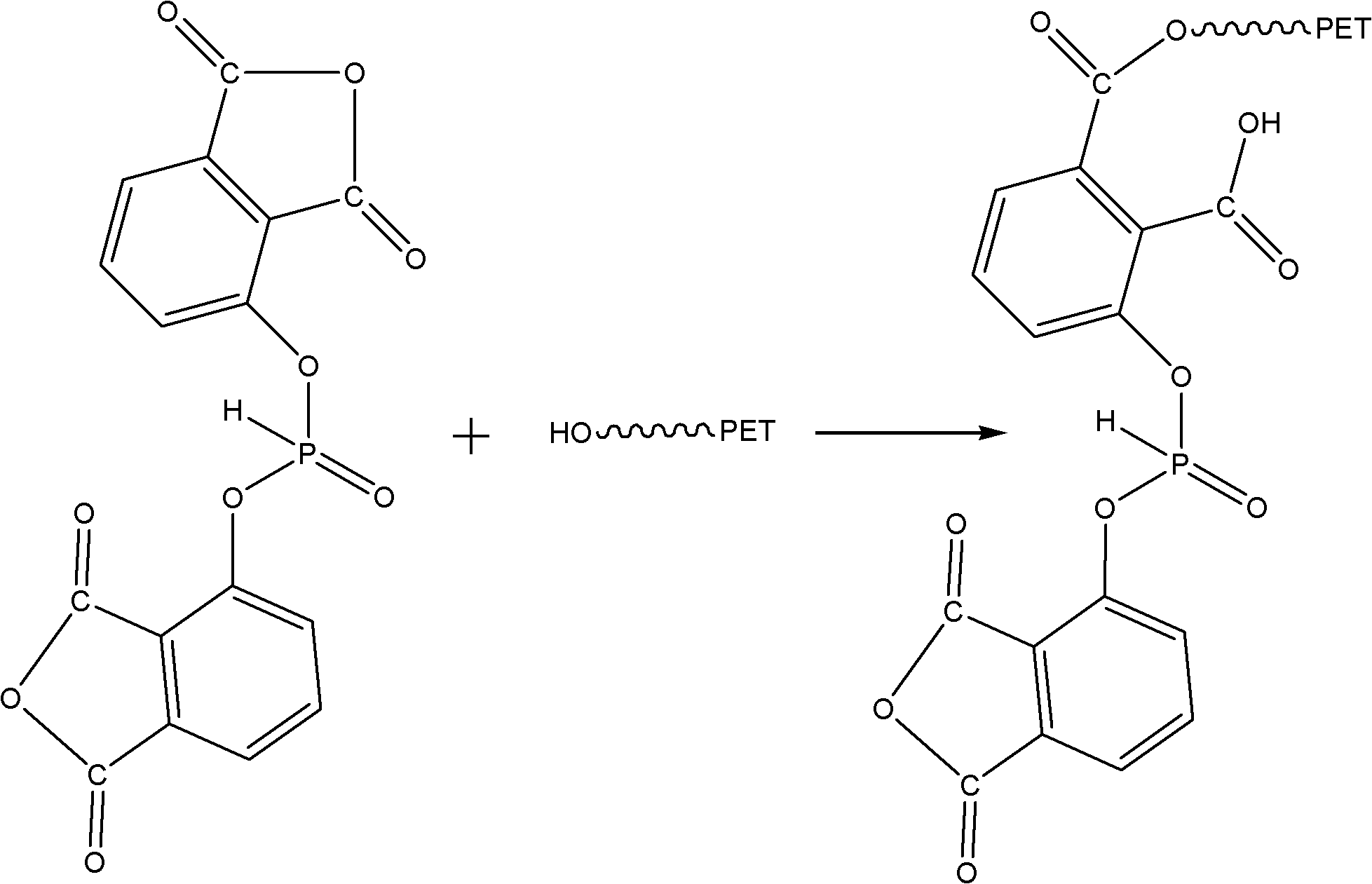

Polyester industrial yarn solid-phase polymerization flame-retarding chain extender and preparing method thereof

ActiveCN102617840AThe synthesis process is simpleMild reaction conditionsGroup 5/15 element organic compoundsMonocomponent copolyesters artificial filamentPolyesterBenzoic acid

The invention provides a polyester industrial yarn solid-phase polymerization flame-retarding chain extender, which mainly comprises a double-end-group benzoic acid anhydride group serving as a chain extension group and a flame-retarding group containing phosphorus. Two acid anhydrides in a molecule can be used for reacting with hydroxyl in dacron molecules so that intrinsic viscosity of dacron is improved. Simultaneously, phosphorus is introduced into the molecule structure so that flame-retarding performance of dacron is improved. The invention further relates to a preparing method of the polyester industrial yarn solid-phase polymerization flame-retarding chain extender, which includes: (1) dissolving PCl3 into mixed solvent of CHCl3 / (CH3CH2O)2, dropwise adding 3-hydroxy phthalic anhydride solution dissolved in the mixed solvent of CHCl3 / (CH3CH2O)2, and performing heat preservation backflow reaction at certain temperature; and (2) evaporating a part of solvent at certain temperature after the reaction proceeds for a certain time, filtering the mixture which generates faint yellow sediments to obtain mixed solvent of CHCl3 / (CH3CH2O)2 for solids, and recrystallizing to obtain required flame-retarding chain extension crystals.

Owner:JIANGSU HENGLI CHEM FIBER

Method for planting Syzygium samarangense

InactiveCN106105986APrevent rotAchieve the function of drainage and water retentionCultivating equipmentsAreolaThinning

The invention relates to the technical field of plant plantation, and specifically relates to a method for planting Syzygium samarangense. The method comprises: (1) selecting land and preparing land; (2) planting; (3) performing field management: a, regulating in a production period, b, forcing flowers, c, blossom and fruit thinning, d, bagging; (4) harvesting fruits: when 70-90% of Syzygium samarangense areola is unfolded and variety inherent color appears, harvesting. The invention provides the method for planting Syzygium samarangense, and provides a technical scheme for Syzygium samarangense standardized planting, and meanwhile using production period regulation, the Syzygium samarangense come into the market staggering a selling season of July to August. The method improves quality of Syzygium samarangens, and improves economical benefits of Syzygium samarangens planting.

Owner:广西田阳共联农业综合开发有限公司

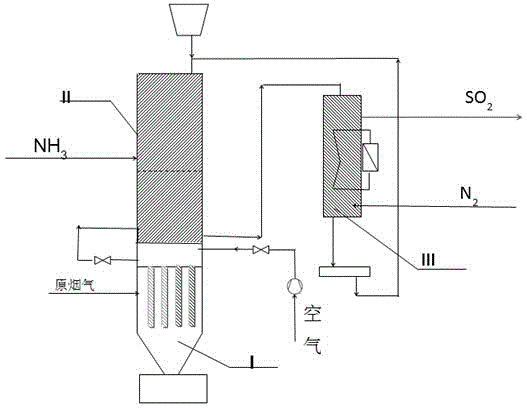

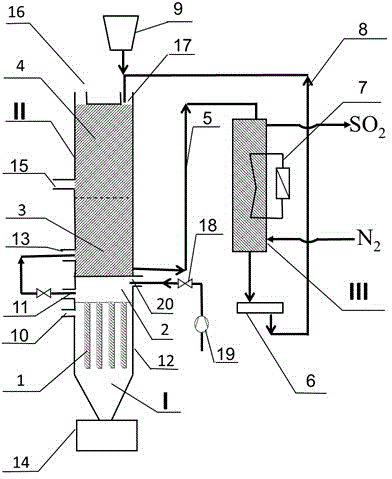

Active coke desulfurization and denitration and membrane separation and dust removal integrated system and active coke desulfurization and denitration and membrane separation treatment method

InactiveCN104548809AAchieve separationTo achieve the purpose of recyclingDispersed particle filtrationThermodynamicsFlue gas

The invention discloses an active coke desulfurization and denitration and membrane separation and dust removal integrated system and an active coke desulfurization and denitration and membrane separation treatment method. The system comprises an inorganic membrane filter, a desulfurization and denitration moving bed reaction tower and a regeneration tower. The method comprises the steps that a high-temperature flue gas flows through a ceramic membrane terminal filter, and the separation of a gas and dust in the flue gas is realized at high temperature by utilizing the selection screening and permeability of a membrane material; the obtained dedusted flue gas flows into a bed body along a side line of the bottom of a moving bed, so that the flue gas is in reverse contact with active coke, and SO2 is removed in a desulfurization layer; the flue gas continues to rise and flows into a denitration layer, so that the flue gas is reacted with ammonia under the action of the active coke to obtain N2 and H2O and other clean gases to be emptied; the active coke is desulfurized and denitrated and then the desulfurized and denitrated active coke enters an adsorption regeneration device to realize the regeneration so as to achieve the purpose of recycling, and the removed SO2 is recycled. The system provided by the invention has the advantages of small occupied area, low treatment cost, no secondary pollution and the like.

Owner:NANJING UNIV OF TECH

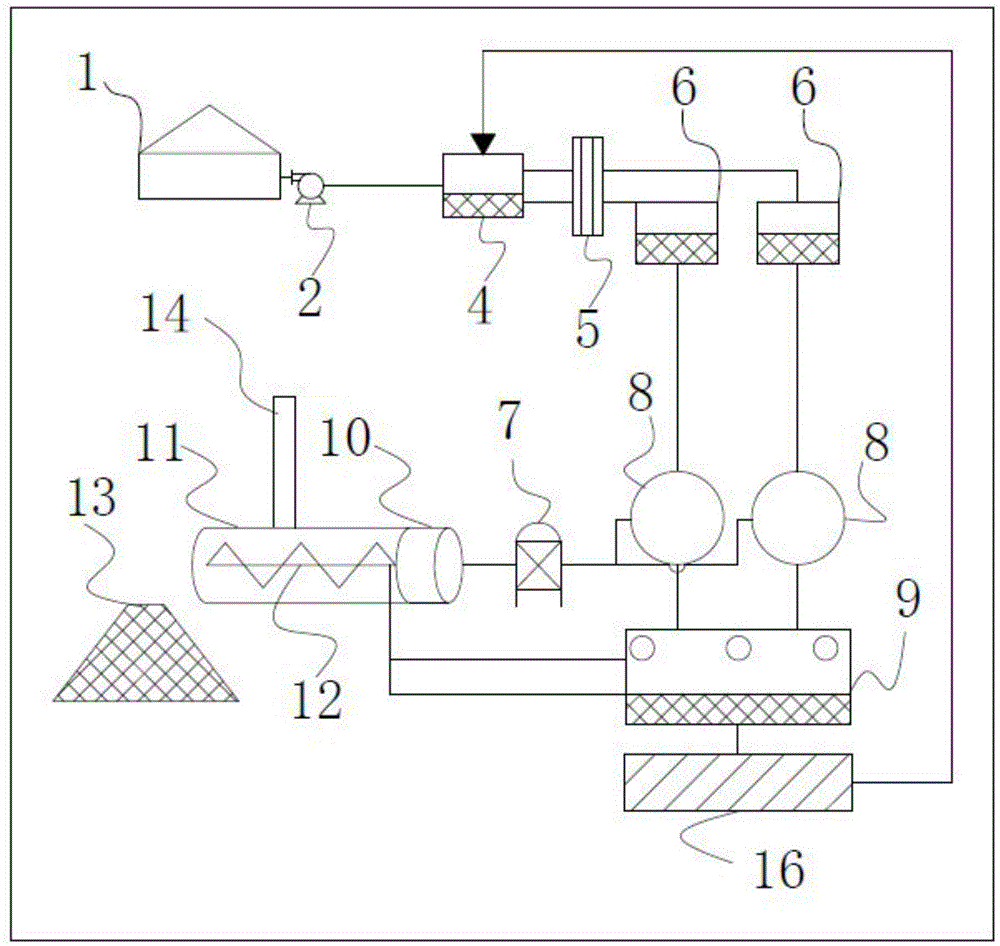

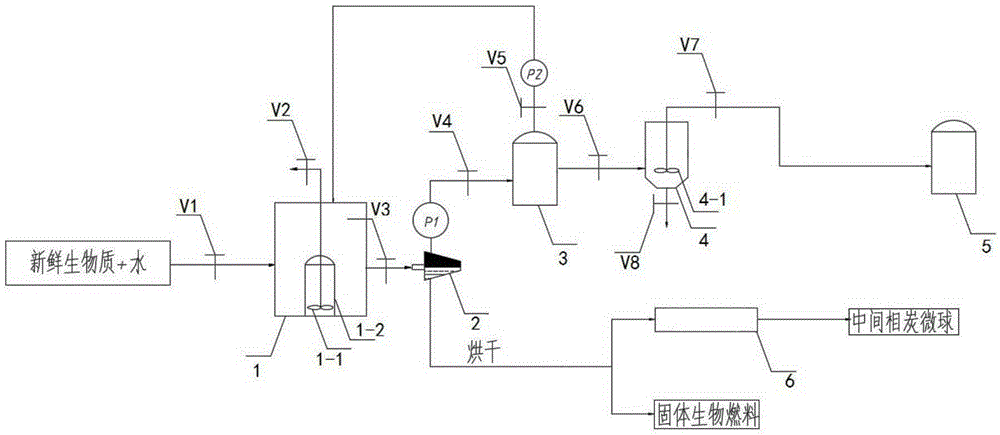

High-valued treatment device and high-valued treatment method for fresh biomass based on microwave hydrothermal carbonization

InactiveCN105331376ASave waterGuaranteed harmless disposalBiofuelsSpecial form destructive distillationBiomassHydrothermal carbonization

The invention discloses a high-valued treatment device or fresh biomass based on microwave hydrothermal carbonization. The high-valued treatment device comprises a microwave reactor, wherein a pressure container is arranged in the microwave reactor and is connected with a solid-liquid separator; a liquid outlet end of the solid-liquid separator is communicated with a liquid storage tank; the liquid storage tank is connected with an anaerobic fermentation tank; the anaerobic fermentation tank is a gas storage tank; the gas storage tank is connected with the pressure container through a second air circulating pump. The invention also discloses a high-valued treatment method for the fresh biomass based on the microwave hydrothermal carbonization. According to the high-valued treatment device and the high-valued treatment method disclosed by the invention, on one hand, the aim of recycling a dehydration liquid is achieved, and on the other hand, the dehydration liquid is used as a fermentation substrate, efficient methane production is realized; high-valued utilization of the fresh biomass is realized; recycling and harmlessness of the fresh biomass are realized.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

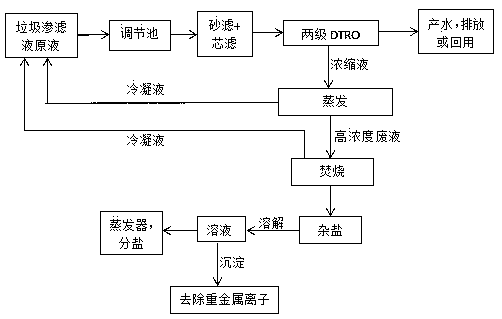

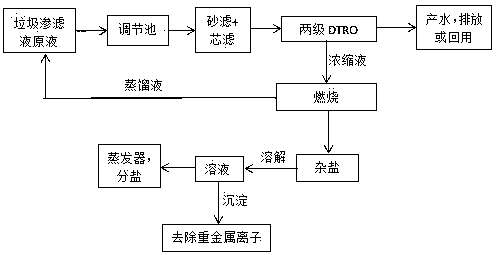

Method using disc-tube reverse osmosis integration technology for treating landfill leachate

InactiveCN109205899AHigh purityAvoid recontaminationTreatment involving filtrationAlkali metal sulfite/sulfate purificationHigh concentrationCombustion

The invention belongs to the field of water treatment, and in particular relates to a method using a disc-tube reverse osmosis integration technology for treating landfill leachate. The method comprises the following steps: pre-treating, allowing filter-effluent to enter two-stage DTRO for concentrating and filtering, incineration or submerged combustion, and impurity salt treatment steps. Compared with membrane bioreactor (MBR) + nanofiltration (NF) / reverse osmosis (RO), pretreatment + DTRO and other processes, the method has a more integrated system, simpler pretreatment, smaller land area, higher recovery rate and lower running cost on the premise of effluent reaching standards. The problem that high-concentration waste liquid is difficult to treat after a reverse osmosis concentratedliquid is evaporated is solved, impurity salts can be recycled, and the purpose of near zero discharge and recycling is achieved.

Owner:烟台金正环保科技有限公司

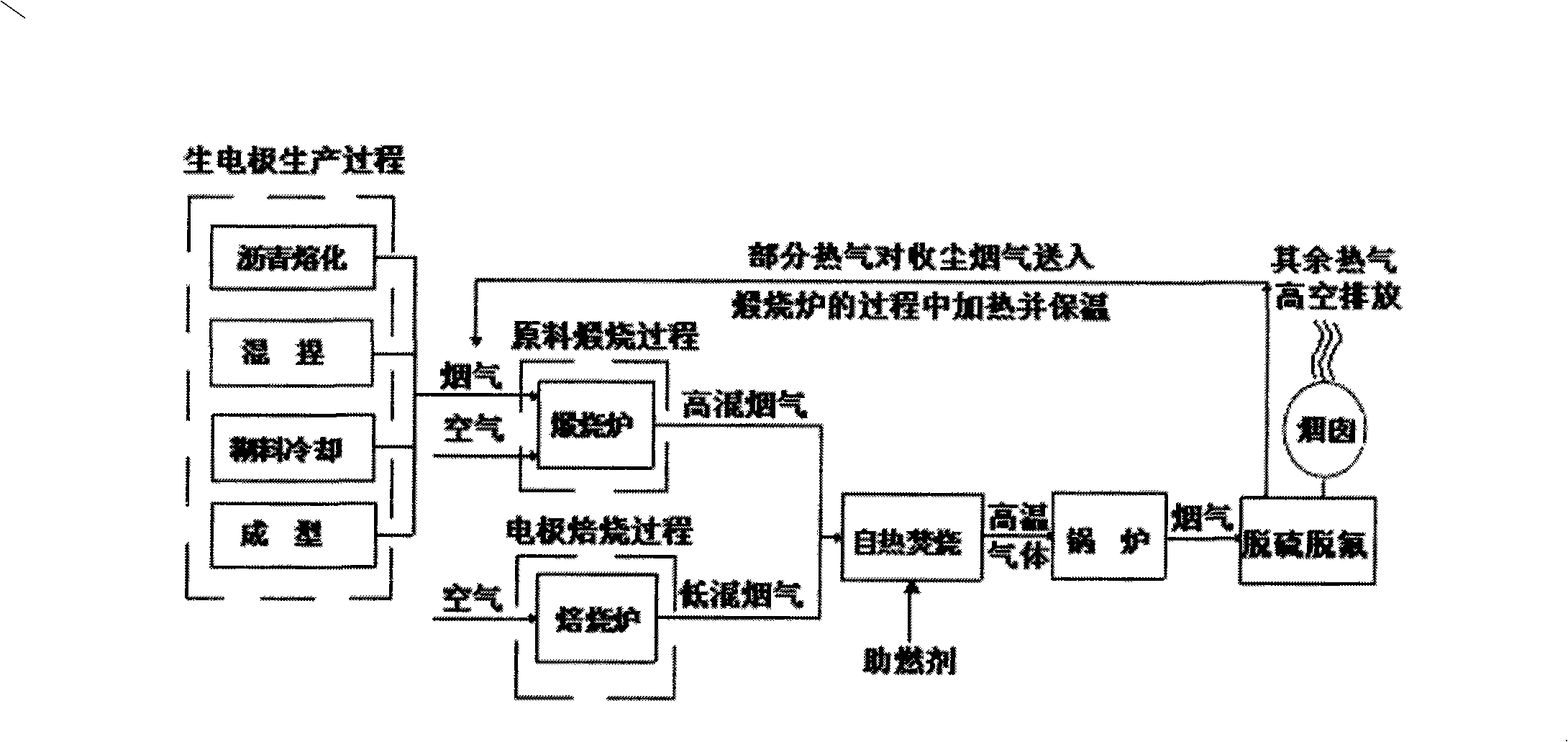

Flue gas cleaning treatment method during producing carbon product

ActiveCN101306312ATo achieve the purpose of recyclingSimple processDispersed particle separationIncinerator apparatusCombustionFlue gas

The invention relates to a flue gas purifying treatment method during the production process of carbon products. The flue gas purifying treatment method is characterized in that the treatment process directly sends flue gas produced in the production process of a green electrode into a calcining furnace for high-temperature calcination, high-temperature gas after the calcination is mixed with low-temperature gas emitted from a roasting furnace, the mixed calcination is carried out under the high temperature via sufficient calorific value thereof or with the help of a combustion adjuvant, the high-temperature gas emitted after the calcination is taken as a heat source to be directly sent to a boiler, the gas emitted from the boiler is finally subjected to desulphurization and defluorination treatment, then a part of the purified gas is returned to the production process of the green electrode, a pipeline is heated and subjected to the temperature keeping during the process of sending the dust collecting flue gas produced during the process to the calcining furnace, and the residual purified gas is subjected to the high-altitude emission. The method of the invention can thoroughly treat the harmful substances in the flue gas and comprehensively take into account the actual production conditions and the heat of the emitted flue gas of various work segments, the process flow is simple, the operation is convenient and the treatment cost is low.

Owner:河南华慧有色工程设计有限公司 +1

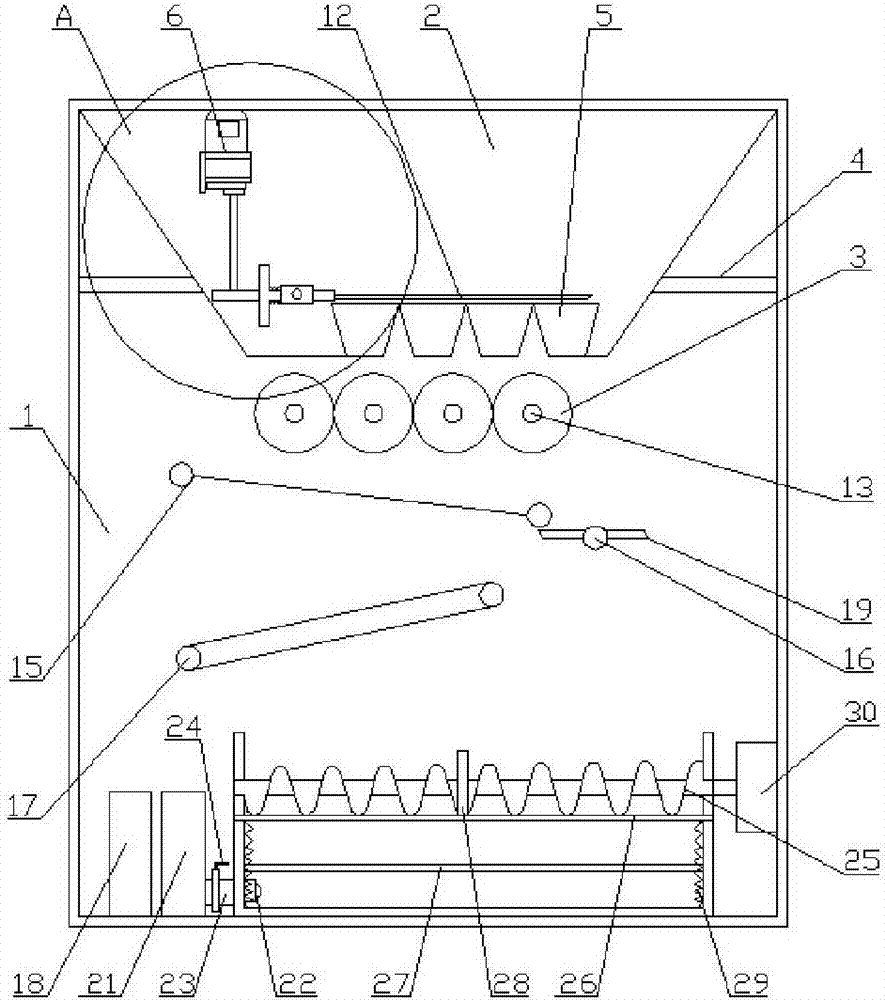

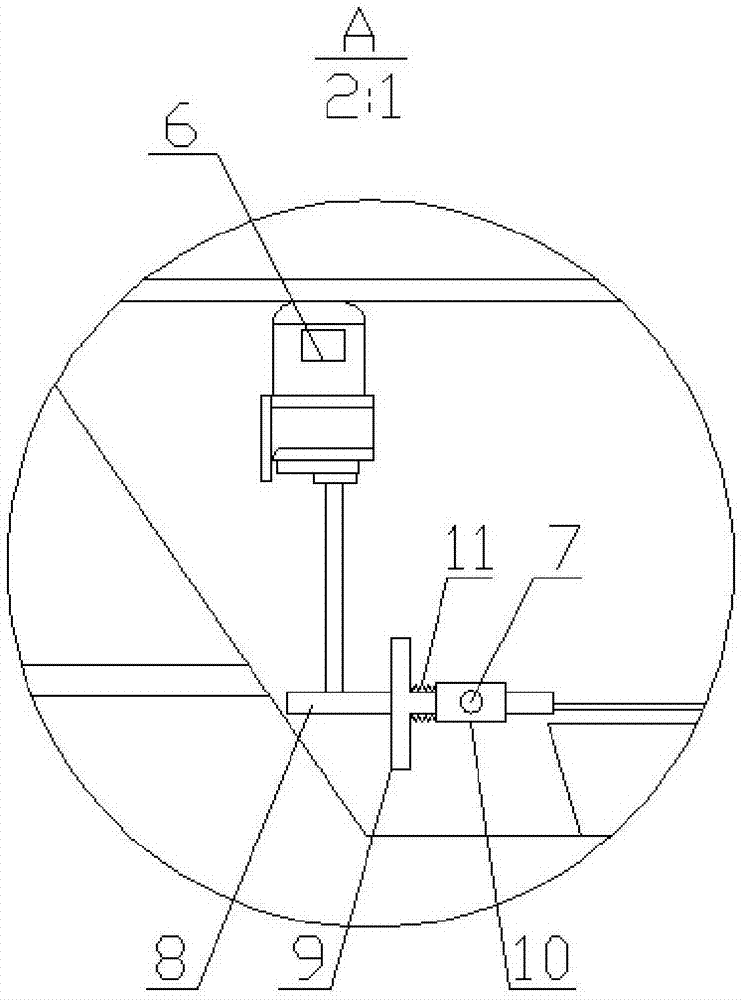

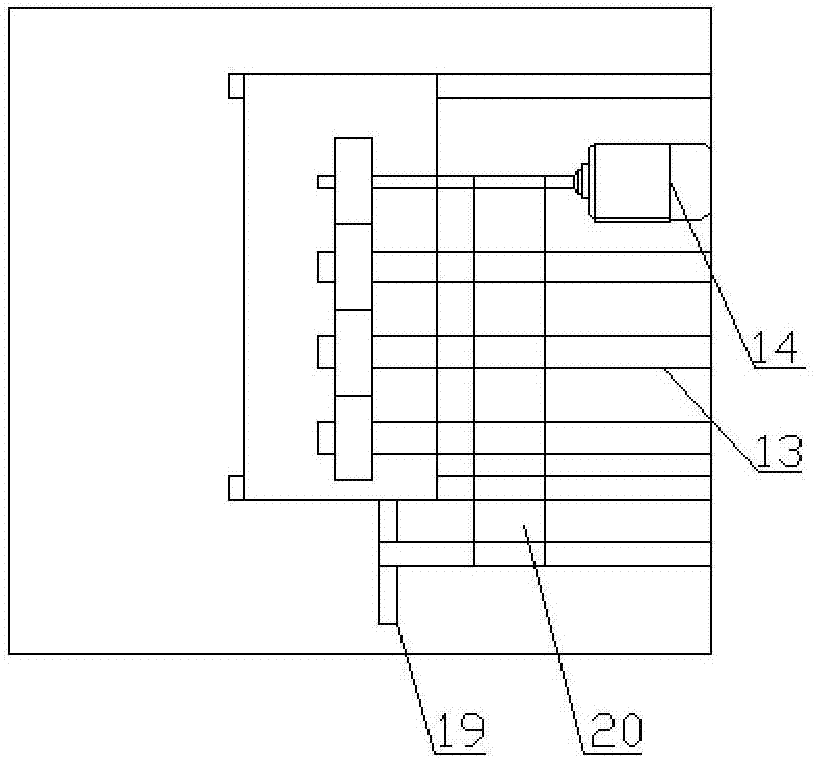

Process for making ginger and garlic flavor fermented chili

The invention discloses a process for making ginger and garlic flavor fermented chili and relates to the technical field of processing of salted vegetables and fruits. A ginger and garlic flavor fermented chili processing device comprises a box body of which the interior is hollow, wherein the interior of the box body comprises a crushing mechanism, a screening mechanism and a separating mechanismfrom top to bottom. The process for making ginger and garlic flavor fermented chili comprises the following steps: (1) selecting raw materials; (2) treating the raw materials; (3) making salted fermented materials; (4) pickling; and (5) flavoring. By virtue of the technical scheme, the problem in the fermented chili making process that chili stems and chili seeds need to be manually removed is solved. The process can be applied to making various chili products.

Owner:贵州湄潭辣妹子食品有限责任公司

Water recovery processing method on spacecraft

InactiveCN101381181ASolving Recycling ProblemsSolve usabilityCosmonautic environmental control arrangementMultistage water/sewage treatmentChemical treatmentFiltration

The invention provides a method for recovering and treating water in spacecrafts. In the spacecrafts, sanitary wastewater used by astronauts is first treated through an ozone / chemical treatment device, so as to be deodorized and disinfected; then the sanitary wastewater is subjected to multi-layer and classified filtration via a filtering device; filtrate enters a heating-distilling device; heated-distilled steam is directly combined with cold gas or cold mist in a cooling device so as to become water drops rapidly; and the water drops are collected and turned into pure distilled water. As the wastewater can meet the requirement of living water after purification, the method achieves the aims of recovering and recycling the sanitary wastewater in the spacecrafts. Precipitates left after filtration and distillation are used as garbage and treated separately.

Owner:范益华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com