Method for comprehensively utilizing electrolytic manganese residues

A technology for electrolytic manganese slag and manganese-rich slag, applied in chemical instruments and methods, preparation/separation of sulfur compounds, ammonia, etc., can solve the problems of not fully utilizing the available resources of manganese slag, achieve low cost, and facilitate promotion , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

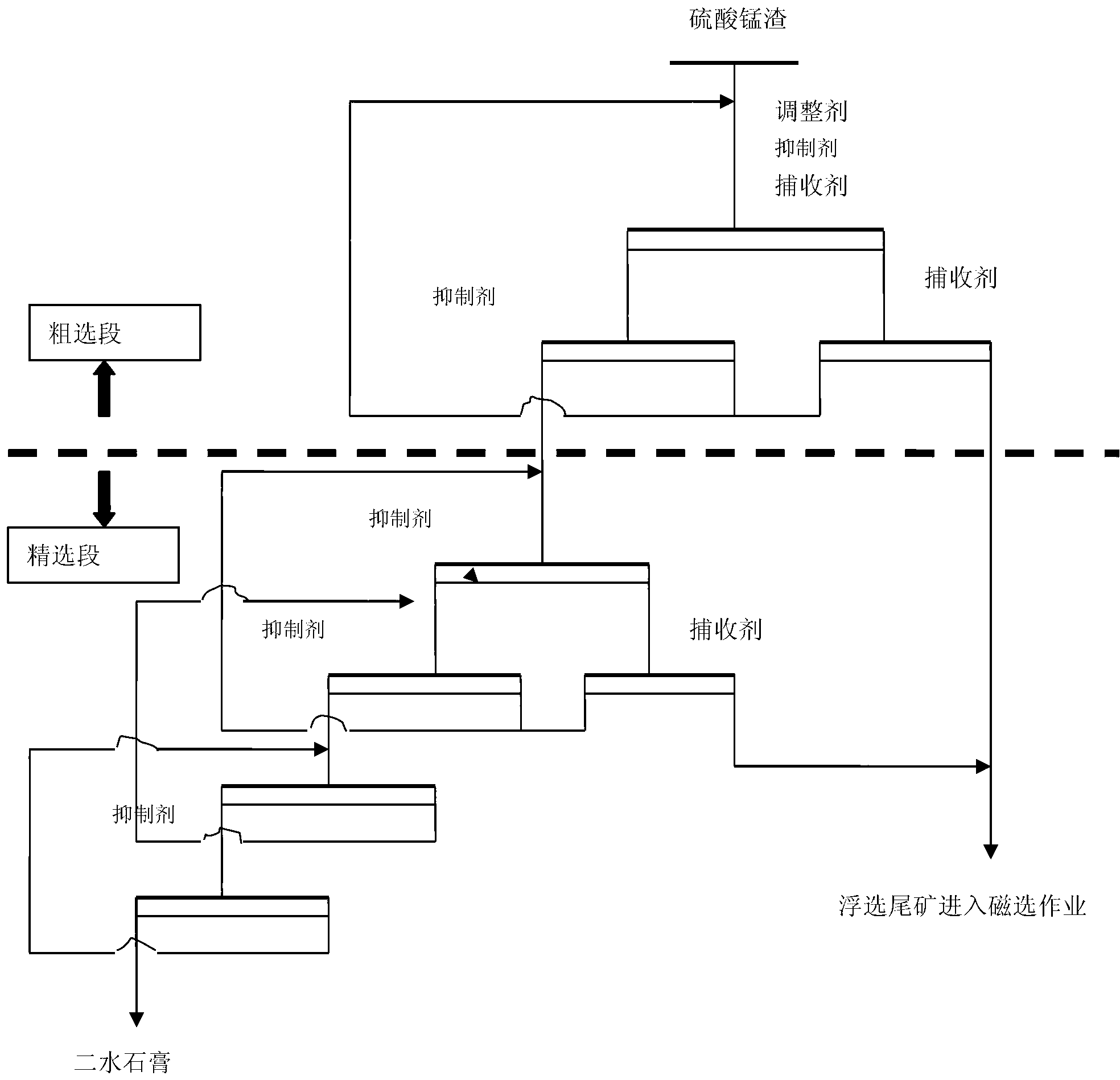

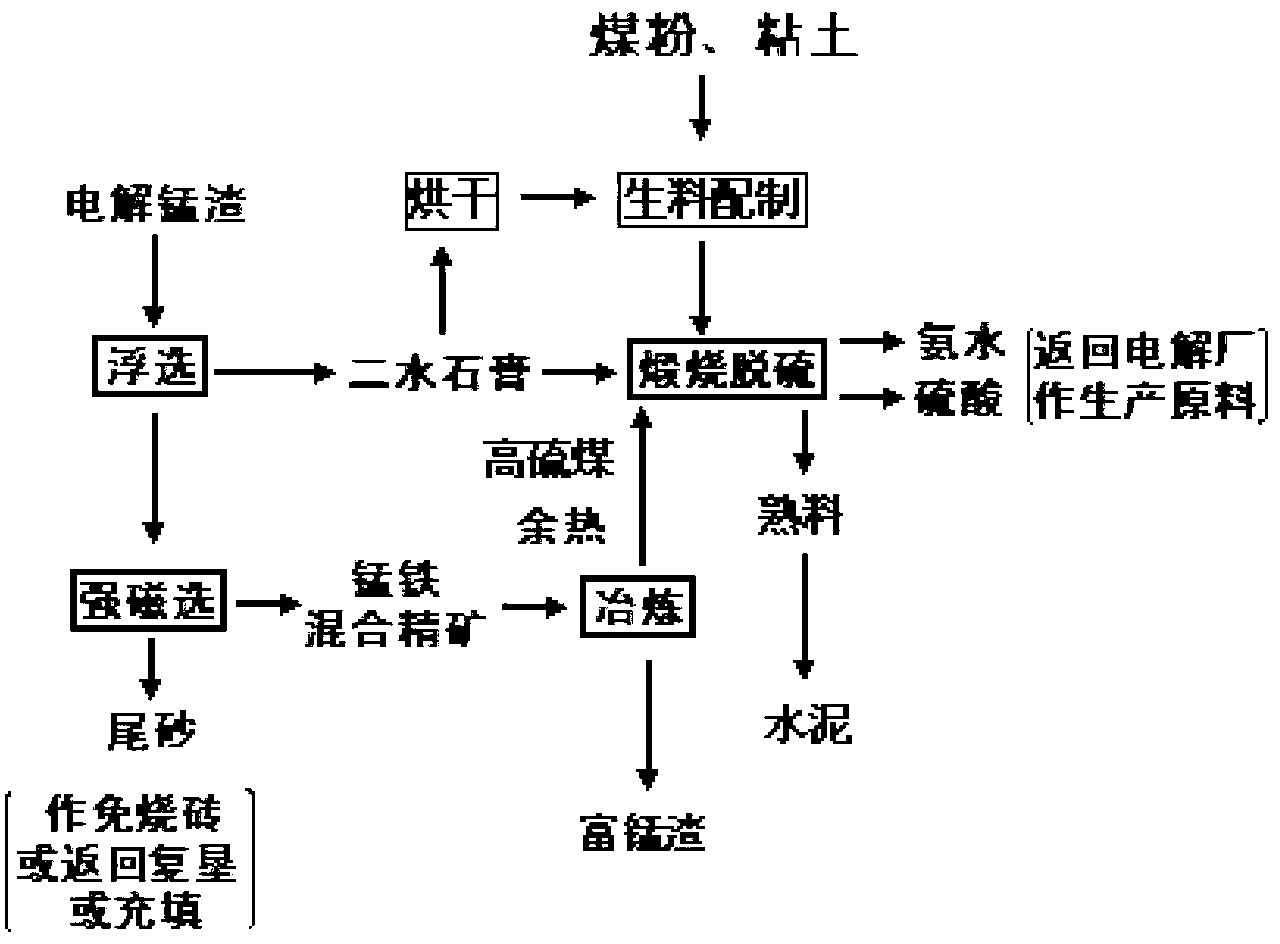

[0021] A method for comprehensive utilization of electrolytic manganese slag. Firstly, electrolytic manganese slag is flotationd in a flotation machine to select dihydrate gypsum. The selected agent is sodium carbonate as the regulator, sodium hexametaphosphate and water glass as the inhibitor, fatty acid salt as the collector, 500 g / ton of sodium carbonate and 600 g of sodium hexametaphosphate as the flotation agent / ton, the consumption of water glass is 1000 grams per ton, and the consumption of fatty acid salt is 400 grams per ton. The flotation agent used in the selected section is acidic water glass as the inhibitor, and fatty acid salt as the collector. The amount of acidic water glass is 1200 g / ton, and the amount of fatty acid salt is 15 g / ton. The two-stage flotation roughing section adopts two roughing, one sweeping and one finening process, and the above-mentioned refining section adopts one roughing, one sweeping and three finening process, and the gypsum content...

Embodiment 2

[0023] A method for comprehensive utilization of electrolytic manganese slag. Firstly, electrolytic manganese slag is flotationd in a flotation machine to select dihydrate gypsum. The selected agent is sodium carbonate as the regulator, sodium hexametaphosphate and water glass as the inhibitor, fatty acid salt as the collector, 700 g / ton of sodium carbonate and 500 g of sodium hexametaphosphate as the flotation agent / ton, the consumption of water glass is 1000 grams per ton, and the consumption of fatty acid salt is 300 grams per ton. The flotation agent used in the selected section is acidic water glass as the inhibitor, and fatty acid salt as the collector. The amount of acidic water glass is 1000 g / ton, and the amount of fatty acid salt is 15 g / ton. The two-stage flotation roughing section adopts two roughing, one sweeping and one finening process, and the above-mentioned refining section adopts one roughing, one sweeping and three finening process, and the gypsum content...

Embodiment 3

[0025] A method for comprehensive utilization of electrolytic manganese slag. Firstly, electrolytic manganese slag is flotationd in a flotation machine to select dihydrate gypsum. The selected agent is sodium carbonate as the regulator, sodium hexametaphosphate and water glass as the inhibitor, fatty acid salt as the collector, 900 g / ton of sodium carbonate and 400 g of sodium hexametaphosphate as the flotation agent / ton, the consumption of water glass is 1000 grams per ton, and the consumption of fatty acid salt is 280 grams per ton. The flotation agent used in the selected section is acidic water glass as the inhibitor, and fatty acid salt as the collector. The amount of acidic water glass is 900 g / ton, and the amount of fatty acid salt is 15 g / ton. The two-stage flotation roughing section adopts two roughing, one sweeping and one finening process, and the above-mentioned refining section adopts one roughing, one sweeping and three finening process, and the gypsum content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com