High-valued treatment device and high-valued treatment method for fresh biomass based on microwave hydrothermal carbonization

A technology of microwave hydrothermal treatment method, which is applied in the direction of biofuel, special dry distillation, petroleum industry, etc., can solve the problem of low utilization rate, achieve the effect of saving water resources, ensuring resource utilization, and ensuring harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

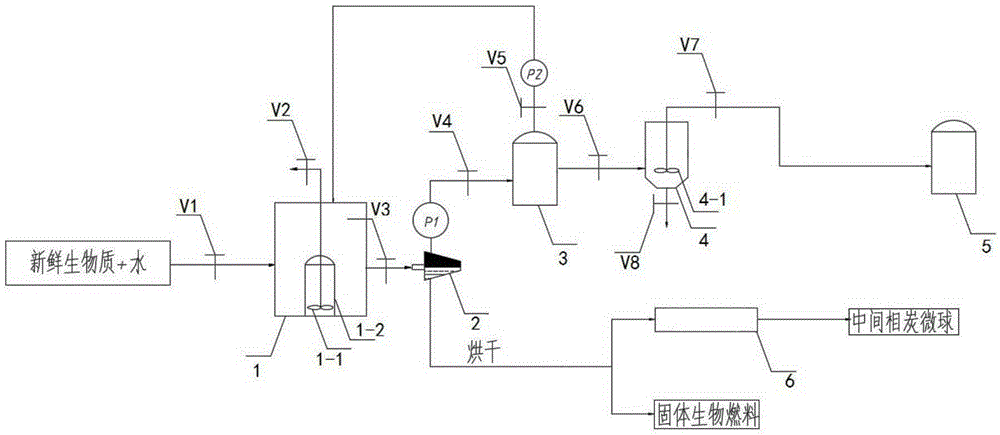

[0031] Such as figure 1 As shown, the fresh biomass high-value treatment device based on microwave hydrothermal carbonization includes a microwave reactor 1. The microwave reactor 1 is provided with a feed inlet and a gas outlet. The feed inlet is provided with a first valve V1, and the gas outlet A second valve V2 is set, a pressure vessel 1-2 is set in the microwave reactor 1, a pressure vessel stirring paddle 1-1 is set in the pressure vessel 1-2, and the pressure vessel 1-2 communicates with the feed port and the gas outlet respectively , the pressure vessel 1-2 is also connected to the input end of the solid-liquid separator 2 through the third valve V3, and the liquid outlet end of the solid-liquid separator 2 is connected to the liquid storage tank 3 through the first air circulation pump P1 and the fourth valve V4 in turn, The liquid storage tank 3 is connected to the anaerobic fermentation tank 4 through the sixth valve V6, the anaerobic fermentation tank 4 is connect...

Embodiment 2

[0042] The high-value processing device for fresh biomass based on microwave hydrothermal carbonization includes a microwave reactor 1. The microwave reactor 1 is provided with a feed inlet and a gas outlet. The feed inlet is provided with a first valve V1, and the gas outlet is provided with a second valve. Two valves V2, the microwave reactor 1 is provided with a pressure vessel 1-2, the pressure vessel 1-2 is provided with a pressure vessel stirring paddle 1-1, and the pressure vessel 1-2 is connected with the feed inlet and the gas outlet respectively, and the pressure vessel 1-2 is also connected to the input end of the solid-liquid separator 2 through the third valve V3, and the liquid outlet end of the solid-liquid separator 2 is connected to the liquid storage tank 3 through the first air circulation pump P1 and the fourth valve V4 in turn, and the liquid storage tank 3 The anaerobic fermentation tank 4 is connected to the anaerobic fermentation tank 4 through the sixth...

Embodiment 3

[0053] The high-value processing device for fresh biomass based on microwave hydrothermal carbonization includes a microwave reactor 1. The microwave reactor 1 is provided with a feed inlet and a gas outlet. The feed inlet is provided with a first valve V1, and the gas outlet is provided with a second valve. Two valves V2, the microwave reactor 1 is provided with a pressure vessel 1-2, the pressure vessel 1-2 is provided with a pressure vessel stirring paddle 1-1, and the pressure vessel 1-2 is connected with the feed inlet and the gas outlet respectively, and the pressure vessel 1-2 is also connected to the input end of the solid-liquid separator 2 through the third valve V3, and the liquid outlet end of the solid-liquid separator 2 is connected to the liquid storage tank 3 through the first air circulation pump P1 and the fourth valve V4 in turn, and the liquid storage tank 3 The anaerobic fermentation tank 4 is connected to the anaerobic fermentation tank 4 through the sixth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com