Separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption

A Fischer-Tropsch synthesis and solvent absorption technology, applied in separation methods, absorption purification/separation, distillation purification/separation, etc., to achieve the effects of low investment and operating costs, high material recovery rate, and improved use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

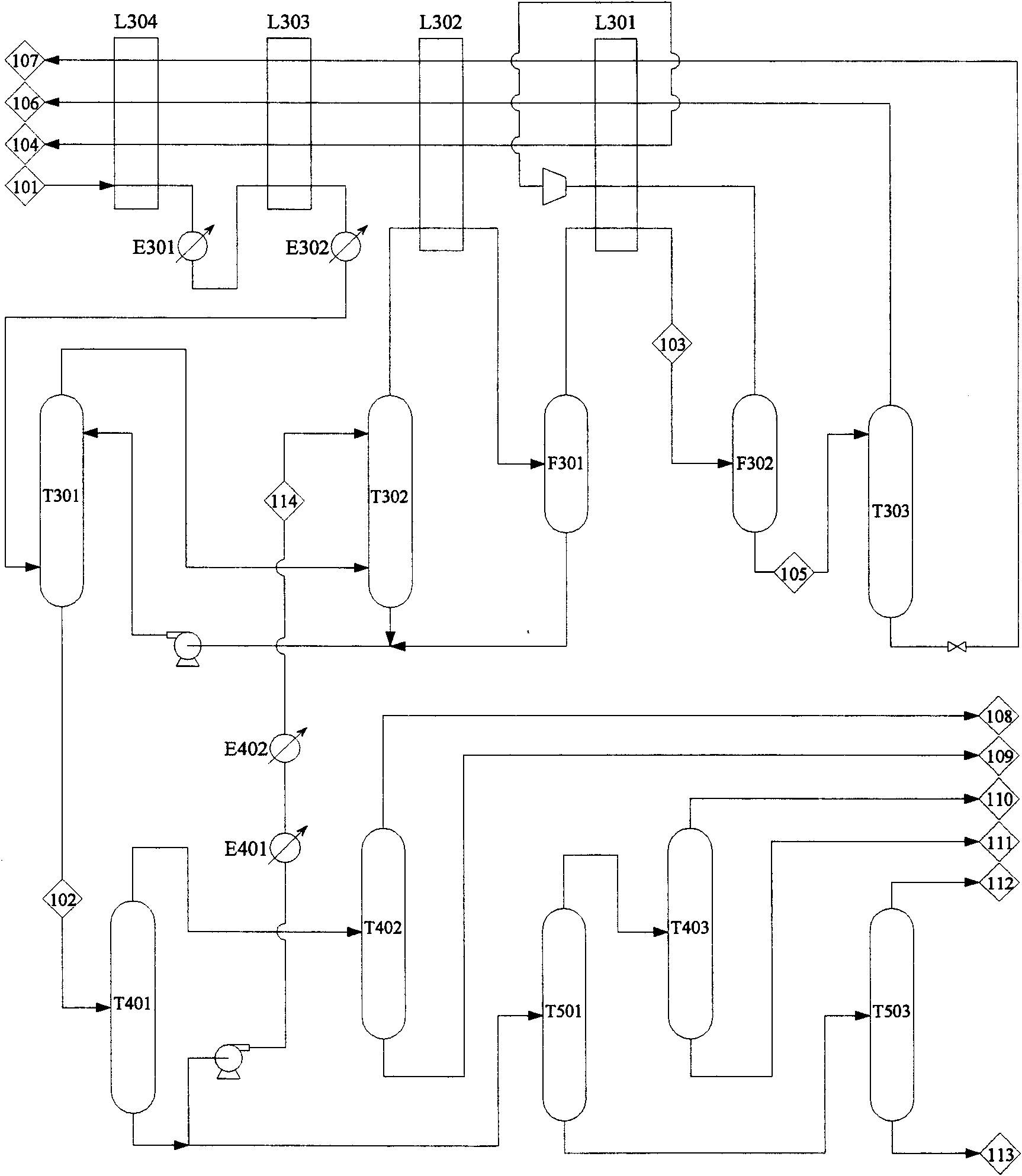

[0041] as attached figure 1 As shown, the pretreated Fischer-Tropsch synthesis tail gas is used as feed, and its composition is shown in stream 101. Stream 101 passes through material heat exchanger L304, cooler E301, material heat exchanger L303 and cooler E302 to reduce the temperature to about -75°C and then enters demethanizer T301 to remove methane and lighter components therein. The top discharge of the demethanizer T301 is sent to the absorption tower T302, and the absorbent (stream 114) is injected into the top of the tower to reduce the content of carbon 2 and heavier components therein. The composition of the bottom liquid of the demethanizer is shown in stream 102, so it can be seen that the concentration of light hydrocarbons in the feed is increased by 5 to 6 times. The cooling and condensation of the above-mentioned feed gas uses the cooling capacity provided by the propylene refrigeration compressor and the ethylene refrigeration compressor in addition to the h...

Embodiment 2

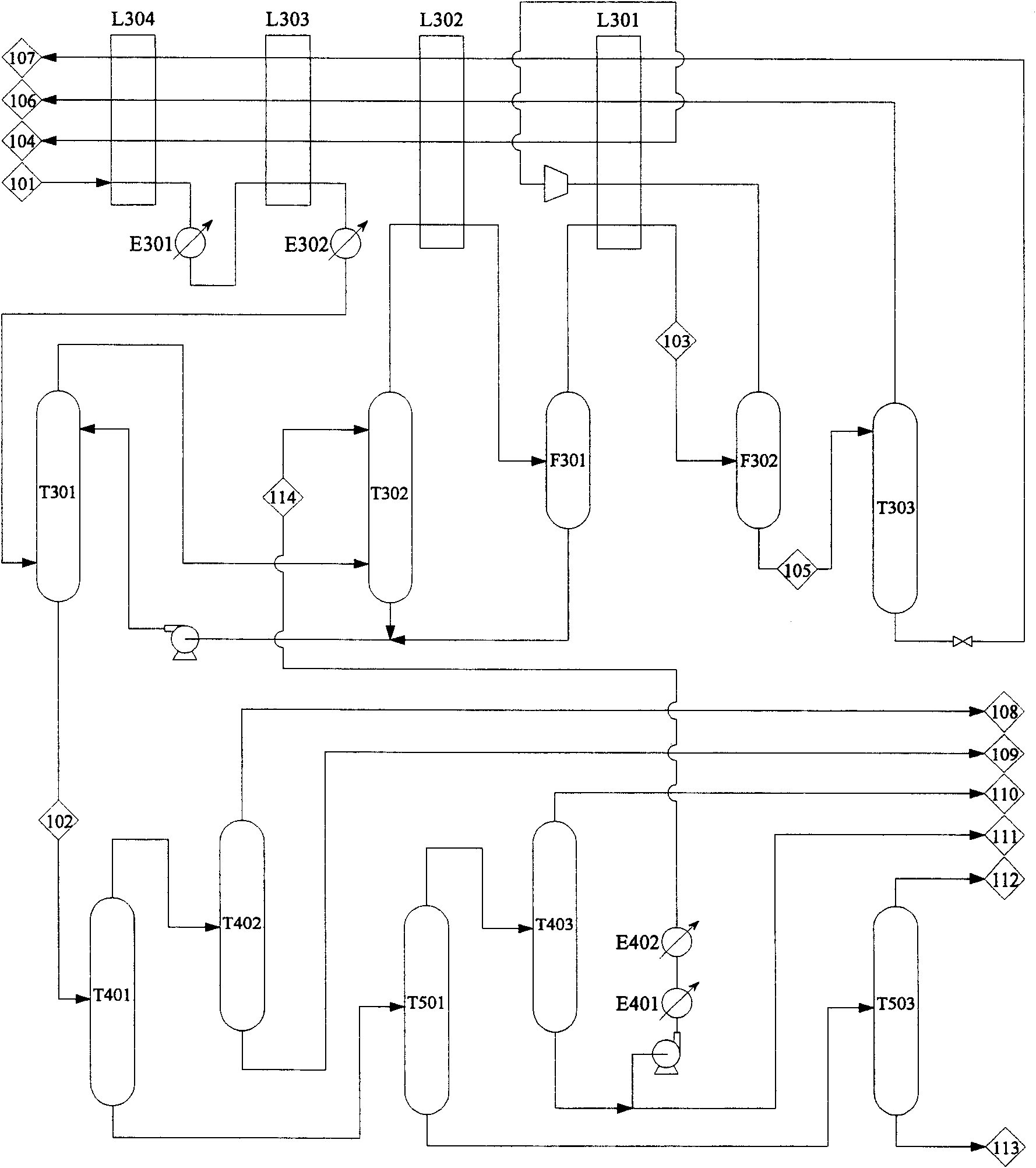

[0050] as attached figure 2 As shown, from the material inlet to the demethanizer, the absorption tower, the first and second gas-liquid separation tanks, and finally to the desorption tower, all the processes are the same as in Example 1, except that the absorbent used in this example is Propane, from the bottom material of the propylene rectification tower T403, is cooled by the coolers E401 and E402 and then enters the absorption tower T302 as an absorbent. See logistics table 2 for the material balance calculation results.

[0051] Embodiment 2 logistics table Mol%

[0052] tracking number

Embodiment 3

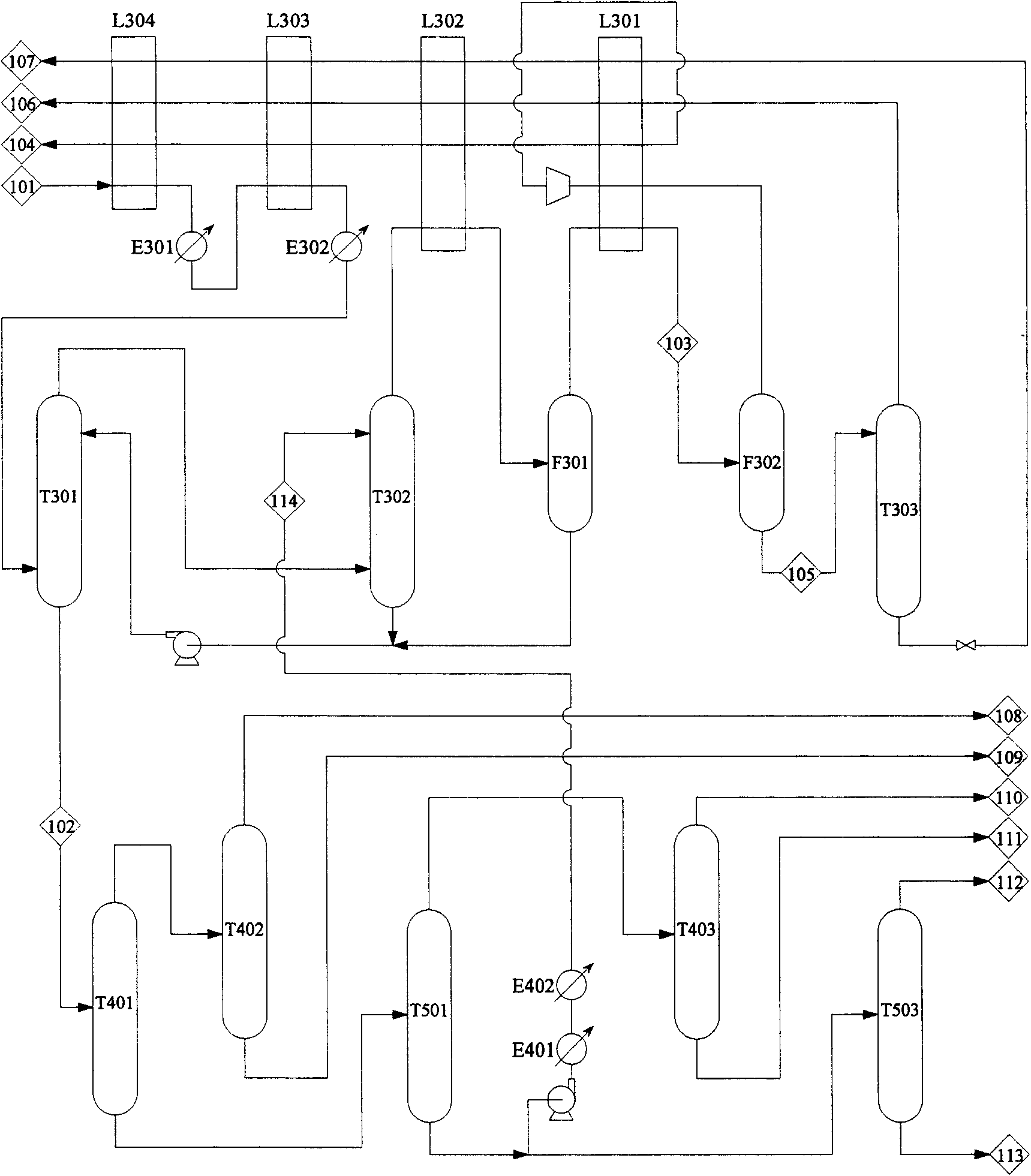

[0054] as attached image 3 As shown, from material import to demethanizer, absorption tower, first and second gas-liquid separation tank, finally to desorption tower, all flow processes are all the same as embodiment 1, and the difference is that the absorbent used in this embodiment is The bottom material from the depropanizer T501 is cooled by the coolers E401 and E402 and then enters the absorption tower T302 as an absorbent. See logistics table 3 for material balance calculation results.

[0055] Logistics Table 3 Mol%.

[0056] tracking number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com