Preparation method of nitrogen-doped porous carbon material

A technology for nitrogen-doped porous carbon and weathered coal, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex preparation process, high production cost, non-adjustable pore size, etc., and achieve rich sources and ash content. Low, improve the effect of carbonization yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

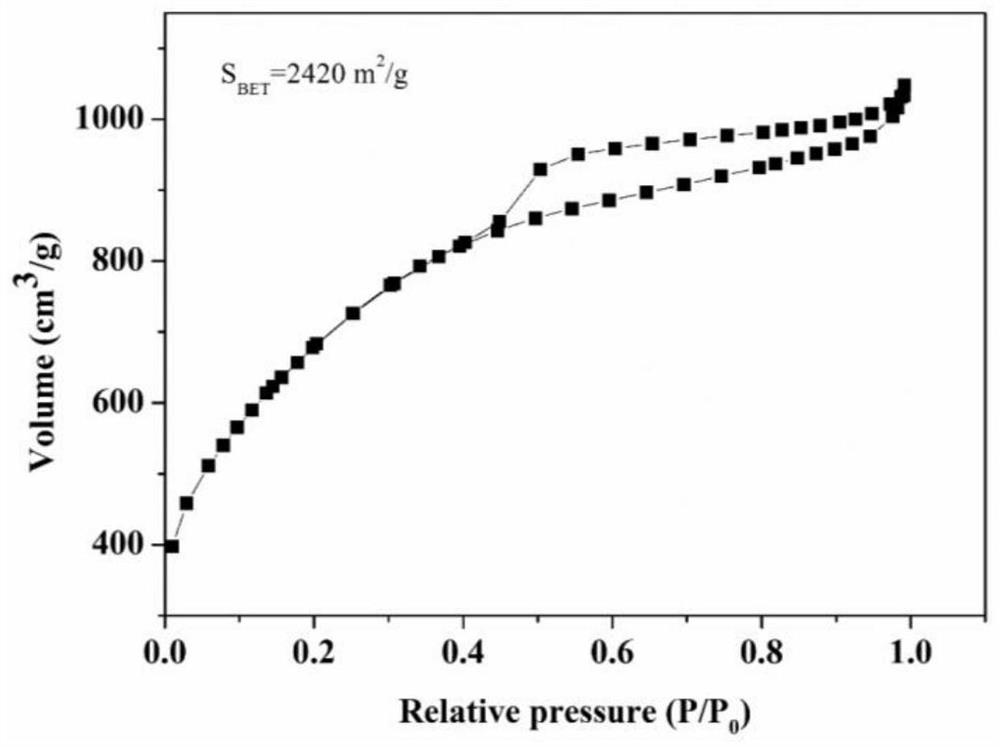

Image

Examples

Embodiment 1

[0047] The preparation method of nitrogen-doped porous carbon material in this embodiment includes the following steps:

[0048] (1) Dissolve 100g of urea and 125g of potassium carbonate in 725g of water to form a mixed aqueous solution, then add 50g of purified weathered coal humic acid, stir for 2 hours, and put it into a blast drying oven for drying at 80°C;

[0049] (2) Put the sample dried in step (1) into an activation furnace, and raise it to 800°C at a rate of 2°C / min for 4 hours;

[0050] (3) Cool naturally after high-temperature calcination, take out the sample, wash 5 times with deionized water, and dry in a blast drying oven at 90° C. for 24 hours to obtain a nitrogen-doped porous carbon material.

Embodiment 2

[0052] The preparation method of nitrogen-doped porous carbon material in this embodiment includes the following steps:

[0053] (1) Dissolve 75g of urea and 100g of potassium carbonate in 725g of water to form a mixed aqueous solution, then add 45g of purified weathered coal humic acid, stir for 2.5 hours, and put it into a blast drying oven for drying at 85°C;

[0054] (2) Put the sample dried in step (1) into an activation furnace, and raise it to 850°C at a rate of 3°C / min for 3 hours;

[0055] (3) Cool naturally after high-temperature calcination, take out the sample, wash with deionized water 4 times, and dry in a blast drying oven at 85° C. for 22 hours to obtain a nitrogen-doped porous carbon material.

Embodiment 3

[0057] The preparation method of nitrogen-doped porous carbon material in this embodiment includes the following steps:

[0058] (1) Dissolve 50g of urea and 75g of potassium carbonate in 675g of water to form a mixed aqueous solution, then add 40g of purified weathered coal humic acid, stir for 3 hours, and put it into a blast drying oven at 90°C for drying;

[0059] (2) Put the sample dried in step (1) into an activation furnace, and raise it to 850°C at a rate of 4°C / min for 4 hours;

[0060] (3) Cool naturally after high-temperature calcination, take out the sample, wash with deionized water for 3 times, and dry at 80° C. for 20 h in a blast drying oven to obtain a nitrogen-doped porous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com