Uniform internal heating stirring type activation kiln

A stirring and internal heating technology, applied in the field of activated carbon, can solve the problems of harsh volatile content of carbonized materials, high labor intensity, high energy consumption of rotary kiln, shorten the activation time, no leakage of three wastes, and low kiln start-up cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

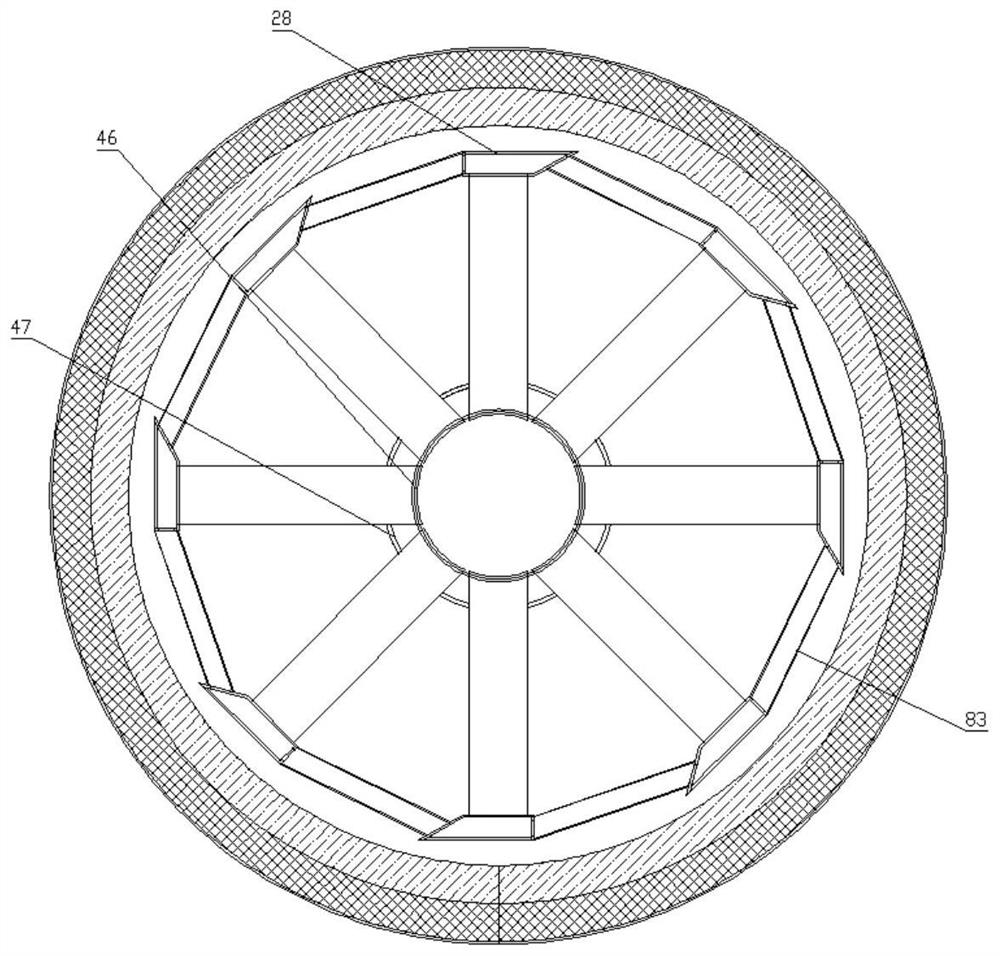

[0044] refer to Figure 1-12 , a uniform internal heat stirring type activation kiln, comprising a kiln main body, a feeding mechanism, a diversion stirring mechanism, a water sealing mechanism, a material discharging mechanism, and a hot blast stove, and the feeding mechanism is arranged on the side wall of the kiln main body;

[0045] The main body of the kiln mainly includes a kiln upper cover and a kiln lower body. The lower body of the kiln mainly includes a hot blast stove body 8 and a hot blast stove shell 9 and a lower body shell 20 fixedly connected thereto. The diversion stirring mechanism is connected in the lower body shell 20;

[0046] The diversion stirring mechanism mainly includes the rising header shell 26, the rising header inner shell 27, the rising header body 28, the main shaft inner sleeve 46, the main shaft outer sleeve 47, and a plurality of connecting plates are welded between the main shaft inner sleeve 46 and the main shaft outer sleeve 47 45 forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com