Preparation method for high-strength flame-retardant wood-plastic floor

A wood-plastic floor, high-strength technology, applied in the field of floor preparation, can solve the problems of easily deformed or cracked wood plastics, such as flame retardant performance and low bonding force, and achieve the effect of improving compressive strength and enhancing interface bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

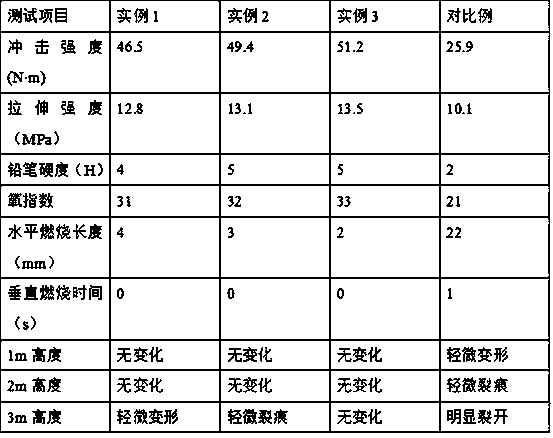

Examples

example 1

[0024]Take 200g of sepiolite, put it in a stone grinder and grind for 2 hours, pass through a 200-mesh sieve to obtain sepiolite powder, add 400mL of phosphoric acid solution with a mass fraction of 30% to the plastic basin, pour the sepiolite powder into the plastic basin, and stir Disperse for 40 minutes to obtain a sepiolite suspension, and feed 8L of ammonia gas into the sepiolite suspension to obtain a mother liquor with flame-retardant function; add 40g of β-cyclodextrin, 12g of sodium hydroxide and 200mL of distilled water into a four-necked flask. Heating the four-necked flask in a water bath to 80°C, starting the agitator, stirring and mixing at a speed of 300r / min for 35min, and putting 60mL of dimethyl sulfoxide solution of E-51 epoxy resin with a mass fraction of 40% into constant pressure drops Liquid funnel, drop the dimethyl sulfoxide solution of E-51 type epoxy resin to the four-necked flask with a constant pressure dropping funnel at a dropping rate of 5mL / min,...

example 2

[0026] Take 225g of sepiolite, place it in a stone grinder and grind for 2.5h, pass through a 200-mesh sieve to obtain sepiolite powder, add 450mL of phosphoric acid solution with a mass fraction of 30% into the plastic basin, pour the sepiolite powder into the plastic basin, Stir and disperse for 45 minutes to obtain a sepiolite suspension, inject 9L of ammonia gas into the sepiolite suspension to obtain a flame-retardant mother liquor; add 45g of β-cyclodextrin, 14g of sodium hydroxide and 250mL of distilled water into a four-necked flask, Heat the four-neck flask in a water bath to 85°C, start the agitator, stir and mix at a speed of 320r / min for 37min, and fill 70mL of dimethyl sulfoxide solution of E-51 epoxy resin with a mass fraction of 40% into the constant pressure Dropping funnel, drop the dimethyl sulfoxide solution of E-51 type epoxy resin to the four-necked flask with a constant pressure dropping funnel at a dropping rate of 7mL / min, keep the temperature for 7h, an...

example 3

[0028] Take 250g of sepiolite, put it in a stone grinder and grind for 3 hours, pass through a 200-mesh sieve to obtain sepiolite powder, add 500mL of phosphoric acid solution with a mass fraction of 30% to the plastic basin, pour the sepiolite powder into the plastic basin, and stir Disperse for 50 minutes to obtain a sepiolite suspension, feed 10L of ammonia gas into the sepiolite suspension to obtain a flame-retardant mother liquor; Heating the four-necked flask in a water bath to 90°C, starting the agitator, stirring and mixing at a speed of 350r / min for 40min, and putting 75mL of dimethyl sulfoxide solution of E-51 epoxy resin with a mass fraction of 40% into constant pressure drops Using a constant pressure dropping funnel, add the dimethyl sulfoxide solution of E-51 type epoxy resin dropwise to the four-necked flask at a dropping rate of 10mL / min, and keep the reaction for 8 hours to obtain the reaction product; Wash the reaction product 5 times, then place the washed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com