Carbon fiber emulsion sizing agent improved by carbon nano tube and preparation method of carbon fiber emulsion sizing agent

A carbon nanotube modification and carbon nanotube technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of difficulty in uniform dispersion and small size, and achieve simple preparation method, high production efficiency and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve 100 parts by weight of epoxy resin in 1 part by weight of acetone, then vacuumize and remove the organic solvent to obtain an epoxy resin mixture; add 3 parts by weight of emulsifier in the epoxy resin mixture, heat After reaching the molten state, stir quickly to make the emulsifier and epoxy mixture evenly mixed, the stirring time is 6h, and cool to obtain a viscous paste carbon fiber sizing agent;

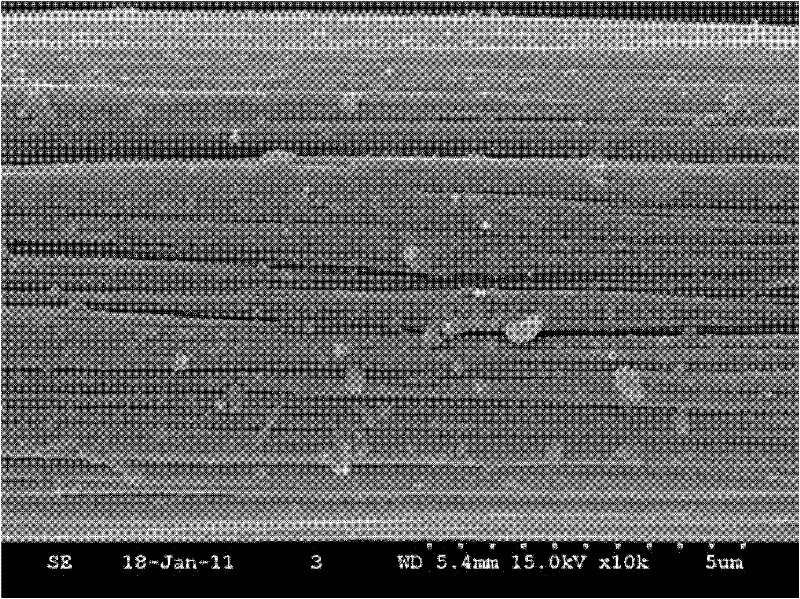

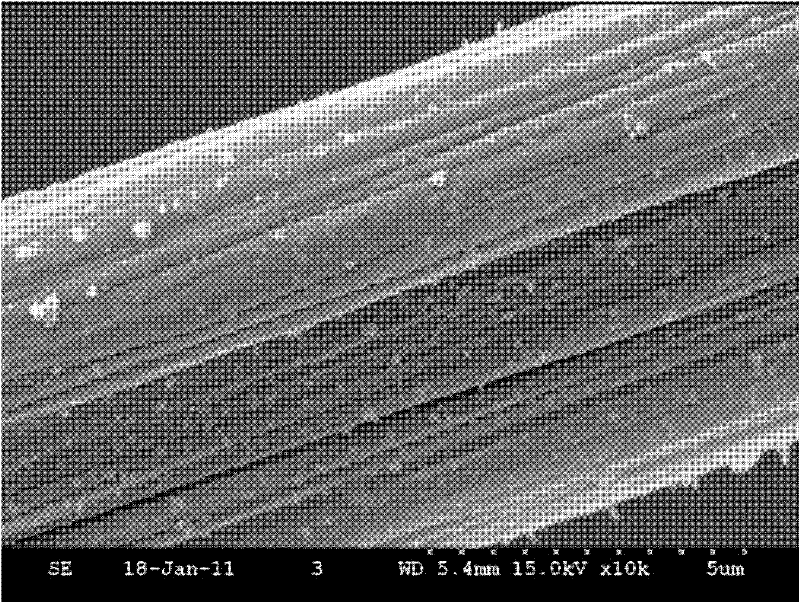

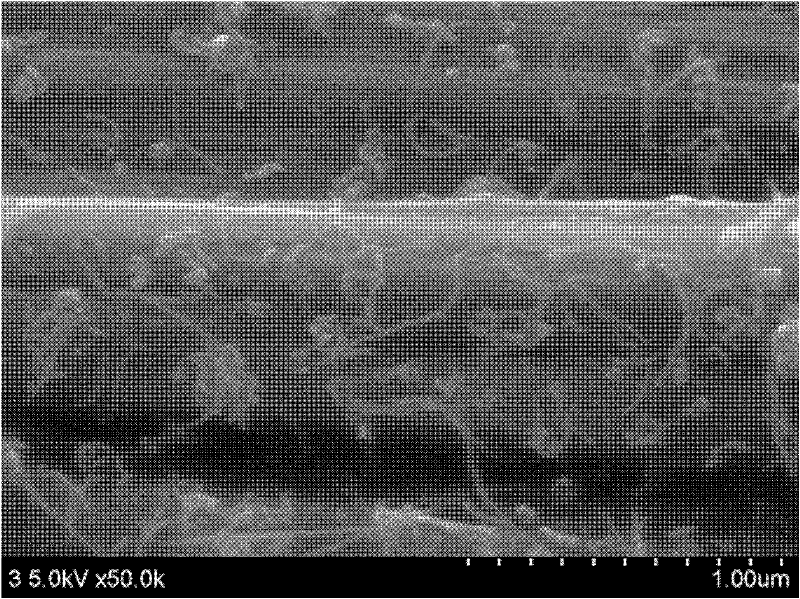

[0026] (2) Mix carbon fiber sizing agent (room temperature) and dimethyl sulfoxide to prepare working solution; carboxylated multi-armed carbon nanotubes (length 10-30μm, inner diameter 10-20nm, outer diameter 5-10nm) and working solution Mix, and use an ultrasonic cell pulverizer to sonicate for 3 hours at a power of 300w; add γ-mercaptopropyltrimethoxysilane (KH590) to the resulting mixed solution, and then ultrasonically disperse at 40°C for 2 hours to prepare a carbon fiber sizing agent: A carbon fiber emulsion sizing agent with a carboxylated multi-armed...

Embodiment 2

[0029] (1) 100 parts by weight of epoxy resin are dissolved in 6 parts by weight of acetone, then evacuated and sloughed off the organic solvent to obtain an epoxy resin mixture; add 20 parts by weight of emulsifier in the epoxy resin mixture, heat After reaching the molten state, stir quickly to make the emulsifier and epoxy mixture evenly mixed, the stirring time is 2h, and cool to obtain a viscous paste carbon fiber sizing agent;

[0030] (2) First heat the carbon fiber sizing agent to 40-50°C, and then mix it with N,N-dimethylformamide to prepare a working solution; carboxylated multi-armed carbon nanotubes (length 10-30μm, inner diameter 10-20nm , outer diameter 5-10nm) mixed with the working solution, and ultrasonicated with a power of 600w for 1.5 hours with an ultrasonic cell pulverizer; γ-mercaptopropyltrimethoxysilane (KH590) was added to the obtained mixed solution for ultrasonic dispersion at room temperature for 4 hours, A carbon fiber emulsion sizing agent with a...

Embodiment 3

[0033] Mix the carbon fiber sizing agent (room temperature) with dimethylacetamide to prepare the working fluid. According to the required sizing amount, the concentration of the working fluid is about 3%; -20nm, outer diameter 5-10nm) 0.05 parts by weight are mixed with 100 parts by weight of the working solution, and ultrasonicated with a power of 600w for 1 hour with an ultrasonic cell pulverizer; 2 parts by weight of γ-(methacryloyloxy ) propyltrimethoxysilane (KH570) was ultrasonically dispersed at room temperature for 6 hours; then the unsized carbon fibers coming out of the silk rolls were subjected to sizing treatment, dried with hot air, and collected to obtain carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com