SIALON whisker reinforced aluminum-based composite material and preparation method thereof

An aluminum-based composite material and composite material technology, applied in the field of reinforced aluminum-based composite materials and its preparation, can solve problems such as poor distribution uniformity, and achieve the effects of good stress transmission, excellent chemical stability, high hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

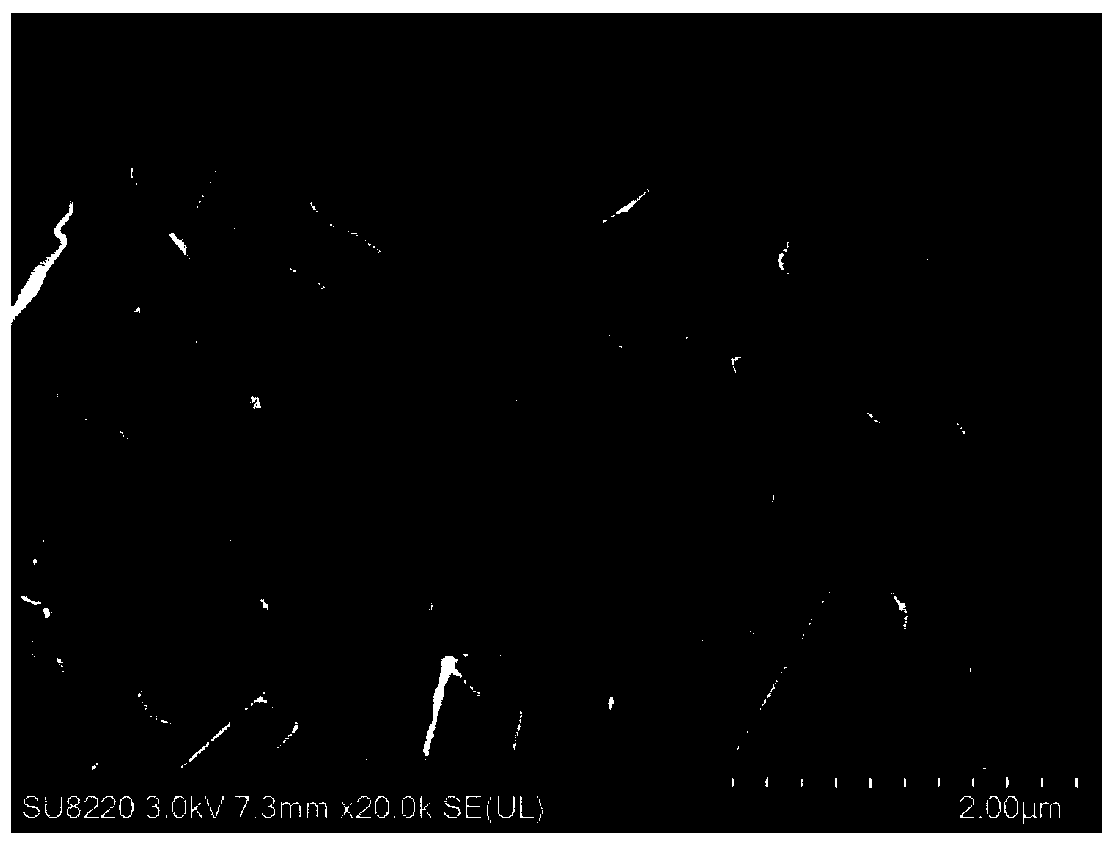

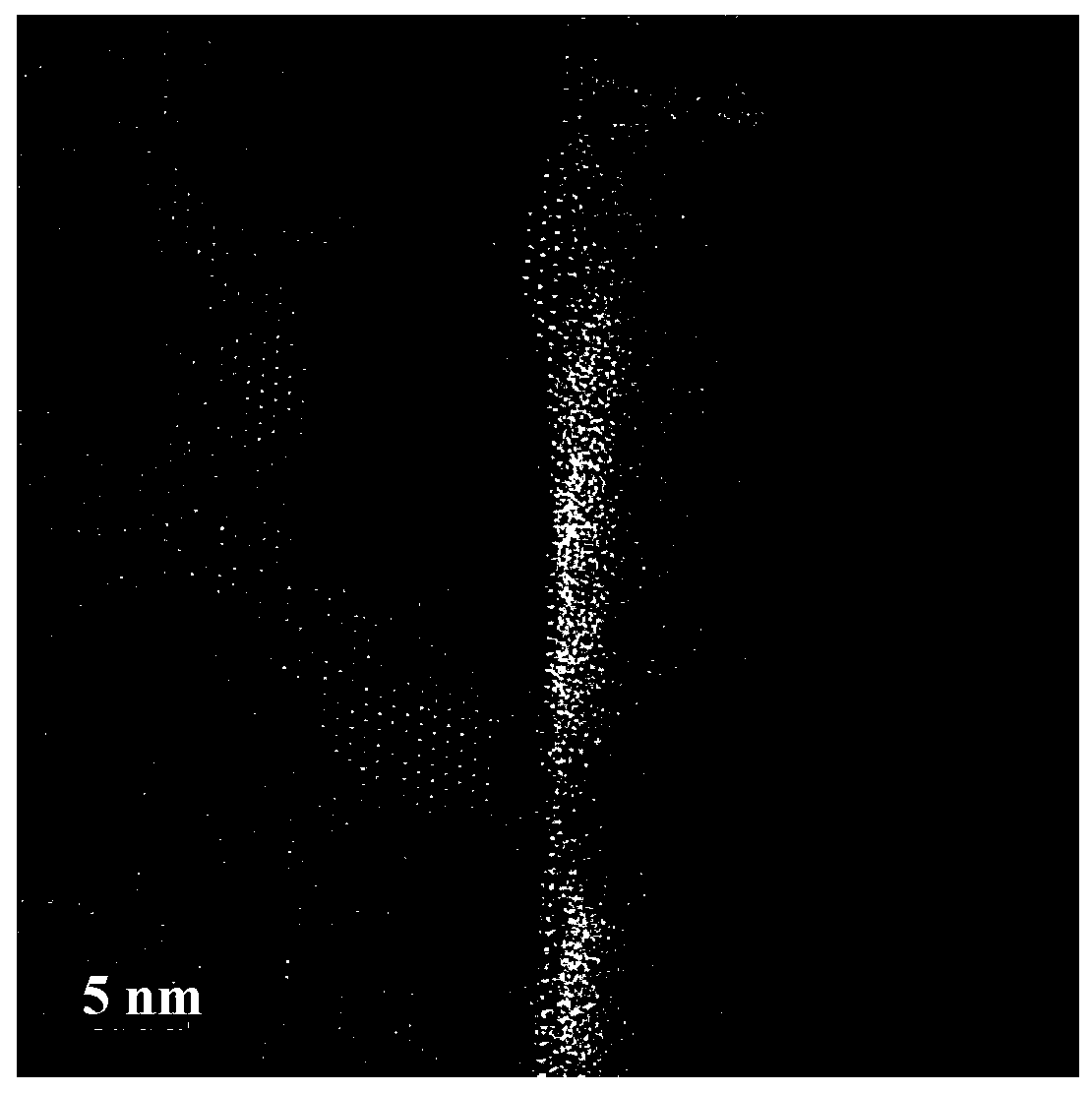

[0029] Preparation of SIA1ON whiskers. Generally can according to prior art (for example refer to: Yue Changsheng etc., the induced synthesis and the growth mechanism research of β-SiAlON whisker, Journal of Synthetic Crystal, 2011 No. 5; Peng Ben etc., adopt coal gangue as raw material synthesis β-SiAlON Whiskers and their microstructure research, Silicate Bulletin, No. 1, 2010, etc.) for preparation. As a preferred solution, the SIALON whiskers are subjected to surface roughening treatment in advance, and the surface roughening treatment includes: dispersing the SIALON whiskers in a hydrofluoric acid solution, mechanically stirring for a period of time, separating, washing and drying. By pre-roughening the surface of SIALON whiskers, the surface roughness of SIALON whiskers can be improved, and the contact area between the whiskers and the matrix alloy material can be increased as much as possible, so that the bonding force between the matrix and the whiskers can be improved...

Embodiment 1

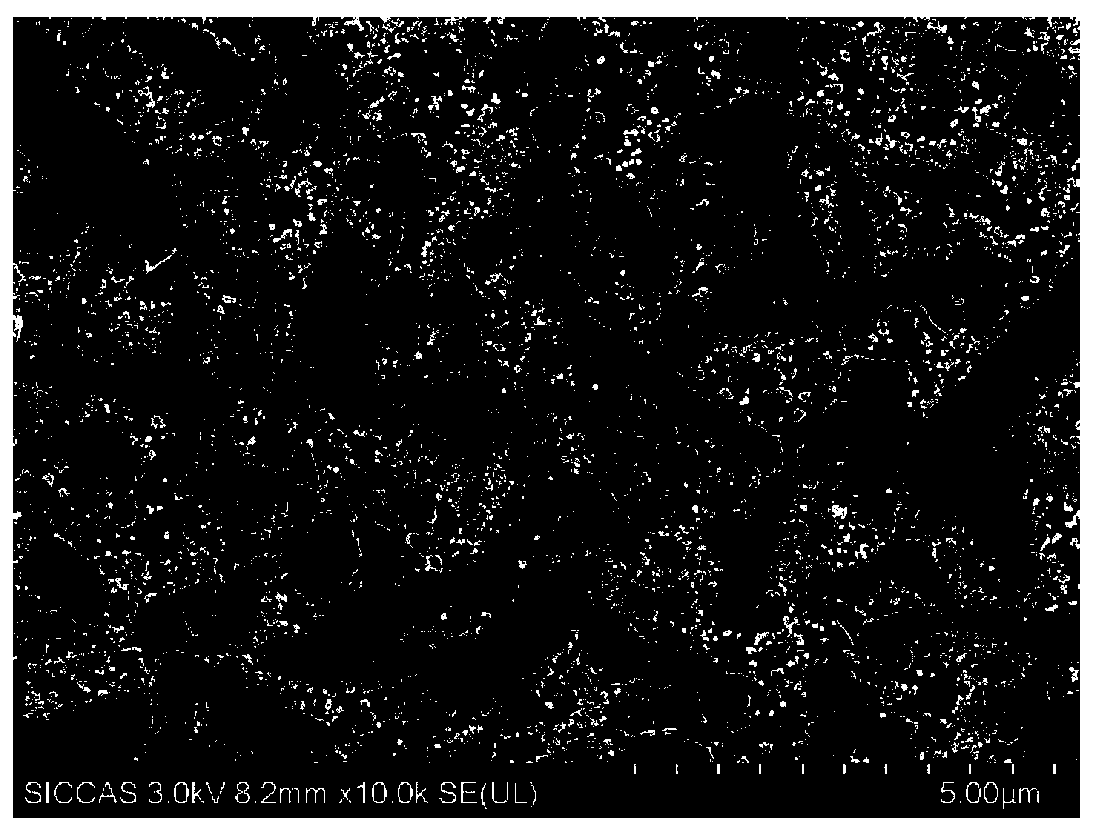

[0037] First use electromagnetic heating device, the pure aluminum ingot of 1800g is heated to 950 ℃ and makes it melt (the contained chemical element mass percent of described pure pure aluminum ingot is: Al≥99.9%, O≤0.1%, following embodiment 2~ 5 The pure aluminum ingot used is the same as that in Example 1), at this time, start the mechanical stirring, and the rotating speed is 350r / min, then add 200g of SIALON whiskers to the aluminum melt in stages, and continue to stir for 3h; then, the ultrasonic The stirring rod is placed inside the melt, the ultrasonic frequency is set to 100kHz, and the ultrasonic time is 30min; then, the surface scum is removed, and the molten aluminum-based composite material is poured into a steel mold, and ultrasonic waves are introduced at the bottom of the outer crucible, The ultrasonic frequency is 100kHz, ultrasonic until the material is solidified; finally, the poured sample is preheated to 500°C, kept for 30 minutes, and then placed in a ho...

Embodiment 2

[0042] First, use an electromagnetic heating device to heat 1600g of pure aluminum ingot to 1000°C to melt it. At this time, start mechanical stirring at a speed of 350r / min, then add 400g of SIALON whiskers to the aluminum melt in stages, and continue stirring for 3h; then , the ultrasonic stirring rod made of Nb-Zr material was placed inside the melt, the ultrasonic frequency was set to 100kHz, and the ultrasonic time was 30min; then, the surface scum was removed, and the molten aluminum-based composite material was poured into a steel mold, and at the same time Introduce ultrasonic at the bottom of the outer side of the crucible, the ultrasonic frequency is 100kHz, until the material is solidified; finally, preheat the poured sample to 500°C, keep it warm for 30min, and then place it in a hot extrusion mold at 500°C for hot extrusion treatment , the extrusion ratio is 4:1, and the SIALON whisker-reinforced aluminum matrix composite material with a whisker content of 20% by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com