Nanometer Al2O3-Ca<2+>-based metakaolin geopolymer road repairing material

An al2o3-ca2, road repair technology, applied in cement production and other directions, can solve the problems of repairing surface layer shedding, long time to form strength, poor mechanical properties, etc. Excellent grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In this embodiment, XRF (X-ray fluorescence spectrometry) method is used to analyze the main chemical components of metakaolin as shown in Table 1.

[0017] Table 1 Chemical composition of metakaolin

[0018] main ingredient

Embodiment 2

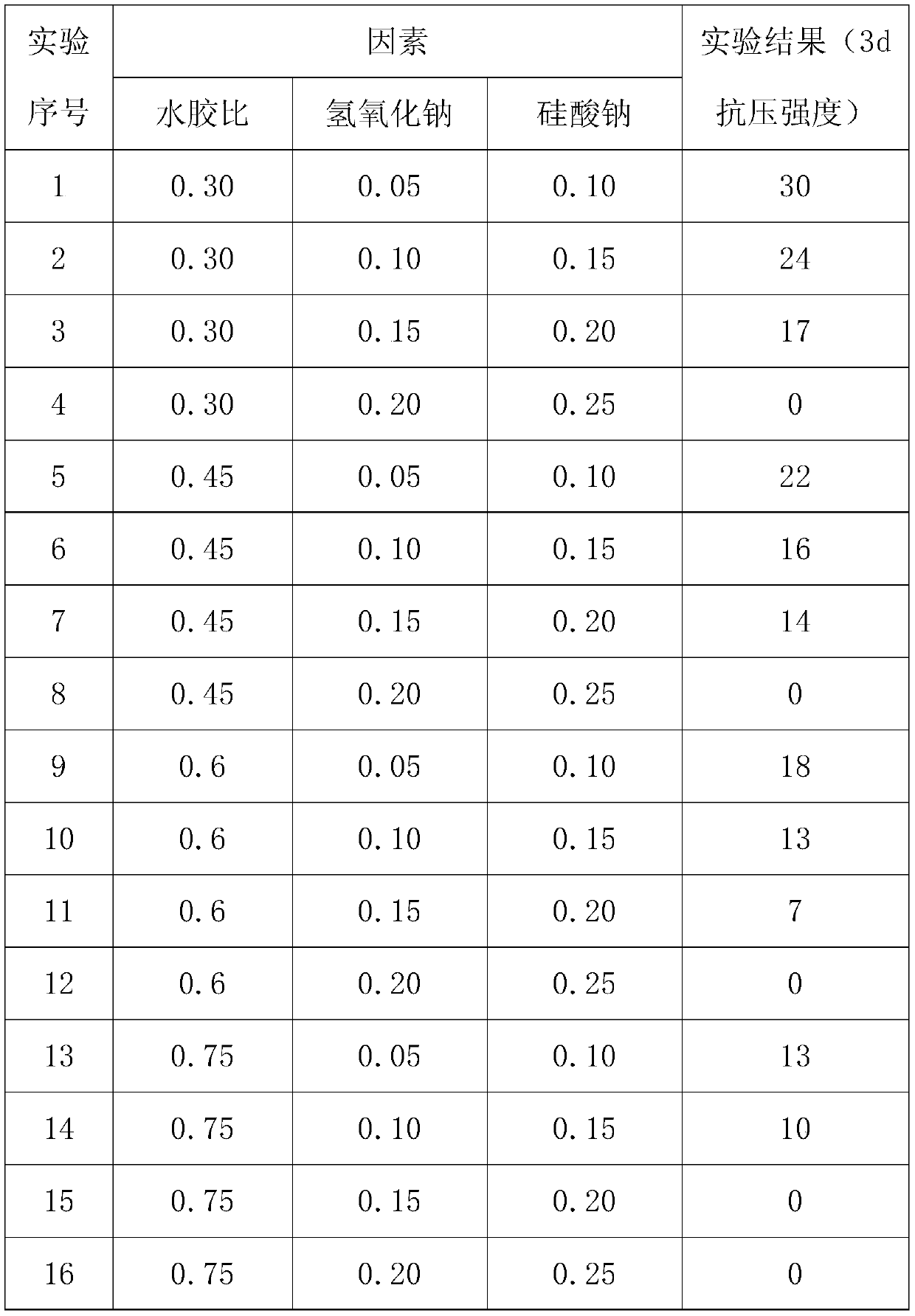

[0020] In this example, experiments were carried out on different proportions of metakaolin land polymer road repair materials. The size of the test block used in this embodiment is 40mm × 40mm × 160mm test pieces, three test pieces for each group, using the orthogonal experiment method with water-cement ratio, sodium hydroxide, sodium silicate as factors, carried out a total of 16 groups of tests, as shown in Table 2.

[0021] Table 2 Test composition and results

[0022]

[0023] The test results show that the early compressive strength is the best when the water-binder ratio is 0.3, the mass fraction of sodium hydroxide is 0.05, and the mass fraction of sodium silicate is 0.10. Therefore, the basic test formula of metakaolin geopolymer is distilled water / sodium hydroxide / sodium silicate / metakaolin=6:1:2:17.

Embodiment 3

[0025] In this embodiment, the curing temperature is compared with the test (the humidity is 95%, and the time is 12h). The size of the test block used in this embodiment is a test piece of 40mm×40mm×160mm. There are three test pieces in each group, and a total of 5 groups are carried out. Test, the test components are the same as test 1, and the test results are shown in Table 3.

[0026] Table 3 Experimental results

[0027] Test serial number

[0028] It can be seen from the test results that high temperature is beneficial to the development of early strength of metakaolin geopolymer road repair materials, and the optimum curing temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com