Co-extrusion wood-plastic composite material and preparation method thereof

A technology for wood-plastic composite materials and raw materials, which is applied in the field of co-extruded wood-plastic composite materials and their preparation, can solve problems such as mechanical properties gap, and achieve excellent mechanical properties and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

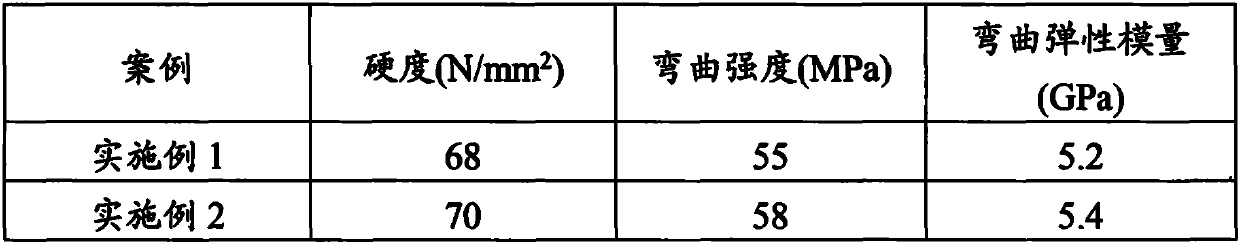

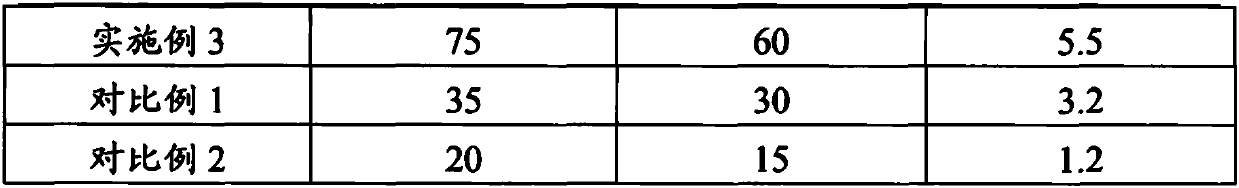

Examples

preparation example Construction

[0026] The raw materials for the preparation of the core layer include matrix materials;

[0027] The raw materials for preparing the middle layer include long fiber reinforced thermoplastic resin and coupling agent, and the mass ratio of the long fiber reinforced thermoplastic resin to coupling agent is (5-30):100;

[0028] The surface layer includes the following preparation raw materials in parts by weight: 100 parts of base resin, 2-30 parts of high molecular polymer, 0.5-5 parts of foaming agent, 5-20 parts of filler, 0.1-1 part of antioxidant, 1-3 parts of 5 parts lubricant.

[0029] The co-extruded wood-plastic composite material provided by the invention includes a core layer, a middle layer and a surface layer, and the preparation raw materials of the core layer include matrix materials. In the present invention, the base material is preferably PP or PE-based wood-plastic composite material. In the present invention, the thickness of the core layer is preferably 5-1...

Embodiment 1

[0057] Core component: PE-based wood-plastic composite material;

[0058] Take by weight the following middle layer components: 100 parts of coupling agent (maleic anhydride grafted polyethylene), 5 parts of fiber-reinforced PP with a length of 0.5 mm;

[0059] Weigh the following surface layer components in parts by weight: 100 parts of base resin (PVC), 5 parts of high molecular polymer (EMAA), 1 part of foaming agent (calcium carbonate), 5 parts of filler (talcum powder), 0.1 part of anti-corrosion Oxygen agent (antioxidant 1010), 2 parts of lubricant (zinc stearate);

[0060] drying the core layer components at 100° C. for 3 hours to obtain core layer pellets;

[0061] Preliminarily mixing and drying the middle layer components, the drying temperature is 100° C., and the drying time is 3 hours to obtain middle layer pellets;

[0062] Preliminarily mixing and drying the surface layer components at a temperature of 100° C. for 3 hours to obtain surface layer pellets;

[0...

Embodiment 2

[0065] Core component: PP-based wood-plastic composite material;

[0066] Weigh the following middle layer components in parts by weight: 100 parts of coupling agent (silane coupling agent), 10 parts of fiber-reinforced PE with a length of 1 mm;

[0067] Weigh the following surface layer components in parts by weight: 100 parts of base resin (ASA), 10 parts of polymer (ethylene-vinyl acetate-vinyl alcohol copolymer), 3 parts of blowing agent (magnesium carbonate), 10 parts of filler (aluminum oxide), 0.5 parts of antioxidant (antioxidant 1010), 3 parts of lubricant (oxidized polyethylene wax);

[0068] drying the core layer components at 105° C. for 2 hours to obtain core layer pellets;

[0069] Preliminary mixing and drying of the middle layer components, the drying temperature is 105°C, and the drying time is 2h, to obtain middle layer pellets;

[0070] Preliminarily mixing and drying the surface layer components, the drying temperature is 105° C., and the drying time is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com