Polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of short fiber retention length and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

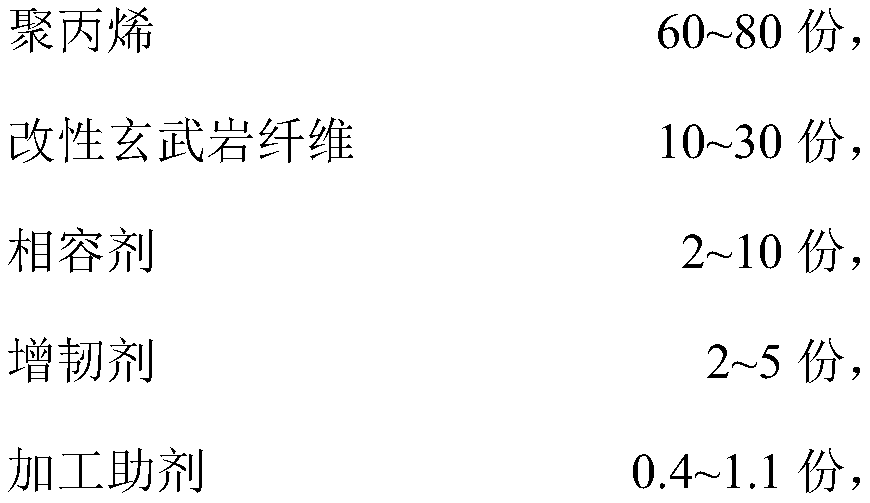

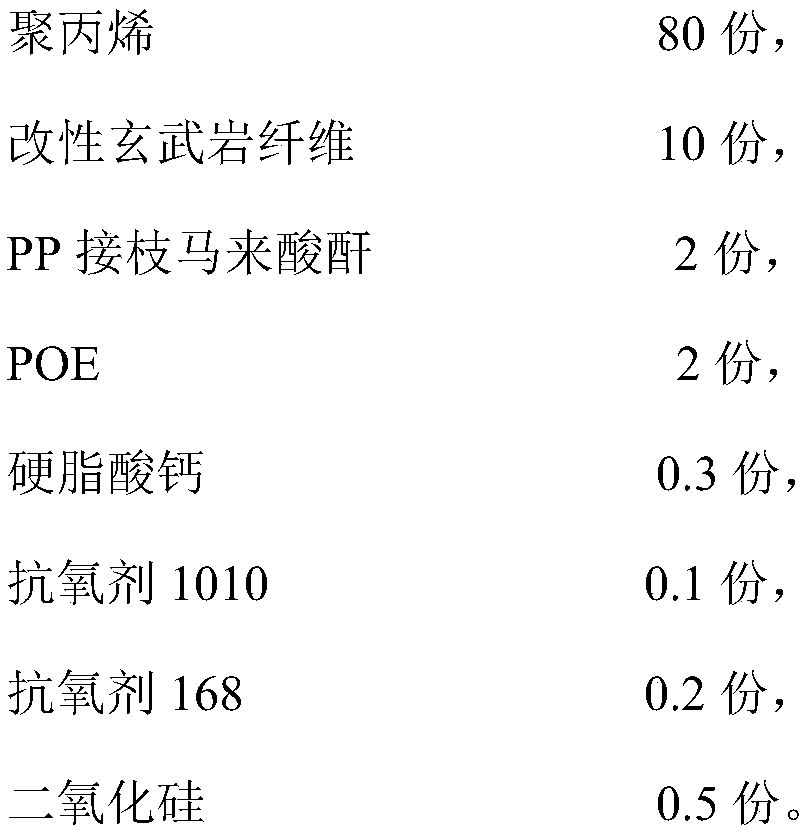

[0025] The polypropylene composite material in the present embodiment is made up of following components by weight:

[0026]

[0027] Among them, the melt flow rate of polypropylene is 60g / 10min (loading condition 230°C, 2.16kg), the particle size of silica is 1μm, and the above raw materials are all commercially available products.

[0028] Concrete preparation steps are as follows:

[0029] (1) Modification of basalt fiber: soak basalt fiber in 2% acetic acid aqueous solution for 3 hours, take it out and dry to obtain basalt fiber with preliminary surface modification; the mass ratio is glycidyl ether epoxy resin: Graphene oxide: KH550=96:2:2 The hybrid slurry formulated is coated on the basalt fiber with preliminary surface modification, and dried to obtain the modified basalt fiber;

[0030] (2) Preparation of polypropylene composite material: Add polypropylene, PP grafted maleic anhydride, POE, calcium stearate, antioxidant 1010, antioxidant 168 and silicon dioxide in...

Embodiment 2

[0032] The polypropylene composite material in the present embodiment is made up of following components by weight:

[0033]

[0034] Among them, the melt flow rate of polypropylene is 30g / 10min (loading condition is 230°C, 2.16kg), the particle size of silicon dioxide is 25μm, and the above raw materials are all commercially available products.

[0035] Concrete preparation steps are as follows:

[0036] (1) Modification of basalt fiber: soak basalt fiber in 5% acetic acid aqueous solution for 2 hours, take it out and dry to obtain basalt fiber with preliminary surface modification; the mass ratio is glycidyl ether epoxy resin: Graphene oxide: the hybrid slurry prepared by KH550=92:4:4 is coated on the basalt fiber with preliminary surface modification, and dried to obtain the modified basalt fiber;

[0037] (2) Preparation of polypropylene composite material: Add polypropylene, POE grafted maleic anhydride, PE, calcium stearate, antioxidant 1010, antioxidant 168 and sili...

Embodiment 3

[0039] The polypropylene composite material in the present embodiment is made up of following components by weight:

[0040]

[0041]

[0042] Among them, the melt flow rate of polypropylene is 90g / 10min (loading condition 230°C, 2.16kg), the compatibilizer mixture is a mixture of PP grafted maleic anhydride and POE grafted maleic anhydride, and the particle size of silica is 75 μm , the above raw materials are commercially available products.

[0043] Concrete preparation steps are as follows:

[0044] (1) Modification of basalt fibers: soak basalt fibers in 7% acetic acid aqueous solution for 6 hours, take them out and dry to obtain basalt fibers with preliminary surface modification; the mass ratio is glycidyl ether epoxy resin: Graphene oxide: KH560=88:6:6 The hybrid slurry formulated is coated on the basalt fiber with preliminary surface modification, and dried to obtain the modified basalt fiber;

[0045] (2) Preparation of polypropylene composite material: Accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com