Method for preparing thermal expansion matching composite thermal barrier coating

A thermal barrier coating and thermal expansion technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of ineffective elimination, complicated preparation process, etc., to eliminate the interface thermal stress, the process is simple, The effect of reducing severe losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

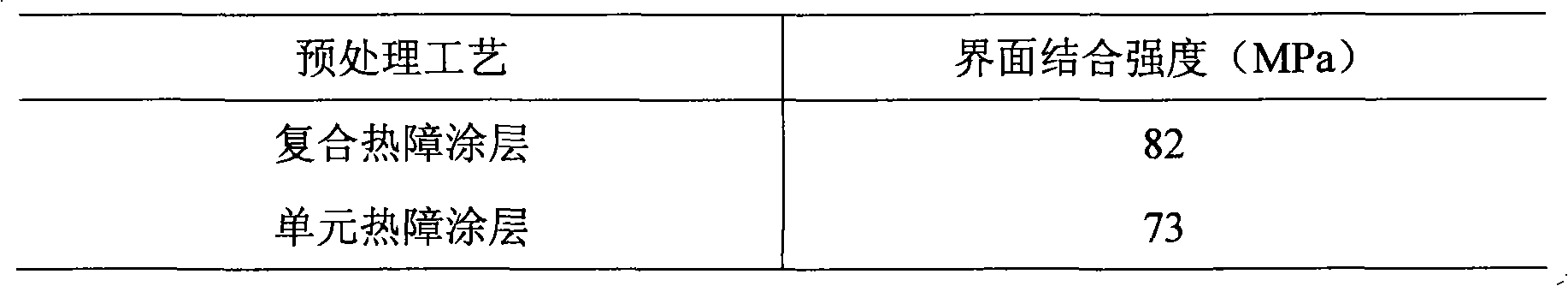

Embodiment 1

[0021] 1) Cut the HRA929 alloy into Φ25mm×4mm;

[0022] 2) According to the principle of thermal expansion matching, the ratio of Zr 0.98 f 0.01 Y 0.01 o 1.995 Thermal barrier coating material nano powder and Zr 0.95 Dy 0.05 W 1.7 Mo 0.3 o 7.975 Negative thermal expansion material micron powder, the average particle size is 20nm and 50μm;

[0023] 3) will prepare Zr 0.98 f 0.01 Y 0.01 o 1.995 with Zr 0.95 Dy 0.05 W 1.7 Mo 0.3 o 7.975 The two kinds of powders are reconstituted by micro-nano composite by encapsulation method;

[0024] 4) Laser irradiate the reconstituted composite particles, the irradiation parameters are: power 200W, spot diameter 10mm, defocus amount 5mm, scanning speed 8mm / s, overlap rate 10%, to increase the bonding strength of the composite particles;

[0025] 5) Put the composite particles into the powder feeder, prepare a 200 μm thick composite thermal barrier coating by vacuum plasma spraying process, the spraying process parameters are...

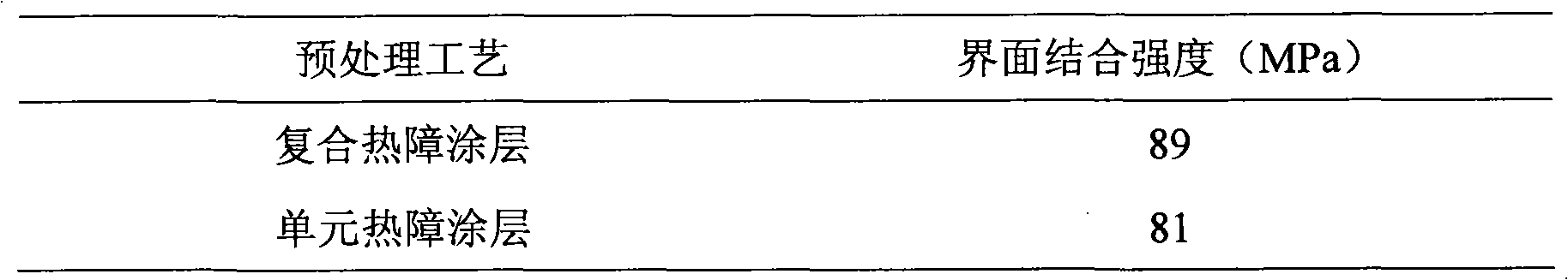

Embodiment 2

[0031] 1) Add Nd 14.5 Dy 1.5 Fe71 co 4.5 B 7.5 The alloy is cut into Φ25mm×4mm;

[0032] 2) According to the thermal expansion matching principle, the ratio Hf 0.97 Nd 0.03 o 1.985 Thermal barrier coating material nano powder and Zr 0.99 Tb 0.01 wxya 7.995 Negative thermal expansion material micron powder, the average particle size is 100nm and 20μm;

[0033] 3) The prepared Hf 0.97 Nd 0.03 o 1.985 with Zr 0.99 Tb 0.01 wxya 7.995 The two kinds of powders are reconstituted by micro-nano composite by encapsulation method;

[0034] 4) Laser irradiate the reconstituted composite particles, the irradiation parameters are: power 100W, spot diameter 8mm, defocus amount -5mm, scanning speed 1mm / s, overlap rate 30%, to increase the bonding strength of the composite particles;

[0035] 5) Put the composite particles into the powder feeder, prepare a 100 μm thick composite thermal barrier coating by vacuum plasma spraying process, the spraying process parameters are: arc ...

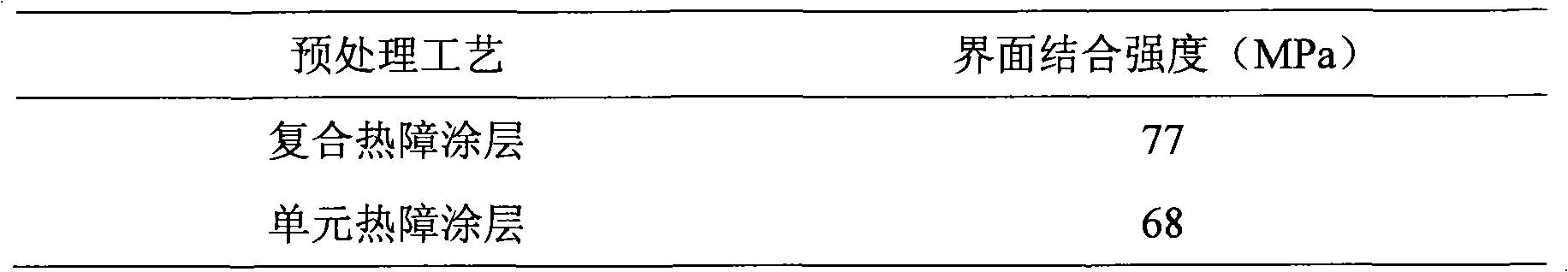

Embodiment 3

[0041] 1) Cut the Ti-6Al-4V alloy into Φ25mm×4mm;

[0042] 2) According to the principle of thermal expansion matching, the ratio of Zr 0.5 h 0.45 Yb 0.05 o 1.975 Thermal barrier coating material nano powder and Zr 0.98 Nd 0.01 Ho 0.01 wxya 7.99 Negative thermal expansion material micron powder, the average particle size is 70nm and 60μm;

[0043] 3) will prepare Zr 0.5 f 0.45 Yb 0.05 o 1.975 with Zr 0.98 Nd 0.01 Ho 0.01 wxya 7.99 The two kinds of powders are reconstituted by micro-nano composite by encapsulation method;

[0044] 4) Laser irradiate the reconstituted composite particles, the irradiation parameters are: power 20W, spot diameter 3mm, defocus amount 0.5mm, scanning speed 5mm / s, overlap rate 90%, to increase the bonding strength of the composite particles;

[0045] 5) Put the composite particles into the powder feeder, prepare a 350 μm thick composite thermal barrier coating by vacuum plasma spraying process, the spraying process parameters are: arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com