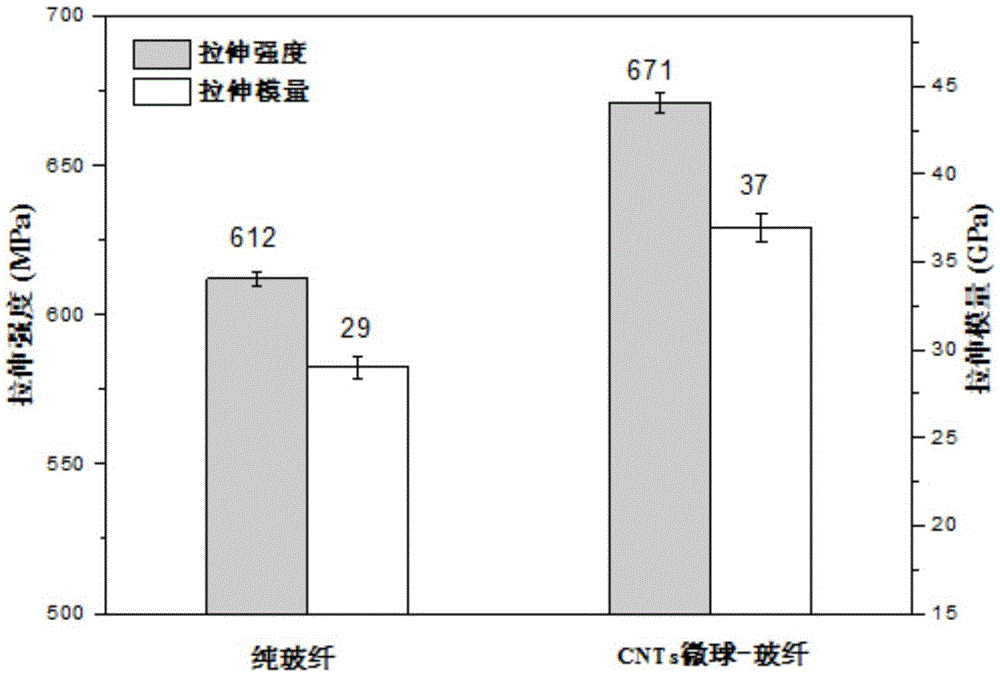

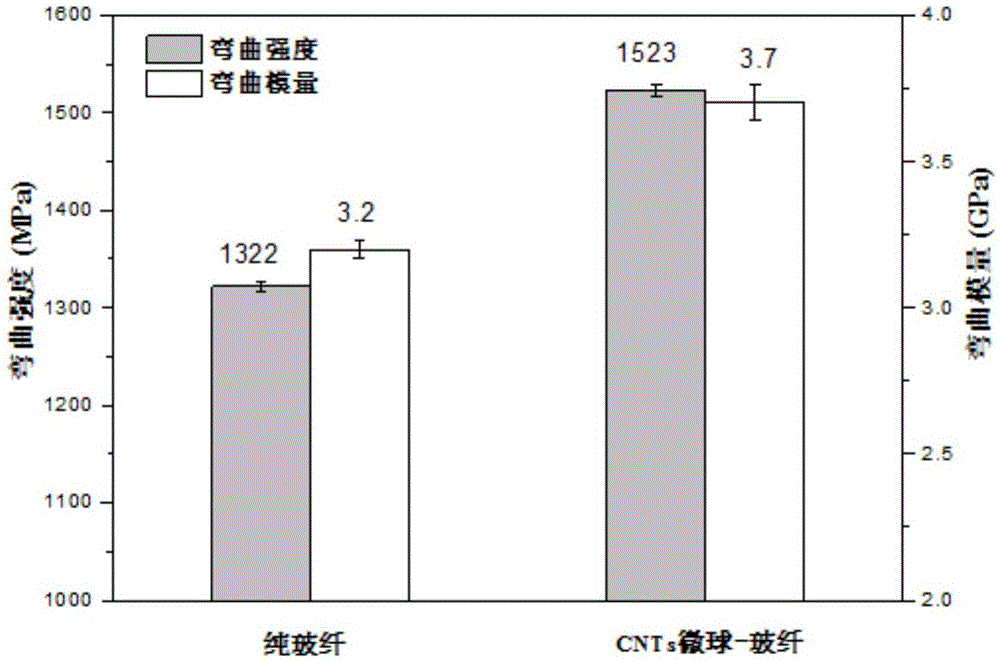

Carbon nano-tube microsphere/glass fiber synergistically-reinforced epoxy composite material preparation method

A carbon nanotube microsphere and glass fiber technology is applied in the field of fiber reinforced composite materials to achieve the effect of improving uniform dispersion, weakening delamination damage and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

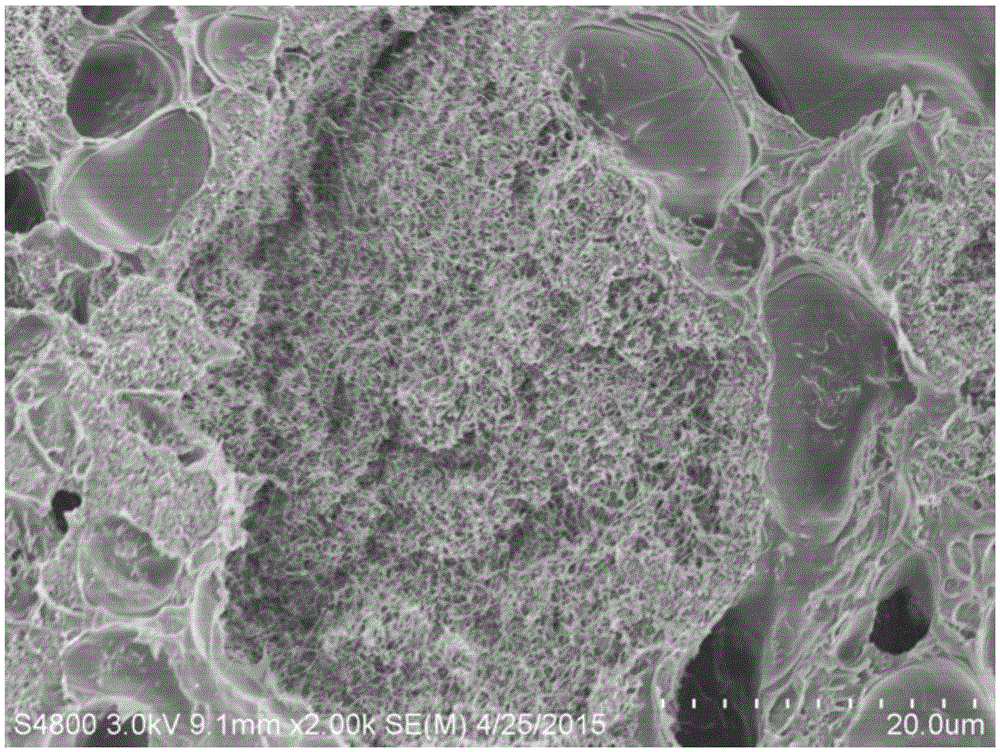

Image

Examples

Embodiment 1

[0032] A method for preparing a carbon nanotube microsphere / glass fiber synergistically reinforced epoxy composite material, the specific steps are as follows:

[0033] (1) Preparation of glass fiber: surface density 100g / m 2 Unidirectional glass fiber fabric, dry at 80°C for 2 hours, set aside;

[0034] (2) Preparation of resin solution: dissolve the solid glycidyl ether epoxy resin in acetone solvent, stir until it is fully dissolved; based on the mass of the solid glycidyl ether epoxy resin, add 0.01wt% carboxylated Carbon nanotubes, 0.01 wt% polyethylene glycol octyl phenyl ether and 15 wt% modified imidazole latent curing agent, stirred for 1 min, ultrasonically dispersed for 30 min; sealed and stored until use.

[0035] (3) Preparation of carbon nanotube microspheres: 2.0% (according to the mass of solid glycidyl ether epoxy resin) polyvinylpyrrolidone dispersant is dissolved in deionized water to obtain 0.002g / ml microsphere forming liquid, pour into the In the micros...

Embodiment 2

[0038] A kind of preparation method of carbon nanotube microsphere / glass fiber synergistically reinforced epoxy composite material, it is different from embodiment 1 in that the solid epoxy resin described in step (2) is glycidyl ester epoxy resin, Water-soluble organic solvent is methyl ethyl ketone, described carbon nanotube is 1.0wt% (resin weight ratio), and described tensio-active agent is 10wt% (resin weight ratio), stirs 2min, ultrasonic dispersion 60min; In step (3) The microsphere molding solution is 0.04g / ml, and the rotating speed is 3000rpm; the low-viscosity epoxy resin described in step (4) is a glycidyl ester epoxy resin with a viscosity of 1000~1800mPa·s, and the resin molding process is vacuum-assisted resin transfer Molding process, the curing agent is triethylenetetramine.

Embodiment 3

[0040] A kind of preparation method of carbon nanotube microsphere / glass fiber synergistically reinforced epoxy composite material, its difference from embodiment 1 is that the surface density in step (1) is 800g / m 2 , the solid epoxy resin described in the step (2) is a glycidyl amine epoxy resin, the water-soluble organic solvent is dehydrated alcohol, and the carbon nanotubes are 0.01wt% (resin weight ratio) hydroxylated carbon nanotubes, the surface Activator is 0.05wt% (resin weight ratio) polyoxyethylene sorbitan monolaurate, and described latent curing agent is 30wt% (resin weight ratio) modified dicyandiamide type curing agent; Step (3 ) in the dispersant is polyethylene glycol, rotating speed 1000rpm, titer 2ml / min; the low-viscosity epoxy resin described in the step (4) is that the viscosity is 1400~2000mPa·s glycidylamine epoxy resin, resin molding The process is resin impregnation molding process, and the curing agent is p-phenylenediamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com