A kind of preparation method of carbon nanotube microsphere/glass fiber synergistically reinforced epoxy composite material

A technology of carbon nanotube microspheres and glass fibers, which is applied in the field of fiber-reinforced composite materials to achieve good compatibility, high material utilization, and easy scale-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

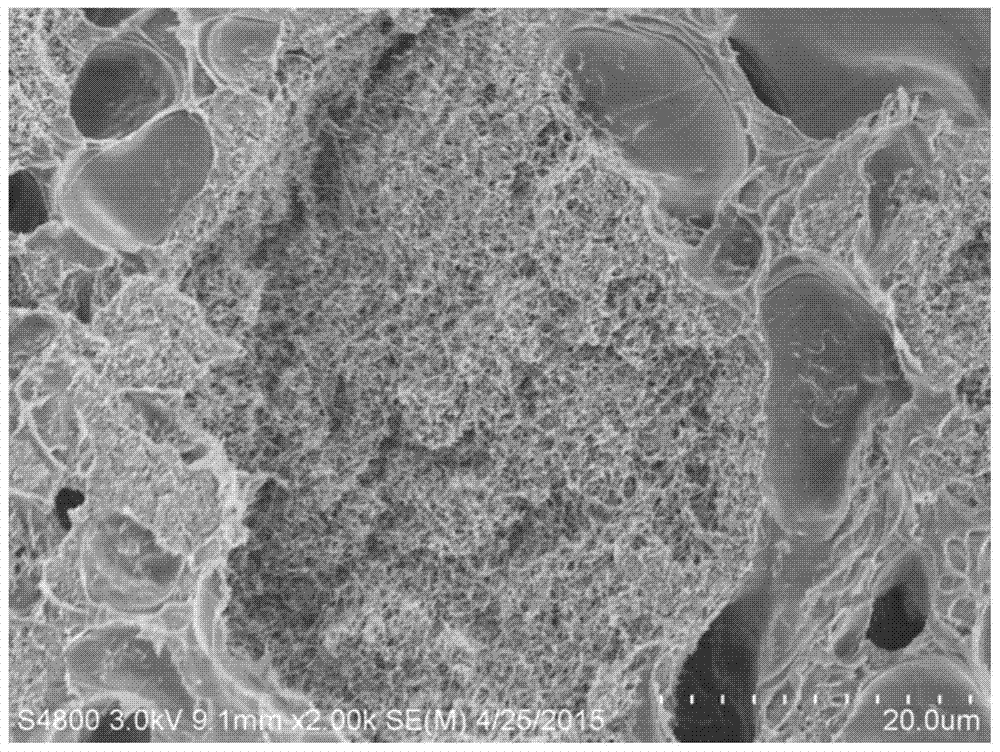

Image

Examples

Embodiment 1

[0032] A method for preparing a carbon nanotube microsphere / glass fiber synergistically reinforced epoxy composite material, the specific steps are as follows:

[0033] (1) Preparation of glass fiber: surface density 100g / m 2 Unidirectional glass fiber fabric, dry at 80°C for 2 hours, set aside;

[0034] (2) Preparation of resin solution: dissolve the solid glycidyl ether epoxy resin in acetone solvent, stir until it is fully dissolved; based on the mass of the solid glycidyl ether epoxy resin, add 0.01wt% carboxylated Carbon nanotubes, 0.01 wt% polyethylene glycol octyl phenyl ether and 15 wt% modified imidazole latent curing agent, stirred for 1 min, ultrasonically dispersed for 30 min; sealed and stored until use.

[0035] (3) Preparation of carbon nanotube microspheres: 2.0% (according to the mass of solid glycidyl ether epoxy resin) polyvinylpyrrolidone dispersant is dissolved in deionized water to obtain 0.002g / ml microsphere forming liquid, pour into the In the micros...

Embodiment 2

[0038] A kind of preparation method of carbon nanotube microsphere / glass fiber synergistically reinforced epoxy composite material, it is different from embodiment 1 in that the solid epoxy resin described in step (2) is glycidyl ester epoxy resin, Water-soluble organic solvent is methyl ethyl ketone, described carbon nanotube is 1.0wt% (resin weight ratio), and described tensio-active agent is 10wt% (resin weight ratio), stirs 2min, ultrasonic dispersion 60min; In step (3) The microsphere molding solution is 0.04g / ml, and the rotating speed is 3000rpm; the low-viscosity epoxy resin described in step (4) is a glycidyl ester epoxy resin with a viscosity of 1000~1800mPa·s, and the resin molding process is vacuum-assisted resin transfer Molding process, the curing agent is triethylenetetramine.

Embodiment 3

[0040] A kind of preparation method of carbon nanotube microsphere / glass fiber synergistically reinforced epoxy composite material, its difference from embodiment 1 is that the surface density in step (1) is 800g / m 2 , the solid epoxy resin described in the step (2) is a glycidyl amine epoxy resin, the water-soluble organic solvent is dehydrated alcohol, and the carbon nanotubes are 0.01wt% (resin weight ratio) hydroxylated carbon nanotubes, the surface Activator is 0.05wt% (resin weight ratio) polyoxyethylene sorbitan monolaurate, and described latent curing agent is 30wt% (resin weight ratio) modified dicyandiamide type curing agent; Step (3 ) in the dispersant is polyethylene glycol, rotating speed 1000rpm, titer 2ml / min; the low-viscosity epoxy resin described in the step (4) is that the viscosity is 1400~2000mPa·s glycidylamine epoxy resin, resin molding The process is resin impregnation molding process, and the curing agent is p-phenylenediamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com