Process for production of warp knitted silver-gilt undergarment lining

A production method and technology for underwear fabrics, applied in textiles, papermaking, fiber processing, etc., can solve the problems of weak bonding force, rough fabric feel, and high cost, achieve good mechanical properties and heat resistance, and the process is simple and effective. The effect of increasing polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] a. Select raw materials

[0034] The non-elastic yarn is made of nylon filament, the fineness is 56dtex, and the number of holes is about 12f.

[0035] The elastic yarn is made of high-quality spandex yarn with a fineness of 133dtex.

[0036] The spandex content is controlled at 6% during production.

[0037] b. Custom faceplates or chain blocks

[0038] The elastic Raschel warp knitting machine imported from West Germany is selected, the model is RSE 4-1, the gauge is E 28 (28 needles per inch), the number of bars is 4, and the number of knitting is 3, and the number of discs is 3. When weaving, the machine speed is controlled at about 2400rpm. The machine has high precision and good weaving performance, and can use high-grade elastic yarn for weaving.

[0039] The faceplate data is as follows:

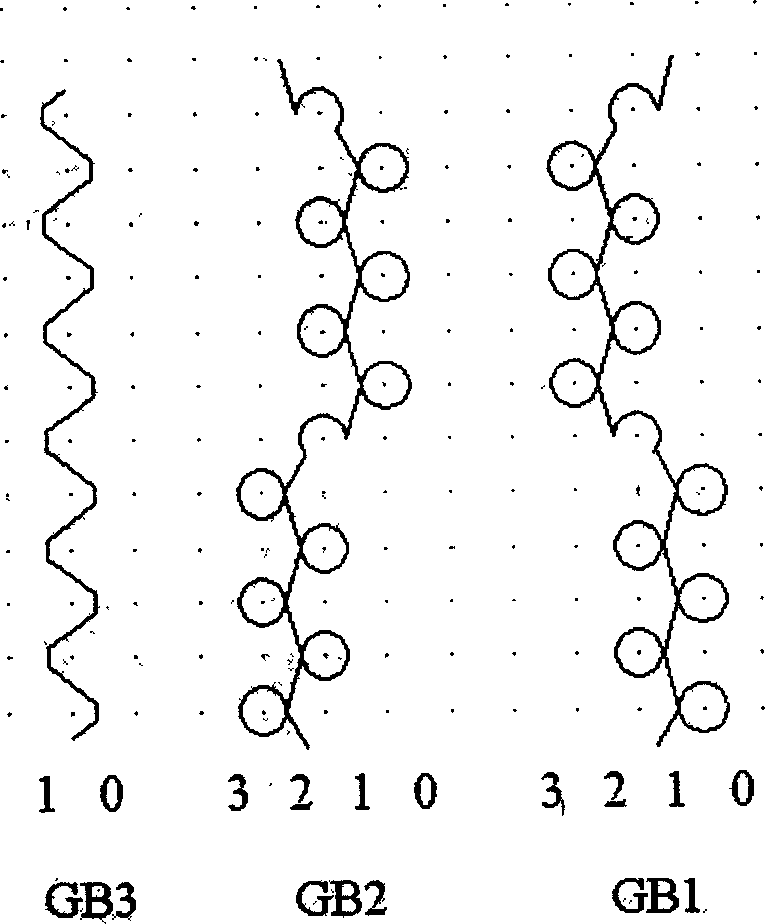

[0040] Front comb GB1: 1-0 / 1-2 / 1-0 / 1-2 / 1-0 / 1-2 / 2-3 / 2-1 / 2-3 / 2-1 / 2-3 / 2- 1 / /

[0041] Middle comb GB2: 2-3 / 2-1 / 2-3 / 2-1 / 2-3 / 2-1 / 1-0 / 1-2 / 1-0 / 1-2 / 1-0 / 1- 2 / /

[0042] Back c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com