Novel degradable composite plastic and preparation method thereof

A composite plastic, a new type of technology, applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of human health, ozone layer destruction, groundwater pollution, etc., achieve uniform mixing, improve surface polarity, and good degradation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

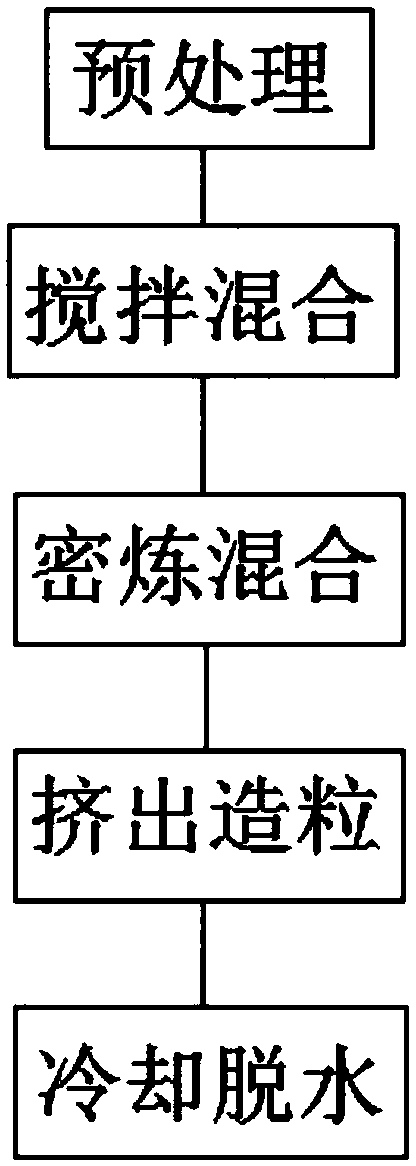

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: A kind of novel degradable composite plastics, comprises 40 parts of polypropylene compounds, 15 parts of micron plant short fibers, 5 parts of fillers, 3 parts of compatibilizers, 0.4 parts of antioxidants, 0.3 parts of lubricants, 3 parts of 1 part of antibacterial additive, 2 parts of biodegradation agent, wherein, the described polypropylene compound of the present embodiment is homopolymerization heat-resistant food-grade polypropylene compound, nontoxic and harmless, helps to protect the environment, and described micron plant short fiber is made of coffee Natural cellulose short fibers extracted from coffee grounds, the mesh number of coffee grounds fibers is 800-1250, efficient use of recycled coffee grounds materials, more environmentally friendly, and the addition of micron plant short fibers extracted from coffee grounds in this embodiment, the first On the one hand, the coffee grounds fiber can change the original color of the polypropylene comp...

Embodiment 2

[0038] Embodiment 2: A kind of novel degradable composite plastic, comprises the component of following parts by weight: 60 parts of polypropylene compound, 30 parts of micron plant short fiber, 15 parts of filler, 5 parts of compatibilizer, 0.5 part of antioxidant , 0.5 parts of lubricant, 4 parts of antibacterial additives, 3 parts of biodegradants, wherein, compared with embodiment 1, the described filler of embodiment 2 is the calcium carbonate that contains iron, tin or manganese metal element, on the one hand carbonic acid Calcium is easily utilized by microorganisms and easily decomposed. On the other hand, doping iron, tin or manganese metal elements in calcium carbonate can effectively promote the degradation of polypropylene compounds at composting temperatures. The iron stearate-manganese stearate composite photosensitizer promotes the composite plastic to have good photo-biodegradability, and under the conditions of composting and landfill treatment, the degradation...

Embodiment 3

[0039] Embodiment 3: A kind of novel degradable composite plastics, comprises the component of following parts by weight: 50 parts of polypropylene compounds, 25 parts of micron plant short fibers, 10 parts of fillers, 4 parts of compatibilizers, 0.6 parts of antioxidants , 0.4 parts of lubricant, 4 parts of antibacterial additives, 2.5 parts of biodegradants, wherein, compared with Example 1, the filler is a mixture of talcum powder and starch, and the hindered phenolic antioxidant in the antioxidant The weight mixing ratio of agent and phosphite antioxidant is 1:1.5, and described biodegradation agent is the iron stearate-manganese stearate composite photosensitizer containing bioactive agent, and described lubricant is stearic acid The mixture of salt and stearic acid amide, the lubricant can improve the processability of polypropylene compound, improve the dispersion effect of micron plant short fiber, and the finished product effect is better, the micron plant short fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com