Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Increased transverse tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

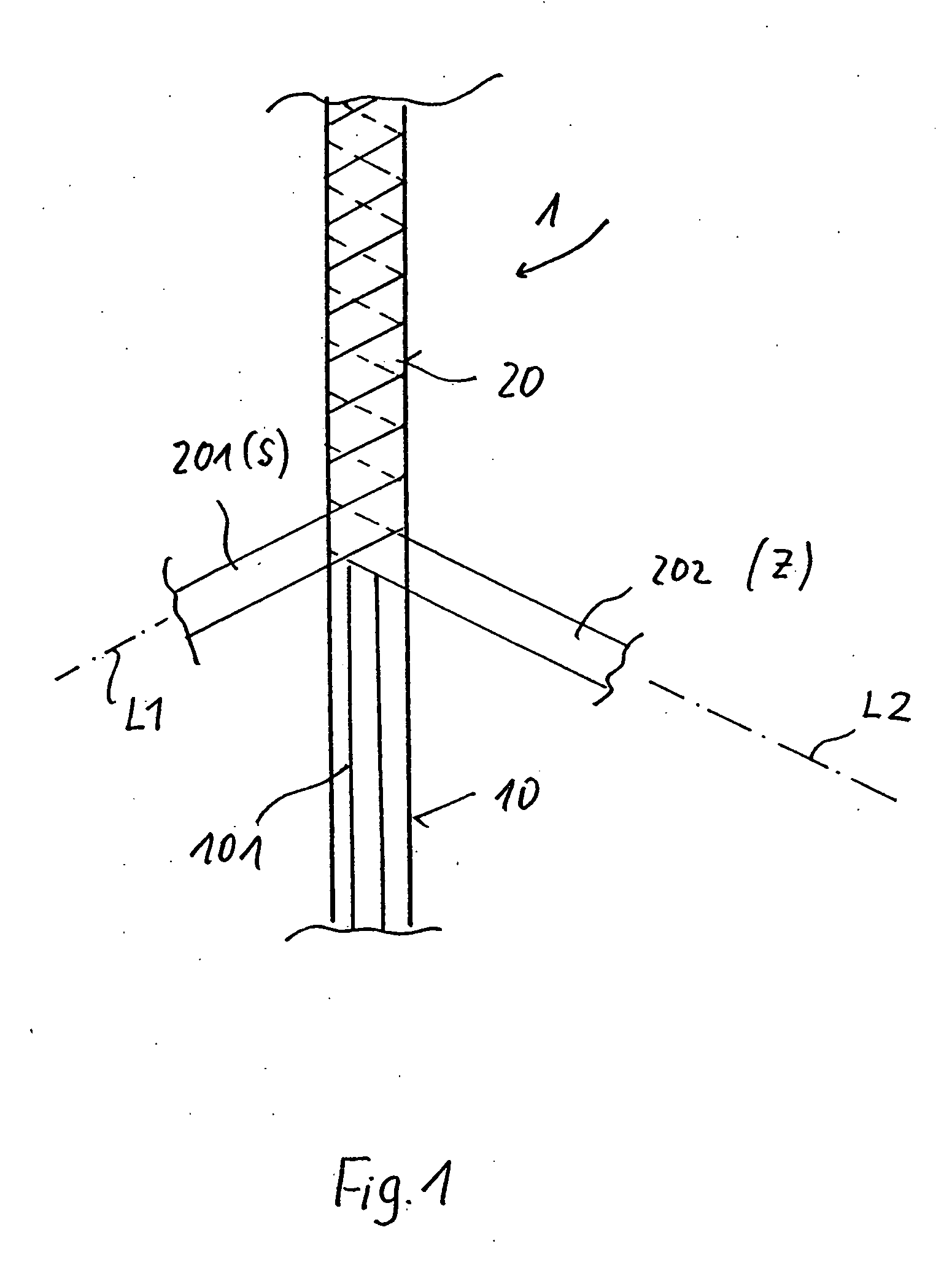

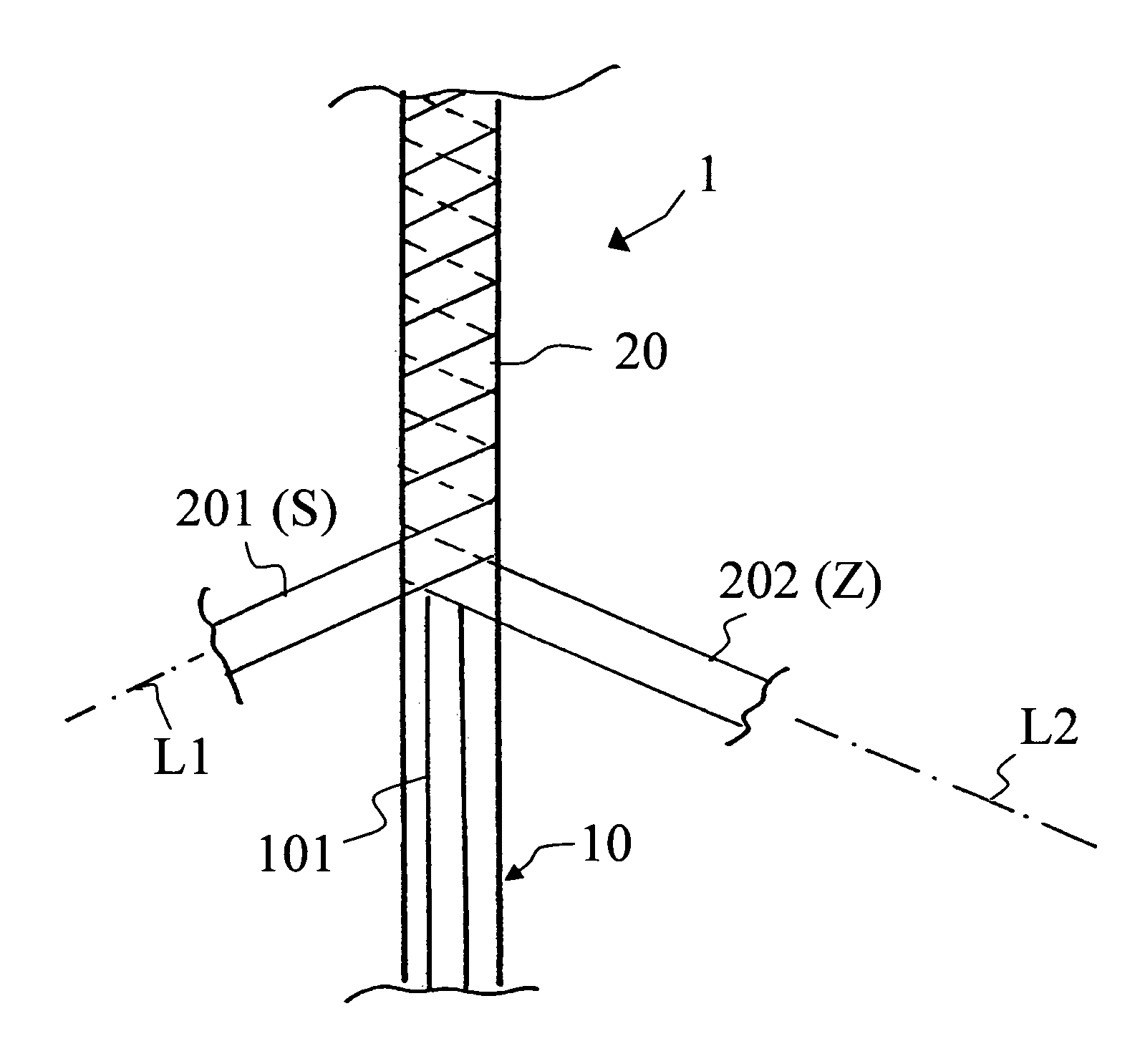

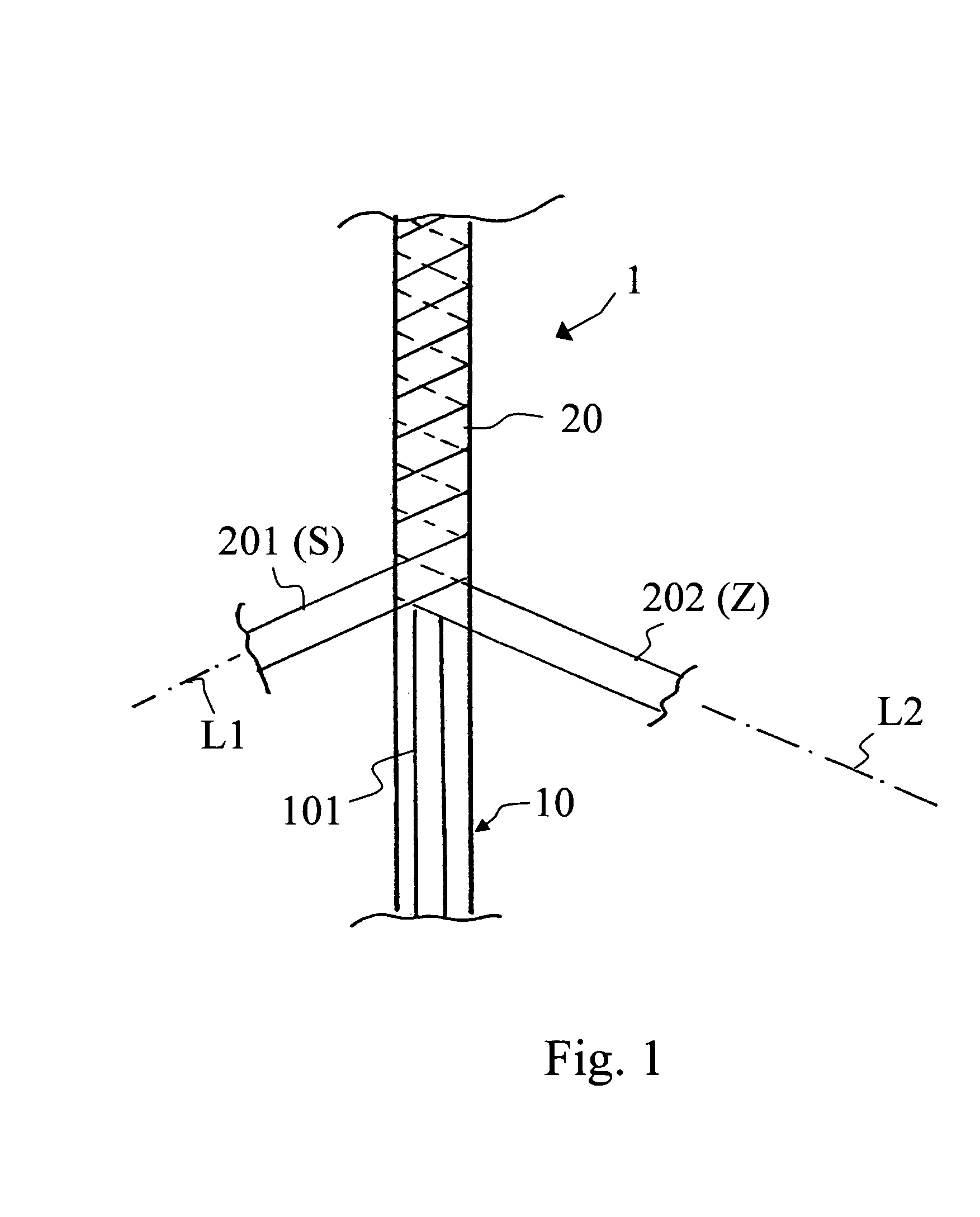

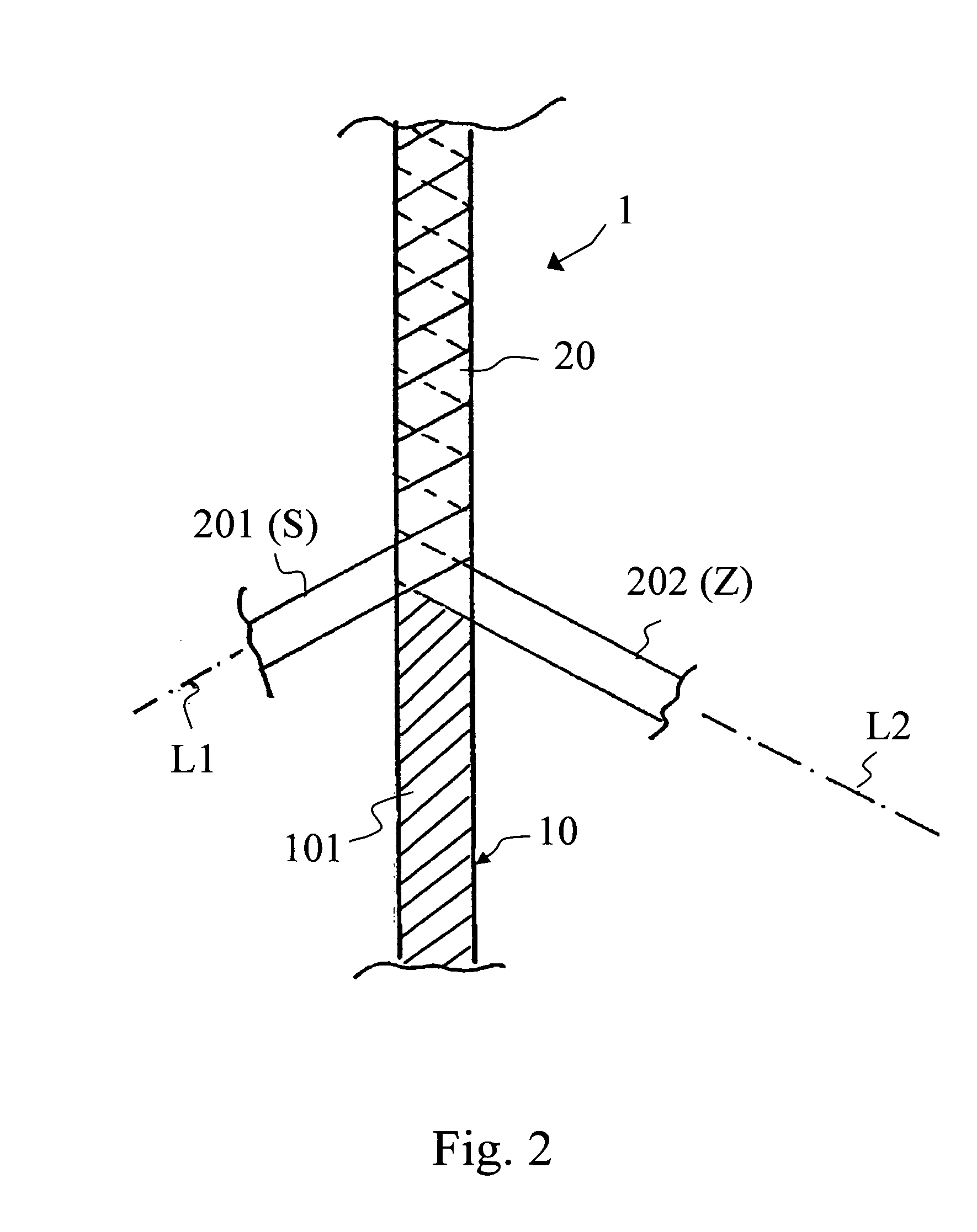

Textile thread

A textile thread having a core and a sheath surrounding the core. The core, formed of high-tenacity synthetic organic endless fibers, is tightly wound by slit film tapes made of polytetrafluoroethylene (PTFE) in the S-direction and the Z-direction, or vice versa, and the slit film tapes forms a sheath.

Owner:BLOCH KLAUS

A process for manufacturing anti-crack bamboo plate

InactiveCN1864953AImprove toughnessIncreased transverse tensile strengthOther plywood/veneer working apparatusWood treatment detailsWater contentRelative humidity

The invention relates to a method for producing anti-crack bamboo sheet. It is characterized in following steps that: poaching the bamboo plane bar at the temperature as 50-95Deg. C and the density of hydrogen dioxide solution as 1.5-6.5%; drying the poached plane bar at the temperature as 45-65Deg. C and air relative humidity as 25-65%, to the water content as 5-9%; making the dried plane bar into fine plane bar to be coated with pastern; plane or side assembling the plane bars, to be compressed and shaped at the temperature as 88+-2Deg. C; the pressure of main compress unit is 0.2-0.6MPa, and the pressure of side compress unit is 5-7MPa; maintaining it for 3-7 days at the temperature as 20-30Deg. C and the air relative humidity as 20-50%. The invention has better anti-crack effect, which can be used in bamboo floor, etc.

Owner:DASSO INDASTRIAL GRUP KO LTD

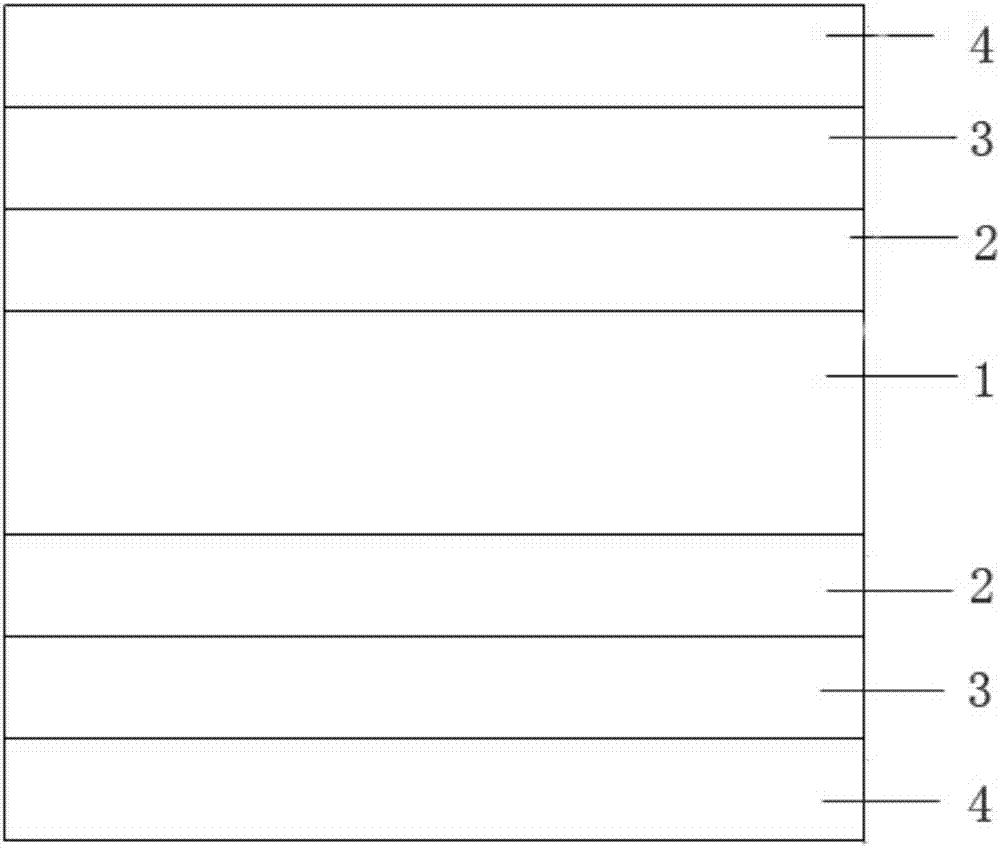

Polymer composite film and preparation method thereof, and lithium ion battery comprising polymer composite film

InactiveCN107799703AImprove high temperature resistanceSmall thermal shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberElectrolytic agent

The invention discloses a polymer composite film and a preparation method thereof, and a lithium ion battery comprising the polymer composite film. The polymer composite film comprises a polymer basefilm, which comprises a first surface and a second surface, wherein the first surface and the second surface are oppositely arranged, the polymer composite film further comprises a first ceramic layer, a first heat-resistant fiber layer and a first adhesion layer, the first ceramic layer, the first heat-resistant fiber layer and the first adhesion layer are sequentially arranged on the first surface of the polymer base film from inside to outside, the materials of the first heat-resistant fiber layer simultaneously contain a first macromolecule material and a second macromolecule material, thefirst macromolecule material is a heat-resistant macromolecule material with a melting point of more than 180 DEG C, the melting point of the second macromolecule material is lower than the melting point of the first macromolecule material, the liquid absorption rate of the second macromolecule material in a 25 DEG C electrolyte is more than 40%, and the error is + / -5%. According to the present invention, by simultaneously using the first macromolecule material and the second macromolecule material, the high temperature stability and the mechanical property under the high temperature condition can be easily improved.

Owner:BYD CO LTD

Modified aramid fiber reinforced PA66 material and preparation method thereof

InactiveCN103709742AIncreased transverse tensile strengthHigh strengthRadio/micro wave fibre treatmentAbrasion resistant fibresRadiation DosagesRadiation frequency

The invention relate to a modified aramid fiber reinforced PA66 material and a preparation method thereof. The preparation method comprises the steps of modifying the aramid fibers by using microwave radiation, with radiation frequency being 0.5-5 GHZ, radiation dosage being 0.1-2 mW / cm<2> and radiation time being 1-240 s; and then processing the modified aramid fibers by using low temperature plasma, with a processing power being 10-400 W, a processing atmosphere being composed of 5-15% of hydrogen, 5-15% of fluorine and 70-90% of helium, a processing temperature being 0-150 DEG C and a processing time being 1-20 min. The surface layer and the core layer of the aramid fibers modified by the microwave radiation are crosslinked, so that transverse tensile strength of the fibers is increased; and after the low temperature plasma modification, the surfaces of the aramid fibers become rough and are rich in active free radicals and functional groups. The mechanical and wear resistant performances of the composite material prepared by blending and extruding the modified aramid fibers together with the PA66 resin through a double-screw extruder are increased by 15-20% than that of similar products at abroad, and can meet the requirements of the fields such as high speed railways and aerospace for high-performance wear-resistant components.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

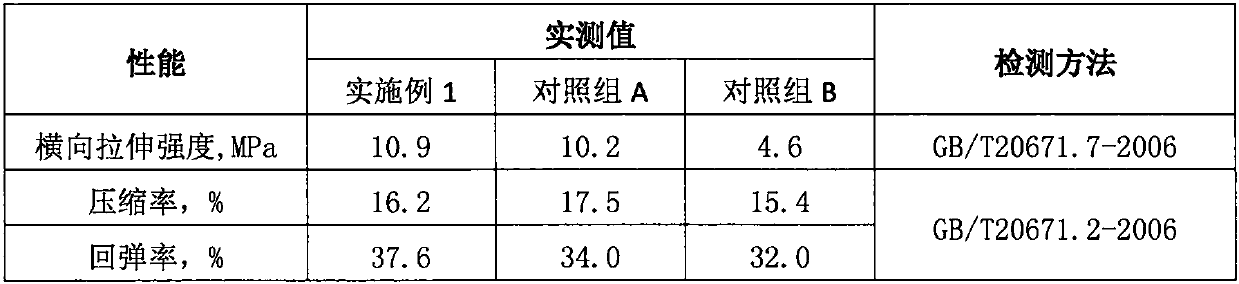

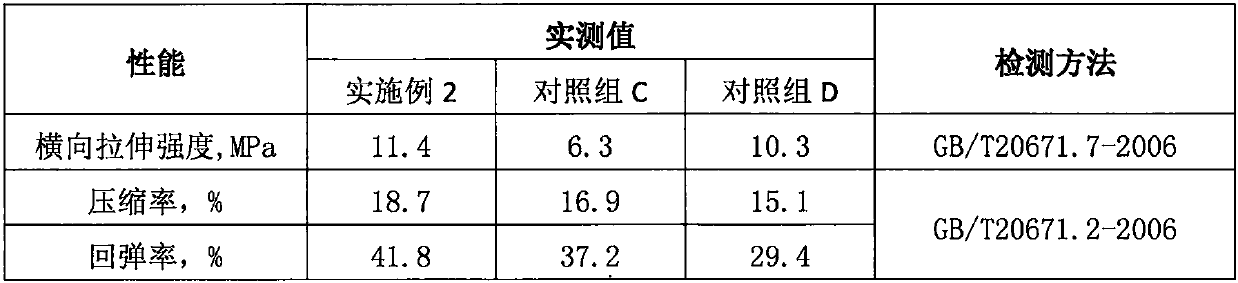

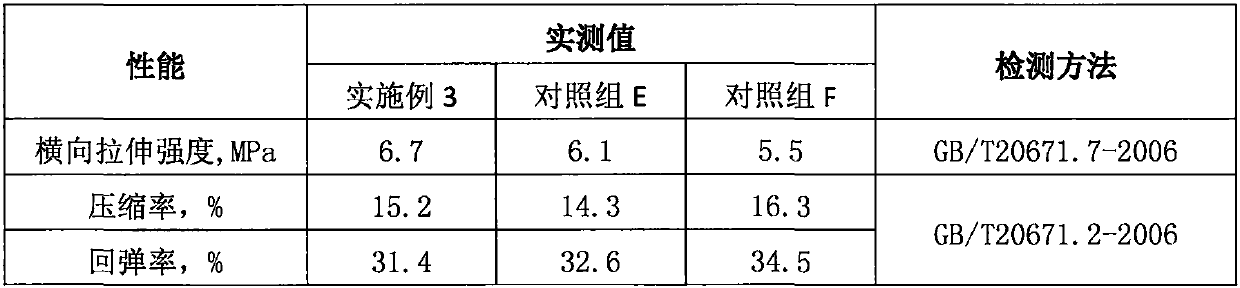

Fiber composite containing microfibrillated cellulose and preparation method of fiber composite

ActiveCN110080036AIncreased transverse tensile strengthImprove sealingNon-macromolecular organic additionPaper/cardboardCelluloseVulcanization

The invention discloses a fiber composite containing microfibrillated cellulose and a preparation method of the fiber composite. Firstly, the microfibrillated cellulose is modified with an anionic auxiliary, meanwhile, inorganic filler is modified with a cationic auxiliary, then, two modified aqueous dispersions are mixed, fiber, latex and an auxiliary are added, obtained slurry is subjected to papermaking, dewatering, drying and vulcanization, and the fiber composite containing the microfibrillated cellulose is obtained. The method is convenient to operate, simple in process, high in adaptability and favorable for large-scale production. The provided fiber composite containing the microfibrillated cellulose has the advantages that the content of the inorganic filler is high, few expensivereinforced fibers are used and the tensile strength of materials is good.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

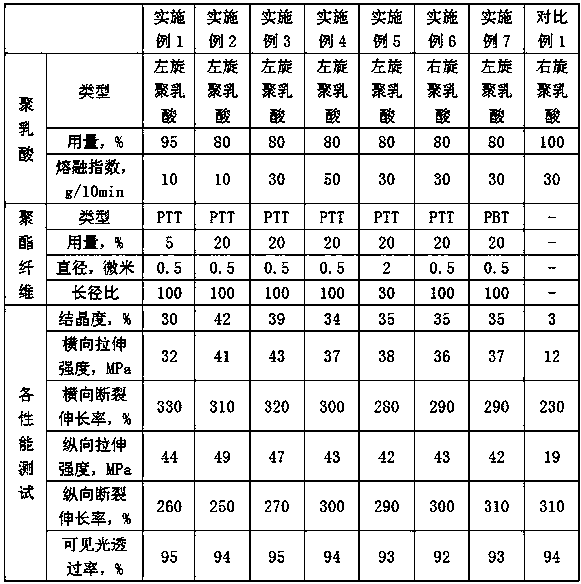

Polylactic acid membrane and preparation method of polylactic acid membrane

ActiveCN108192304AExcellent longitudinal tensile strengthExcellent transverse tensile strengthFiberPolytetramethylene terephthalate

The invention discloses a polylactic acid membrane which comprises the following components in percentage by weight: 80-95wt% of polylactic acid and 5-20wt% of a polyester fiber, wherein the polylactic acid is selected from at least one of a levorotatory polylactic acid resin and a dextrorotatory polylactic acid resin; the melting index of the polylactic acid is 10-50g / 10 minutes; the testing condition is that testing is carried out with a load of 2.16Kg at 190 DEG C; the polyester fiber is selected from one of a polyterephthalic acid propylene glycol ester fiber or polyterephthalic acid butanediol ester fiber. The polylactic acid membrane disclosed by the invention is of a cross crystal structure, and has excellent longitudinal tension strength and excellent transverse tension strength aswell. The invention further discloses a preparation method of polylactic acid. The polyester fiber is adopted as a nucleating agent, and the cross crystal structure is directly prepared in a one-waymelt tension fluid field by using a melt tension technique. Relatively high transverse tension strength can be achieved when transverse tension is not carried out, and meanwhile a relatively high crystallization degree can be achieved for the polylactic acid in the melt tension process.

Owner:GUANGDONG UNIV OF TECH

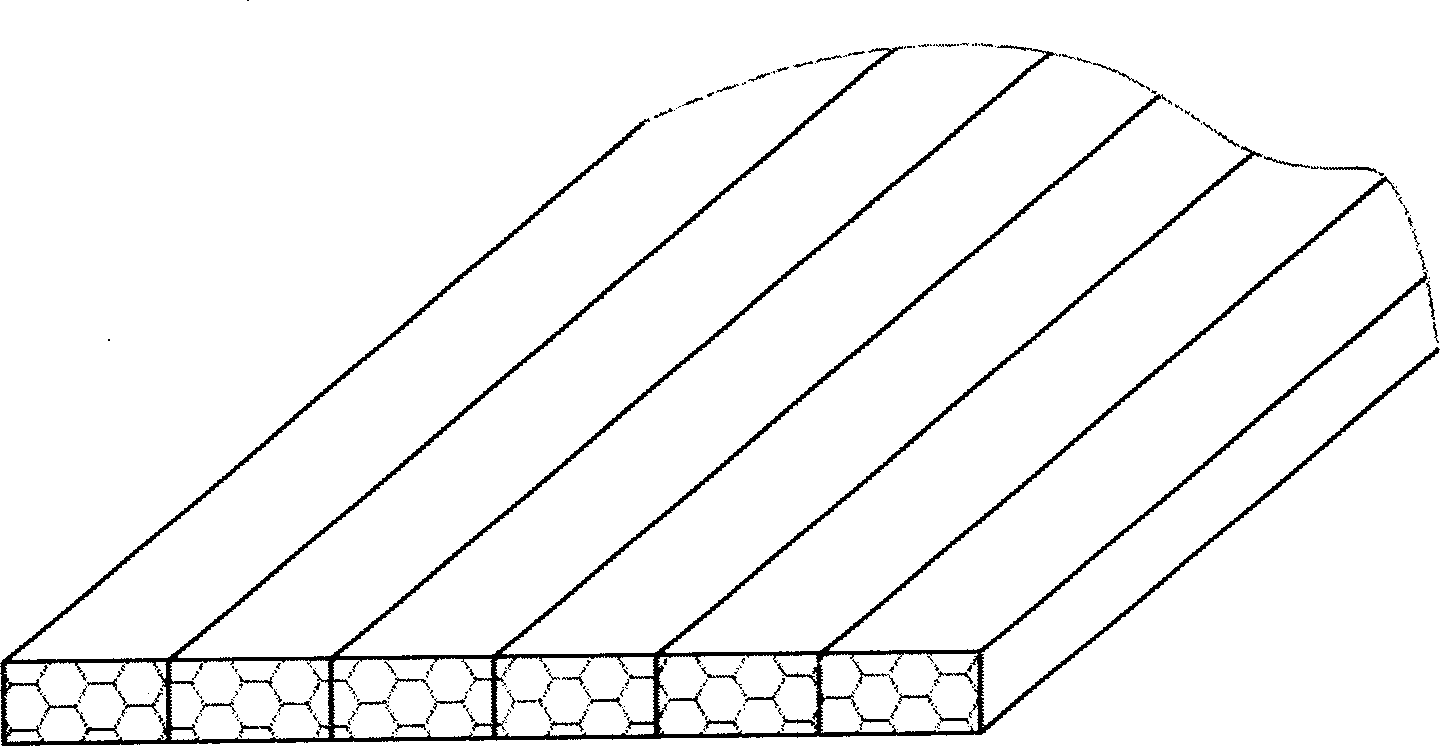

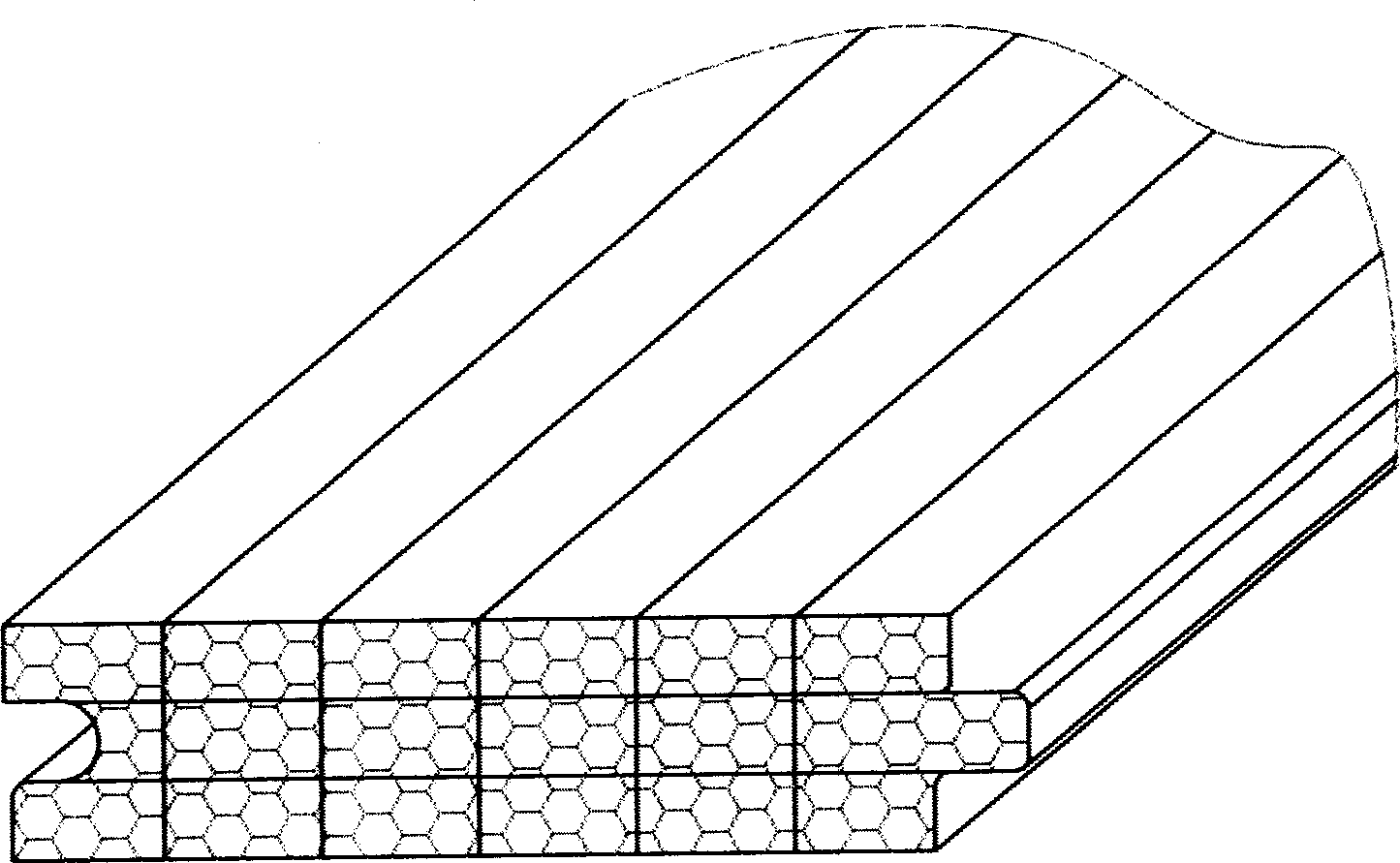

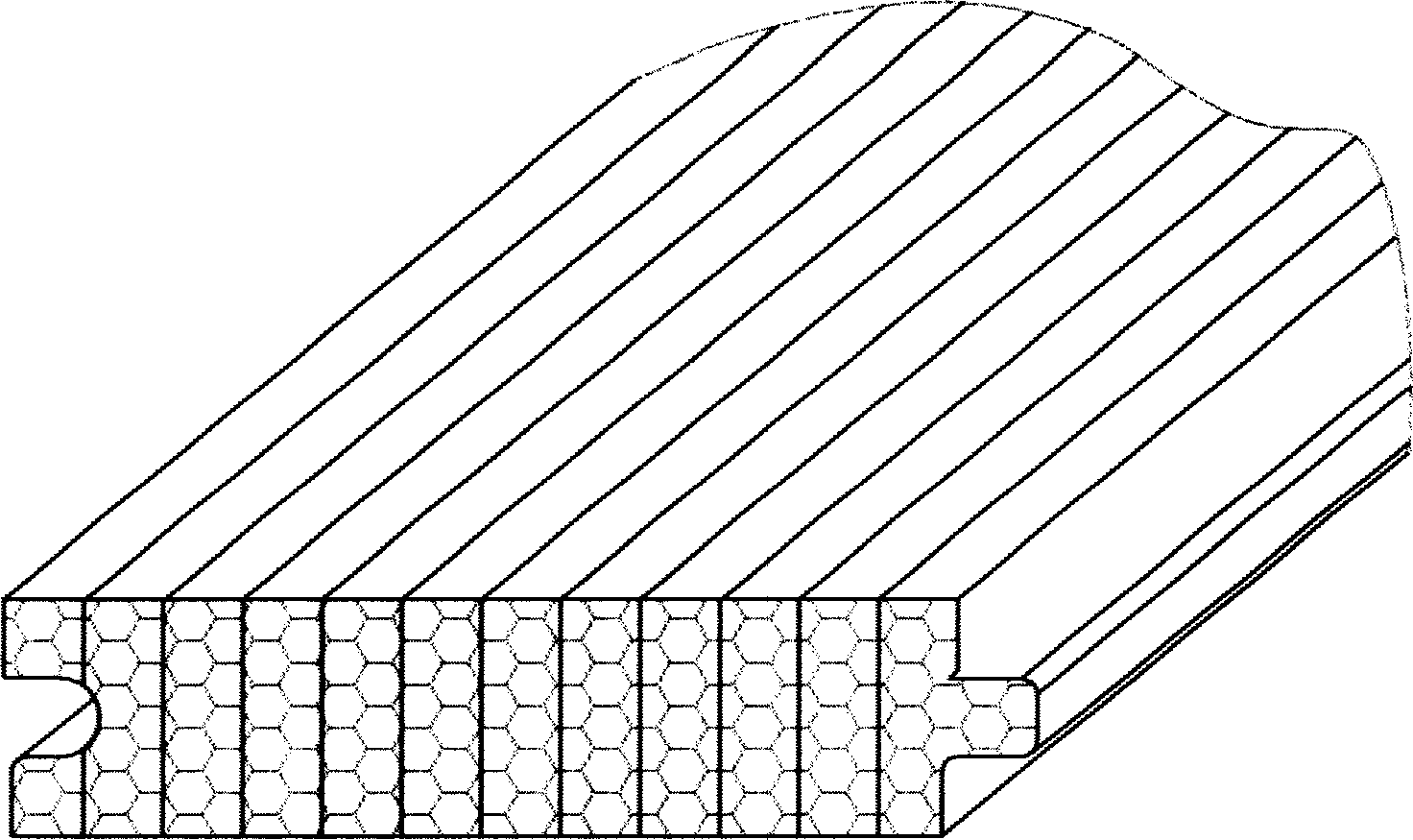

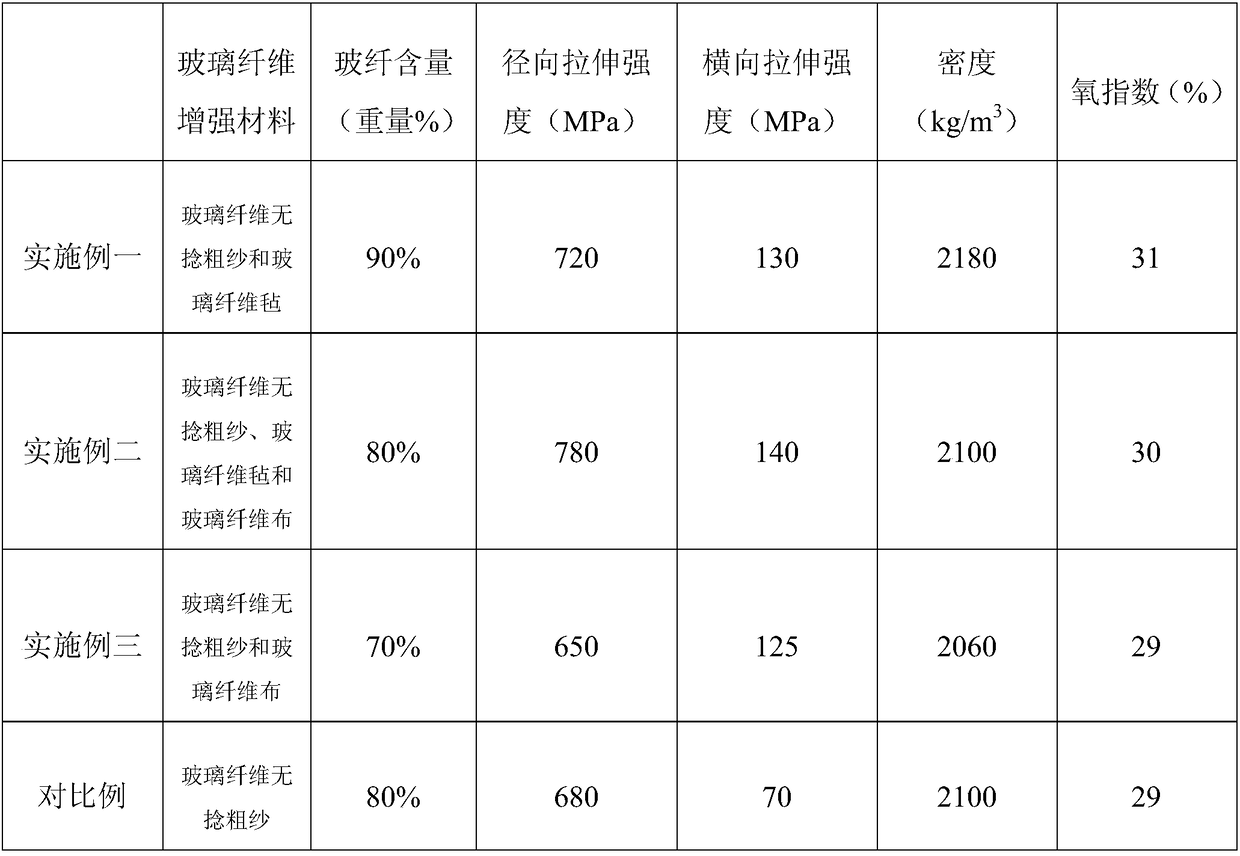

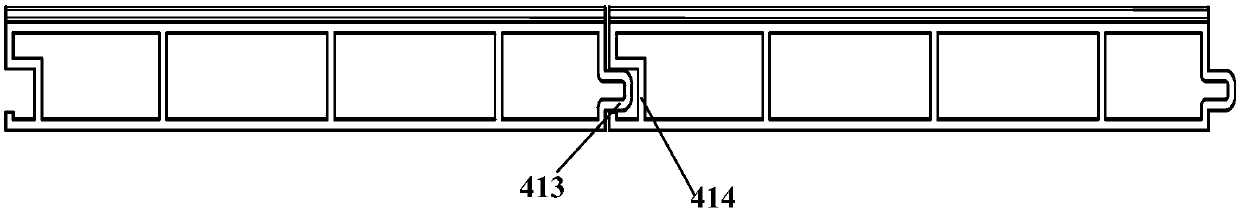

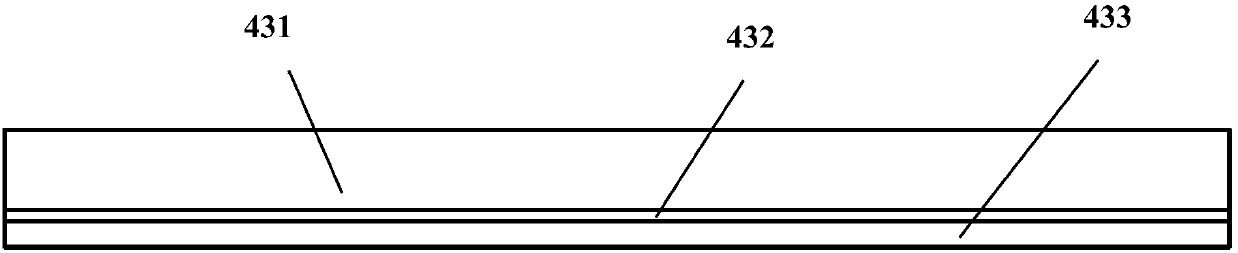

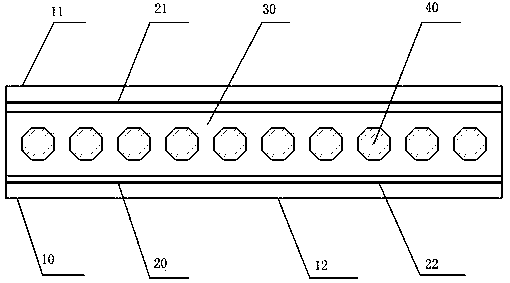

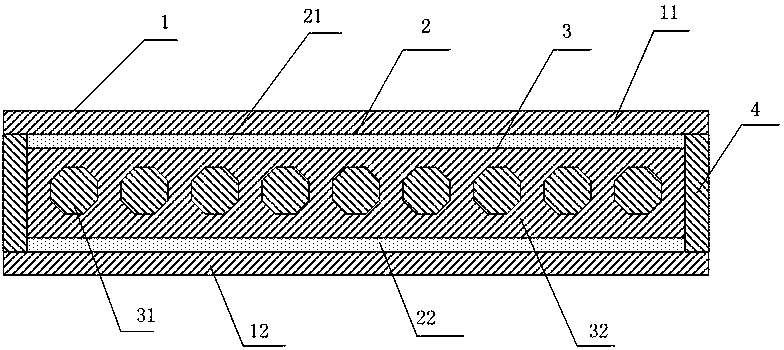

Bidirectionally-reinforced polyurethane pultrusion plate and preparation method thereof

InactiveCN108329681AIncreased transverse tensile strengthEnhanced radial tensile strengthFlat articlesGlass fiberUltimate tensile strength

The invention discloses a bidirectionally-reinforced polyurethane pultrusion plate comprising the following components in percentage by weight: 10%-30% of polyurethane resin and 70%-90% of glass fiberreinforced material, wherein the glass fiber reinforced material comprises glass fiber roving and a glass fiber mat, or glass fiber roving and glass fiber cloth, or the glass fiber roving, the glassfiber mat and the glass fiber cloth. The invention further discloses a preparation method of the bidirectionally-reinforced polyurethane pultrusion plate. Due to the matching of the roving, the mat and the cloth, the obtained product, namely the bidirectionally-reinforced polyurethane pultrusion plate disclosed by the invention, has high transverse tensile strength higher than 120MPa, and meanwhile, the radial tensile strength is also improved.

Owner:山西凝固力新型材料股份有限公司

Method for enhancing transverse strength of FRP (fiber reinforced plastics) pultruded profile by utilizing weaving technology

ActiveCN103707523AIncreased transverse tensile strengthImprove lateral strengthCoatingsHelical lineFiber

The invention discloses a method for enhancing the transverse strength of an FRP (fiber reinforced plastics) pultruded profile by utilizing a weaving technology, relates to a method for enhancing an FRP material, and aims to solve the problem of low transverse strength of the FRP pultruded profile prepared by a conventional method. The method comprises the following steps of 1, preparing a resin substrate; 2, drying and arranging fibers; 3, wetting the fibers; 4, pre-forming longitudinal fibers; 5, weaving a surface layer; 6, pre-forming a woven layer; and 7, performing solidification shaping. The method for enhancing the transverse strength of the FRP pultruded profile by utilizing the weaving technology has the advantages that the transverse tensile strength of the prepared FRP pultruded profile reaches 50 to 90MPa, and is improved by 20 to 50 percent compared with that of the FRP pultruded profile prepared by the conventional method; the longitudinal tensile strength of the FRP pultruded profile reaches 600 to 900MPa; the surface layer fibers of the pultruded profile form a spiral trajectory, and are interwoven into a seamless whole.

Owner:HARBIN FRP INST

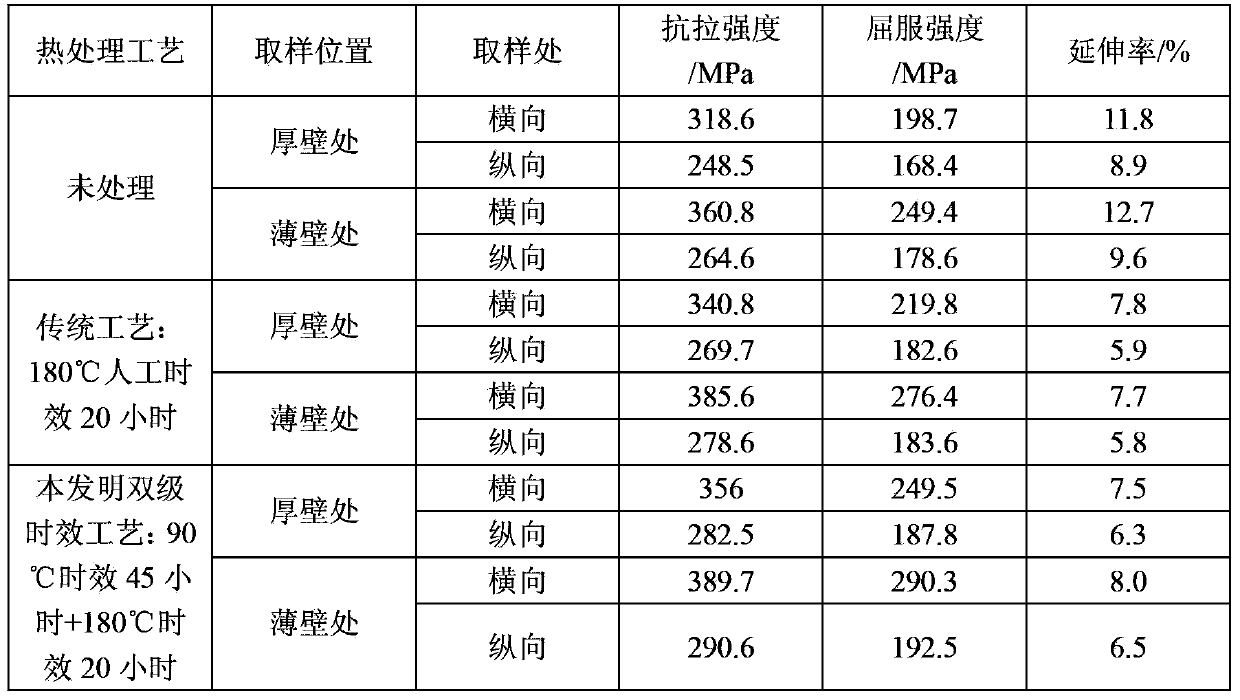

Thermal treatment technology of large-size high-strength wrought magnesium alloy forging

The invention relates to a thermal treatment technology of a large-size high-strength wrought magnesium alloy forging, and particularly relates to a thermal treatment technology of a wrought magnesium alloy forging of an Mg-Al-Zn system. The implementation scheme of the invention is as follows: preserving heat of the large-size wrought magnesium alloy forging with the wall thickness of 30-100mm, the diameter (phi) of greater than or equal to 680mm and the maximum horizontal projection area of greater than or equal to 0.4m<2> at 80-100 DEG C for 36-48 hours; heating to 160-180 DEG C at a rate of 15-30 DEG C per hour, and preserving heat for 15-20 hours; and cooling to room temperature to obtain the large-size high-strength wrought magnesium alloy forging, wherein the magnesium alloy forging comprises the following elements in percentage by mass: 8.2-8.5% of Al, 0.4-0.5% of Zn, 0.2-0.25% of Mn, less than or equal to 0.05% of Cu, less than or equal to 0.005% of Ni, less than or equal to 0.15% of Si, less than or equal to 0.02% of Be, less than or equal to 0.05% of Fe, less than or equal to 0.3% of other impurities and the balance of Mg. By adopting the technology provided by the invention, the prepared large-size high-strength wrought magnesium alloy forging can meet the using requirements for the parts of the fields of transportation, aerospace and the like; and the preparation technology is simple and easy to implement, and industrial production is facilitated.

Owner:CENT SOUTH UNIV

Textile thread having a polytetrafluoroethylene wrapped core

Owner:BLOCH KLAUS

Preparation method of high-performance bamboo steel composite material

InactiveCN112356196ARemove completelyRetain natural colorWood compressionWood treatment detailsEpoxyFreeze-drying

The invention discloses a preparation method of a novel bamboo steel composite material, and belongs to the technical field of bamboo artificial boards and bamboo engineering materials. The method comprises the following steps: (1) removing lignin and hemicellulose in the bamboo wood by a two-step method, (2) breaking through a pore structure in the bamboo wood by using a freeze-drying process, (3) carrying out vacuum impregnation epoxy resin treatment on an obtained bamboo wood framework, and (4) carrying out hot-pressing curing to realize densification of the bamboo wood, thereby obtaining the bamboo-steel composite material with high fiber content. The bamboo steel material provided by the invention has the advantages of high bamboo utilization rate, excellent mechanical properties, high dimensional stability, low thermal conductivity and the like, and is expected to be applied to the fields of energy-saving buildings, bridges, transportation, aerospace and the like.

Owner:CHONGQING UNIV

CON-AID plate and manufacturing method thereof

ActiveCN107309978AReduce decoration costsReduce pollutionCovering/liningsSolid waste managementSurface layerPaper manufacturing

The invention relates to a CON-AID plate and a manufacturing method thereof. The CON-AID plate comprises a center base material layer, and is characterized in that a balance layer, a buffering layer and a decorative layer are sequentially arranged outside the base material layer; the balance layer is made from homogenous MDF or HDF; the buffering layer is made from dipping ecological paper; and the environment-friendly level of each layer is the E0 level. Manufacturing of the CON-AID plate includes the following steps of base material manufacturing, buffering layer manufacturing, surface layer decorative dipping paper manufacturing and CON-AID plate manufacturing. According to the CON-AID plate and the manufacturing method thereof, needed raw materials are subjected to environment-friendly control, the formaldehyde release amount achieves the E0 level, meanwhile, the subsequent painting and colored drawing process is not needed, the decorative cost is saved, and pollution is reduced.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

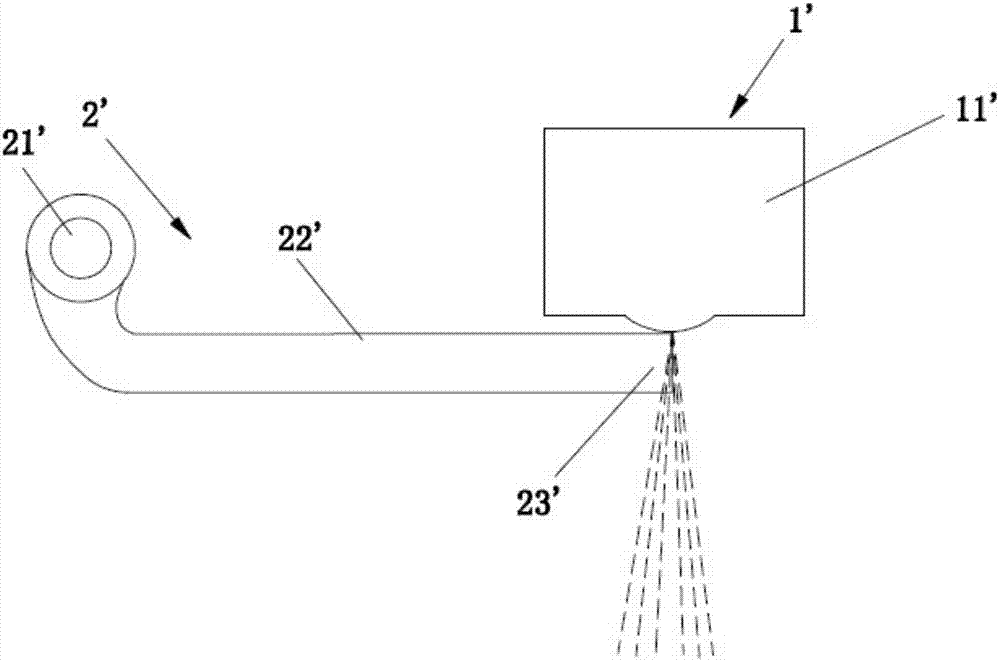

Double-component melt-blowing equipment

InactiveCN107217392AImprove mixing uniformityIncreased transverse tensile strengthNon-woven fabricsEngineeringMelt blowing

A kind of two-component melt-blown equipment provided by the present invention comprises a melt-blown device, a fiber supply device to be mixed, and a web-forming device. The melt-blown device includes a spinneret die and a spinneret, and the spinneret is fixed on the side of the spinneret die. Below, the spinneret has several spinneret holes for spraying melt-blown fibers. The fiber supply device to be mixed includes a feeding air duct and a fan. The fiber to be mixed and the melt-blown fiber provided by the fiber supply device to be mixed are melted The vertical wind force provided by the spray device and the horizontal wind force generated by the fan are mixed to form mixed spray fibers, and a needle punching device is also included. The needle punch device is arranged below the melt blown device and the fiber supply device to be mixed, and Above the web forming device, the needle punching device includes a pair of rotatable needle punching rollers, which are respectively arranged on both sides of the co-sprayed fiber, and each needle punching roller contains a plurality of needles. The mixed-blown fibers and fiber layers produced by the two-component melt-blown equipment have better mixing uniformity and transverse tensile strength.

Owner:徐家潼

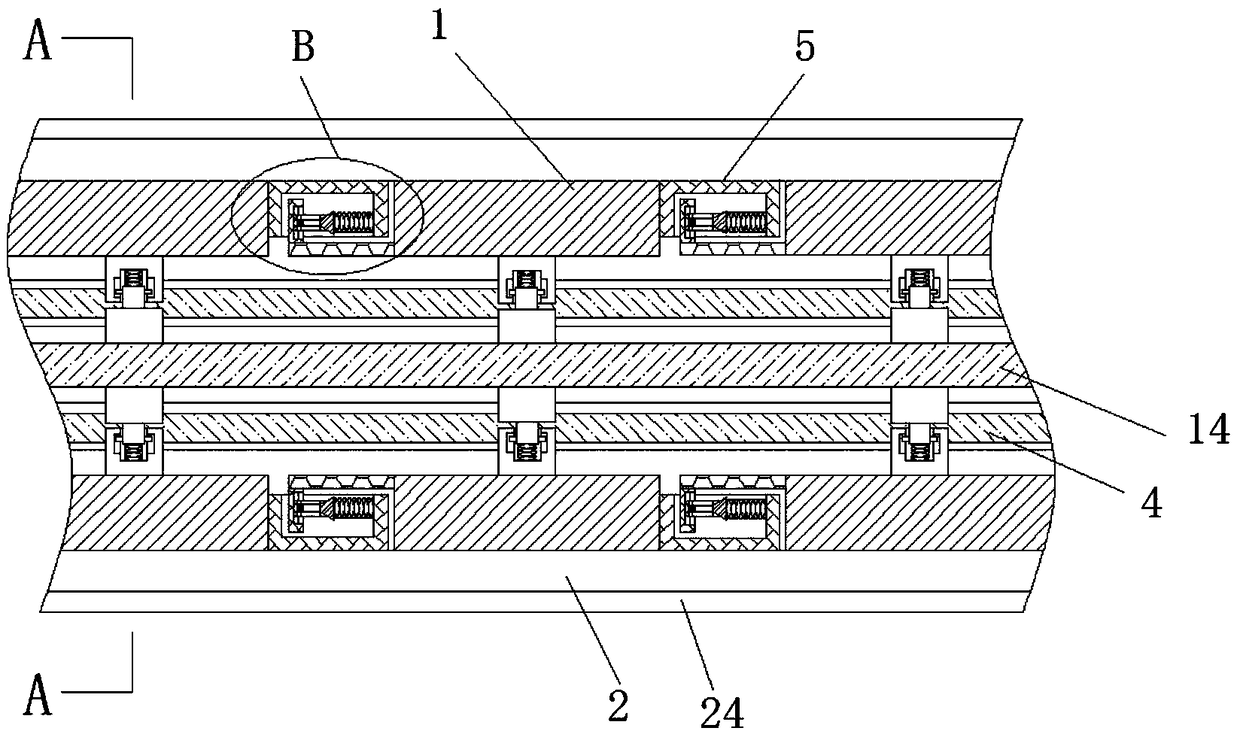

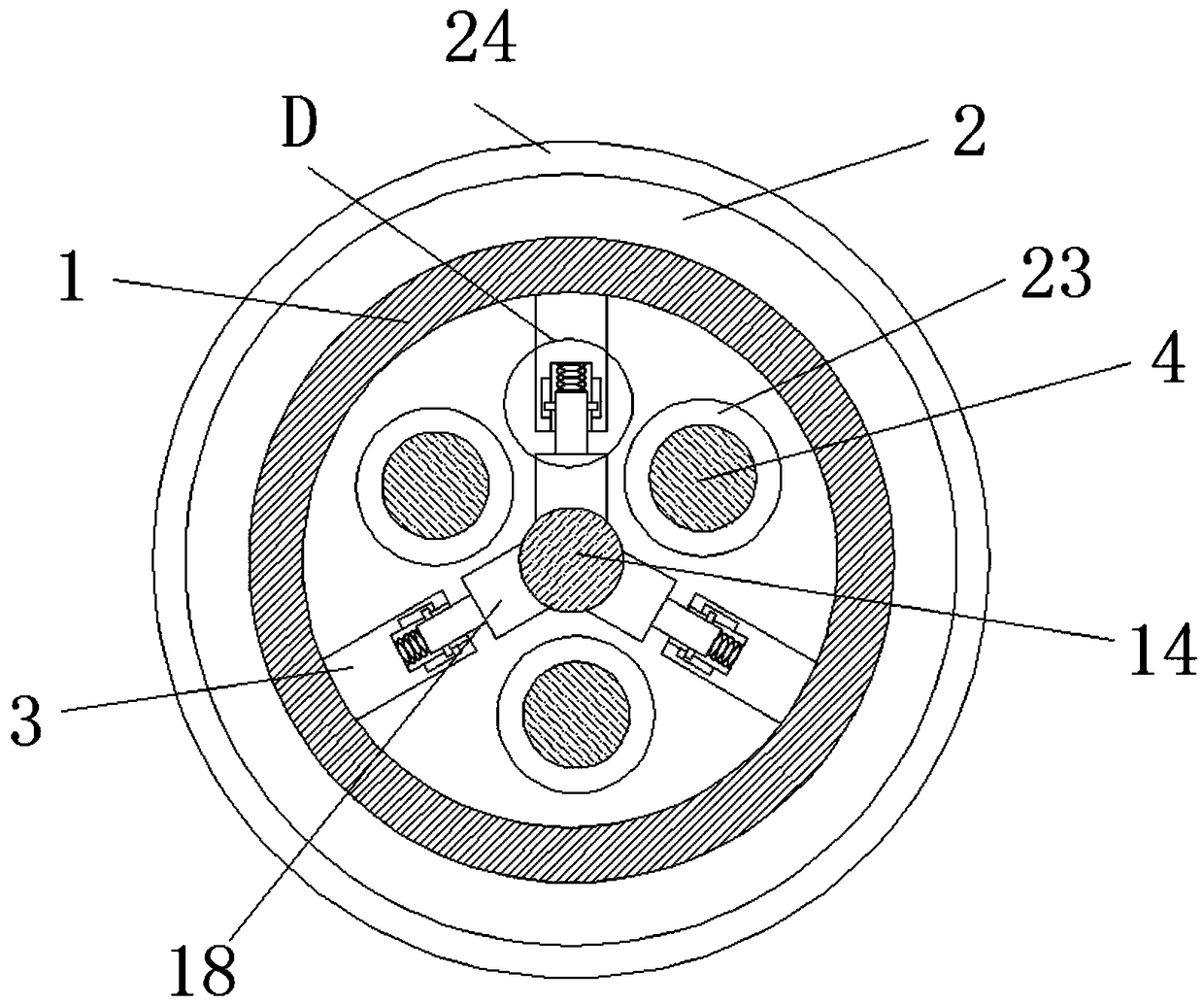

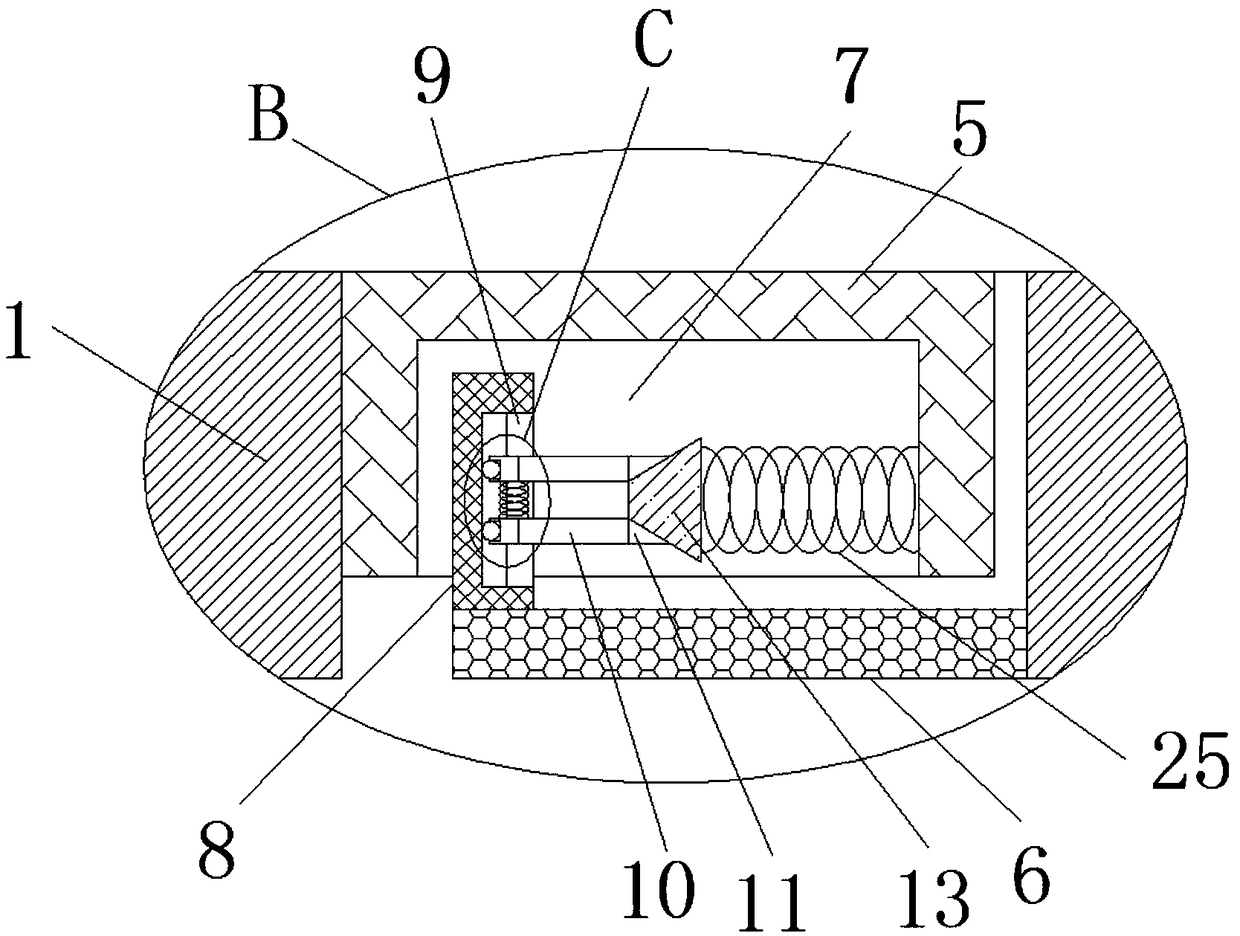

A high-strength cable

PendingCN109215864AIncreased transverse tensile strengthHigh longitudinal tensile strengthInsulated cablesInsulated conductorsElectrical and Electronics engineeringUltimate tensile strength

The invention discloses a cable with high strength, comprises a plurality of protective cylinders uniformly distributed along a straight line, Between any two adjacent protective cylinder is connectedby a buff mechanism, the outer surfaces of the plurality of protective cylinders are coated with a protective layer, the protective layer is made of elastic material, a plurality of connecting bodiesare uniformly and equally spaced and fixedly connected on the annular cylinder wall in the protective cylinder, A cable body is arranged between two connectors which are optionally located in the same plane and adjacent to each other, The cushioning mechanism comprises a first connecting block and a second connecting block, wherein the cross sections of the first connecting block and the second connecting block are annular, and the first connecting block and the second connecting block are fixedly connected between two adjacent protective cylinders, respectively, and the second connecting block is interposed in the first connecting block. The connecting mechanism and the buffer mechanism consume the pull force of the cable under the harsh environment, thereby improving the tensile strength of the cable as a whole and protecting the cable.

Owner:天津山旗线缆有限公司

High-strength high-softness high-antibacterial-performance paper for daily use and preparation method thereof

InactiveCN105155341ANo biocompatibilityNon-biodegradableSpecial paperPaper coatingBronopolMicrosphere

The invention discloses high-strength high-softness high-antibacterial-performance paper for daily use and a preparation method thereof. According to the method, chitosan powder is dissolved in a lactic acid water solution, chitosan is completely dissolved, a bronopol solution is added into the mixture to be evenly mixed, then a negative ion polyacrylamide solution is dripped, a lactic acid / chitosan-bronopol nano microsphere compound is prepared through reaction, the obtained compound is sprayed to the surface of paper for daily use, and then the high-strength high-softness high-antibacterial-performance paper for daily use is obtained. By the utilization of the lactic acid / chitosan-bronopol nano microsphere compound, the paper for daily use has high strength, high antibacterial performance and high softness, the three defects that according to common paper for daily use, strength and softness are low, and no antibacterial performance exists are overcome, and high application value is obtained.

Owner:FUJIAN AGRI & FORESTRY UNIV

Embedded strip for epoxy resin-based fiber-reinforced high-modulus wind turbine blade, equipment and process

PendingCN111873490AHigh strengthGood adhesionFinal product manufactureMachines/enginesEpoxyGlass fiber

The invention discloses an embedded strip for an epoxy resin-based fiber-reinforced high-modulus wind turbine blade, equipment and a process. The embedded strip comprises a composite material body andcomposite surface felts which are arranged on the upper surface and the lower surface of the composite material body; the composite material body is a glass fiber reinforced epoxy resin composite material; and glass fibers comprise twistless roving glass fibers, bulked yarn glass fibers and glass fiber cloth, the twistless roving glass fibers and the bulked yarn glass fibers are uniformly arranged in the composite material body in multiple layers in the length direction to form a multi-layer structure, and at least one layer of glass fiber cloth is arranged in the multi-layer structure in thelength direction. The embedded strip is a high-modulus embedded strip reinforced by epoxy resin-based fibers, and the embedded strip manufactured by the method has the advantages of high modulus, certain toughness and ageing resistance, and can meet the production requirements of blades of units with the power of less than 7MW at present.

Owner:西安永兴科技发展有限公司

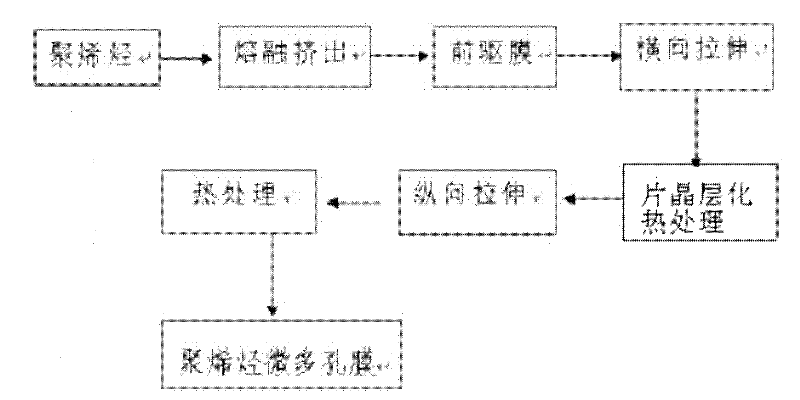

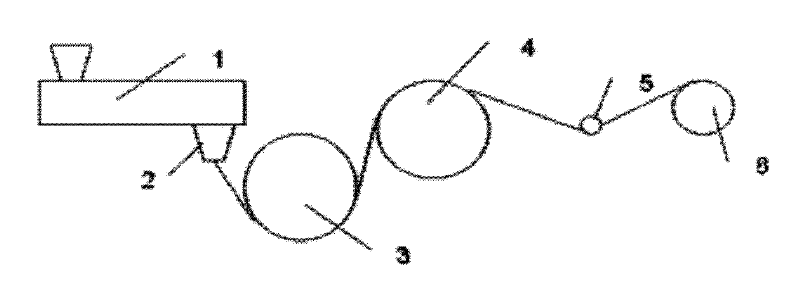

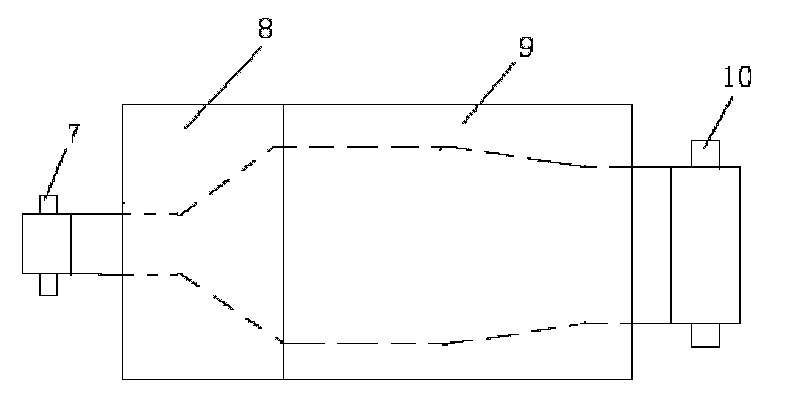

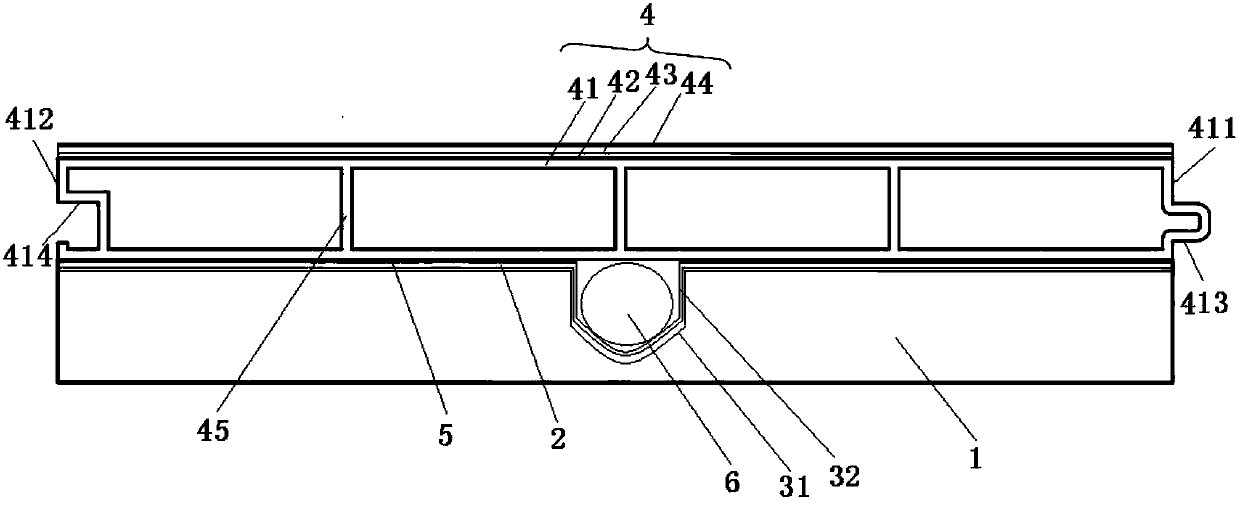

A kind of preparation method of polyolefin microporous film and its obtained microporous film

ActiveCN102285108AReduce manufacturing costIncreased transverse tensile strengthFlat articlesPolymer sciencePolyolefin

The invention discloses a preparation method for a polyolefin micro-porous membrane and a micro-porous membrane prepared by using the same. The preparation method comprises the following steps: melting, extruding, stretching and cooling polyolefin, thereby forming a nonporous membrane; after laterally stretching the nonporous membrane, performing layering and thermal treatment on a lamella; and after longitudinally stretching the nonporous membrane acquired from the step b, performing thermal treatment on the nonporous membrane. The prepared polyolefin micro-porous membrane contains the holes, longitudinal and lateral length-diameter ratio of which is (1.1:1)-(5:1); the longitudinal and lateral tensile strength ratio is (1.2:1)-(4:1); the fluctuation range of thickness is equal to or morethan -2.5% and equal to or less than +2.5%; the longitudinal thermal contraction is equal to or less than 2%; and the lateral thermal contraction is equal to or less than 1%. The preparation method for the polyolefin micro-porous membrane has the advantages that the production facility is simple, the cost is low, the environment is protected, the prepared membrane contains the holes having a shape approaching to ellipse and meanwhile has higher lateral tensile strength, better tearing strength, small contractibility rate and small thickness fluctuation, no crystal form nucleating agent or hole-forming material capable of forming holes is added in the preparation process, and the like.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

Aluminum-wood water heating system and paving method thereof

PendingCN108036385AShort thermal pathFast heat conductionCovering/liningsLighting and heating apparatusWater pipeSolid wood

The invention discloses an aluminum-wood water heating system and a paving method thereof. The aluminum-wood water heating system comprises a heat preservation plate, a reflecting film, a cyclic heating water pipe and an aluminum-wood composite floor. The reflecting film is laid on the heat preservation plate. Linear or arc-shaped heat preservation plate grooves are formed in the heat preservationplate. Linear or arc-shaped reflecting grooves are formed in the reflecting film and matched with the heat preservation plate grooves. The cyclic heating water pipe is located in the reflecting filmgrooves. The aluminum-wood composite floor is laid on the top of the reflecting film. The aluminum-wood composite floor comprises an aluminum alloy base plate, a first PUR glue layer and a solid woodplate. The first PUR glue layer and the solid wood layer are sequentially laid on the top of the aluminum alloy base plate. The solid wood plate is bonded and connected to the aluminum alloy base plate through the first PUR glue layer. The aluminum-wood water heating system is fast in heat conduction, the room temperature can be raised rapidly during a short time, the laid floor is free of cracking or deformation, the stability is good, the safety and reliability are high, and the aluminum-wood water heating system has the characteristic of being convenient to disassemble and assemble.

Owner:金华意萨曼新材料科技有限公司

Anti-tearing steel wire rope core conveying belt

InactiveCN108146989AIncreased transverse tensile strengthAvoid tearingConveyorsPolyesterAdhesive glue

The invention belongs to the field of conveying belts, and particularly relates to an anti-tearing steel wire rope core conveying belt. The anti-tearing steel wire rope core conveying belt comprises acovering layer, an intermediate layer, an adhesive glue layer and a steel wire rope; the intermediate layer comprises an upper intermediate layer body and a lower intermediate layer body which are each impregnated fiber cloth; the impregnated fiber cloth is made in the manner that fiber cloth is impregnated with covering rubber pulp; and the fiber cloth is formed by warp polyester silk and weft aramid fiber silk in a woven manner. The impregnated fiber cloth is added for the anti-tearing steel wire rope core conveying belt, the transverse stretching strength of the steel wire rope core conveying belt is improved, and the tearing phenomenon of the steel wire rope core conveying belt can be effectively prevented.

Owner:XIAN FEIDONG ELECTRONICS TECH

Anti-tearing steel wire rope core conveying belt

The invention particularly relates to an anti-tearing steel wire rope core conveying belt comprising covering layers, anti-tearing layers, an intermediate layer and an edge glue layer. The anti-tearing layers comprise the upper anti-tearing layer and the lower anti-tearing layer, the upper anti-tearing layer is arranged on the intermediate layer, and the lower anti-tearing layer is arranged underthe intermediate layer; the anti-tearing layers are glue dipped fiber cloths, the glue dipped fiber cloths are made in the mode that fiber cloths are dipped in covering glue, and the fiber cloths aremade by weaving polyester silk serving as longitude lines and latitude lines; the covering layers comprise the upper covering layer and the lower covering layer; a layer of non-woven cloth is arrangedon the upper covering layer; and the edge glue layer comprises aramid short fibers, adhesives and covering glue. According to the anti-tearing steel wire rope core conveying belt, the tearing phenomenon of the steel wire rope core conveying belt can be prevented, the rigid strength and the anti-tearing property of the edge glue layer are good, and bubbles are not liable to be generated in the manufacturing process, so that the repair workload is reduced, and the product quality is improved.

Owner:西安发威电子科技有限公司

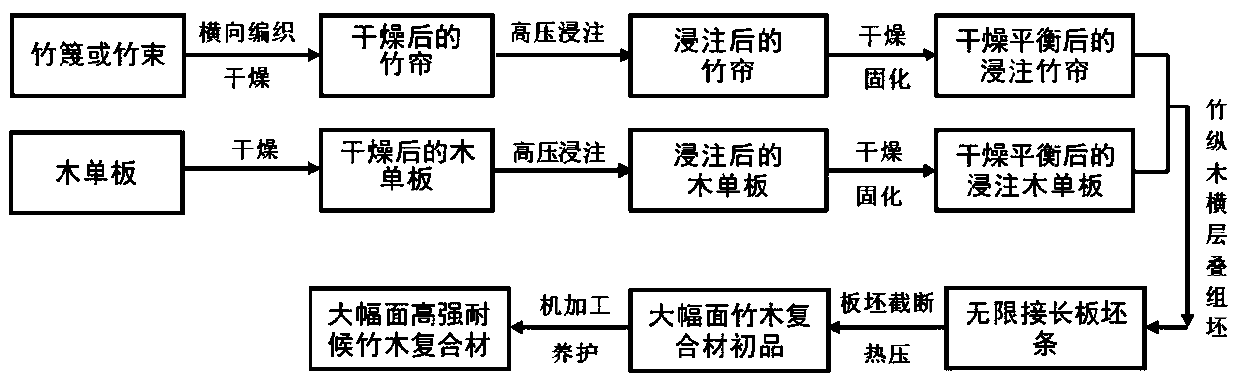

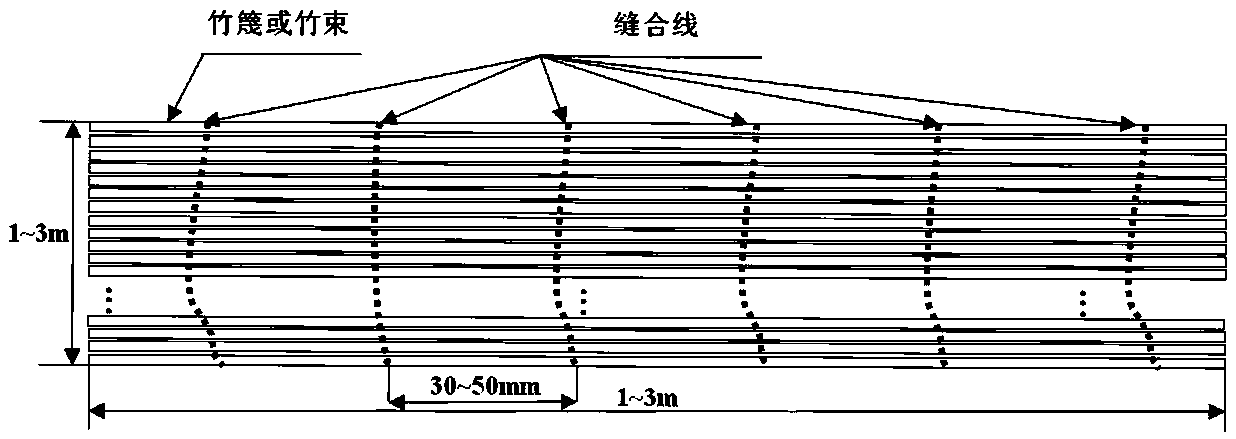

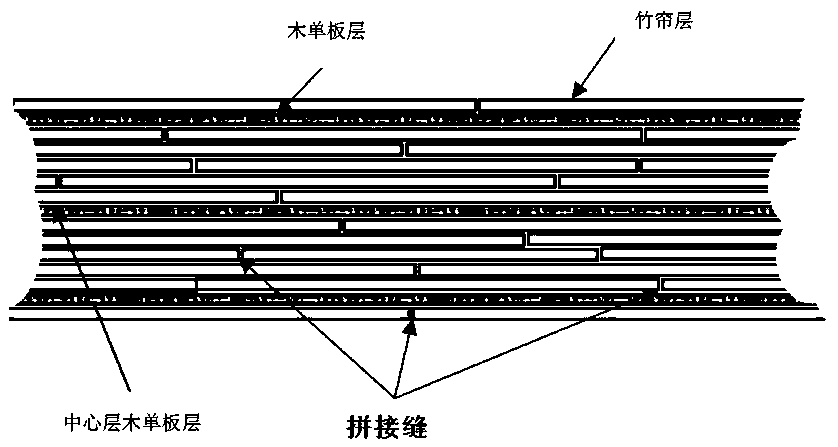

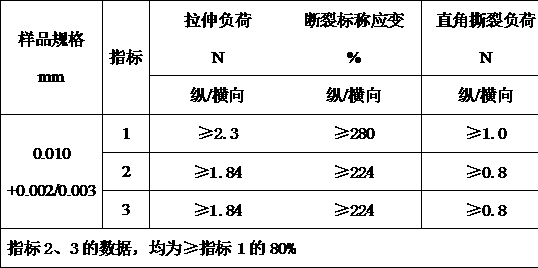

Large-breadth high-strength weather-proof bamboo-wood composite material and manufacturing method thereof

ActiveCN111037674AWith weather resistanceIncreased transverse mechanical strengthWood treatment detailsCane mechanical workingAdhesive cementWood veneer

The invention discloses a manufacturing method of a large-breadth high-strength weather-proof bamboo-wood composite material. The method comprises the following steps: putting a dried bamboo curtain unit and a wood veneer into a high-pressure impregnation treatment tank, and adding a treatment solution which comprises a phenolic resin adhesive and a mildew-proof preservative into the high-pressureimpregnation treatment tank for impregnation treatment; drying and balancing the impregnated bamboo curtain unit and the impregnated wood veneer, placing the bamboo curtain unit and the wood veneer on a conveying belt for continuous lengthening and assembling treatment, arranging longitudinal bamboo and horizontal wood in a plate blank in a staggered lap joint mode, and performing cutting to obtain the plate blank when the preset thickness and length are achieved; and performing hot press molding and post-treatment on the plate blank in order to obtain the large-breadth high-strength weather-proof bamboo-wood composite material. The bamboo-wood composite material prepared by the invention is infinitely lengthened in the length direction, the transverse binding force is large, and the mildew-proof and corrosion-proof capacity is high.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Preparation method of carbon nanotube modified fiber reinforced thermosetting resin-based prepreg

PendingCN112980026AGood dispersionImprove mechanical propertiesPolymer scienceUltimate tensile strength

The invention discloses a preparation method of a carbon nanotube modified fiber reinforced thermosetting resin-based prepreg. The carbon nanotube modified fiber reinforced thermosetting resin-based prepreg is prepared by mixing the carbon nanotubes and the thermosetting resin in proportion and then preparing the prepreg, and the prepreg has high comprehensive mechanical properties, especially high compression strength, and can effectively solve the problem of compression resistance when a composite material is used as a main bearing component; and meanwhile, the transverse tensile strength of the composite material can be improved, the mechanical property among composite material fibers is effectively improved, and the application range of the composite material on structural components requiring high bearing in three-dimensional and multi-dimensional directions is expanded. In addition, the preparation method has the advantages of being convenient to operate, good in repeatability and the like.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

Agricultural plastic polyethylene mulching film

InactiveCN109485988AIncrease production capacityGood dispersionPlant protective coveringsPlastic mulchSilicon dioxide

The invention relates to a formula of agricultural plastic mulching films and in particular relates to an agricultural plastic polyethylene mulching film. The agricultural plastic polyethylene mulching film comprises the following raw materials in parts by weight: 86-90 parts of linear polyethylene, 10-14 parts of metallocene polyethylene, 2-3 parts of an anti-ageing master batch special for Demelon mulching films and 0.5-3 parts of an opening master batch special for Demelon mulching films, wherein the anti-ageing master batch special for Demelon mulching films comprises the following components: 86-90 parts of polyethylene, 14-20 parts of a light stabilizer 944, 3-5 parts of an antioxidant 1010, 0.5-1 part of zinc oxide and 0.5-1 part of zinc stearate; and the opening master batch special for Demelon mulching films comprises the following components: 80-90 parts of calcium carbonate / silica having the granularity of 20000 meshes, 10-15 parts of wax and 7-10 parts of polyethylene. According to the agricultural plastic polyethylene mulching film disclosed by the invention, the production cost increased because the thickness of the mulching film is increased by 20% during agricultural production can be reduced, the acceptance criteria enthusiasm of peasant households is improved, and the efficiency of DB 65 3189-2014 enforced standard implementation is improved.

Owner:URUMCHI DEMEILONG PLASTIC CHEM

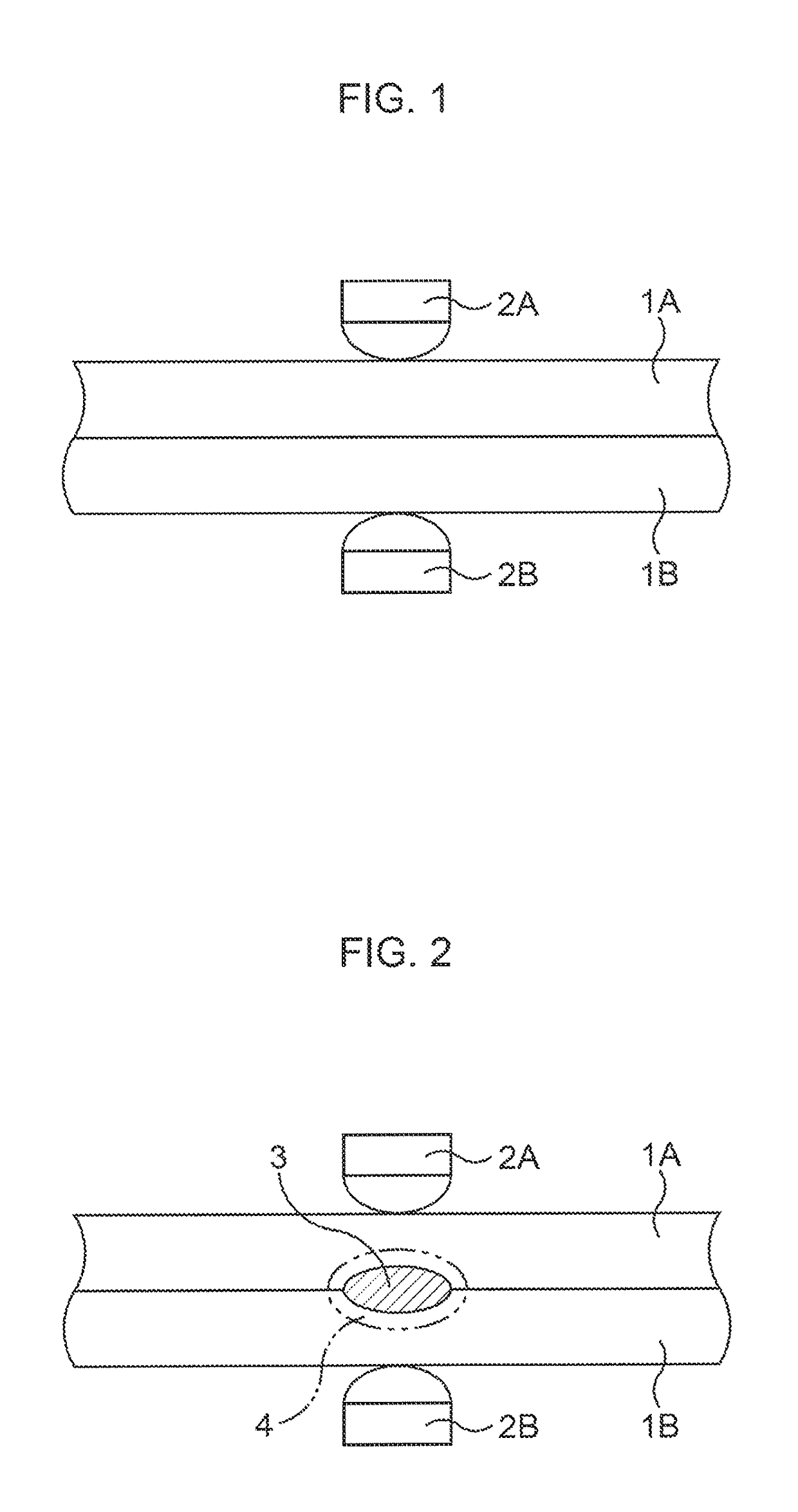

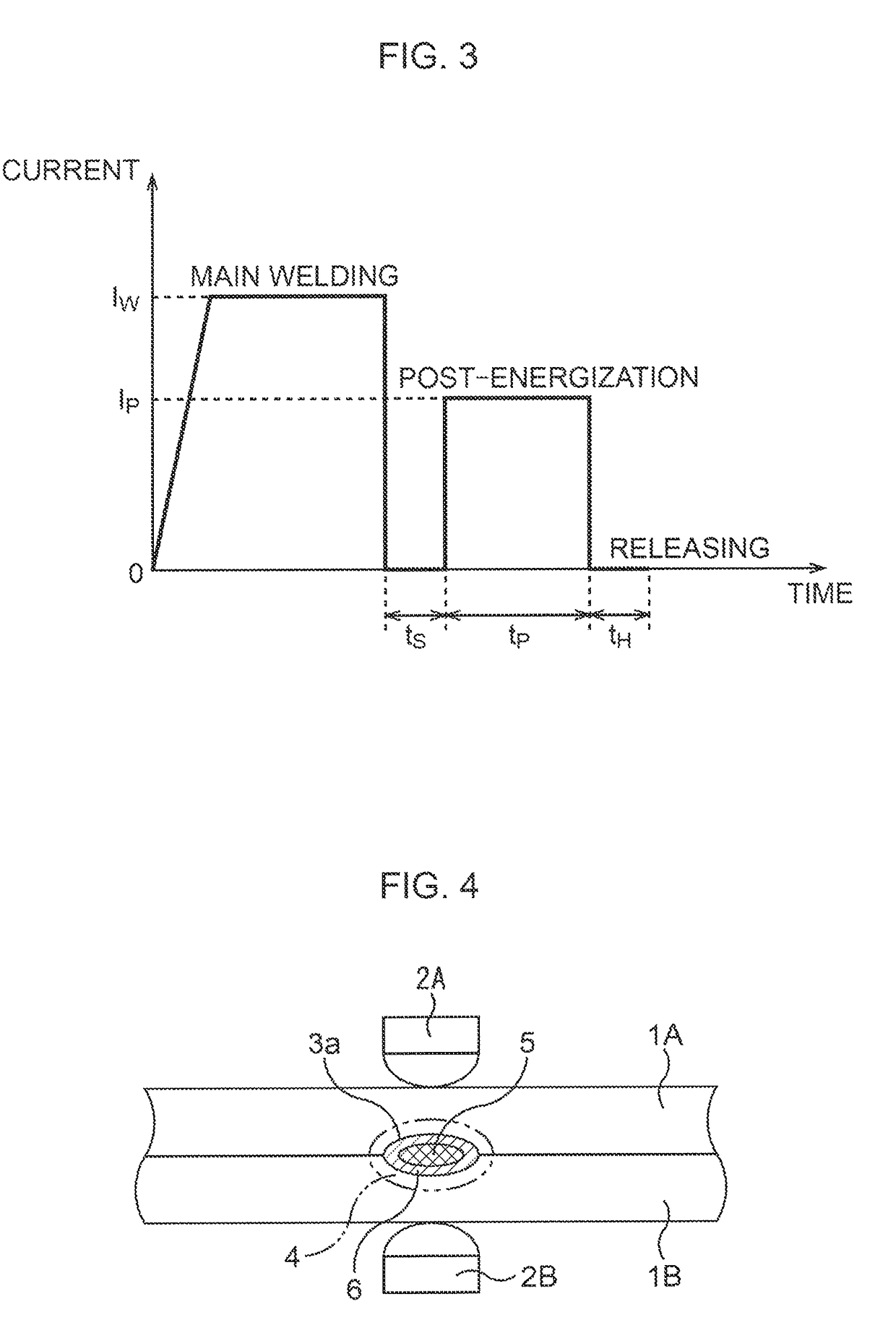

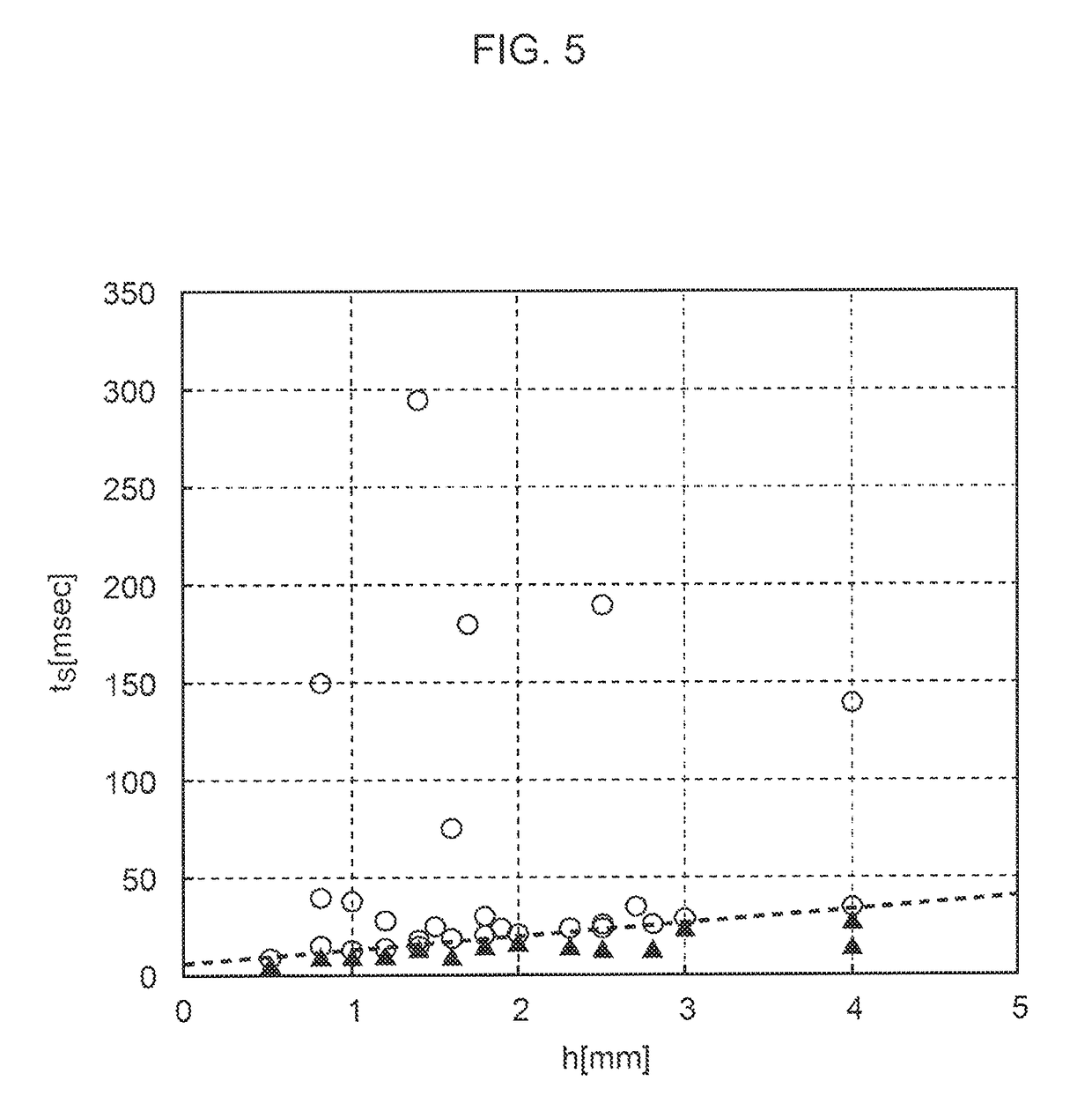

Spot-welded joint and spot welding method

ActiveUS20190030637A1Increased transverse tensile strengthWelding/soldering/cutting articlesResistance welding apparatusHeat-affected zoneCarbide

By obtaining a spot-welded joint being a spot-welded joint formed by overlapping a plurality of pieces of steel plates (1A, 1B) and performing spot welding on the steel plates, including a high-strength steel plate whose tensile strength is 750 (MPa) to 2500 (MPa), being at least one piece of steel plate out of the plurality of pieces of steel plates, in which a carbon equivalent Ceq of the high-strength steel plate is 0.20 mass % to 0.55 mass %, and ten or more of iron-based carbides in each of which a length of a longest portion is 0.1 (μm) or more exist in a square region 103 within a heat-affected zone 4 of a cross section that passes through a center of a welding mark, and is cut along a plate thickness direction of the steel plates (1A, 1B), a cross tensile strength of the spot-welded joint to be formed is improved.

Owner:NIPPON STEEL CORP

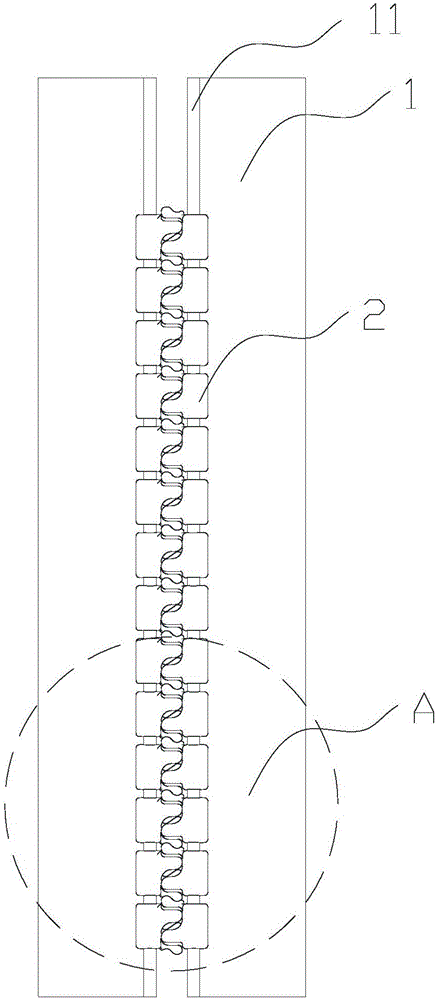

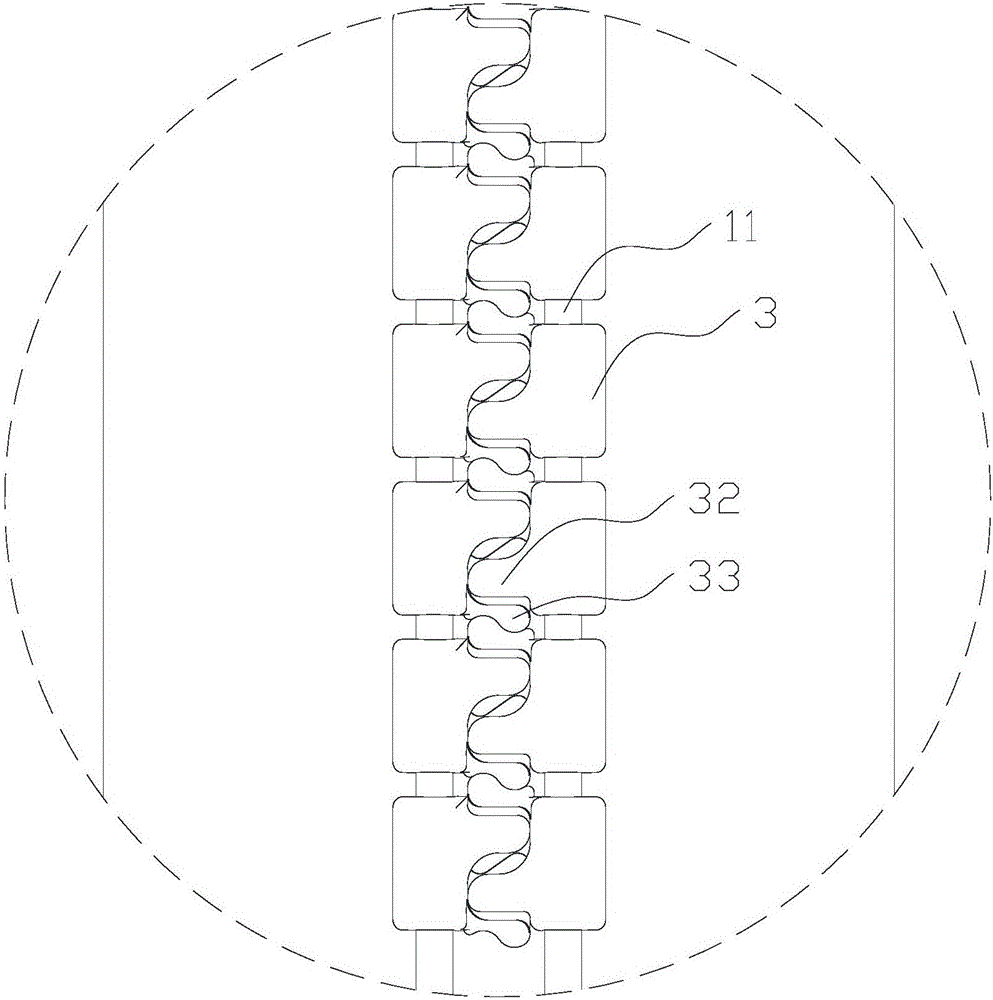

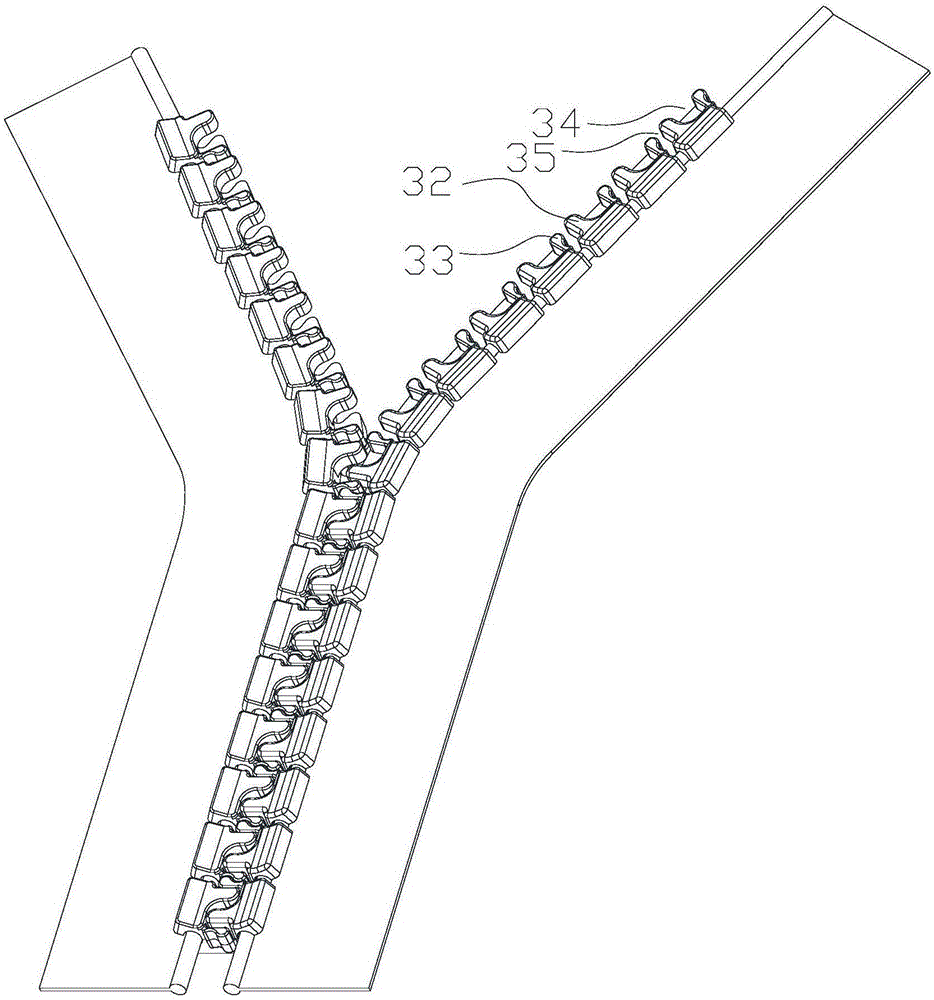

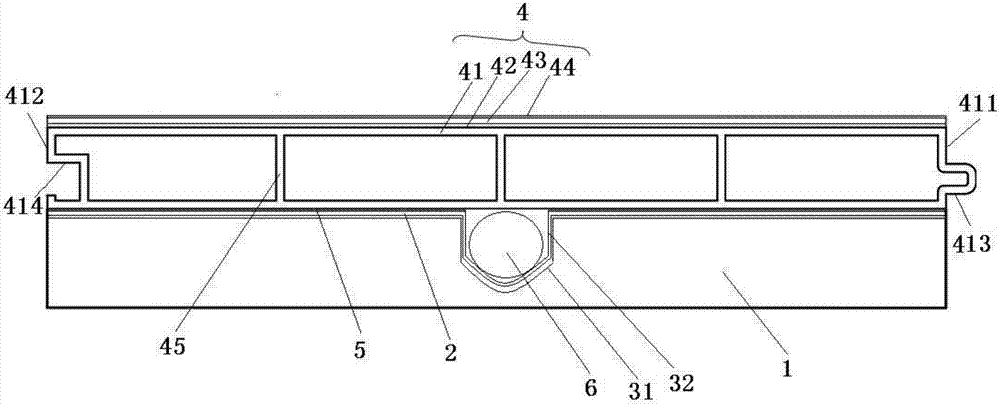

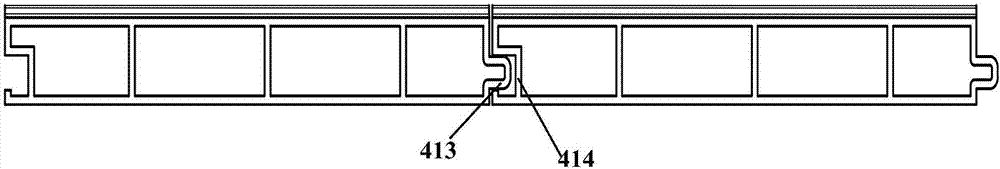

Zipper

ActiveCN106136480AIncreased transverse tensile strengthNot easy to decomposeSlide fastenersEngineering

Owner:广东欧亚宝拉链服装配件有限公司

Cable heating aluminum-wood floor heating system and paving method thereof

PendingCN108005344ARapid rise in temperatureImprove stabilityLighting and heating apparatusElectric heating systemSolid woodRoom temperature

The invention discloses a cable heating aluminum-wood floor heating system and a paving method thereof. The cable heating aluminum-wood floor heating system comprises a heat preservation plate, a reflection film, heating cables and an aluminum-wood composite floor, wherein the reflection film is arranged on the heat preservation plate in a paved mode, heat preservation plate grooves with straight-line-shaped or circular-arc-shaped tracks are formed in the heat preservation plate, reflection film grooves with straight-line-shaped or circular-arc-shaped tracks are formed in the reflection film,and the heat preservation plate grooves are matched with the reflection film grooves. The heating cables are located in the reflection film grooves, the aluminum-wood composite floor is arranged at the top of the reflection film in a paved mode, and the aluminum-wood composite floor comprises an aluminum alloy base plate, a first PUR glue layer and a solid wood plate. The first PUR glue layer andthe solid wood plate are sequentially arranged at the top of the aluminum alloy base plate in a paved mode, and the solid wood plate is in adhesive connection with the aluminum alloy base plate through the first PUR glue layer. The cable heating aluminum-wood floor heating system is not only rapid in heat conduction, the room temperature can be increased rapidly in a short time, the paved floor does not crack and deform, the stability is good, the safe reliability is high, and the characteristic of convenient dismounting and mounting is achieved.

Owner:金华意萨曼新材料科技有限公司

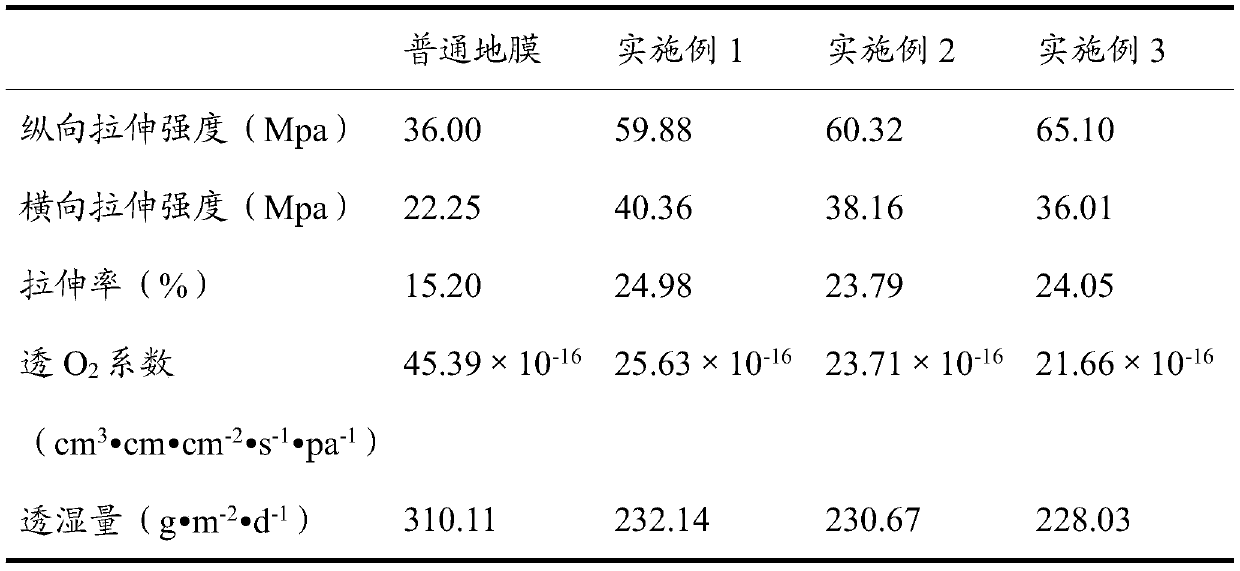

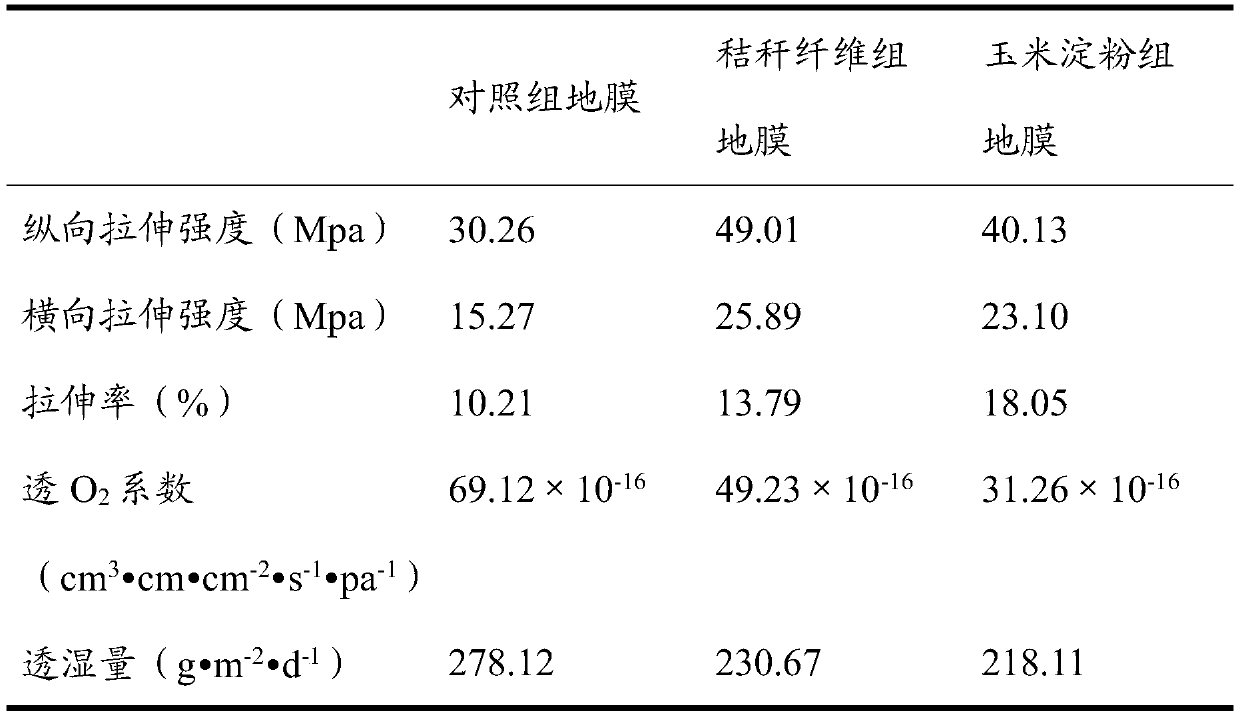

A kind of high-barrier biodegradable mulch film and its preparation method

The invention discloses a high-barrier-property biodegradable mulching film. The high-barrier-property biodegradable mulching film is prepared from the following raw materials in parts by weight: 9 to 12 parts of wheat straw fibers, 25 to 35 parts of corn starch, 3 to 5 parts of sodium hydroxide, 1 to 2 parts of polyvinyl alcohol, 1 to 2 parts of carboxymethylcellulose, 3 to 5 parts of glyoxal, 5 to 10 parts of glycerinum, 0.5 to 1 part of cellulase, 1 to 2 parts of stabilizer, and 90 to 100 parts of deionized water. According to the high-barrier-property biodegradable mulching film, corn starch and wheat straw fibers are used as main preparation raw materials, so that the preparation cost is low, the preparation method is simple, and a novel way is provided for recycling the crop straws; compared with the ordinary mulching film, the longitudinal tensile strength of the high-barrier-property biodegradable mulching film is increased by 66 percent or more, the transverse tensile strength is increased by 66 percent or more, and the stretch rate is increased by more than 58 percent, and the mulching film is uneasy to damage; the water vapor transmission rate is reduced by more than 25 percent, and the barrier property is good; and in addition, the mulching film can be completely degraded after being buried in soil for 60 days, so that the degradation effect is good.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Bamboo carbon fiber reinforced resin material

The invention relates to the technical field of resin materials, in particular to a bamboo carbon fiber reinforced resin material. The bamboo carbon fiber reinforced resin material comprises the following raw materials by weight: 70-85 parts of polyvinyl chloride resin, 45-55 parts of light calcium carbonate, 10-20 parts of modified bamboo carbon fiber, 5-15 parts of bamboo fiber, 3-8 parts of a calcium-zinc stabilizer, 1-2.5 parts of an AC foaming agent, 5-13 parts of a PVC foaming regulator, 0.5-2 parts of polyethylene wax, 0.2-1.5 parts of stearic acid, 0.2-1.3 parts of an environment-friendly toughening agent, 1-2.5 parts of rutile titanium dioxide, and 2-4.5 parts of wood fiber. The bamboo carbon fiber reinforced resin material provided by the invention has excellent mechanical properties.

Owner:安徽省科晟生态木装饰材料有限公司

Coated wood veneer and method for treating wood veneer

PendingUS20210039134A1Improve rigidityHigh strengthOther chemical processesCellulose coatingsWood veneerNanocellulose

Disclosed is a method for treating wood veneer, including the steps of providing at least one sheet of wood veneer; coating at least one side of the sheet of wood veneer with an aqueous coating composition including nanocellulose to obtain a coated sheet of wood veneer; and drying the coated sheet using compression pressure and heat. Also disclosed is a coated wood veneer including a sheet of wood veneer and a coating including nanocellulose arranged on at least one surface of the sheet.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT +1

A heat treatment process for large-scale high-strength deformed magnesium alloy forgings

The invention relates to a thermal treatment technology of a large-size high-strength wrought magnesium alloy forging, and particularly relates to a thermal treatment technology of a wrought magnesium alloy forging of an Mg-Al-Zn system. The implementation scheme of the invention is as follows: preserving heat of the large-size wrought magnesium alloy forging with the wall thickness of 30-100mm, the diameter (phi) of greater than or equal to 680mm and the maximum horizontal projection area of greater than or equal to 0.4m<2> at 80-100 DEG C for 36-48 hours; heating to 160-180 DEG C at a rate of 15-30 DEG C per hour, and preserving heat for 15-20 hours; and cooling to room temperature to obtain the large-size high-strength wrought magnesium alloy forging, wherein the magnesium alloy forging comprises the following elements in percentage by mass: 8.2-8.5% of Al, 0.4-0.5% of Zn, 0.2-0.25% of Mn, less than or equal to 0.05% of Cu, less than or equal to 0.005% of Ni, less than or equal to 0.15% of Si, less than or equal to 0.02% of Be, less than or equal to 0.05% of Fe, less than or equal to 0.3% of other impurities and the balance of Mg. By adopting the technology provided by the invention, the prepared large-size high-strength wrought magnesium alloy forging can meet the using requirements for the parts of the fields of transportation, aerospace and the like; and the preparation technology is simple and easy to implement, and industrial production is facilitated.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com