Bidirectionally-reinforced polyurethane pultrusion plate and preparation method thereof

A technology of polyurethane and polyurethane resin, applied in the field of bidirectionally reinforced polyurethane pultruded sheet and its preparation, can solve the problems of limitation and low tensile strength, and achieve the effect of improving radial tensile strength and high transverse tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

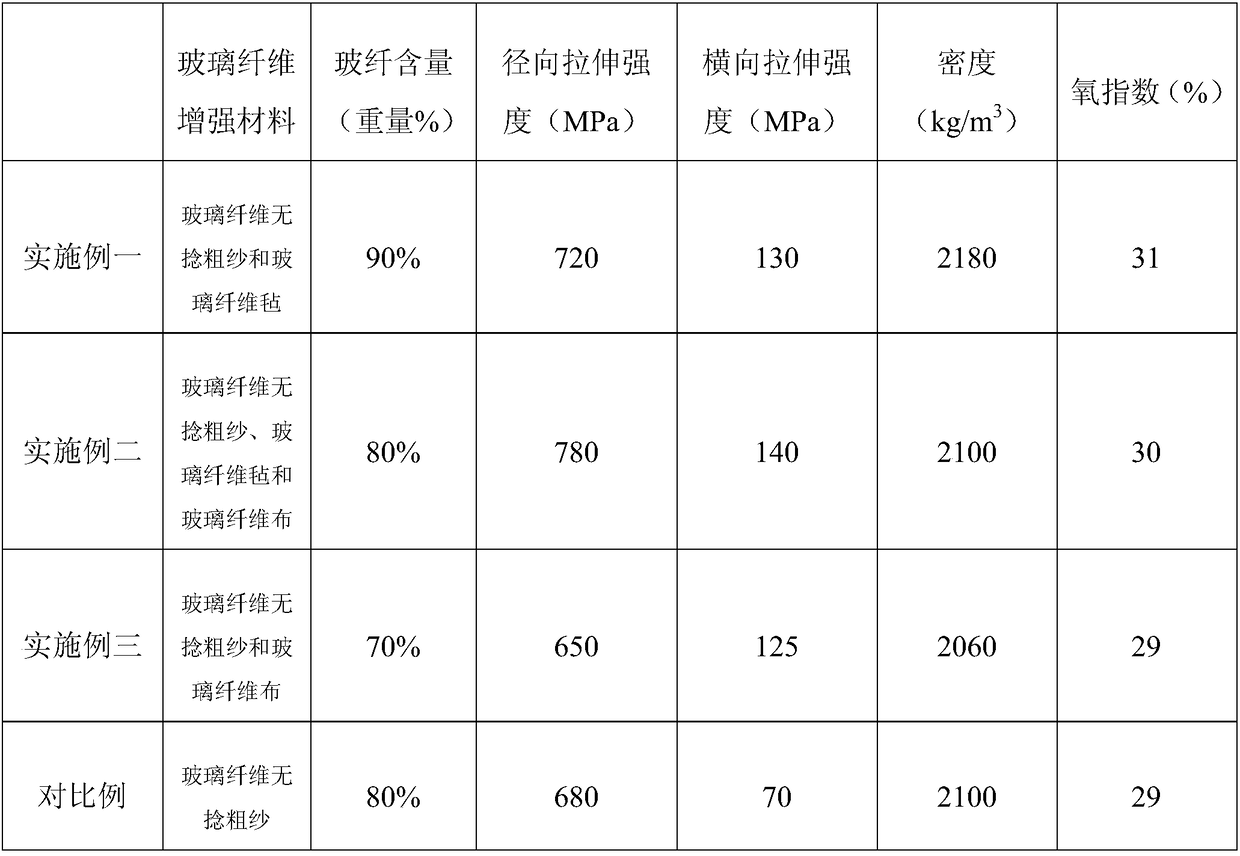

Embodiment 1

[0022] A two-way reinforced polyurethane pultruded board comprising components by weight of:

[0023] Polyurethane resin 10%;

[0024] Glass fiber reinforcement 90%;

[0025] Wherein, the glass fiber reinforced material is glass fiber roving and glass fiber mat.

[0026] The polyurethane resin includes a polyurethane A component and a polyurethane B component; wherein, the polyurethane A component is a reactive component formed by mixing polyether polyols, water and auxiliary agents, and the polyurethane B component is a multi-substance Methyl polyphenyl polyisocyanate and its derivatives (such as modified MDI). The auxiliary agent includes a catalyst, a flame retardant, an anti-aging agent, a leveling agent, and a crosslinking agent.

[0027] A preparation method of a two-way reinforced polyurethane pultruded board, comprising the following steps:

[0028] In step (1), after the glass fiber reinforced material is drawn from the creel, it enters a resin metering / mixer and ...

Embodiment 2

[0033] A two-way reinforced polyurethane pultruded board comprising components by weight of:

[0034] Polyurethane resin 20%;

[0035] Glass fiber reinforcement 80%;

[0036] Wherein, the glass fiber reinforced material is glass fiber roving, glass fiber mat and glass fiber cloth.

[0037] The polyurethane resin includes a polyurethane A component and a polyurethane B component; wherein, the polyurethane A component is a reactive component formed by mixing polyether polyols, water and auxiliary agents, and the polyurethane B component is a multi-substance Methyl polyphenyl polyisocyanate and its derivatives (such as modified MDI). The auxiliary agent includes a catalyst, a flame retardant, an anti-aging agent, a leveling agent, and a crosslinking agent.

[0038] A preparation method of a two-way reinforced polyurethane pultruded board, comprising the following steps:

[0039] In step (1), after the glass fiber reinforced material is drawn from the creel, it enters a resin ...

Embodiment 3

[0044] A two-way reinforced polyurethane pultruded board comprising components by weight of:

[0045] Polyurethane resin 30%;

[0046] Glass fiber reinforcement 70%;

[0047] Wherein, the glass fiber reinforced material is glass fiber roving and glass fiber cloth.

[0048] The polyurethane resin includes a polyurethane A component and a polyurethane B component; wherein, the polyurethane A component is a reactive component formed by mixing polyether polyols, water and auxiliary agents, and the polyurethane B component is a multi-substance Methyl polyphenyl polyisocyanate and its derivatives (such as modified MDI). The auxiliary agent includes a catalyst, a flame retardant, an anti-aging agent, a leveling agent, and a crosslinking agent.

[0049] A preparation method of a two-way reinforced polyurethane pultruded board, comprising the following steps:

[0050] In step (1), after the glass fiber reinforced material is drawn from the creel, it enters a resin metering / mixer an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com