Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141 results about "Bronopol" patented technology

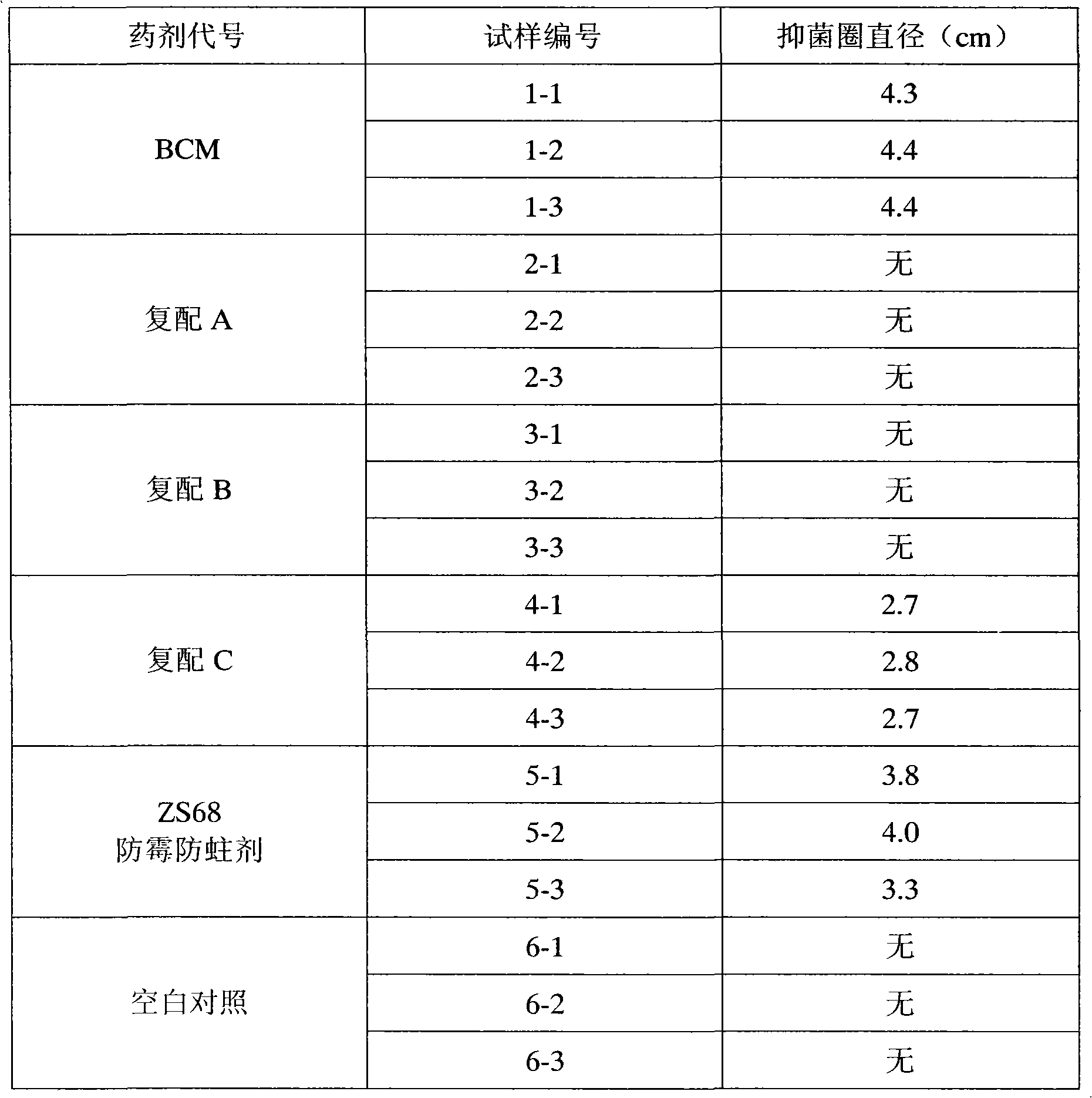

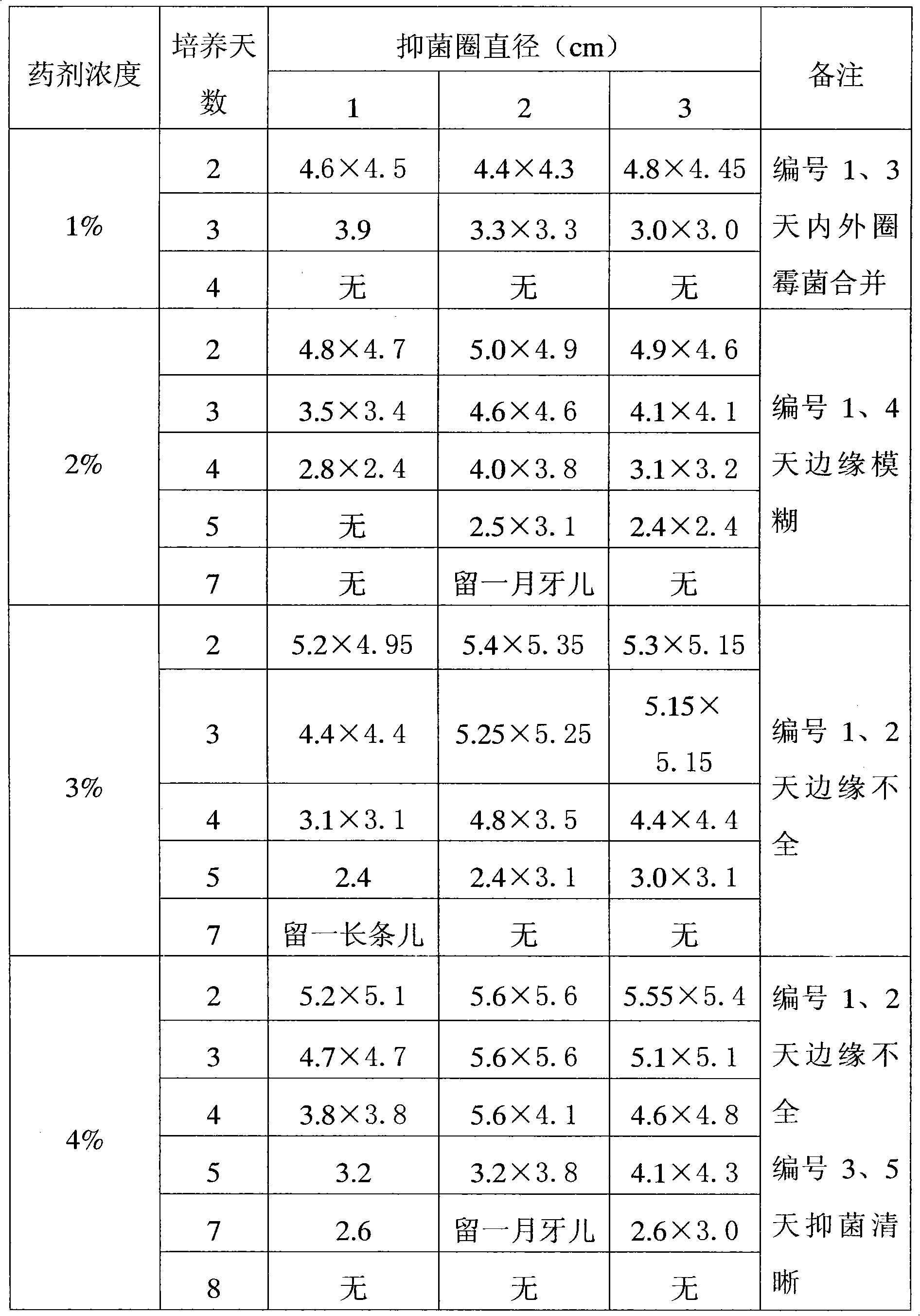

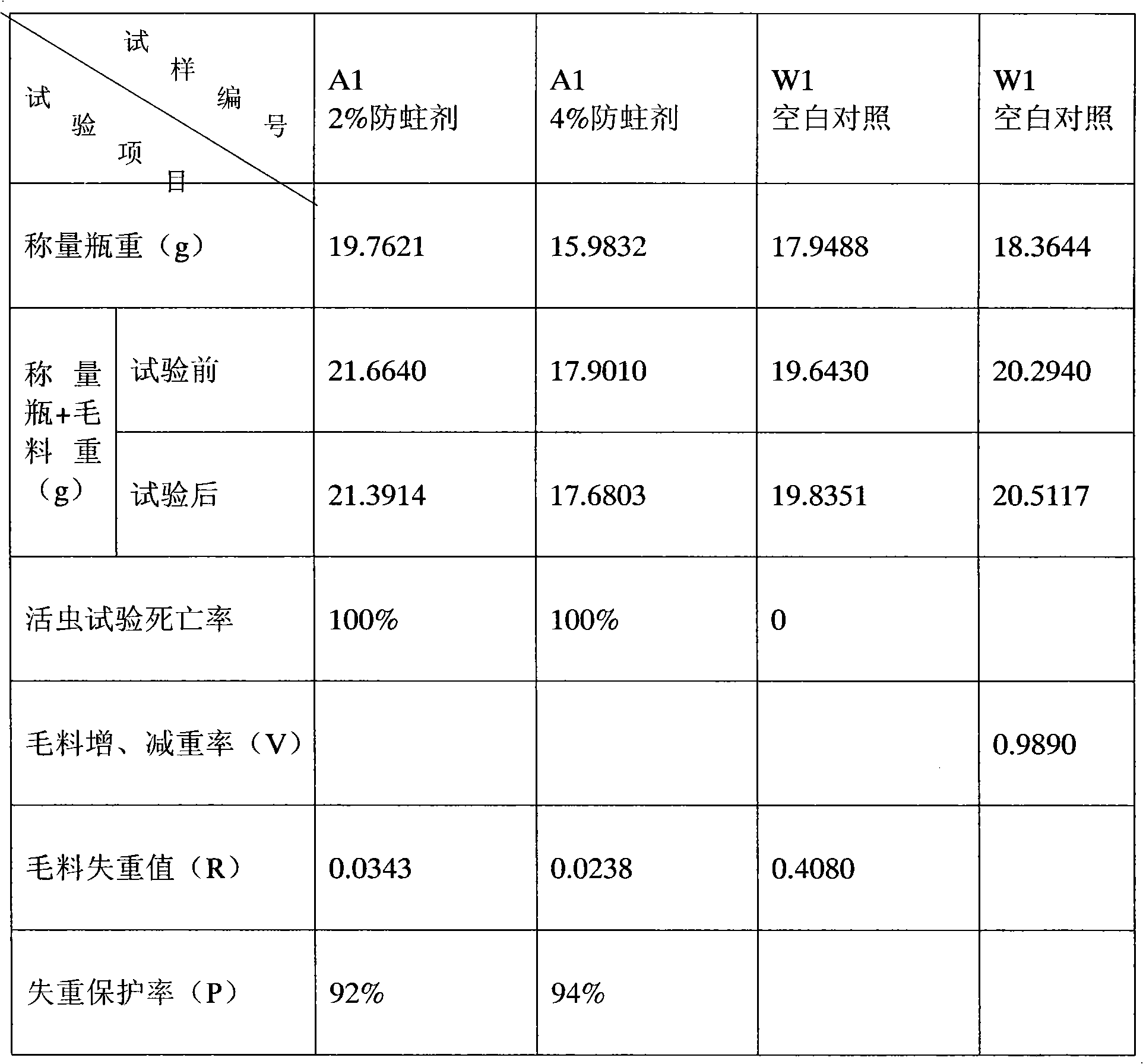

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bronopol (INN; chemical name 2-bromo-2-nitro-1,3-propanediol) is an organic compound that is used as an antimicrobial. It is a white solid although commercial samples appear yellow. The first reported synthesis of bronopol was in 1897.

Skin treatment compositions

InactiveUS20120077784A1Suited and effective in treating varietyIncrease effective drug concentrationAntibacterial agentsBiocideTriclosanBronopol

The present invention relates to compositions, kits and methods for treating skin at sites of concerns such as infectious lesions and / or points of insertion of an insertable medical device to prevent contamination such as infections or protein absorption that may interfere with the function of the device. The composition can be a topical skin treatment composition that includes polyethylene glycol (PEG), triclosan, one or more of a salicylate, bronopol, and an acrylic emulsion, and, optionally, a solvent.

Owner:EX TEK

A kind of compound powder for preventing and treating saprolegnia of aquatic animals and preparation method thereof

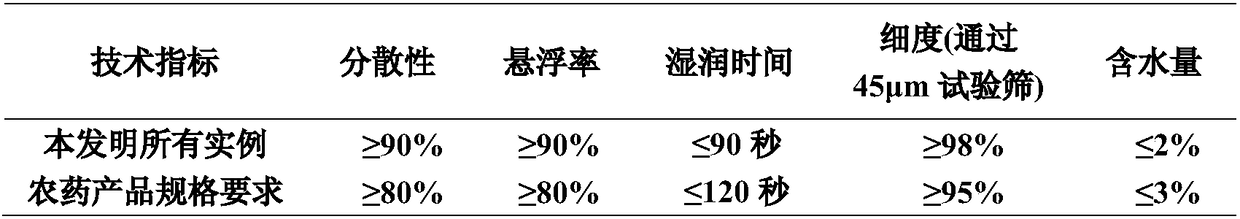

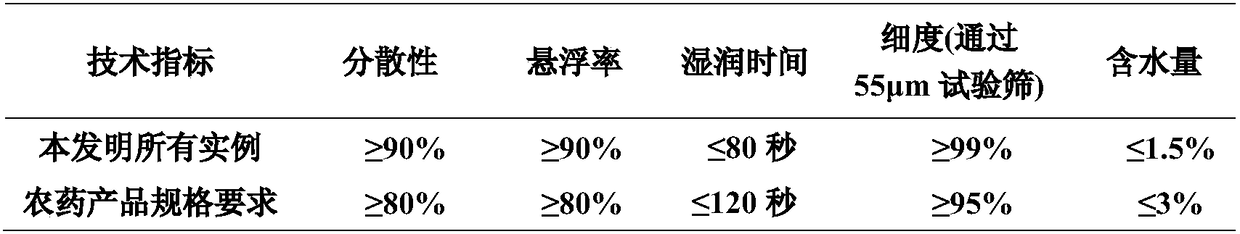

The invention discloses a compound pulvis for controlling saprolegniasis of aquatic animals and a preparation method thereof. The compound pulvis is prepared from Chinese gall, rheum officinale, bronopol and dispersant in a certain weight percentage. The preparation method comprises steps of: A. drying the Chinese gall and the rheum officinale decoction pieces; B. crushing and sieving the Chinesegall and the rheum officinale respectively; C. weighing the Chinese gall and the rheum officinale according to the proportion and mixing; weighing the traditional Chinese medicine mixture, preblending with bronopol; weighing the preblended mixture according to an equivalent progressive increase method, and mixing with the dispersant; well mixing and subpackaging to obtain the compound pulvis. Themethod is practical and easily operated; the compound pulvis has a reasonable formula, usage convenience, low costs, substantial effects, and no toxic or side effects; the bronopol is widely used in water treatment, medicine, pesticide, cosmetic and washing agent, and has interacted ingredients and effects of quick-acting, slow action and simultaneous treatment of principal and subordinate symptoms; the dispersant in the composition improves medicament leachability and can substantially improve curative effect.

Owner:武汉中博水产生物技术有限公司 +1

Water treatment medicament with functions of inhibiting corrosion and scale and killing microbes

ActiveCN102730851AExcellent corrosion and scale inhibitionGuaranteed corrosion and scale inhibitionScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processBronopolMedicine

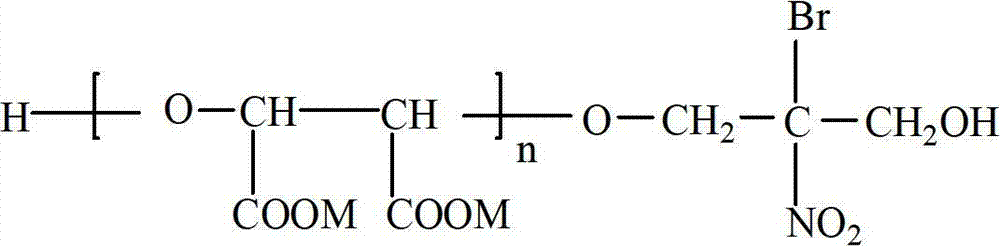

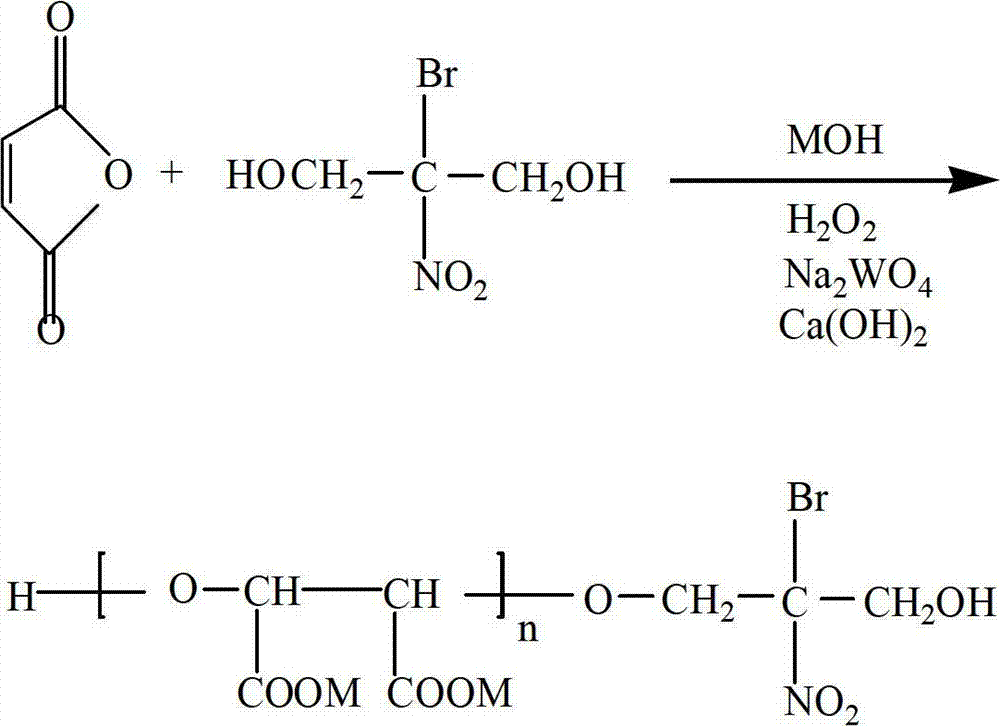

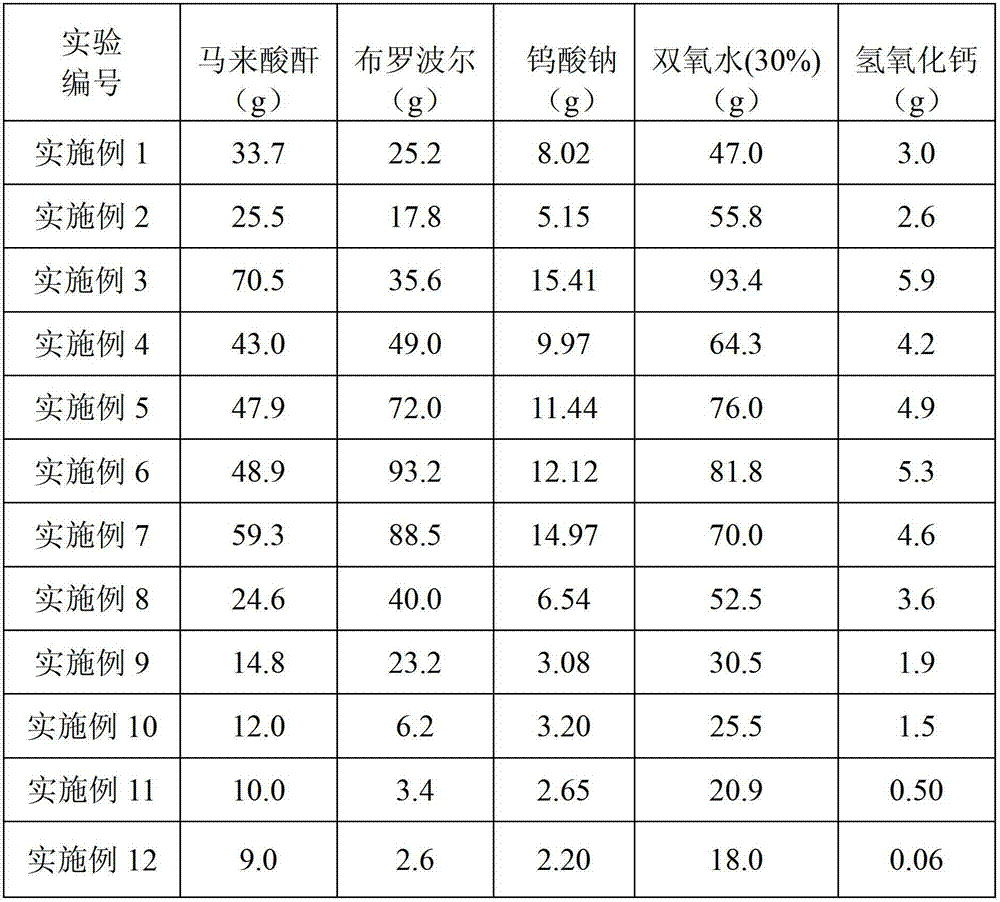

The invention discloses a water treatment medicament with functions of inhibiting corrosion and scale and killing microbes. The water treatment medicament is a polyepoxysuccinic acid / bronopol copolymer, wherein polyepoxysuccinic acid serves as a main body, and then is subjected to polymerization after being grafted with bronopol so as to obtain the polyepoxysuccinic acid / bronopol copolymer, the copolymer does not contain phosphorus, can be biodegradable, has a very good effect of inhibiting the corrosion and the scale, and has certain effect of killing the microbes due to the existence of oxidising bromine atom. The polyepoxysuccinic acid / bronopol copolymer prepared by using the method disclosed by the invention has the scale inhibition rate on calcium carbonate and corrosion inhibition rate on carbon steel similar to those of the polyepoxysuccinic acid, so that the effects of scale inhibition and corrosion inhibition of the water treatment medicament can be ensured.

Owner:CHENGDU ROSUN DISINFECTION PHARMA

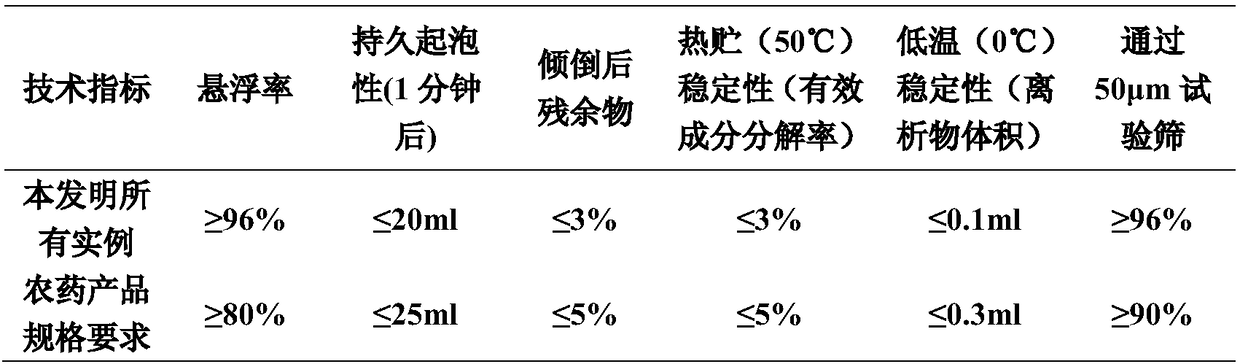

Phosphate-free highly concentrated aqueous dispersion composition of biocides and process for preparing the same

A phosphate-free, highly-concentrated aqueous dispersion composition comprising at least one biocide, sulfosuccinate based surfactant, block copolymer, suspending agent, and optionally an antifoaming agent and desired additives if any. The composition of the present application is significantly stable against heat, cold, transit, storage and dilution for at least 18 months. The preferred biocides of the dispersion composition are 2-meth-4-isothiazolin-3-one (MIT), 1,2-Benzisothiazolin-3-one (BIT), 5-Chloro-2-methyl-4-isothiazolin-3-one (CMIT), 2-Octyl-4-isothiazolin-3-one (Off) 3-Iodo-2-propynylbutyl carbamate (IPBC), oxyfluorfen, thiabendazole, terbutryn, zinc pyrithione (ZnPy), bronopol, folpet, diiiron, dehydroacetic acid (DHA), dazomet and carbendazim alone or in combination. Also disclosed is a process for preparing the dispersion composition and appropriate applications thereof.

Owner:TROY TECH II

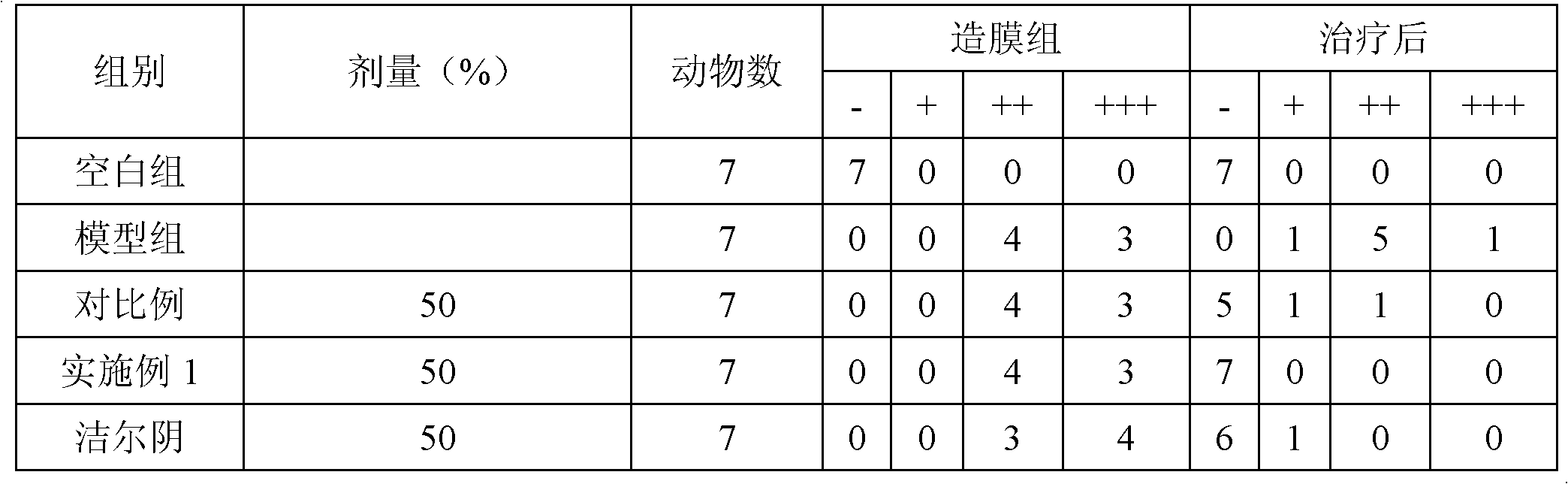

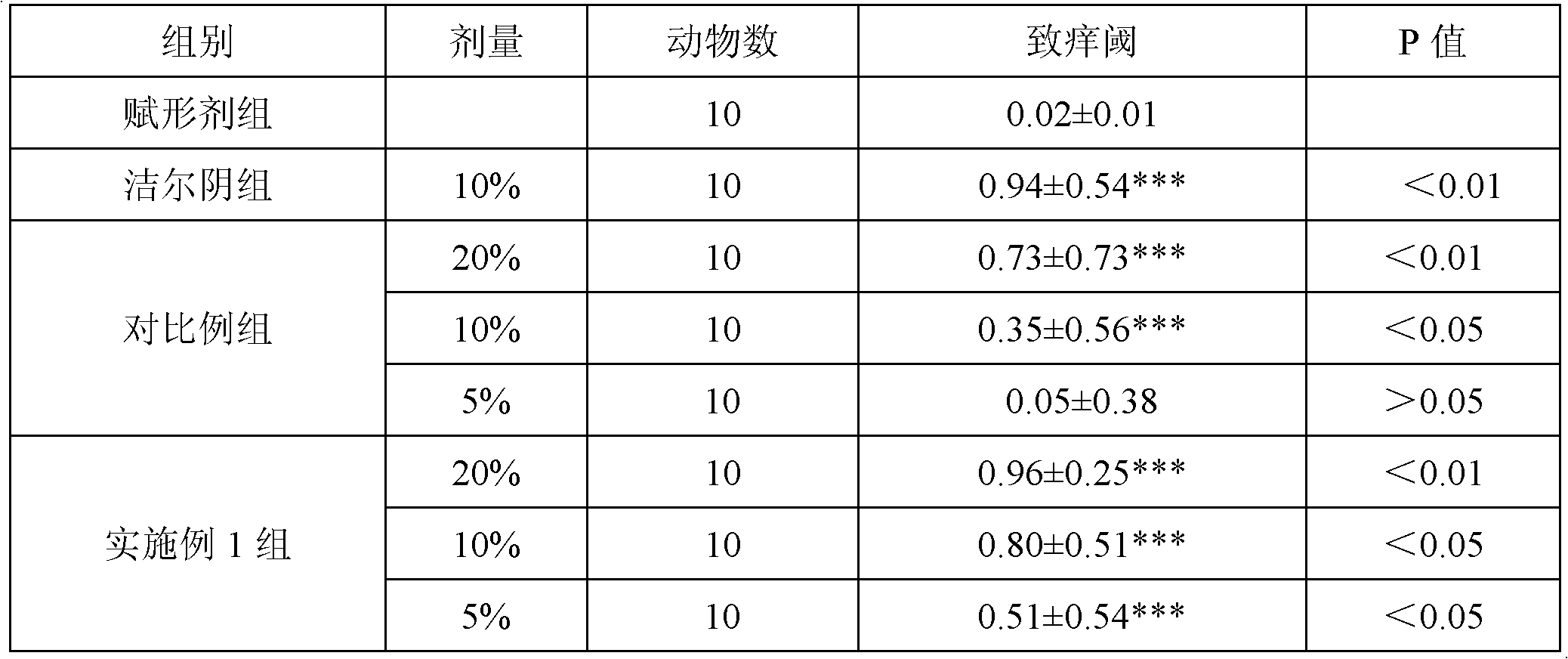

Externally-applied traditional Chinese medicine and preparation method thereof

InactiveCN102068640AInorganic boron active ingredientsHydroxy compound active ingredientsMentholBronopol

The invention provides an externally-applied traditional Chinese medicine, which comprises the following active ingredients in percentage by weight: 0.1 percent of menthol, 0.05 to 0.15 percent of triclosan, 0.1 percent of bronopol and the balance of traditional Chinese medicine extract. The traditional Chinese medicine extract is prepared from 11 traditional Chinese medicines such as lightyellow sophora root, baical skullcap root, amur corktree bark and the like. The externally-applied traditional Chinese medicine has good bacteriostasis, itching relieving and anti-inflammation effects and can be used for treating damp-heat and damp (heat) toxic diseases in traditional Chinese medical science such as skin itch, neurodermatitis, urticaria, eczema, tinea manus and pedis, cervical erosion, vaginitis, morbid leucorrhea and the like. The invention also provides a preparation method of the externally-applied traditional Chinese medicine.

Owner:SHANXI KANGJIE SILE PHARMA

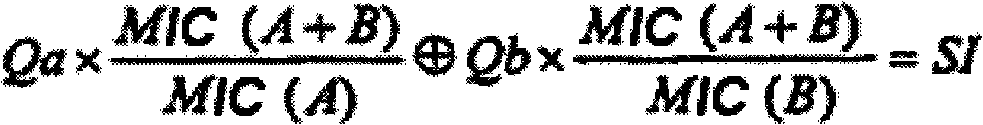

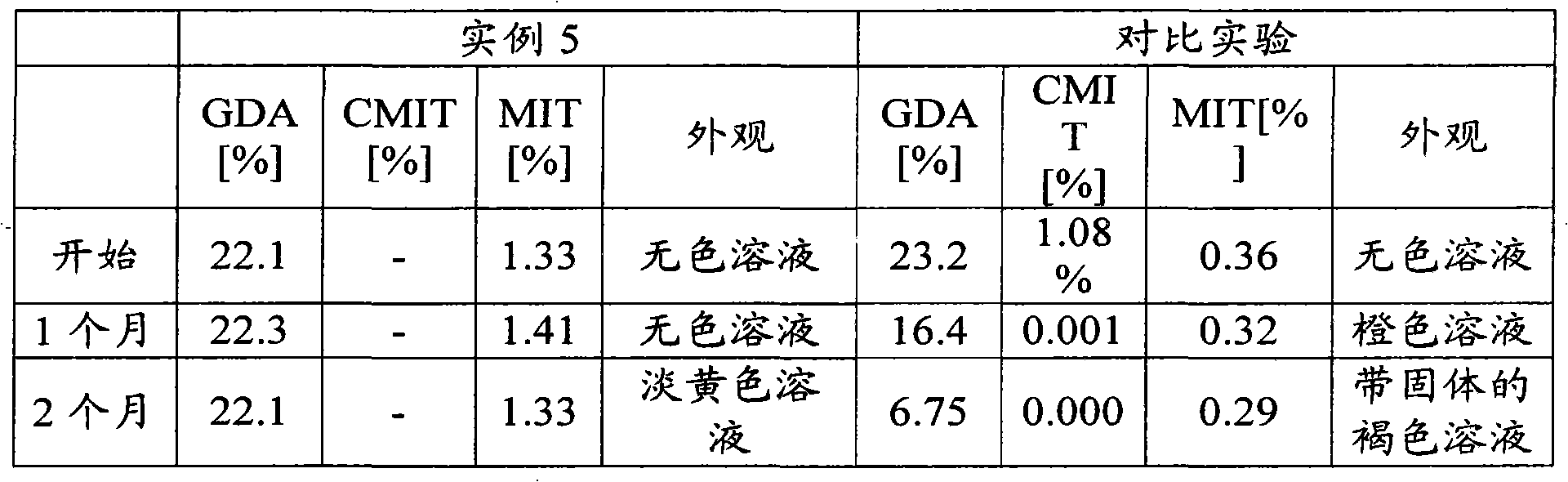

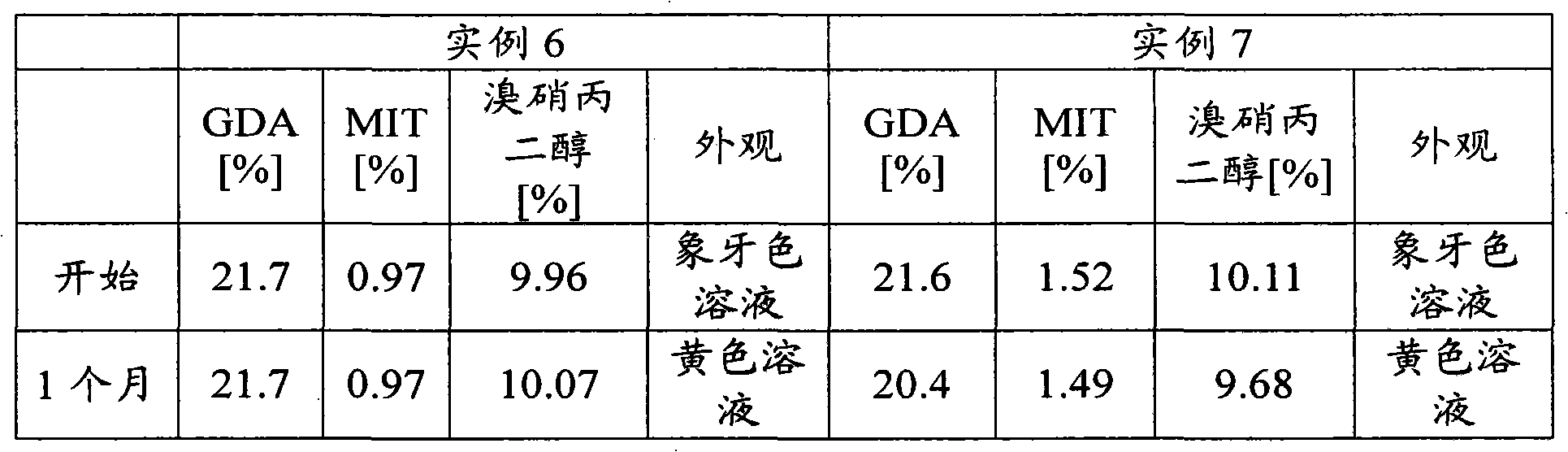

Stable, synergistic mixtures

The present invention relates to storage-stable, synergistically acting combinations comprising glutaraldehyde (GDA) and 2-methyl-2H-isothiazol-3-one (methylisothiazolinone, MIT) and, where appropriate, 2-bromo-2-nitropropane-1,3-diol (bronopol) and / or other active substances for protecting industrial materials.

Owner:LANXESS DEUTDCHLAND GMBH

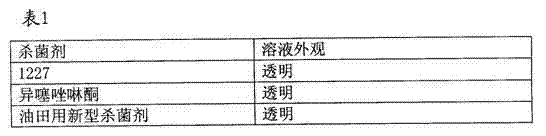

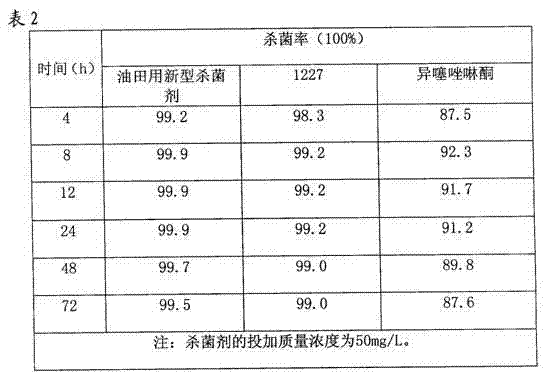

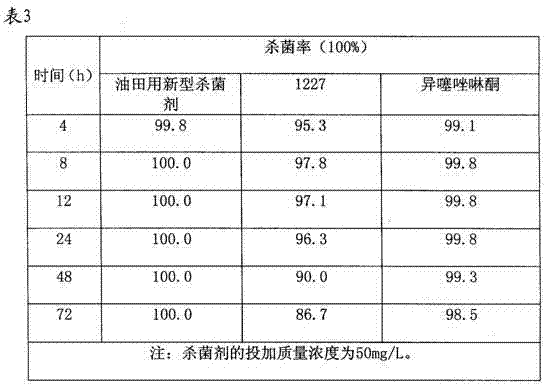

Novel bactericide for oil fields

The invention relates to a novel bactericide for oil fields. The novel bactericide is prepared from the following raw materials, by weight, 55-65 parts of dodecyl dimethyl benzyl ammonium chloride (1227), 18-22 parts of water, 8-12 parts of a didecyl quaternary ammonium salt, 4-6 parts of bronopol, and 4-7 parts of glutaraldehyde. The novel bactericide is prepared through placing 1227 and water in a reaction vessel in order under normal temperature and normal pressure conditions, adding the didecyl quaternary ammonium salt with stirring, uniformly mixing, slowly adding bronopol and glutaraldehyde, and stirring for 20-30min. The effective content of the selected didecyl quaternary ammonium salt is equal to or greater than 30.0%. The novel bactericide which has good water solubility and has an extremely good corrosion resistance to metals has a sterilization rate of above 95%. The novel bactericide of the invention can be evaluated as a standard reaching product according to "a method for evaluating performances of a bactericide" of a petroleum standard SY / T5890-93.

Owner:XINJIANG DELAND

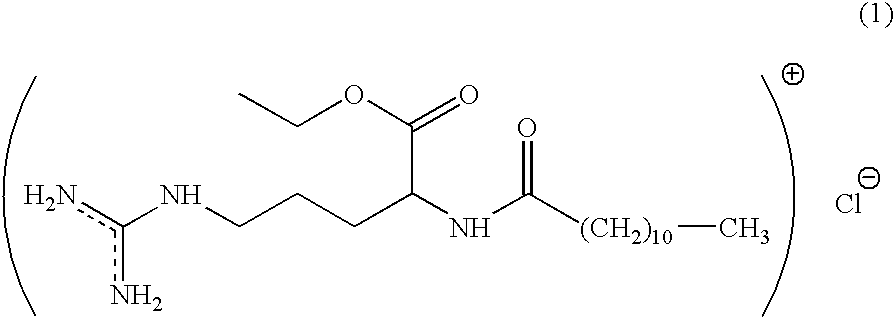

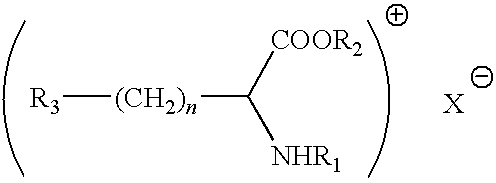

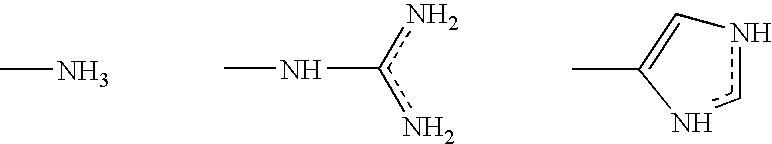

Preservative systems and their use in cosmetic preparations

The invention relates to preservative systems which are particularly suitable in cosmetic and dermatological preparations. The preservative system which comprises a cationic surfactant, derived from the condensation of fatty acids and esterified dibasic amino acids, having the formula (I) where: X− is Br−, Cl−, or HSO4 R1: is a straight alkyl chain from an acid or saturated fatty hydroxy acid from 8 to 14 atoms of carbon bonded to the α-amino acid group through amidic bond. R2: is a straight or branched alkyl chain from 1 to 18 carbon atoms or aromatic. R3: is: (II) where n can be from 0 to 4, is combined with at least one other ionic or non-ionic preservative agent, whereby the combination displays a synergetic activity. A preservative system, wherein the cationic surfactant preservative derived from the condensation of fatty acids and esterified dibasic amino acid is LAE is particularly preferred. The other ionic or non ionic preservative agent is preferably at least one component selected from the group consisting of 2-bromo-2-nitro-1,3-propanediol (bronopol), parbens, imidazolidinyl urea, phenoxyethanol, DMDM hydantoin, 2-methyl-5-chloro-3,4-isothiazolinone / 2-methyl-3,4-isothiazolinone and quaternium-15.

Owner:LAB MIRET

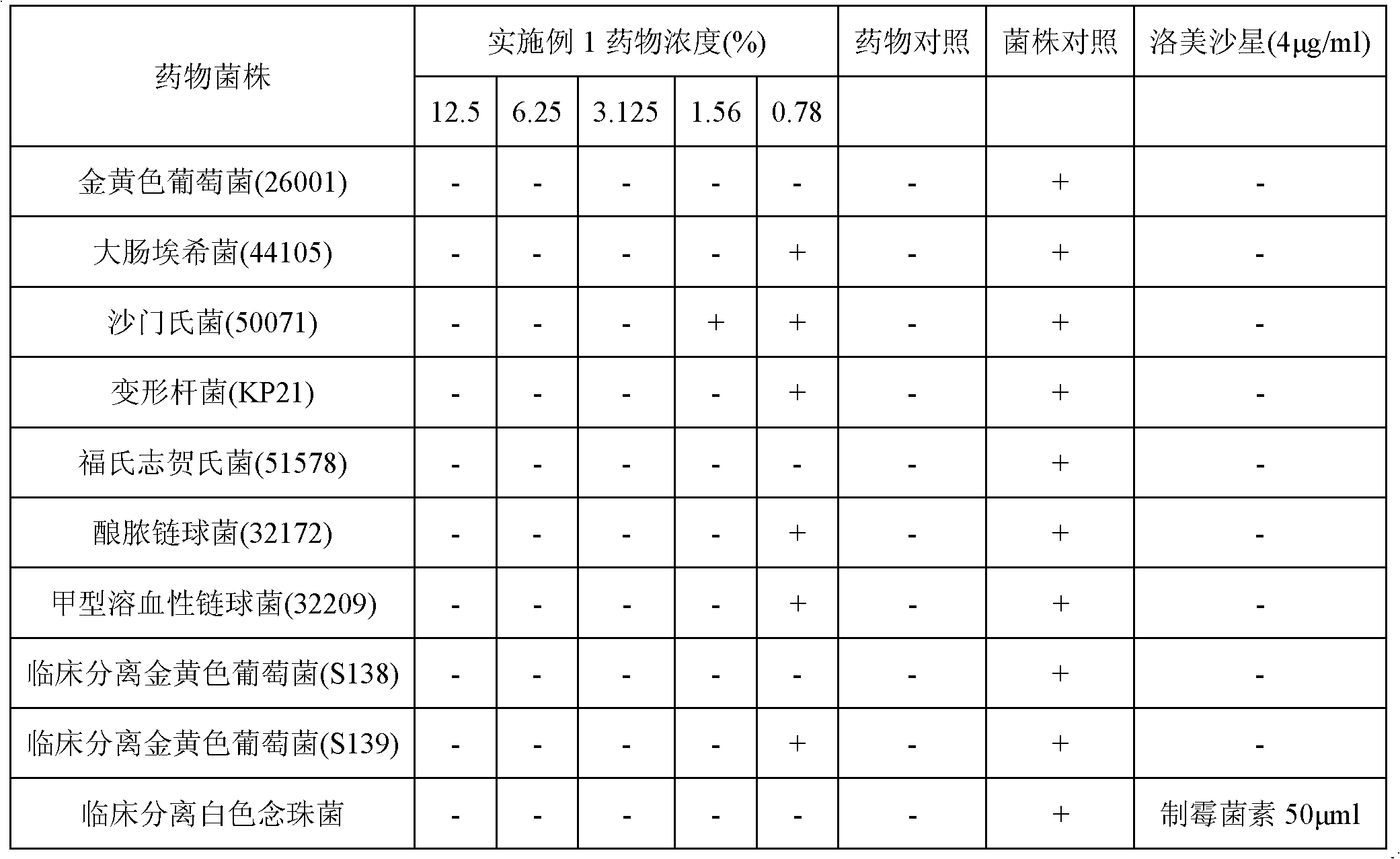

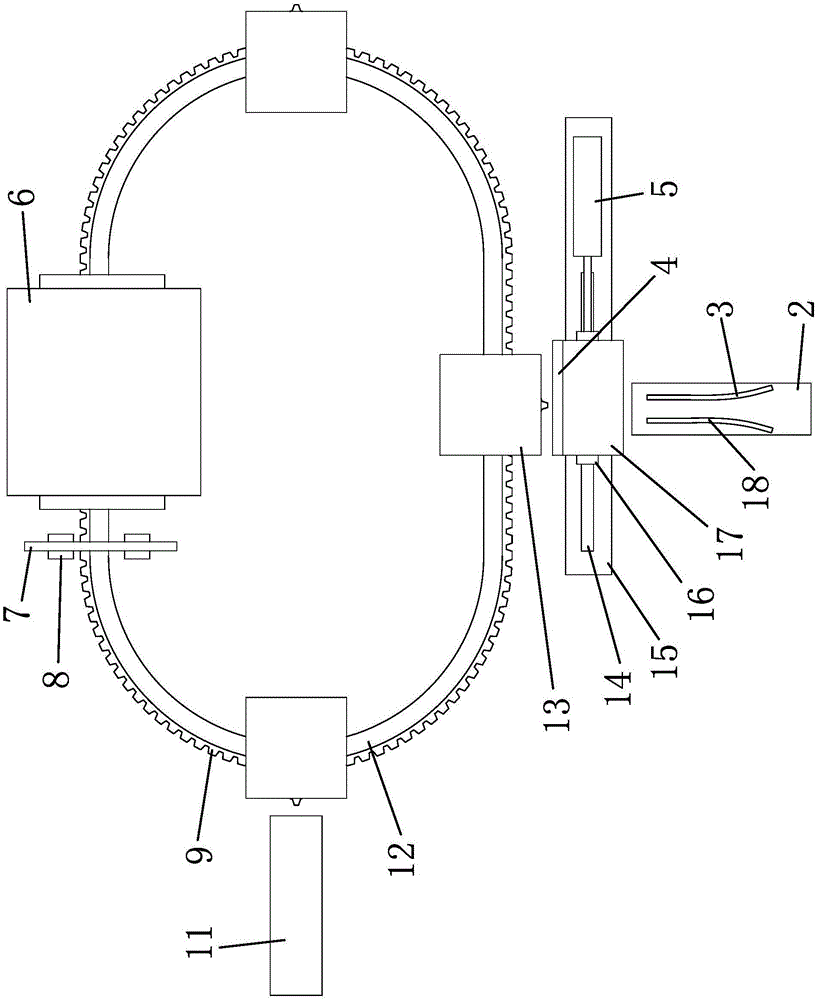

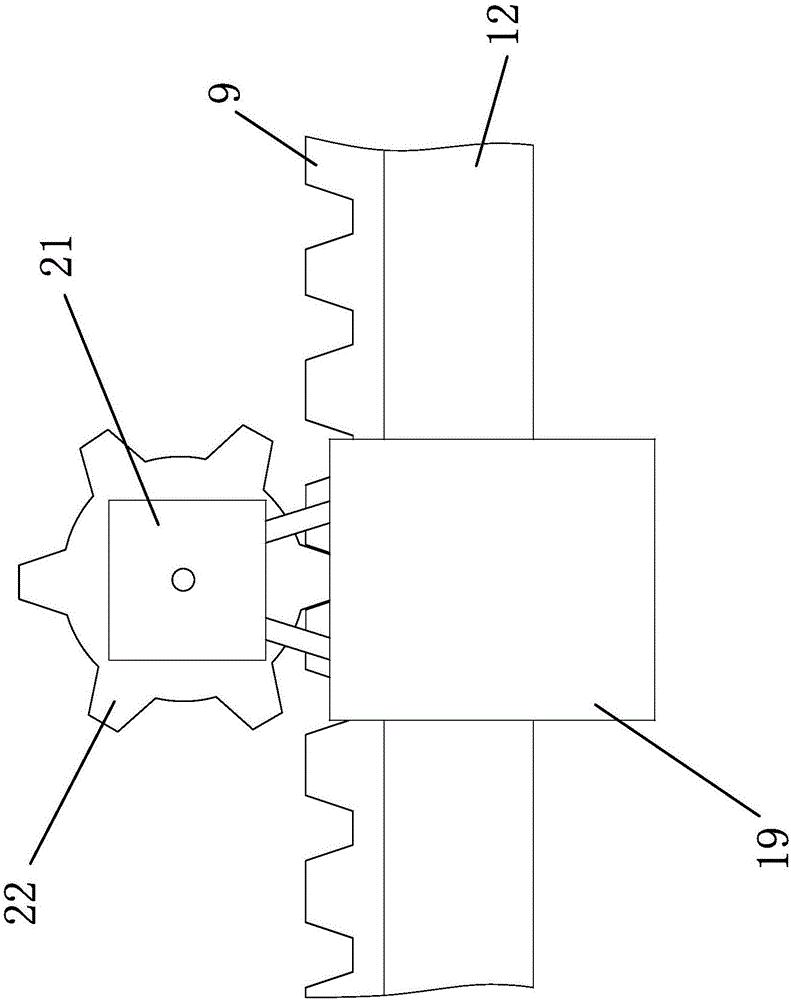

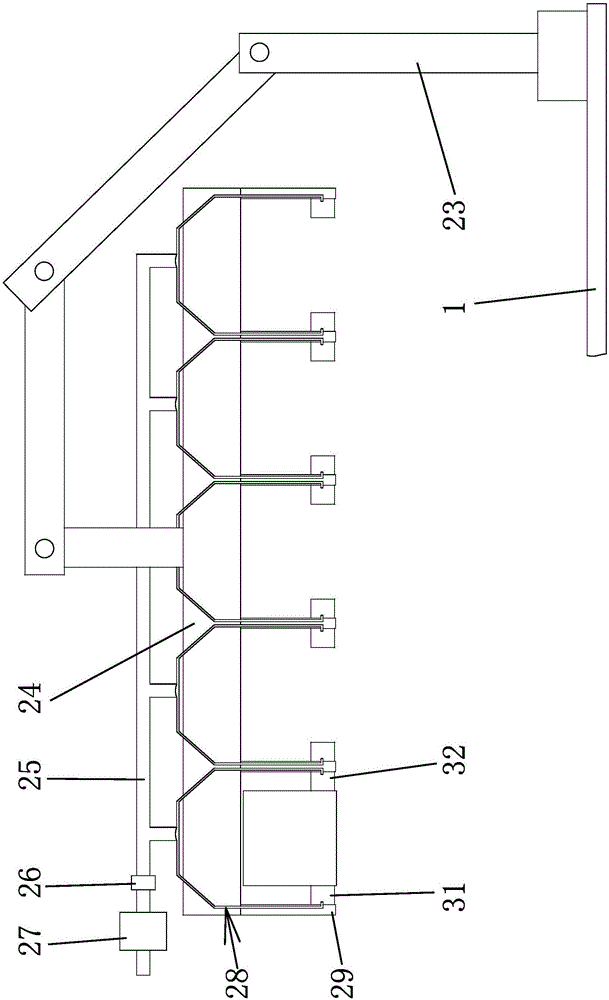

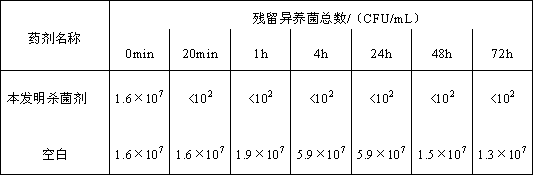

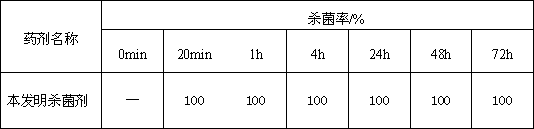

Bronopol-containing bactericidal composition

InactiveCN108112592AGood synergyGood lasting effectBiocideDead animal preservationBronopolBULK ACTIVE INGREDIENT

The invention discloses a bronopol-containing bactericidal composition. The bactericidal composition contains an active ingredient A and an active ingredient B, the active ingredient A is selected from bronopol, the active ingredient B is any one compound selected from the following compounds: copper oxychloride, cuppric nonyl phenolsulfonate, oxine-copper, kasugamycin, validamycin, moroxydine hydrochloride, polyoxin, copper(succinate+glutarate+adipate), zhongshengmycin, xinjunan acetate, and zinc thiazole, and the weight ratio of the active ingredient A to the active ingredient B is 1:70 to 70:1. The composition provided by the invention has higher activity on various diseases of a plurality of crops, and an obvious synergistic effect, enlarges the bactericidal spectrum, and has the characteristics of a small medicine using amount, resistance to rain erosion, and an obvious synergistic effect.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

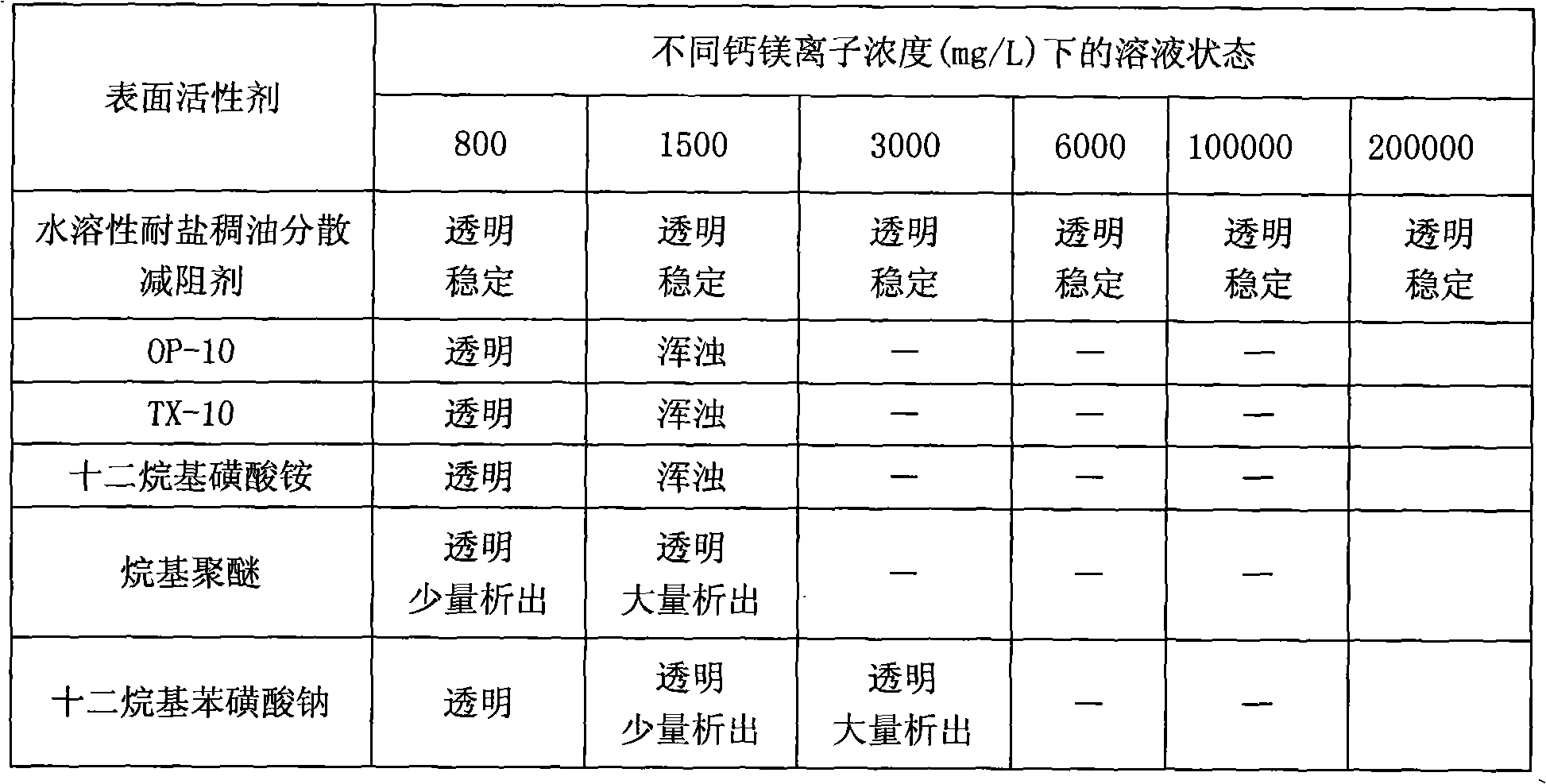

Preparation of water-soluble salt-resistant dispersing drag reducer for heavy oil exploitation

The invention provides preparation of a water-soluble salt-resistant dispersing drag reducer for heavy oil exploitation. The water-soluble salt-resistant dispersing drag reducer can be used after 1 percent solution prepared from an A agent and 0.125 percent solution prepared from a B agent are mixed. A method for preparing the water-soluble salt-resistant dispersing drag reducer comprises the following steps of: putting 155 to 170 weight parts of nonyl phenol and 2 to 3 weight parts of potassium hydroxide into an agitated reactor; introducing nitrogen into the reactor, displacing for three to four times; stirring and raising temperature to be 110 to 120 DEG C; vacuumizing for 60 to 65 minutes; inflating nitrogen until the pressure is 0.01 Mpa; reducing the temperature to be 98 DEG C after keeping the constant temperature for 60 minutes; adding 80 to 90 weight parts of allyl glycidyl ether dropwise and reacting for 6 hours; reducing the temperature to be 30 DEG C after keeping the temperature of between 90 and 98 DEG C for 2 hours; adding 30 to 32 weight parts of sulfamic acid, 11 to 14 weight parts of urea and 0.3 to 0.7 weight part of thiourea into the reactor; then introducing nitrogen and vacuumizing and keeping the constant temperature for 60 minutes; adding 3 to 5 weight parts of ammonia water into the reactor; after 60 minutes, adding 620 to 670 weight parts of pure water and 45 to 55 weight parts of trichloroethylene into the reactor; controlling the temperature to be 60 to 70 DEG C for 60 to 65 minutes to obtain the A agent; and mixing 65 to 75 weight parts of anionic polyacrylamide, 10 to 14 weight parts of guar gum, 8 to 12 weight parts of polyanionic cellulose, 4 to 6 weight parts of sodium dodecyl benzene sulfonate, 2-3 weight parts of aminotriacetic acid and 0.7 to 1.2 weight part of Bronopol and mechanically stirring the mixture for 58 to 65 minutes to obtain the B agent.

Owner:XINJIANG DELAND

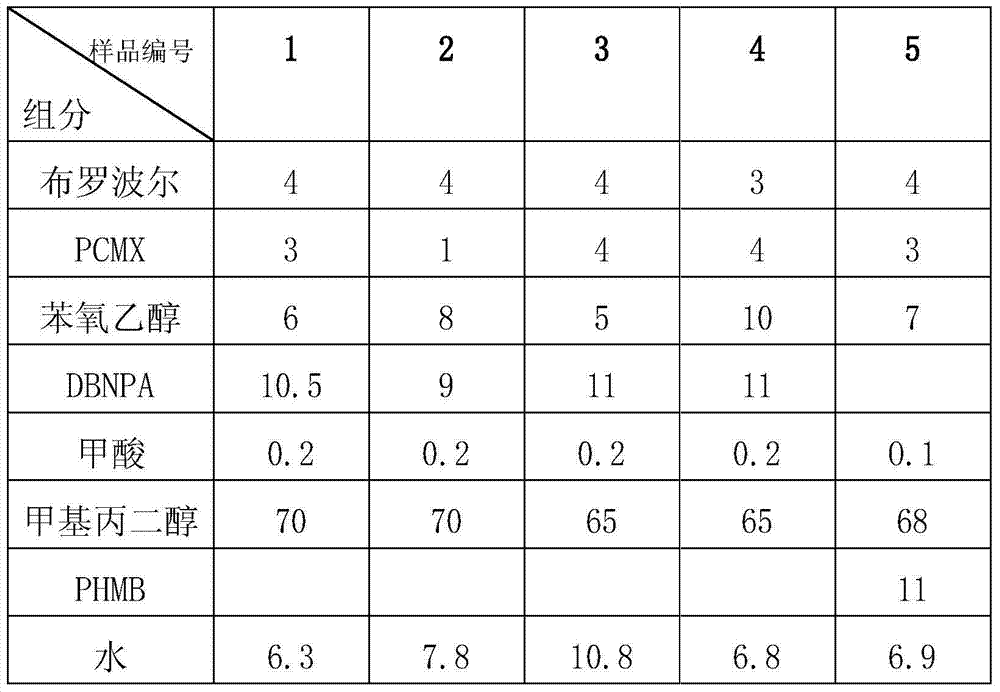

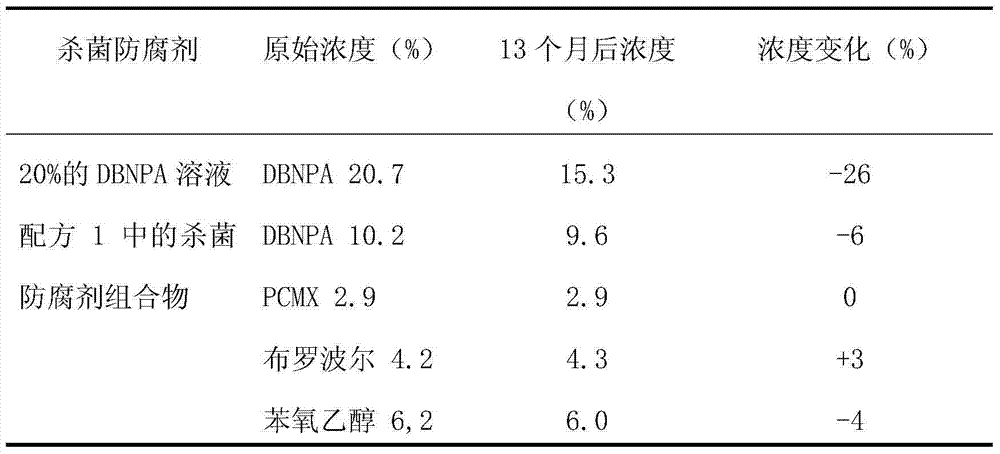

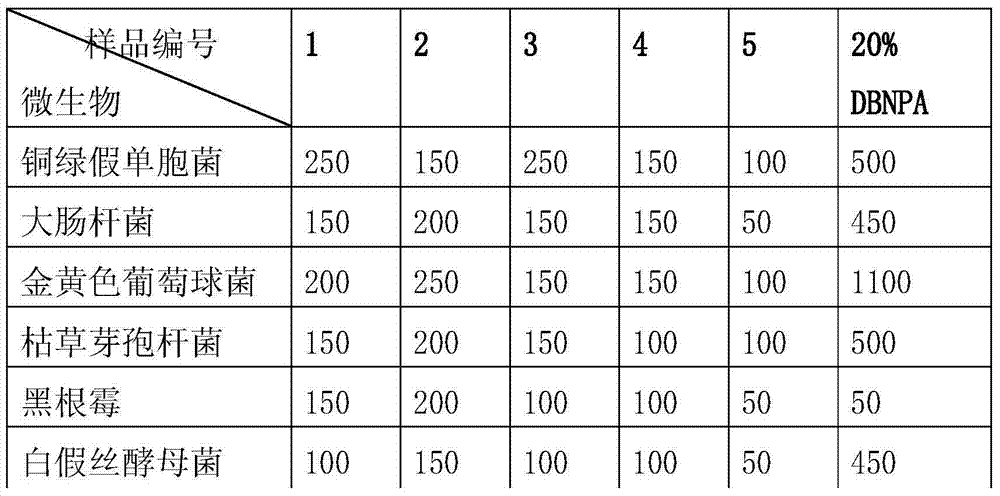

Bactericidal and preservative agent combination for repair-regeneration of microbial pollution products

The invention relates to a bactericidal and preservative agent combination for the repair-regeneration of microbial pollution products, which comprises the following active ingredients: a preservative agent A, a preservative agent B, a bactericide, solvents, additives and water, wherein the preservative agent A is formed by bronopol, the preservative agent B is formed by parachlorometaxylenol PCMX and a phenoxyethanol mixture, and the bactericide is formed by 2,2-dibromo-3-nitrilo-propionamide DBNPA or polyhexamethylene biguanidine hydrochloride PHMB. Through one-time addition, the bactericidal and preservative agent combination disclosed by the invention has strong synergistic, preservative and bactericidal effects, and can concurrently have the functions of bactericidal repair and corrosion and mildew prevention in the period of re-storage, thus most of industrial water-based products metamorphosed by microbial pollution are reused. The bactericidal and preservative agent combination disclosed by the invention has the advantages of reasonable formula, advanced process, high cost performance, low toxicity, good operational feasibility, bactericidal and preservative effect, and the like, and is verified through a lot of industrial practices.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Skin-care bath cream

InactiveCN103006475AMoisturizeHave smooth skinCosmetic preparationsToilet preparationsBronopolGlyceryl monostearate

The invention discloses skin-care bath cream, which is prepared from the following components in parts by mass: 18 to 20 parts of coconut oleic acid alkanolamide, 3 to 5 parts of white oil, 2 to 4 parts of almond oil, 5 to 8 parts of sodium dodecyl sulfate, 2 to 4 parts of glyceryl monostearate, 4 to 6 parts of hyaluronic acid, 4 to 6 parts of wiredrawing powder, 0.15 to 0.2 part of bronopol, 0.05 to 0.1 part of pigment, 0.1 to 0.2 part of essence, and 55 to 60 parts of deionized water. As being additionally provided with emollients such as the white oil and the almond oil, the skin-care bath cream has the effects of moisturizing, whitening and skin smoothing and the like.

Owner:袁亚群

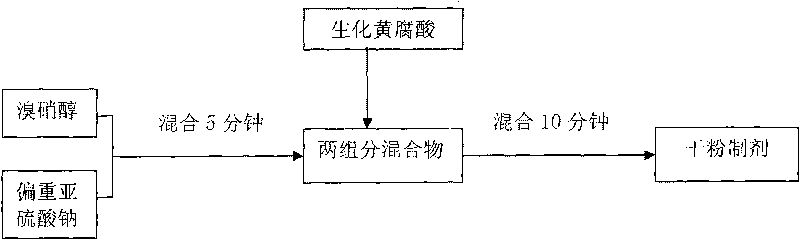

Dry powder preparation for preventing and controlling saprolegniasis of aquatic animals and preparation method thereof

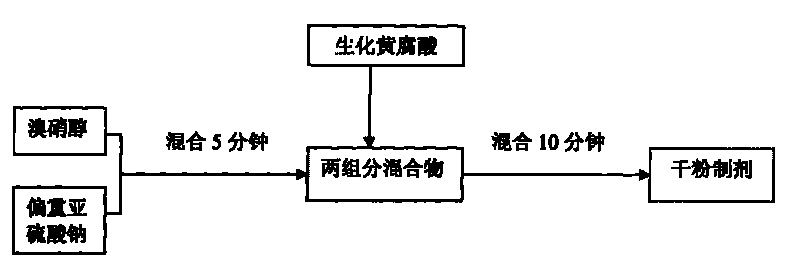

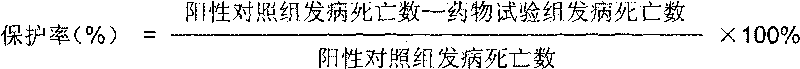

The invention discloses a dry powder preparation for preventing and controlling saprolegniasis of aquatic animals, which is characterized in that: the dry powder preparation consists of the following components in percentage by weight: 71 to 79 percent of biochemical fulvic acid, 10 to 15 percent of disodium metabisulfite and 10 to 15 percent of bronopol. A preparation method for the dry powder preparation for preventing and controlling the saprolegniasis of the aquatic animals is characterized in that: the method comprises the following steps: (1) putting the 10 to 15 percent of disodium metabisulfite and 10 to 15 percent of bronopol into a mixer for mixing for 5 minutes to obtain a two-component mixture; and (2) adding the 71 to 79 percent of biochemical fulvic acid to the mixed mixture in the mixer, and continuously mixing for 10 minutes to prepare the dry powder preparation for preventing and controlling the saprolegniasis of the aquatic animals, wherein the steps are all carried out at room temperature. The dry powder preparation mainly prevents and controls pathogenic fungi of aquatic products, also has good bacteriostatic and bactericidal effects on pathogenetic bacteria of the aquatic products, particularly on Gram negative bacteria, has the external effect of killing fungi and the bacteria and internal effects of adjusting organisms and strengthening immunity of the aquatic animals, and has the advantages of safe use and environmental protection.

Owner:CHANGSHA BEST BIOLOGICAL TECH INST

Wet tissue special for commerce

InactiveCN101869449AKeep moistTreat inflammationCosmetic preparationsToilet preparationsChlorhexidine AcetateBronopol

The invention relates to the field of wet tissues, in particular to a wet tissue special for commerce. The wet tissue is manufactured through the following steps of: adding chlorhexidine acetate, bronopol, olive oil extract, aloe extract and propylene glycol into RO pure water; filtering the mixture to prepare sterilizing solution; cutting, sterilizing and dissecting cotton spunlace cloth serving as base cloth; immersing cut, sterilized and disinfected cotton spunlace cloth in the prepared sterilizing solution; and sealing and aseptically packaging the cotton spunlace cloth. The wet tissue special for the commerce can be used for sterilization, deodorization, antifouling and cleaning.

Owner:DALIAN OUPAI TECH

Wood surface corrosion control method

InactiveCN104723424AImprove anti-corrosion performanceImprove mildew resistanceBiocideWood treatment detailsBronopolPolyvinyl chloride

The invention discloses a wood surface corrosion control method. The method comprises the following steps: (1) drying the wood until the water content is about 18%; (2) injecting the preservatives, namely 2-4 parts of propylene glycol, 30-48 parts of propene carbonate, 1-2.3 part of DCOIT, 10-25 parts of p-chloroxylenol, 1-4 parts of alkyl dimethyl benzyl ammonium chloride, 1-2.8 part of sodium chloride, 1-3 parts of sodium chlorate, 1-3 parts of potassium bromide, 5-8 parts of bronopol, 35-46 parts of dithiocyano-methane and 108-116 parts of fatty alcohol polyvinyl chloride ether in part by weight, into the wood under the vacuum high pressure condition; (3) performing high-temperature qualitative treatment for 6-12 hours on the wood after the preservatives are added; and (4) carrying out air drying on the high-temperature qualitatively treated wood to obtain the wood subjected to preservative treatment. The corrosion control method disclosed by the invention is good in corrosion control effect, the preservatives can permeate into the part being 1-2mm of the wood surface, and good mold prevention and corrosion resistance are obtained; the wood is strong in waterproof durability, is loss resistant and long in residual action, the raw materials is easily available, and the cost can be saved.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

Anticorrosive wood production method

InactiveCN104858964ASimple processEfficient treatment processBiocideWood treatment detailsBronopolMethyl carbamate

The invention discloses an anticorrosive wood production method including five steps of wood pretreatment, preservative preparation, preservative liquid preparation, dipping treatment and post-drying treatment, a preservative comprises polyethylene glycol (peg), bronopol, 4, 5-dichloro-N-octyl-4-isothiazoline-3-one, imidacloprid, 2-chloro-5-hydroxy meta-xylene, dithiocyano-methane, dodecyl dimethyl benzyl ammonium chloride and N-(2-benzimidazole)-methyl carbamate and fatty alcohol polyvinyl chloride (PVC) ether. The beneficial effects are that the anticorrosive wood production method has the advantages of simple process, high efficiency, and easy operation, and the like, the processed wood maintains the original features, meanwhile has excellent anti-corrosion, mouldproof, insect-resistant, antibacterial and other effects, and is good in environmental protection property, stable in performance, and durable.

Owner:王玉燕

Wood pest control agent and method using wood pest control agent for treating wood

InactiveCN104859012AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsPretreatment apparatusBronopolKetone

The invention discloses a wood pest control agent and a method using the wood pest control agent for treating wood. The wood pest control agent comprises the following components by mass: 15%-20% of carbendazim, 3%-10% of imidacloprid, 1%-3% of bronopol, 2%-8% of 4, 5-dichloro-N-octyl-4-isothiazolin-3-one, 3%-10% of 8-hydroxyquinoline, 8%-12% of dithiocyano-methane, 10%-15% of dodecyl dimethyl benzyl ammonium chloride, 1%-4% of fatty alcohol polyoxyethylene ether and 20%-50% of water. The beneficial effect is that the wood pest control agent has the advantages of high efficiency and broad-spectrum pest control and sterilization effects, the processed wood maintains the original features, meanwhile has excellent anti-corrosion, mouldproof, insect-resistant, antibacterial properties, and is simple in process, practical, environmentally-friendly, easy to control, low in cost, and easy to popularize and apply.

Owner:王玉燕

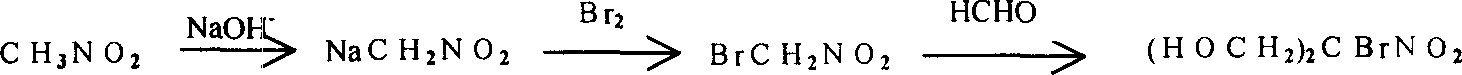

Improved method for synthesizing bronopol

InactiveCN101200430AReduce consumptionAvoid explosionOrganic chemistryOrganic compound preparationNitro compoundBronopol

Theoretic dosage of 50-percent of bromine is dropped into the sodium hydroxide solution of nitromethane or 2-nitro propylene glycol; firstly, 50-55 percent of raw material is bromized to achieve bromonitromethane or 2-bromine-2-nitro propylene glycol; then, chlorine gas is injected into the reaction fluid under -5-20 DEG C and normal pressure to transform the sodium bromide byproduct into bromine, the produced bromine bromizes all the raw materials, and the 2-chlorine-2- nitro propylene glycol impurity in the achieved bronopol is 0.06-0.2 percent. The method only consumes 50 percent of bromine needed by the traditional method; thereby, the explosion of nitro compound is avoided during sodium bromide concentration and reclamation, and the production cost is largely reduced. The product can be applied to cosmetics, pesticides, medicines and universal bactericides for water treatment.

Owner:TIANJIN VOCATIONAL INST

Wood treating agent

InactiveCN104802255AExtended service lifeImprove anti-corrosion performanceWood treatment detailsWood impregnation detailsO-Phosphoric AcidBronopol

A wood treating agent is prepared from the following raw materials in part by weight: 3-10 parts of phenol, 4-7 parts of melamine, 5-10 parts of potassium isopropoxide, 5-8 parts of calcium chloride, 3-8 parts of phosphoric acid, 3-5 parts of boric acid, 1-4 parts of zinc chloride, 6-10 parts of trimethyl borate, 7-10 parts of dodecyl dimethyl benzyl ammonium chloride, 5-9 parts of lignin, 4-8 parts of waterborne zinc stearate emulsion, 5-11 parts of sodium tripolyphosphate, 2-6 parts of folic acid, 3-9 parts of parachlorometaxylenol, 8-11 parts of bronopol, and 6-8 parts of sodium chlorate. The wood treating agent has the benefits that the wood treating agent has good corrosion prevention and insect prevention effects, can form a good breathable layer, and can prolong the service life of wood.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Anti-mould and anti-moth formula of special paper for files and use method

The invention relates to and discloses an anti-mould and anti-moth formula of special paper for files and a use method. The anti-mould and anti-moth formula of special paper for files is characterized in that the used medicine is a chemical product with high effect, broad spectrum and low toxicity. The use method comprises the following steps of respectively dissolving 0.5% to 15% of isothiazolinone, 0.5% to 15% of chamomile, 0.002% to 10% of TLC (Bronopol), 0.04% to 10% of LY-A310 and 0.1% to 10% of 75 industrial anti-mould agent in water and uniformly stirring the mixed solution; filling a paper pulp flume with the mixed solution so that finished products manufactured through a paper making machine meet requirements of long-tern storage as well as mould and moth prevention of paper for files.

Owner:夏祖洪 +2

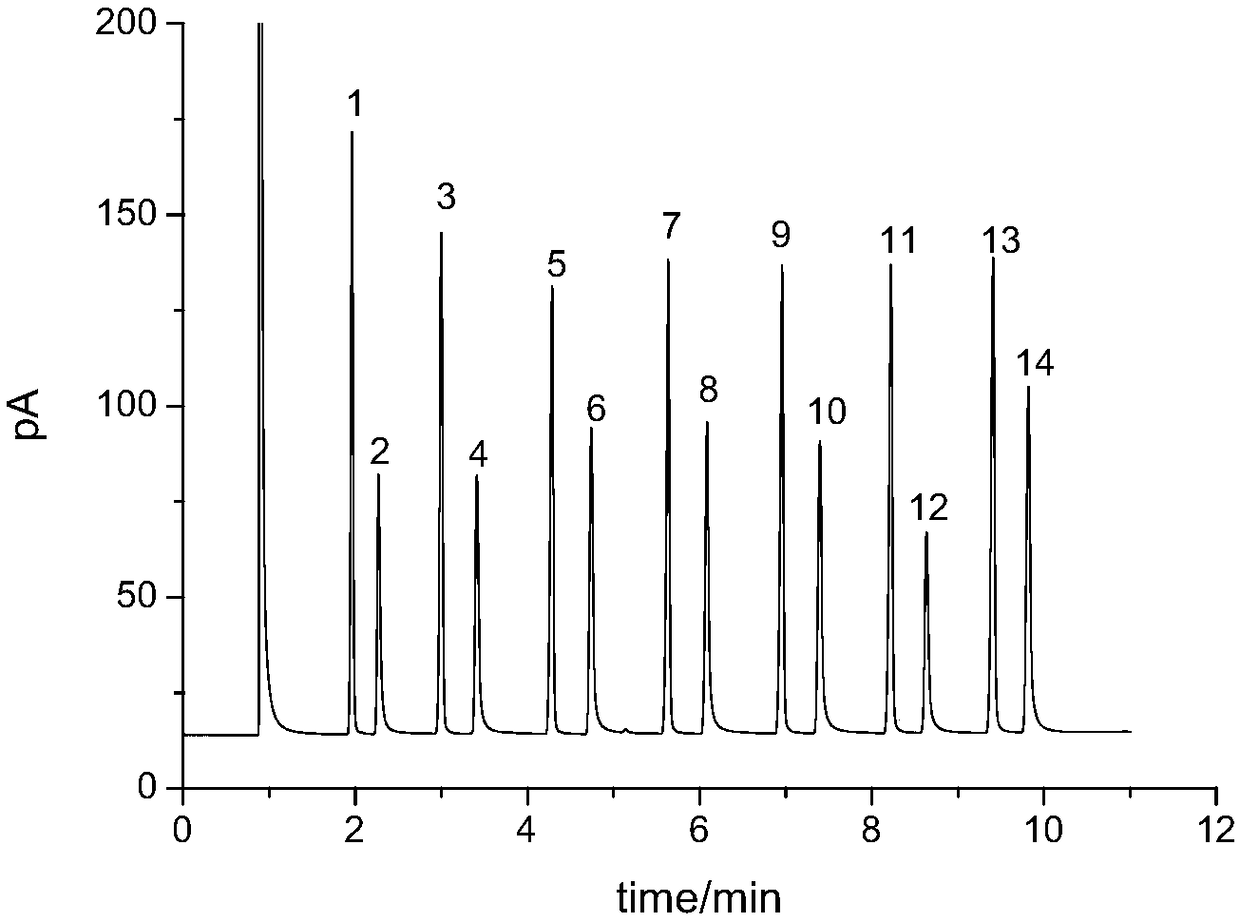

Method for detecting multiple antiseptics in cosmetics

ActiveCN108693262AEfficient extractionEasy to operateComponent separationBenzoic acidDehydroacetic acid

The invention discloses a method for detecting multiple antiseptics in cosmetics. The antiseptics are: benzoic acid, sorbic acid, dehydroacetic acid, methyl paraben, benzyl paraben, benzyl alcohol, phenoxyethanol, o-phenyl phenol, triclosan, triclocarban, methylchloroisothiazolinone, bronopol, chlorphenesin, and iodopropynyl butylcarbamate. The method comprises following steps: tetrahydrofuran liquid-liquid extraction, solid phase extraction column purification, and gas chromatography separation and analysis. The results of tests show that the provided method is suitable for many cosmetics onthe market and can accurately detect antiseptics in the cosmetics.

Owner:伯德创研(广州)生物科技有限公司

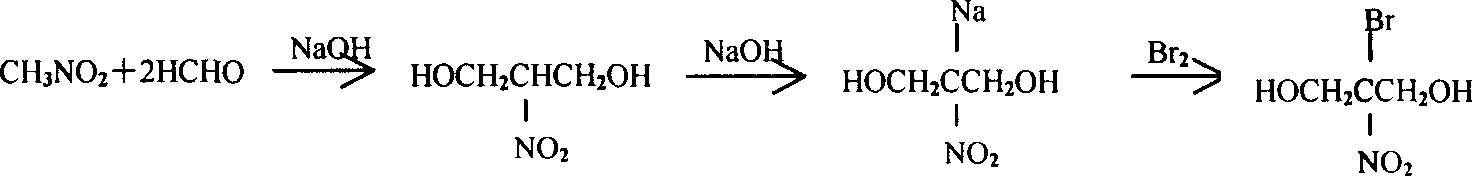

Synthetic method for bronopol

InactiveCN104926661AAvoid explosionSynthetic reaction conditions are stableOrganic chemistryOrganic compound preparationBronopolBromine

The invention discloses a synthetic method for bronopol. The synthetic method comprises the following steps: under an alkaline condition, condensing nitromethane and formaldehyde to generate 2-nitryl propylene glycol; then, synthesizing bronopol by virtue of a bromination route. The synthetic method is characterized in that bromine is generated by carrying out in-situ oxidization on sodium bromide in a reaction liquid by chlorine gas to replace a mode of directly adding bromine into 2-nitryl propylene glycol salt to synthesize the bronopol. According to the method, a bromine raw material which is liable to volatilize and strong in corrosion is not used, the synthetic reaction conditions are stable, the reaction process is easy to control, and the synthetic yield is increased.

Owner:TIANJIN VOCATIONAL INST

Wood fire retardant anticorrosive processing method

InactiveCN104858958ASimple processEasy to controlBiocideWood treatment detailsMethyl carbamateKetone

The invention discloses a wood fire retardant anticorrosive processing method including five steps of wood preprocessing, preparation of a flame retardant preservative, preparation of a flame retardant preservative solution, impregnation and post-drying processing. The fire retardant preservative is prepared from propylene glycol, bronopol, 4, 5-dichloro-N-octyl-4-isothiazolin-3-one, 2-chloro-5-hydroxy meta-xylene, dithiocyano methane, dodecyl dimethyl benzyl ammonium chloride, N-(2-benzimidazole)-methyl carbamate, diammonium phosphate, zinc borate, ammonium molybdate and fatty alcohol polyoxyethylene ether compound. The beneficial effect is that the wood fire retardant anticorrosive processing method is simple in process, practical, efficient, environmentally-friendly, and easy to control, and the like, the processed wood maintains the original features, meanwhile has excellent flame retardant, anti smoke, anti-corrosion, anti mildew, pest control, antibacterial, anti erosion and other muti-function modification effect, is stable in performance, non-toxic, and environmentally-friendly, and can be widely used in indoor and outdoor decoration, building material, furniture material and other fields.

Owner:王玉燕

Preservation method for fitment wood

ActiveCN106313222AExtended use timeClamp firmlyWood treatment detailsPretreatment apparatusAcetic acidSodium chlorate

The invention provides a preservation method for fitment wood. The preservation method solves the technical problems that the steps of an existing treatment method are too complex, a large amount of time needs to be consumed, and operation is complex. The preservation method for the fitment wood comprises the following steps that a, the wood is subjected to drying treatment through a drying system; b, the wood is placed in a closed pressure impregnation tank, a preservative prepared from, by weight, 9-12 parts of an emulsifying agent, 4-6 parts of tribromophenol, 0.5-2 parts of chitin, 3-12 parts of kaolin, 3-8 parts of potassium bromide, 3-7 parts of nitroglycerin, 4-16 parts of sorbic acid, 3-5 parts of bronopol, 5-8 parts of acetic acid, 0.8-2.6 parts of kieselguhr, 2-5 parts of sodium chlorate, 1-2 parts of xylogen and 8-14 parts of quaternary ammonium salt is injected into the tank, the pressure is increased to range from 0.9 MPa to 1.2 MPa, after the pressure is kept for 4 h to 6 h, pressure relief is carried out, the preservative is discharged, and the wood is taken out of the tank; c, the wood obtained after the preservative is added is subjected to high-temperature nature determination treatment for 8 h to 12 h; and d, the wood obtained after high-temperature qualitative treatment is subjected to airing treatment, and then the fitment wood subjected to preservative treatment can be obtained. The preservation method has the beneficial effect of being easy and convenient to operate.

Owner:海宁恒森家具有限公司

Bactericide used for reverse osmosis membrane and preparation method thereof

ActiveCN102794112AGood material compatibilityImprove compatibilityBiocideSemi-permeable membranesBronopolCyanogen bromide

The invention discloses a bactericide used for a reverse osmosis membrane and a preparation method thereof. The bactericide is prepared by compounding the following components in percentage by weight: 20-30 percent of cyanogen bromide propanamide, 5-10 percent of bronopol, 40-60 percent of solvent, 1-10 percent of auxiliary agent and the balance of deionized water. The preparation method comprises the following steps of: adding the solvent into a reaction kettle at room temperature; adding the cyanogen bromide propanamide and the bronopol and stirring for 50-60 minutes; adding the auxiliary agent and the deionized water and stirring for 20-30 minutes; and standing still for 10 minutes. The bactericide used for the reverse osmosis membrane can be used for quickly penetrating through a microbial cell membrane and acting on certain protein groups to ensure that the normal oxidation and reduction of cells are stopped so as to cause cell death, and the bactericide used for the reverse osmosis membrane has the advantages of quick and efficient performance and convenience in use.

Owner:安徽精高水处理有限公司

High-strength high-softness high-antibacterial-performance paper for daily use and preparation method thereof

InactiveCN105155341ANo biocompatibilityNon-biodegradableSpecial paperPaper coatingBronopolMicrosphere

The invention discloses high-strength high-softness high-antibacterial-performance paper for daily use and a preparation method thereof. According to the method, chitosan powder is dissolved in a lactic acid water solution, chitosan is completely dissolved, a bronopol solution is added into the mixture to be evenly mixed, then a negative ion polyacrylamide solution is dripped, a lactic acid / chitosan-bronopol nano microsphere compound is prepared through reaction, the obtained compound is sprayed to the surface of paper for daily use, and then the high-strength high-softness high-antibacterial-performance paper for daily use is obtained. By the utilization of the lactic acid / chitosan-bronopol nano microsphere compound, the paper for daily use has high strength, high antibacterial performance and high softness, the three defects that according to common paper for daily use, strength and softness are low, and no antibacterial performance exists are overcome, and high application value is obtained.

Owner:FUJIAN AGRI & FORESTRY UNIV

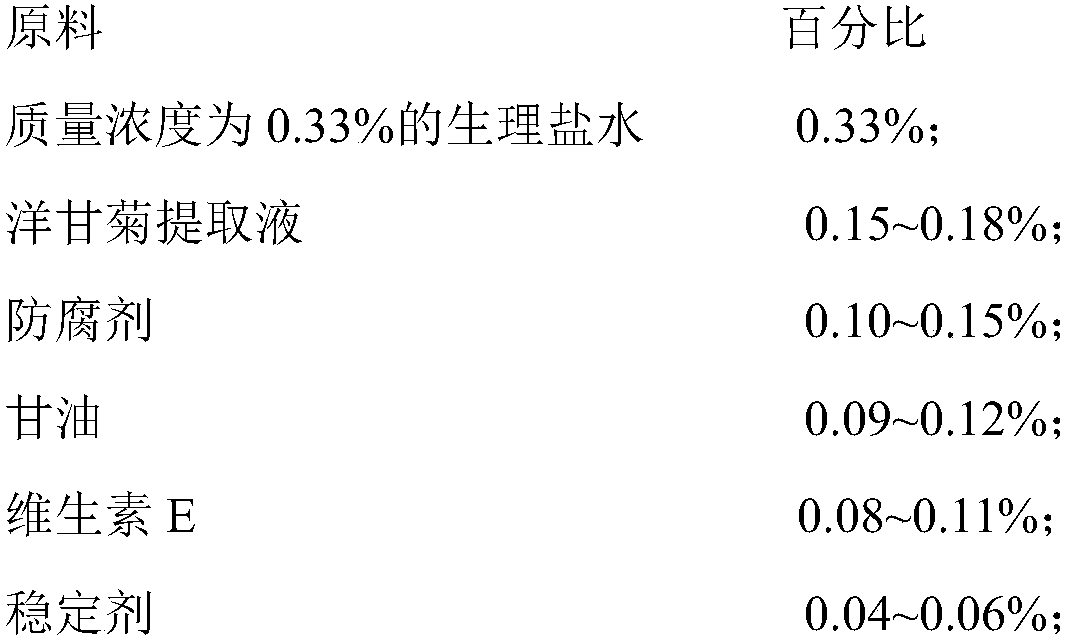

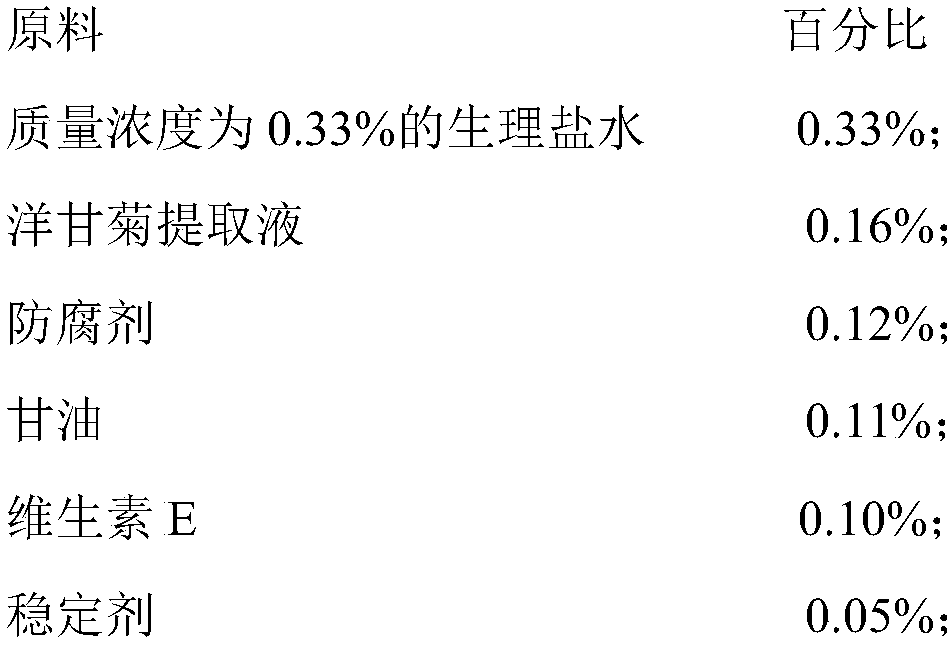

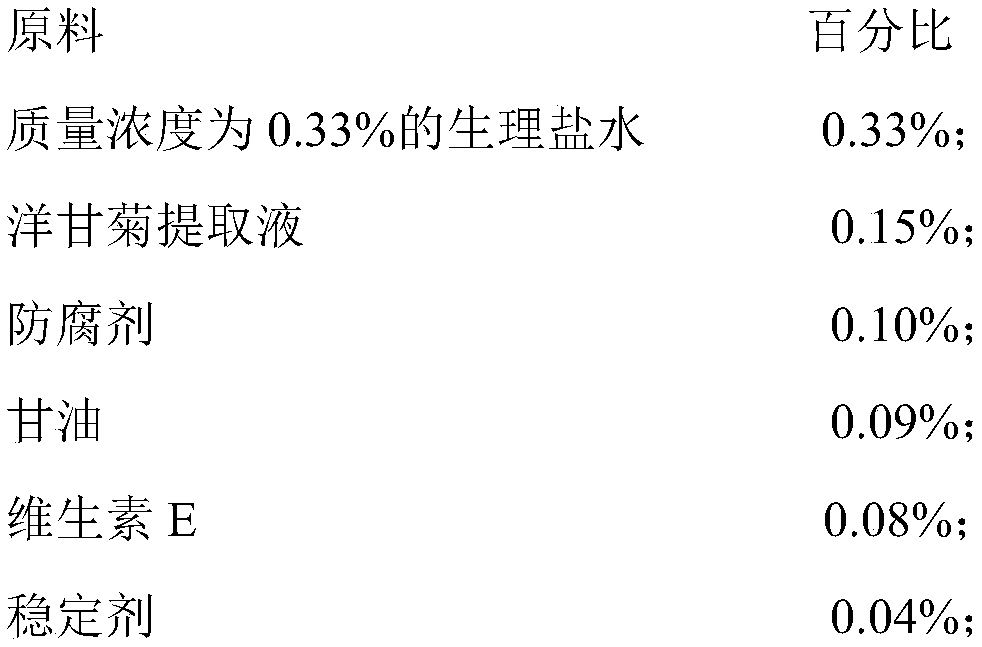

Nose mucus-cleaning soft wet wipes for babies and preparation process thereof

InactiveCN108078839AMild in natureStable in natureCosmetic preparationsToilet preparationsSide effectBronopol

The invention provides nose mucus-cleaning soft wet wipes for babies; an original liquid comprises 0.33% normal saline, a chamomile extract liquid, a preservative, glycerin, vitamin E, a stabilizer, and the balance RO pure water or deionized water, wherein the preservative is at least one of bronopol and polyaminopropyl biguanide; the stabilizer is at least one of EDTA-2Na and EDTA-4Na. The nose mucus-cleaning soft wet wipes for babies provided by the invention have the advantages of mild nature, simple preparation process, no damage to baby skin when in use, disinfection and sterilization effects, and no toxic or side effects.

Owner:福建鼻涕虫护理用品股份有限责任公司

Method for controlling water molds in aquaculture water

InactiveUS20160278348A1Effective controlImprove securitySpecific water treatment objectivesClimate change adaptationChlorine dioxideBronopol

Disclosed herein is a method for controlling water molds in aquaculture water by using chlorine dioxide that is less toxic and safer than bronopol.The method includes adding chlorite to aquaculture water with a pH of 5.5 or higher but 8.5 or lower at a concentration of 2.5 ppm or higher but 200 ppm or lower in terms of effective chlorine dioxide and performing a reaction for 60 minutes or longer to control water molds. At this time, an organic or inorganic acid is not added to the aquaculture water. The aquaculture water includes water for hatching or water for fanning. Further, the aquaculture water includes both seawater and freshwater.

Owner:SUKEGAWA CHEM

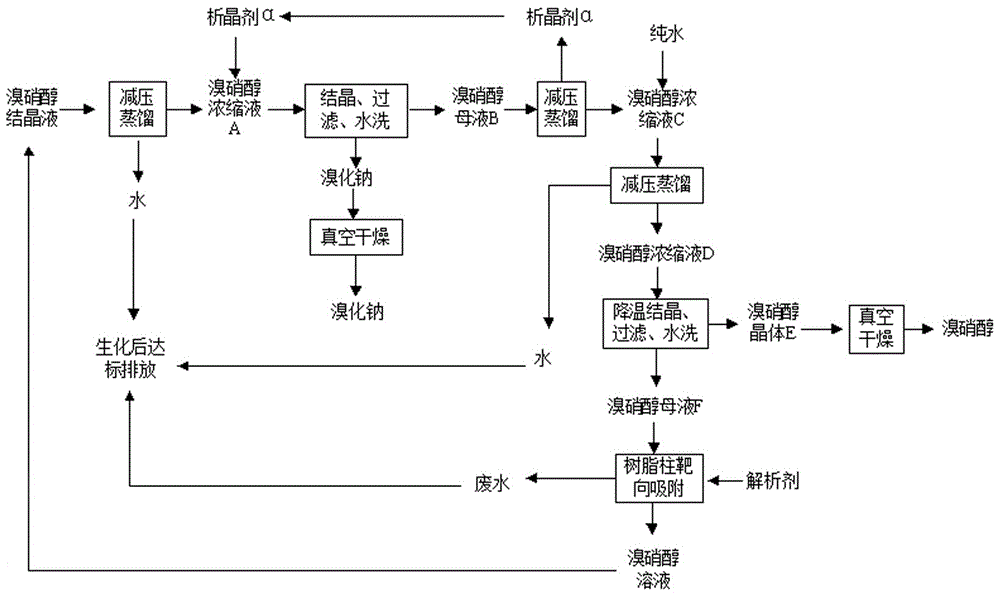

Bronopol refining process

ActiveCN106631813AHigh quality and purityImprove qualityOrganic chemistryOrganic compound preparationBronopolDistillation

The invention discloses a bronopol refining process. The process comprises the following steps: performing reduced pressure distillation on a bronopol crude product crystalline liquid prepared by a conventional method to obtain a concentrate, adding crystallization agent into the concentrate, and crystallizing to obtain a sodium bromide product; further distilling the mother solution, adding pure water, and crystallizing to obtain a bronopol product; and performing resin adsorption on the residual bronopol in the obtained mother solution, resolving, and returning to the bronopol crude product crystalline liquid, wherein in the whole technical process, no loss of bronopol exists, and wastewater is directly subjected to biochemical treatment. According to the invention, sodium bromide and bronopol products with purities of 99% or above can be obtained, and the yield of the bronopol is more than 99%.Compared with the existing one-step reduced pressure distillation and crystallization process, the bronopol refining process increases the bronopol yield and lowers the bronopol and sodium bromide contents in wastewater, so that the wastewater can be directly discharged into a biochemical system, thereby lowering the wastewater treatment cost and reducing environmental pollution.

Owner:河北美邦工程科技股份有限公司

Preservative for skin care product

InactiveCN104800134AHas broad-spectrum antimicrobial activityGood compatibilityCosmetic preparationsToilet preparationsBronopolAdditive ingredient

The invention discloses a preservative for a skin care product. The preservative comprises the following components in parts by weight: 1 to 3 parts of bronopol, 4 to 8 parts of methyl parahydroxybenzoat, 0.1 to 0.5 part of benzoisothiazolinone and 1 to 3 parts of plant preservative ingredients, wherein the plant preservative ingredients are prepared by the following method of mixing and crushing 1 to 6 parts by weight of mangnolia officinalis, 3 to 5 parts by weight of clove, 1 to 3 parts by weight of tea leaves, 3 to 6 parts by weight of orange peel, 3 to 6 parts by weight of witch hazel and 1 to 6 parts by weight of rose, and adding ethanol for reflux extraction; performing vacuum concentration on extraction liquid to obtain extract with the relative density of 1.1 to 1.3; performing spray drying to obtain the plant preservative ingredients. The preservative disclosed by the invention can be better matched with raw materials of most skin care products; the bacteriostatic ability of the preservative is not influenced by surfactant, protein and Chinese herbal medicinal additives in the skin care product; in addition, the preservative is high in safety and low in stimulation.

Owner:胡红慧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com