CON-AID plate and manufacturing method thereof

A manufacturing method and technology of Copaign board, which are applied in the direction of manufacturing tools, chemical instruments and methods, wood layered products, etc. The effect of cracking performance, improving flatness and structural stability, and improving transverse tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

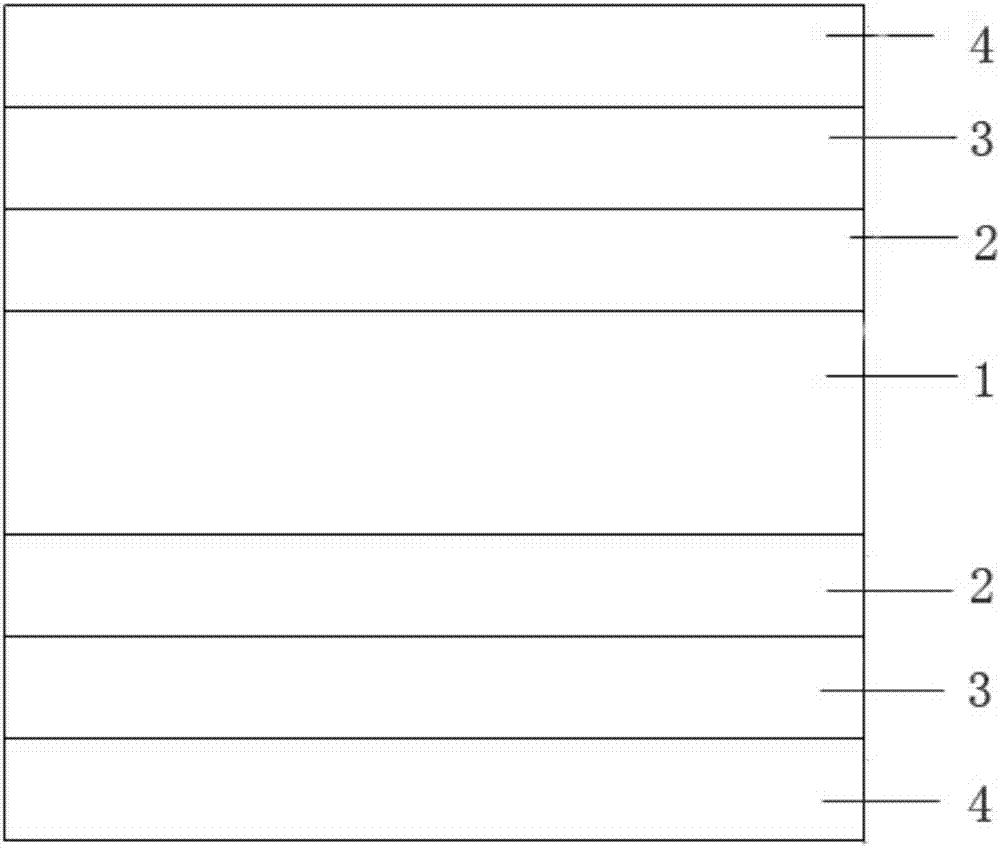

Image

Examples

Embodiment 1

[0045] Embodiment one (17.5mm plywood core corrugated board)

[0046] 1. Substrate production (15mm plywood substrate):

[0047] 1. Glue coating and blank assembly: Glue 5 pieces of 1.8mm eucalyptus short-core veneer, and the glue is soybean glue. Glue amount 200g / m 2 , The veneers are sorted according to the feeding standards, mainly sorted according to their appearance grades, and the moisture content of the materials that meet the standards must be strictly controlled. According to the design plan, 5 layers of glued short cores and 4 layers of uncoated long cores are assembled, criss-crossing;

[0048] 2. Cold pressing: put the slabs assembled into the cold pressing machine for cold pressing, the time is 90min, and the pressure is 1.0MPa;

[0049] 3. Hot pressing: Hot press the cold-pressed slab at a temperature of 120°C for 18 minutes and a pressure of 1.0 MPa. After hot pressing, the moisture content of the slab is controlled within 12%.

[0050] 4. Sanding: sanding t...

Embodiment 2

[0066] Embodiment two (17.5mm blockboard core Kangnai board)

[0067] Production of a substrate (17mm blockboard substrate):

[0068] 1. Glue coating and billet assembly: Glue coating for 12mm glulam, the glue is soybean glue. Glue level 220g / m 2 , according to the design plan, paste a layer of 2.0mm poplar short core on the top and bottom of the glued wood;

[0069] 2. Cold pressing: put the slab that has been formed into a cold pressing machine for cold pressing, cold pressing for 90 minutes, and a pressure of 0.8 MPa;

[0070] 3. Hot pressing: Hot press the cold-pressed slab at a temperature of 120°C, a time of 500 seconds, and a pressure of 0.8 MPa. After hot pressing, the moisture content of the slab is controlled within 10%.

[0071] 4, sanding: the slab that hot-pressing is finished carries out constant-thickness sanding, and constant thickness is to 15mm, and abrasive belt is the combined abrasive belt of 60 orders and 150 orders.

[0072] 5. Scraping and greasy: F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com