Double-component melt-blowing equipment

A two-component, melt-blown technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of uneven mixing of flakes, poor transverse tensile properties, and unsatisfactory warmth retention effects, so as to ensure resilience and enhance Transverse tensile strength, effect of improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

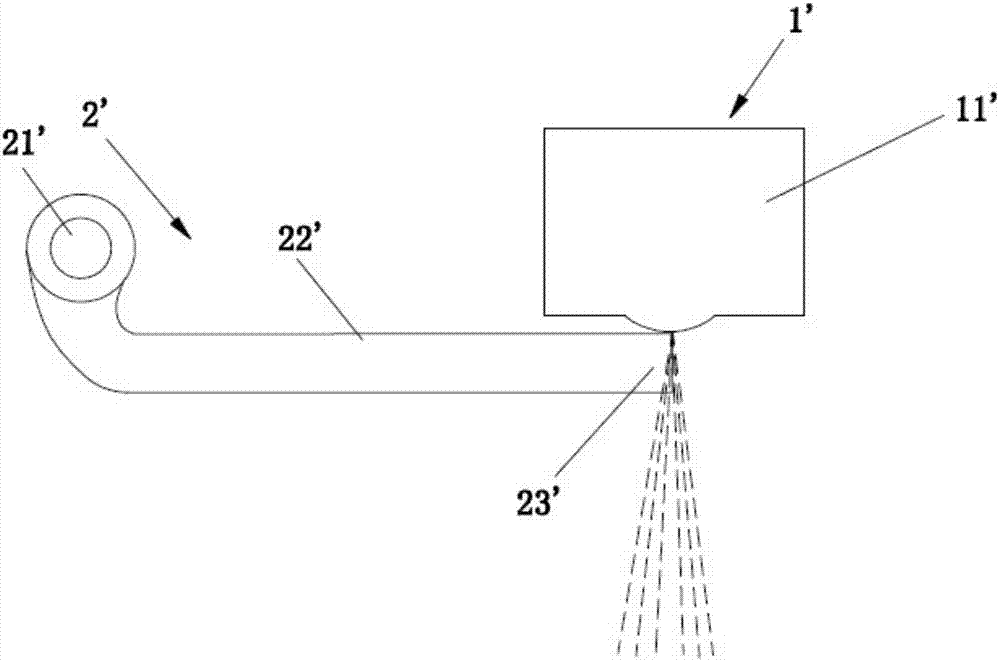

[0020] Such as image 3 As shown, the two-component melt-blown equipment of the preferred embodiment of the present invention includes a melt-blown device 1 , a fiber supply device 2 to be mixed, a needling device 3 , and a web-forming device 4 .

[0021] The melt-blowing device 1 comprises a spinneret 11, and the spinneret 11 comprises a spinneret 12 fixedly mounted on the bottom of the spinneret 11, and the spinneret 12 has several spinneret holes. The melt-blowing device 1 uses high-speed hot air to draw the thin stream of polymer melt extruded from the spinneret hole of the spinneret die 11, thereby forming ultra-fine melt-blown fibers.

[0022] The fiber supply device 2 to be mixed includes a feeding air duct 21 and a fan 22 . The material conveying channel 21 has a material outlet 21a. When the blower fan 22 rotates, it generates wind along the material conveying air channel 21 and blows toward the material outlet 21a. Under the action of wind force, the fibers to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com