Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181results about How to "Small thermal shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

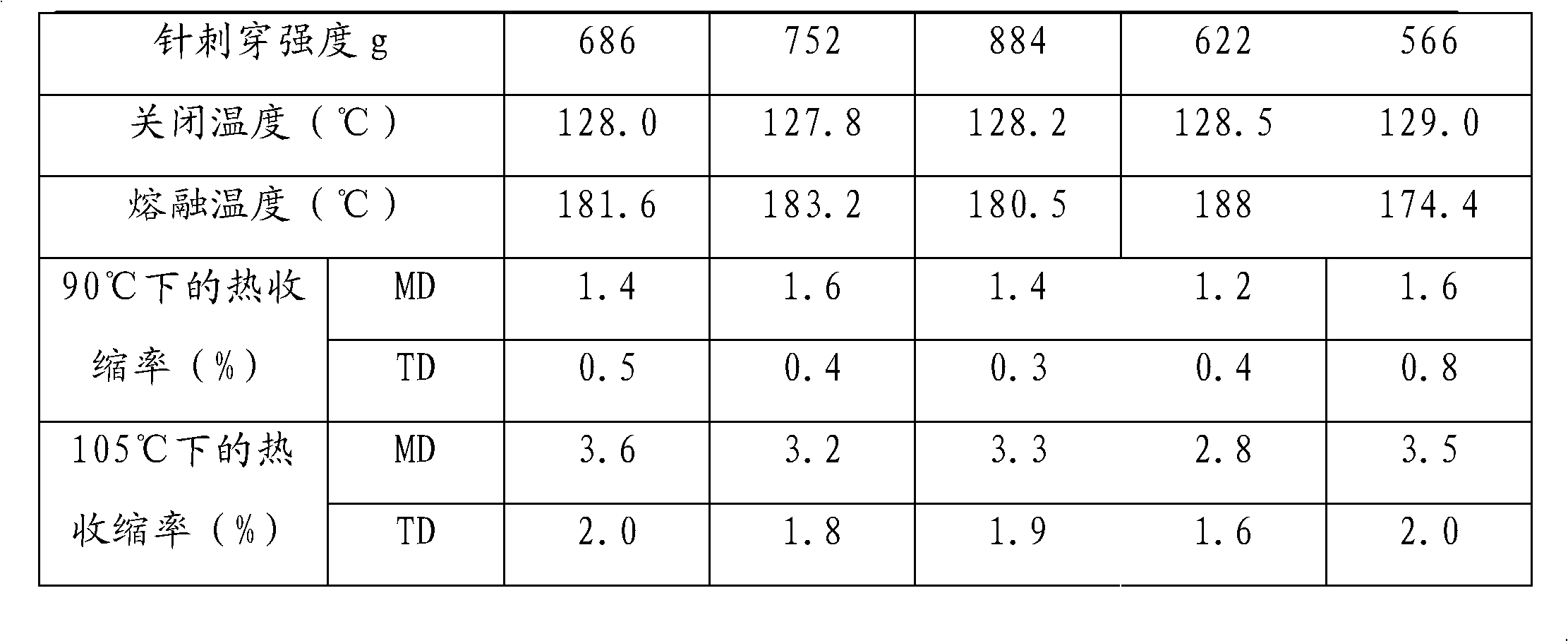

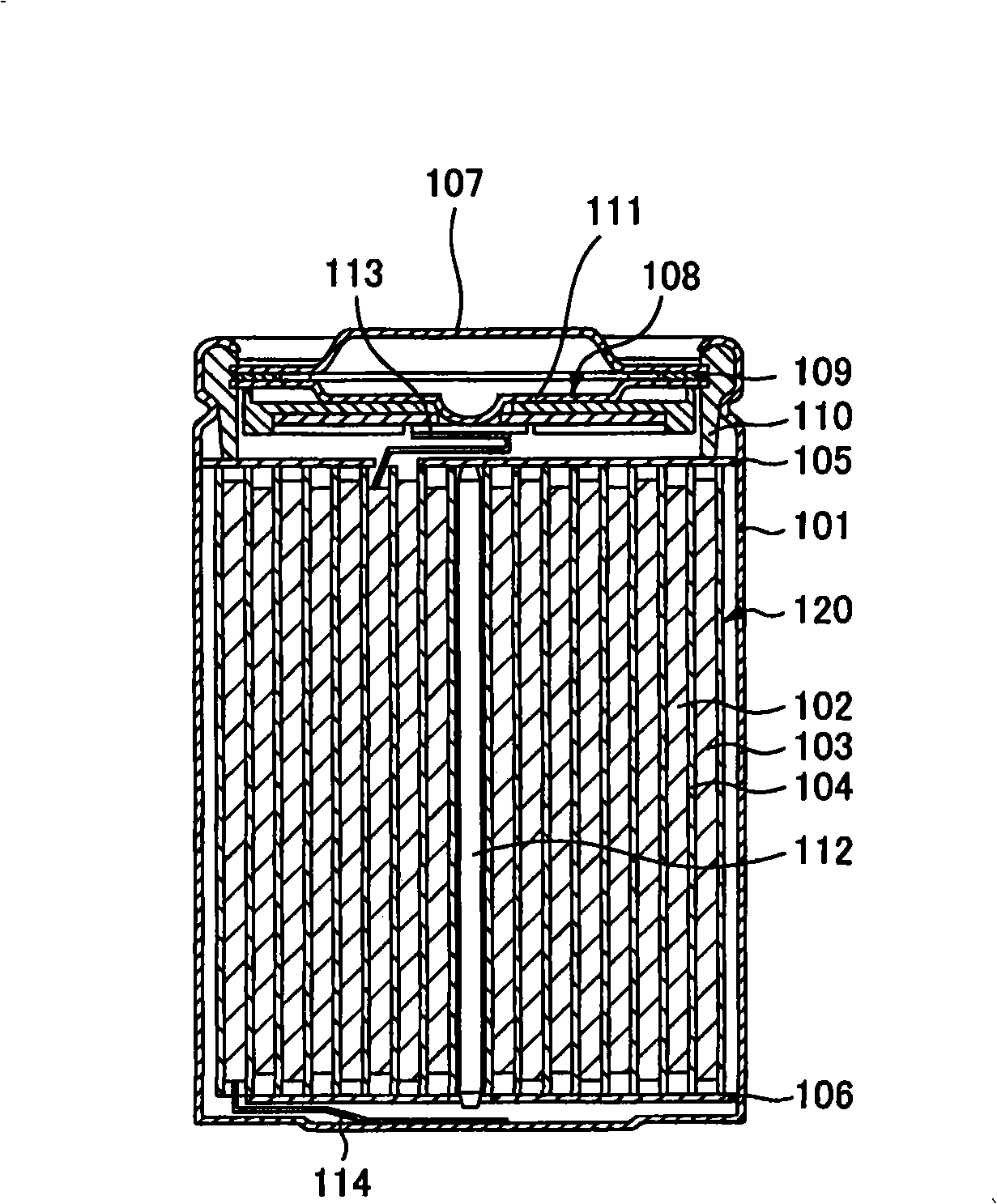

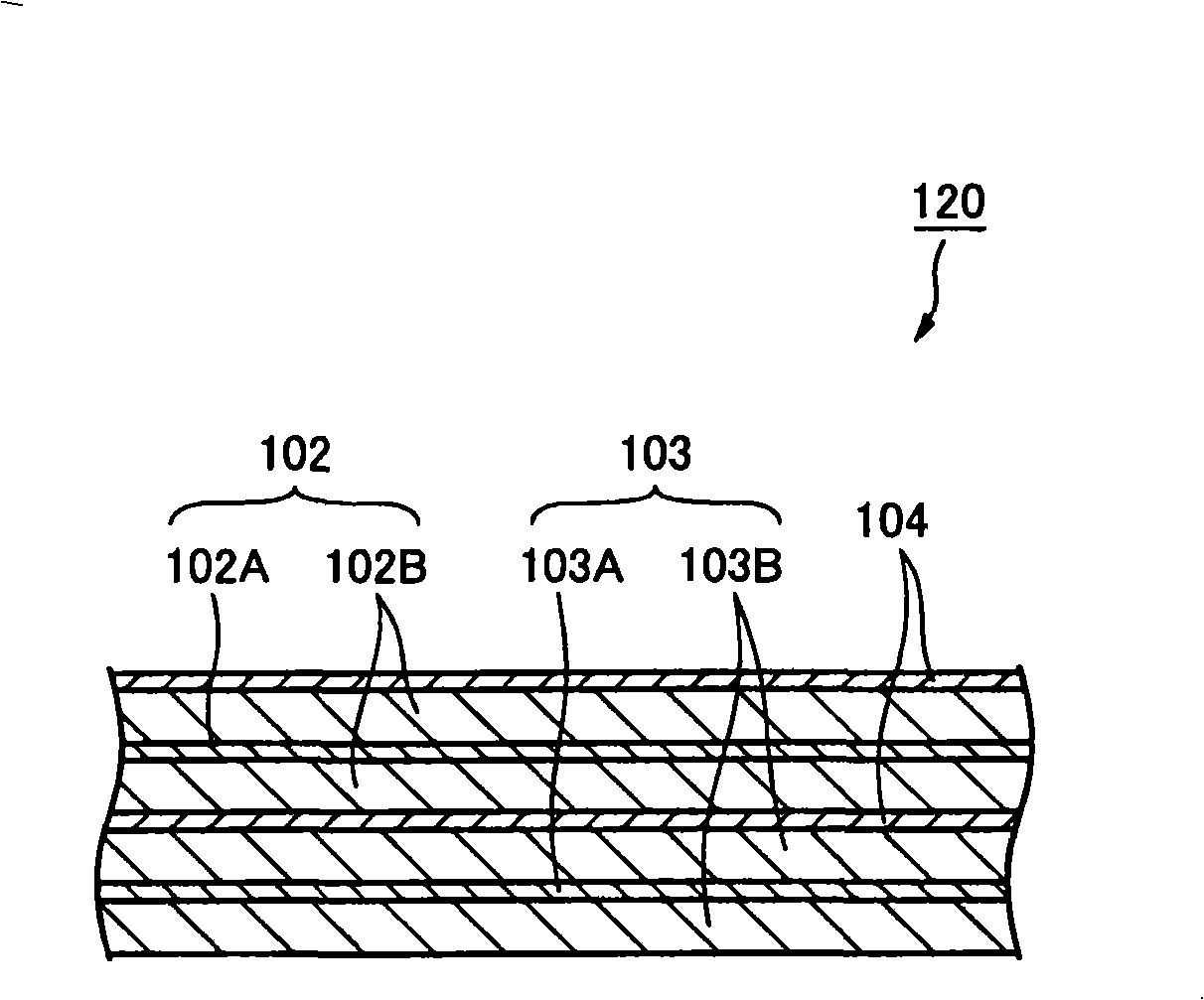

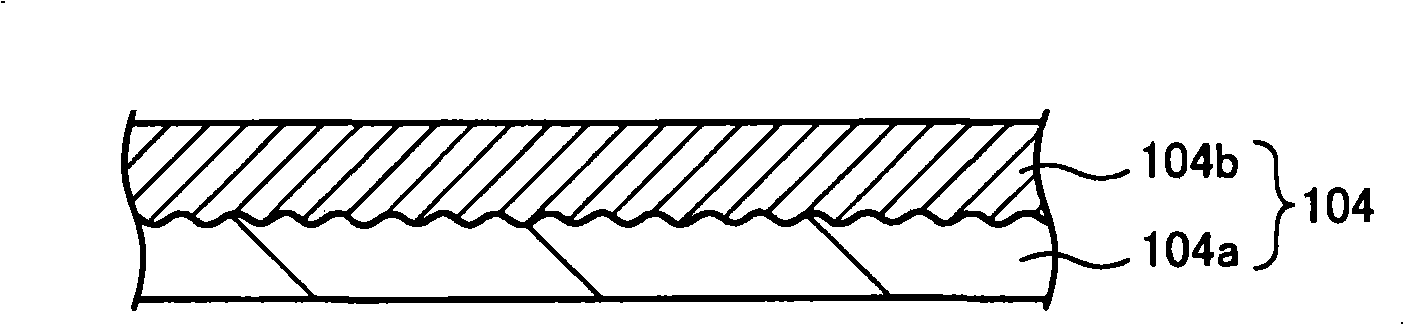

Separator for non-aqueous electrolyte battery and non-aqueous electrolyte battery

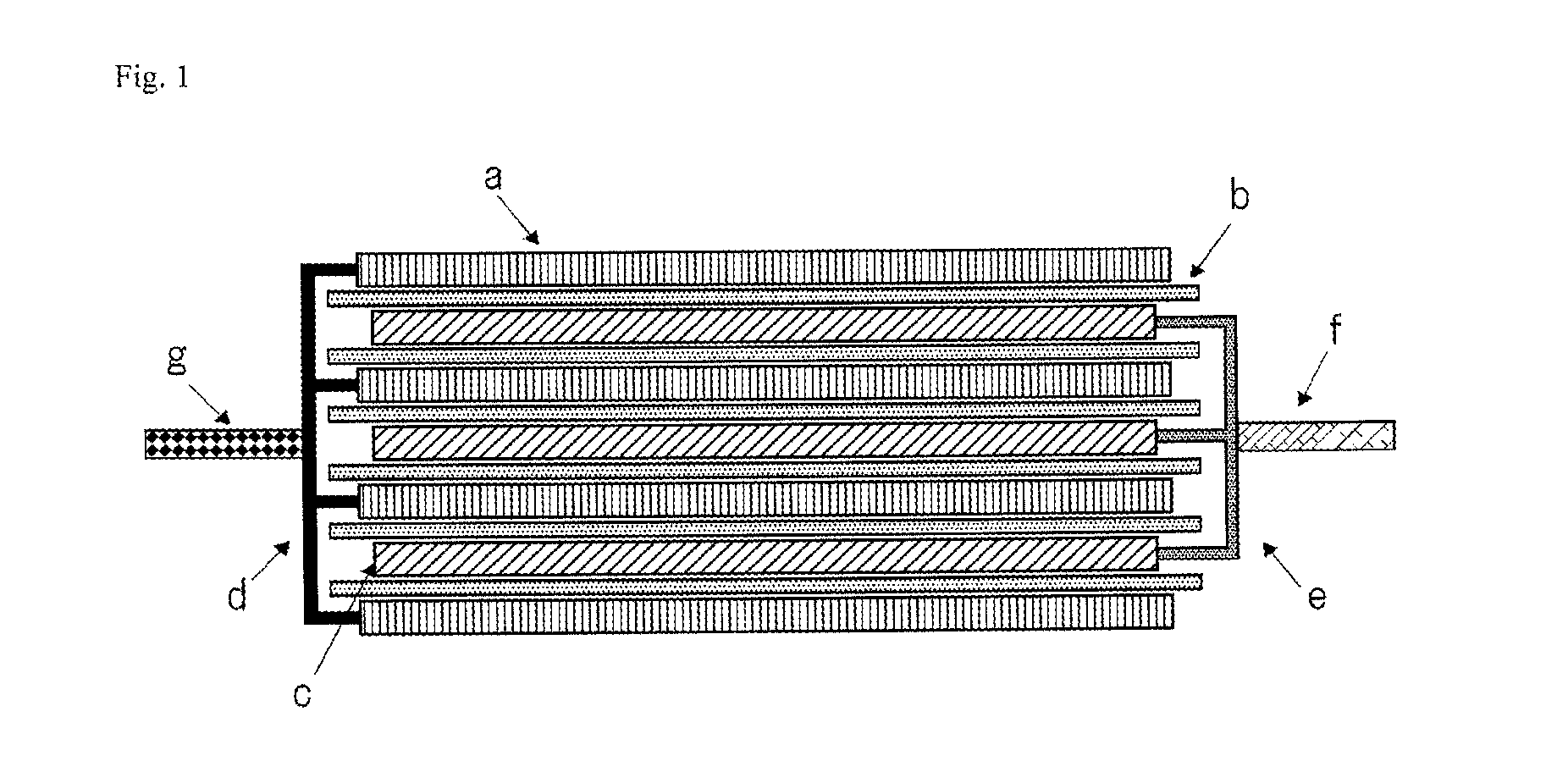

InactiveCN1725524ASmall thermal shrinkageImprove heat resistanceElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersPolyolefinHeat resistance

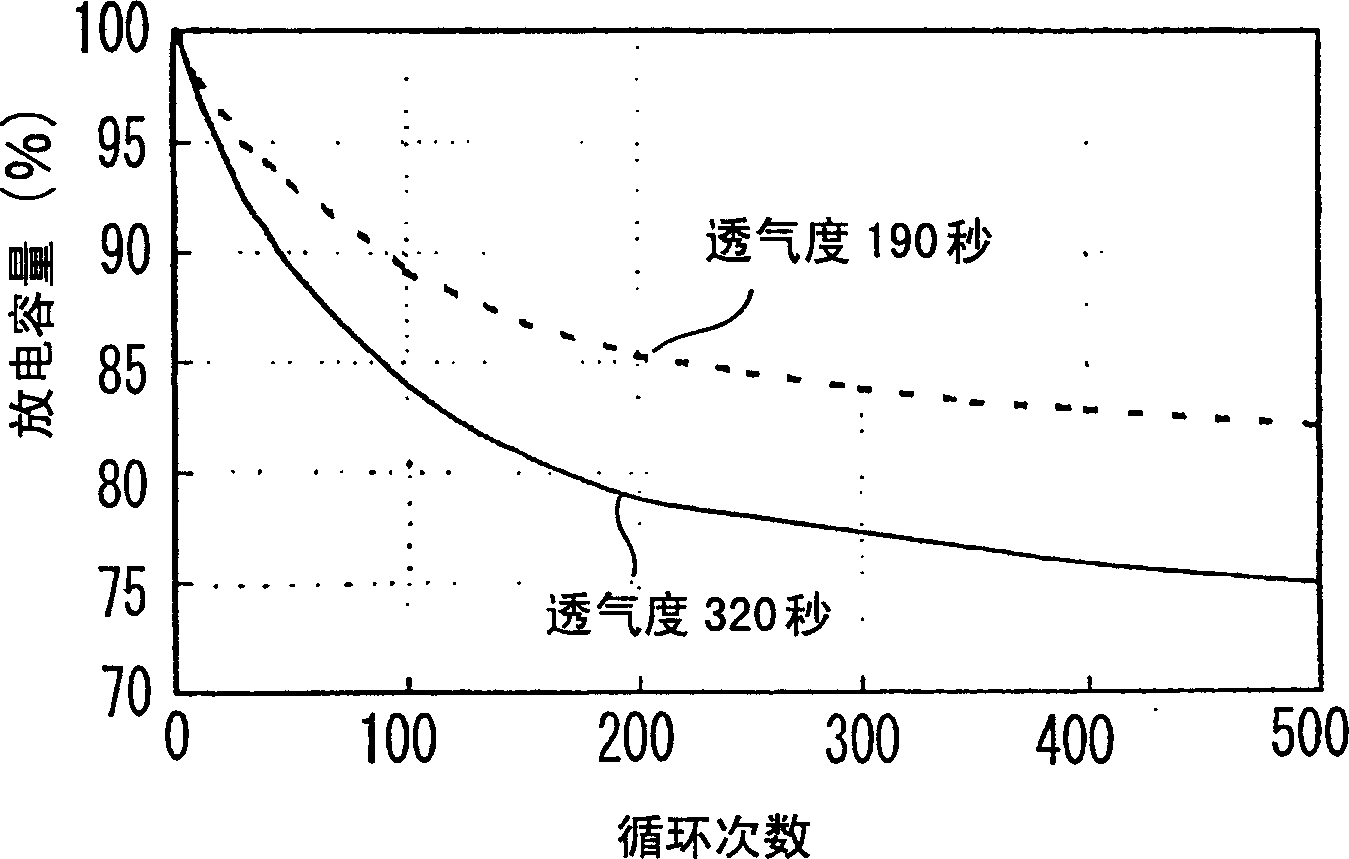

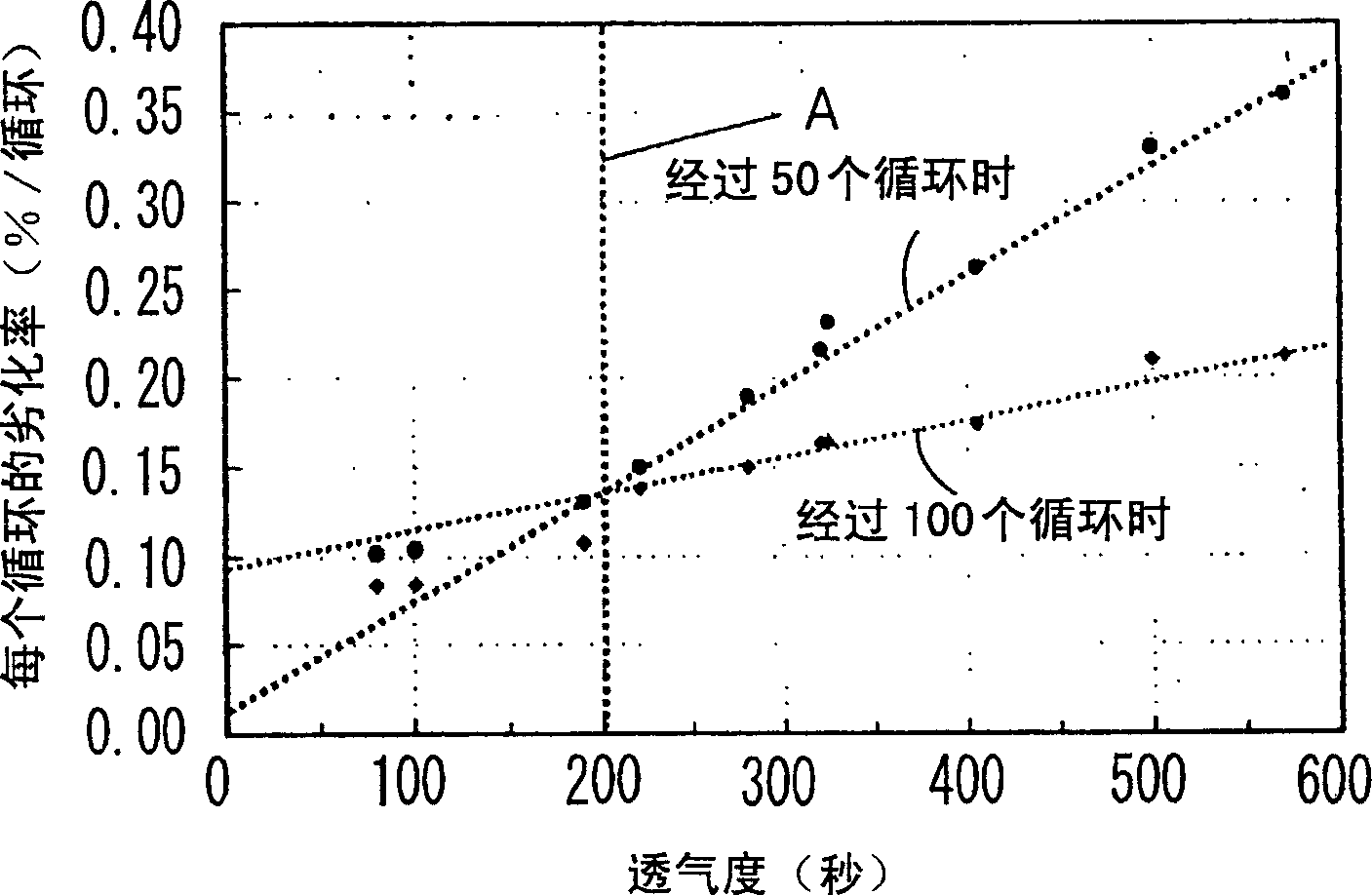

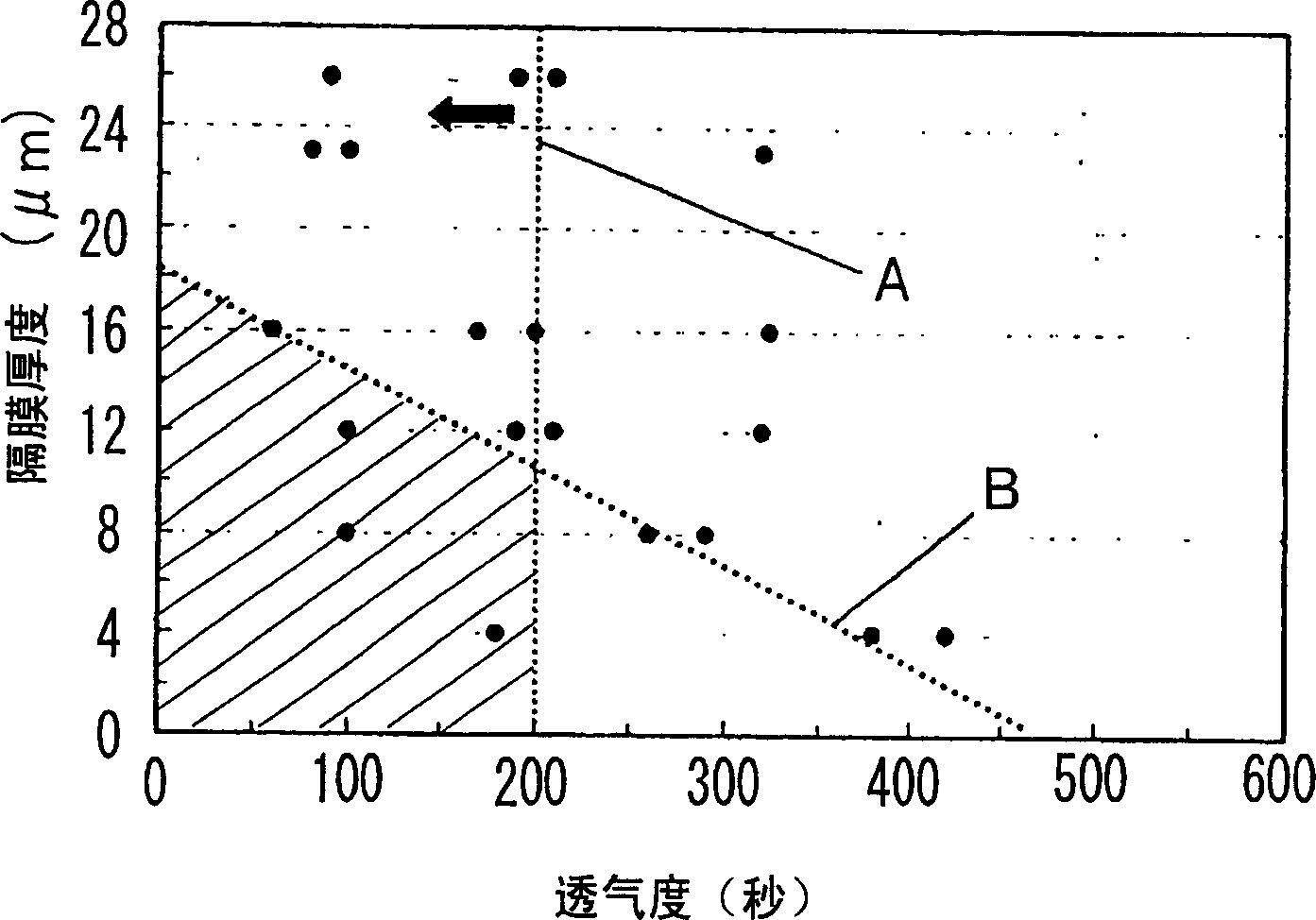

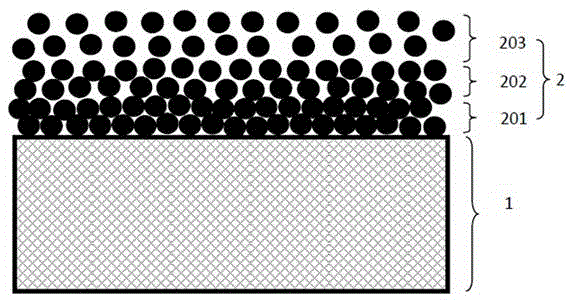

The present invention provides a membrane that is used in non aqueous electrolyte batteries. And the present invention is characterized in that the membrane is formed by a micro-porous membrane that consists of a polyolefin layer and a heat-resistant layer, which overlap on each other. The heat-resistant layer is 1 Mu m to 4 Mu m thick and is formed by polyamide, polyimide, or polyamide imide, the melting point of which is above 180 DEG C. The air permeability of the membrane is less than 200 seconds. And the present invention can be used for preparing the membrane, which is used in non aqueous electrolyte batteries and has small thermal shrinkage, excellent heat resistance and excellent cycling characteristics, and also the non aqueous electrolyte batteries that adopt the membrane.

Owner:SANYO ELECTRIC CO LTD

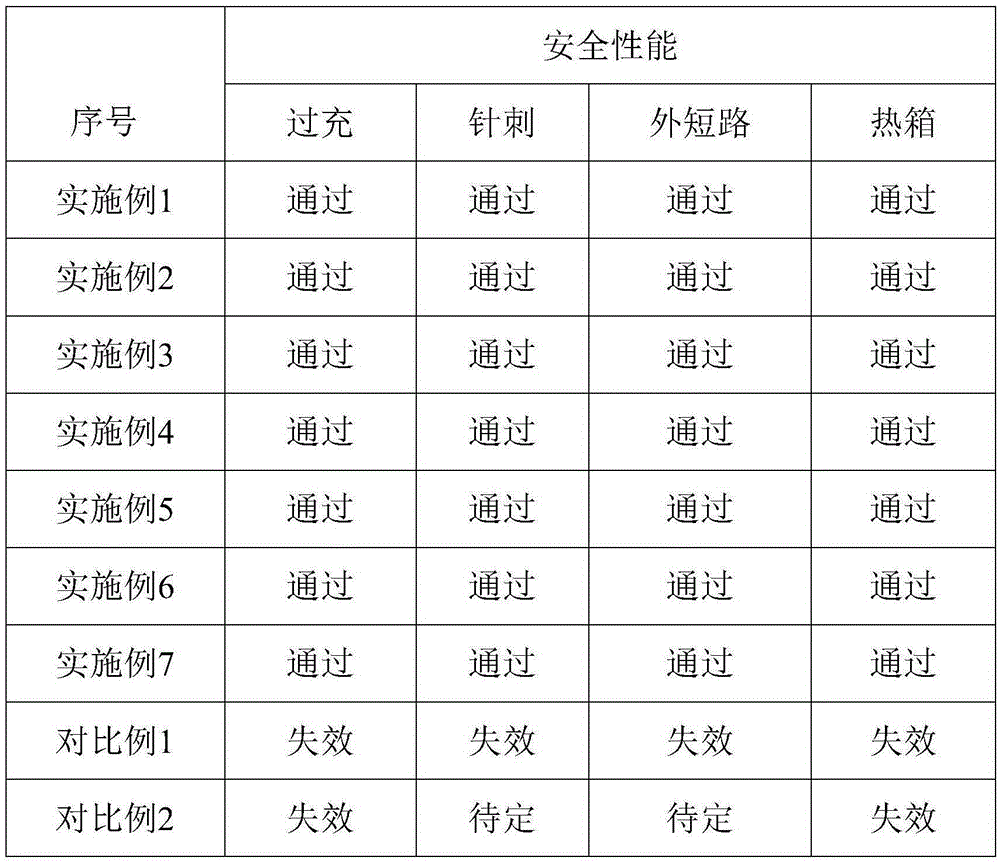

Composite membrane for lithium ion secondary battery, manufacturing method of composite membrane and electrochemical device containing membrane

ActiveCN104064705AImprove electrochemical performanceImprove securityCell seperators/membranes/diaphragms/spacersSecondary cellsInorganic particleElectrical battery

The invention discloses a composite membrane for a lithium ion secondary battery. The composite membrane comprises a porous membrane and a plurality of porous insulating layers, wherein at least one surface of the porous membrane is covered by the porous insulating layers, the hole diameters of the porous insulating layers are distributed from small to large in a gradient manner from the porous membrane to the direction of a pole piece, and the porous insulating layers contain inorganic particles and binding agents. The invention further discloses a preparation method of the composite membrane. The preparation method comprises the following steps: firstly, mixing and dispersing the inorganic particles, the binding agents and a hole forming agent in a solvent to obtain slurry, coating the surface of the porous membrane with the slurry, and drying to obtain the composite membrane. The invention further discloses an electrochemical device containing the composite membrane. According to the composite membrane, the preparation method of the composite membrane and the electrochemical device which are disclosed by the invention, the composite membrane has the advantages of good thermostability, low thermal shrinkage, excellent safety performance and good electrochemical performance, the preparation method of the composite membrane has the advantages of simplicity in operation and convenience, and the electrochemical device has excellent safety performance and good electrochemical performance.

Owner:东莞市魔方新能源科技有限公司

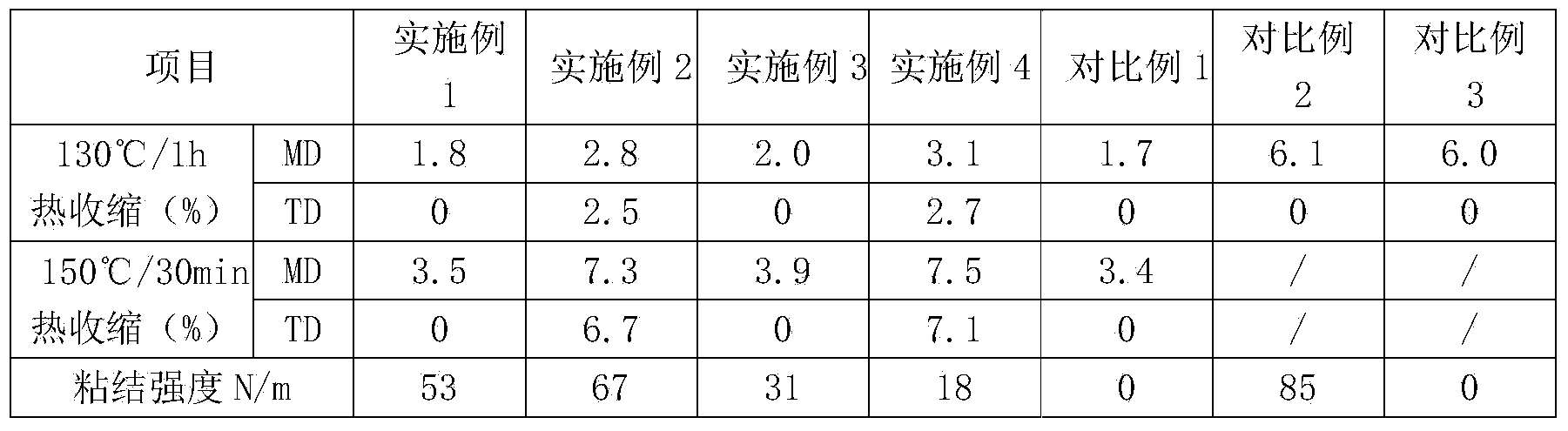

Adhesive composite diaphragm and manufacturing method thereof

InactiveCN104332578AImprove heat resistanceSmall thermal shrinkageCell seperators/membranes/diaphragms/spacersPolyolefinPorous membrane

The invention discloses an adhesive composite diaphragm, comprising a polyolefin porous membrane and one or two hybrid coatings applied onto one or two sides of the polyolefin porous membrane, wherein each hybrid coating is 2-8 microns thick and comprises 10-50 parts by mass of polymer particles and 50-90 parts by mass of ceramic particles. The invention also discloses a manufacturing method of the composite diaphragm. The diaphragm disclosed by the invention has the advantages that the thermal stability of the diaphragm is effectively improved, and the diaphragm and a battery pole piece can bond with each other.

Owner:SHENZHEN SENIOR TECH MATERIAL

Microporous polymer isolating film for Li-ion battery and method for producing the same

ActiveCN101212036AIncrease surface areaHigh porositySolid electrolytesFinal product manufactureHydrophilic monomerPolymer science

The invention relates to a diaphragm used for power maintaining device as a lithium ion secondary battery and a preparation method thereof, which belongs to a field of manufacturing battery and capacitor. The diaphragm of the invention takes water as reaction medium; polymers colloid and emulsion are obtained through polymerization reaction generated by polyvinyl alcohol, hydrophobic monomer and hydrophilic monomer with an initiator in water solution; by adopting tape-casting and coating process, the polymers colloid and emulsion are coated on a plastic baseband; the diaphragm is obtained through stripping after drying. The diaphragm has good liquid absorbability, high liquid absorption rate and retention, low resistivity, good mechanical strength and good thermal stability (little thermal shrinkage and little size distortion) as well as electrochemical stability; and the prepared lithium ion battery is characterized by good cycle stability and long service life.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

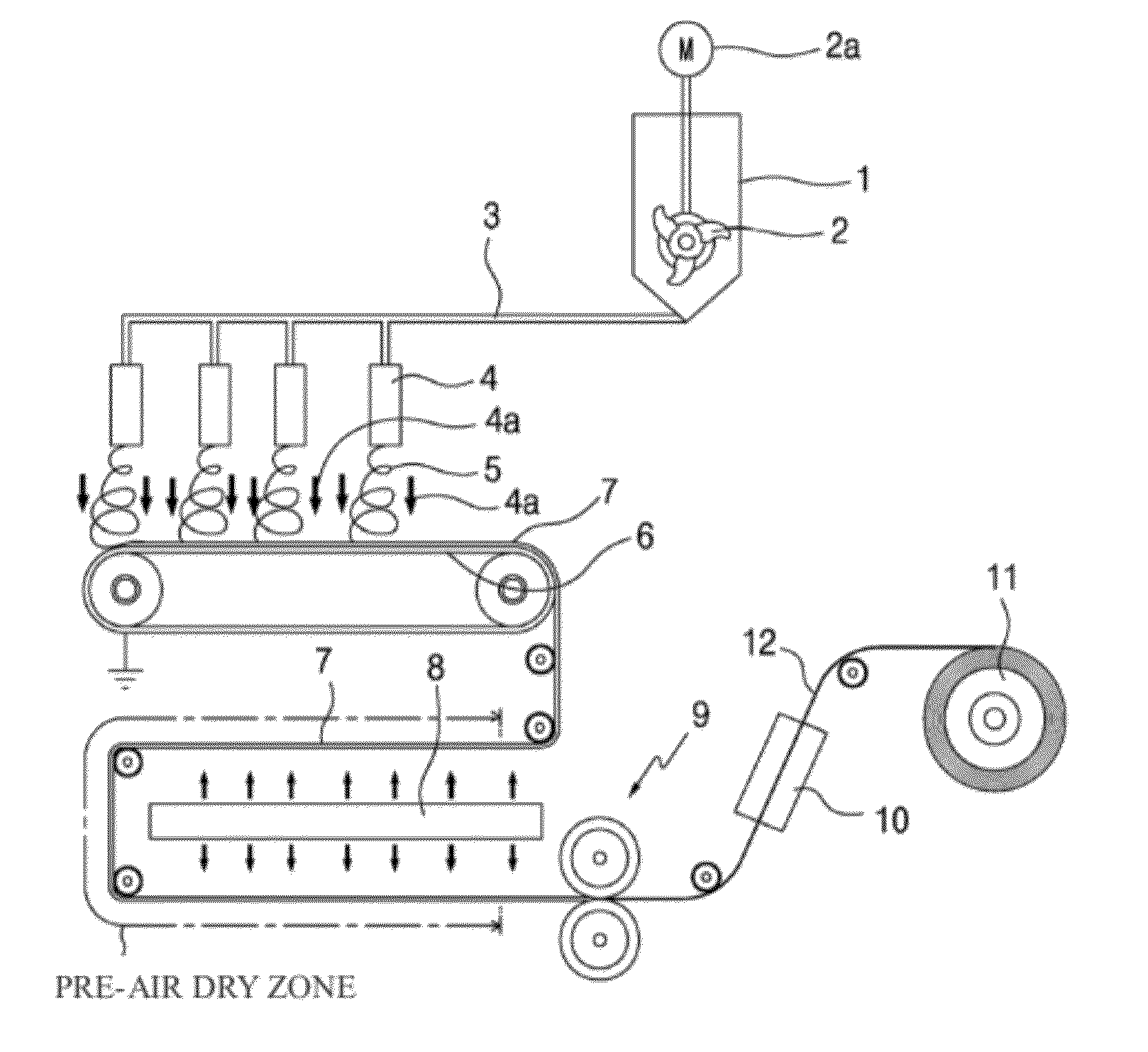

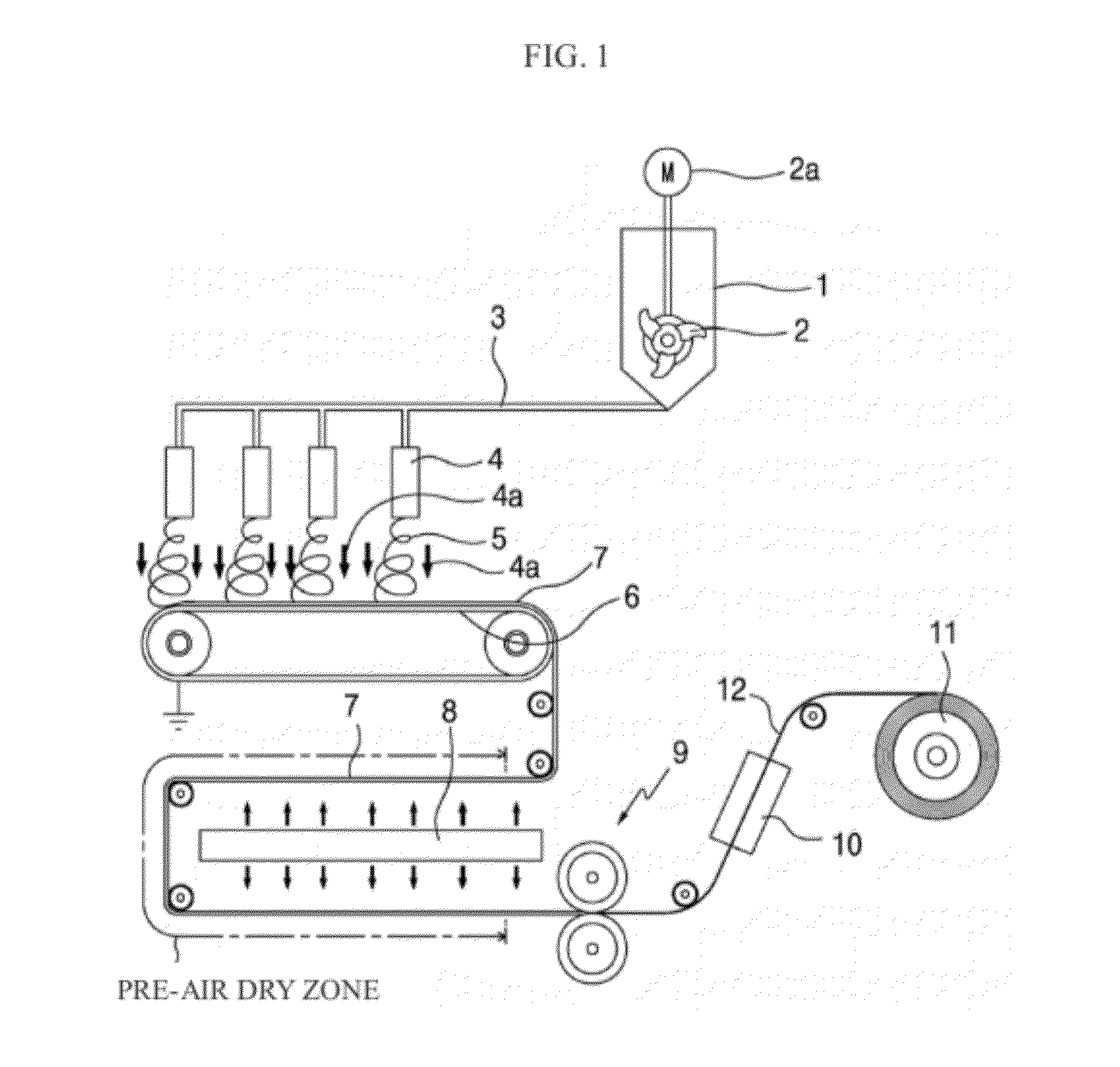

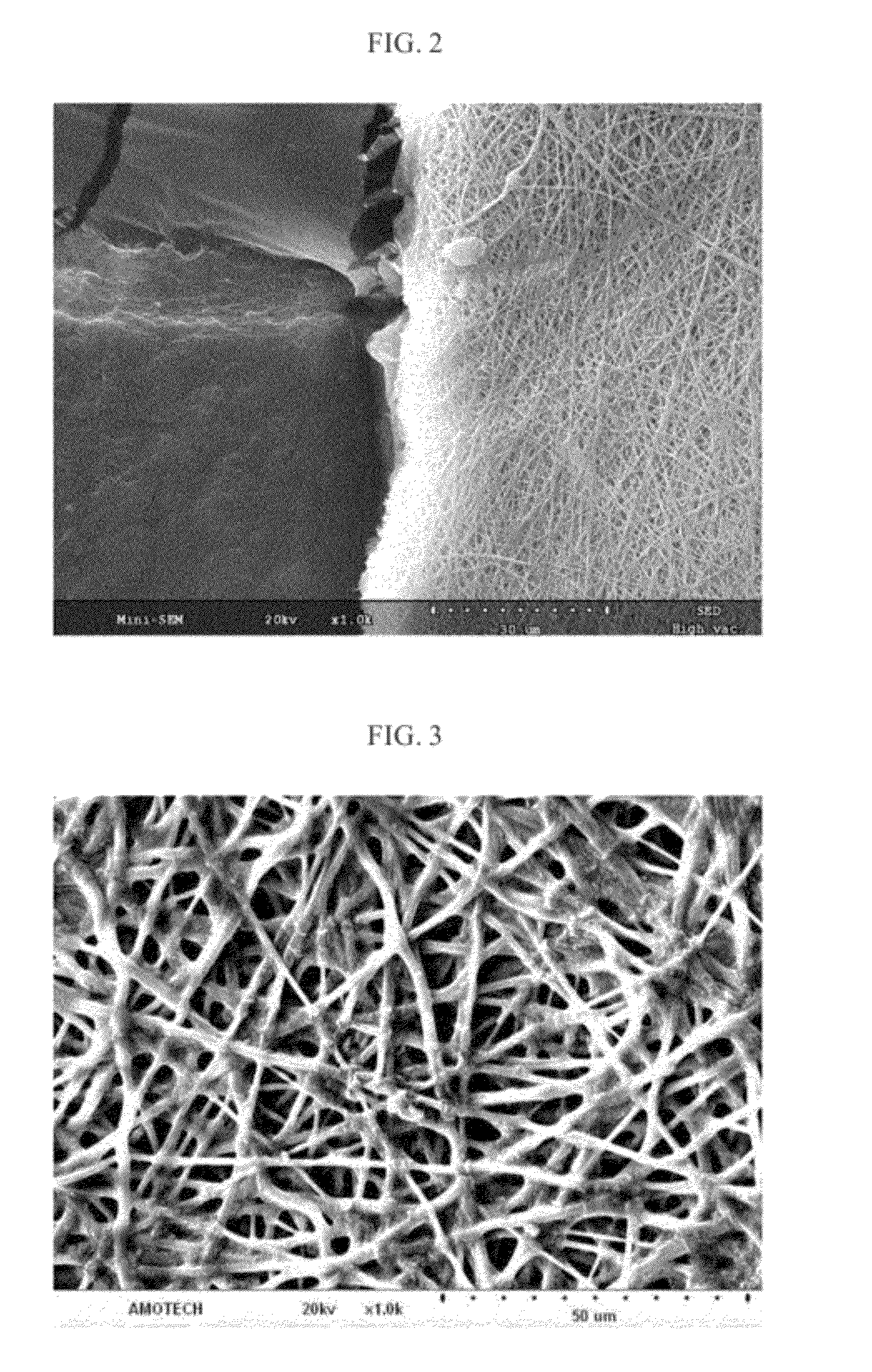

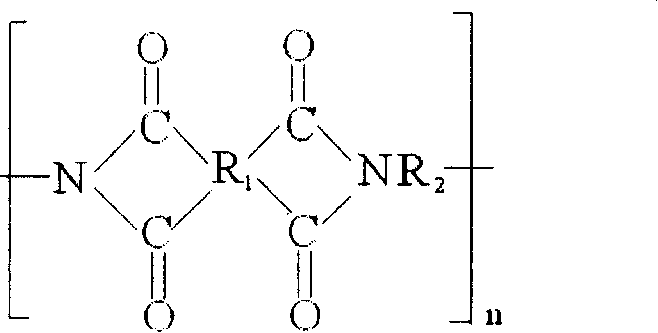

Heat-resistant and high-tenacity ultrafine fibrous separation layer, method for manufacturing same, and secondary cell using same

ActiveUS20120225358A1Small thermal shrinkageHigh mechanical strengthHybrid capacitor separatorsElectric discharge heatingFiberPolymer science

Provided is an ultrafine fibrous porous separator with heat resistance and high-strength and a manufacturing method thereof, which enables mass-production of a heat-resistant and high-strength ultrafine fibrous separator by using an air-electrospinning (AES) method, and to a secondary battery using the same. The method of manufacturing a heat-resistant and high-strength ultrafine fibrous porous separator includes the steps of: air-electrospinning a mixed solution of 50 to 70 wt % of a heat-resistant, polymer material and 30 to 50 wt % of a swelling polymer material, to thereby form a porous web of a heat-resistant ultrafine fiber in which the heat-resistant polymer material and the swelling polymer material are consolidated in an ultrafine fibrous form; performing drying to control a solvent and moisture that remain on the surface of the porous web; and performing thermal compression on the dried porous web at a temperature of between 170° C. and 210° C. so as to obtain the separator.

Owner:AMOGREENTECH CO LTD

Polyolefin composite thin film and preparation and application thereof

ActiveCN101209609AHigh strengthImprove heat resistanceLamination ancillary operationsSynthetic resin layered productsPolyolefinPolymer science

The invention relates to a polyolefin compound film, comprising a polyolefin layer and a refractory coating which are adhered together. The refractory coating comprises a refractory material and vents distributed on the material, wherein, an average diameter of the vents on the material is not greater than 1 micron. The polyolefin compound film provided by the invention is provided with high strength and independent film layer structure can be preserved even after the polyolefin layer is melted and collapses. If the polyolefin compound film provided by the invention is used as a diaphragm of a lithium ion battery, the refractory layer of the compound film can avoid a contact between an anode and a cathode of the battery and prevent short circuit of the battery even though the polyolefin layer of the diaphragm is melted and collapses so as to really enhance the thermal security capability of the lithium ion battery. The polyolefin compound film provided by the invention has the advantages that the refractory capability is excellent; heat-shrinking is little and the strength is high. By being adopted as the diaphragm of a lithium ion secondary battery, the invention can effectively enhance the thermal security capability and circulation capability of the battery.

Owner:BYD CO LTD

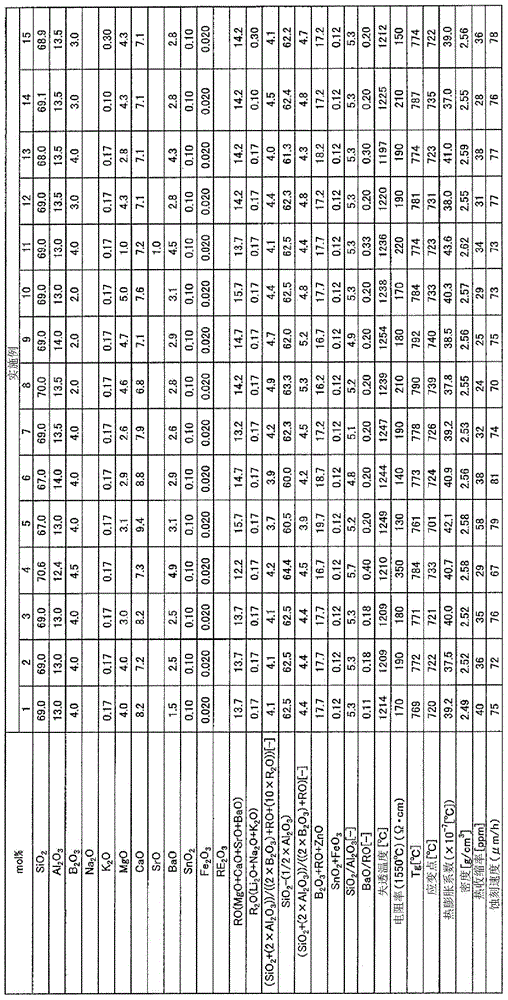

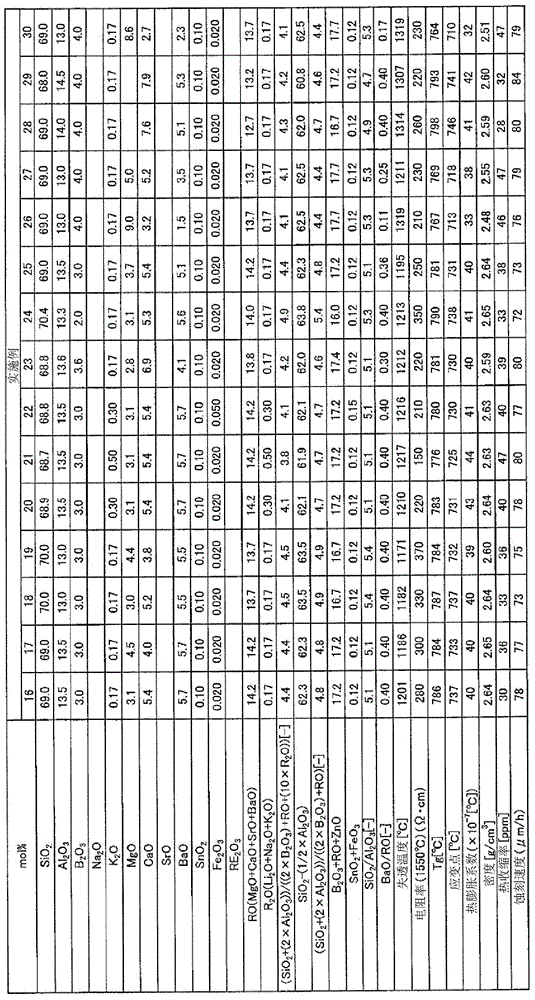

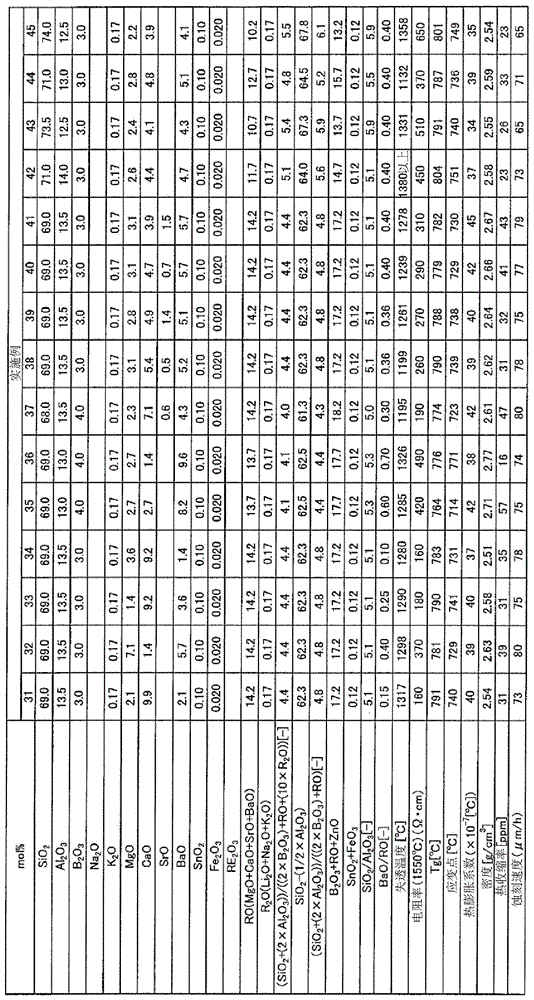

Glass substrate for display device and method for manufacturing same

ActiveCN103910487AInhibit or avoid melt lossInhibit devitrificationGlass productionDevitrificationMelting tank

The invention relates to a glass substrate for display device and a method for manufacturing same and provides a glass substrate which is high in strain point and capable of preventing a melting tank from melting loss, a glass substrate which is high in strain point and capable of suppressing devitrification, a glass substrate which is high in strain point and etching speed, and a method for manufacturing the glass substrate. The glass substrate contains Sio2 and Al2O3, 0-8% of B2O3, 0.01-0.8 % of R2O, and 0.05-1 of BaO / RO in mol%, and the strain point is over 670 DEG C. The glass substrate may contain Sio2, Al2O3 and MgO, 0.1-0.9 of MgO / (RO+ZnO), the strain point is over 700 DEG C, and the contraction rate is 5ppm-75ppm. The glass substrate may contain Sio2, Al2O3 and BaO, 0-7% of B2O3, 1-15% of BaO, and less than 6.0 of Sio2 / Al2O3, and the strain point is over 700 DEG C. RO represents (MgO+CaO+SrO+BaO), and R2O represents (Li2O+Na2O+K2O).

Owner:AVANSTRATE INC

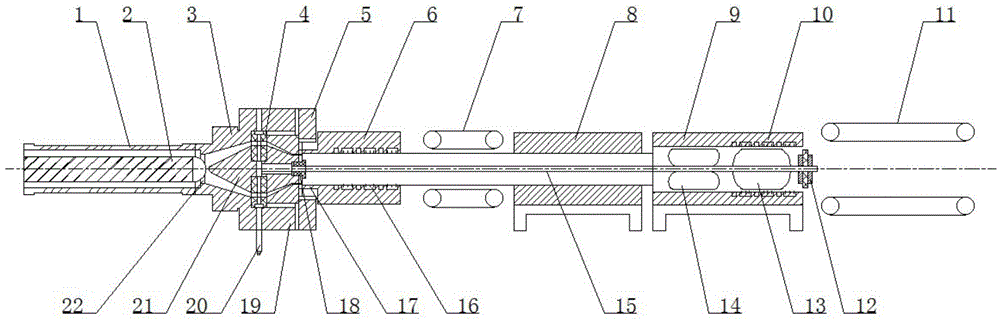

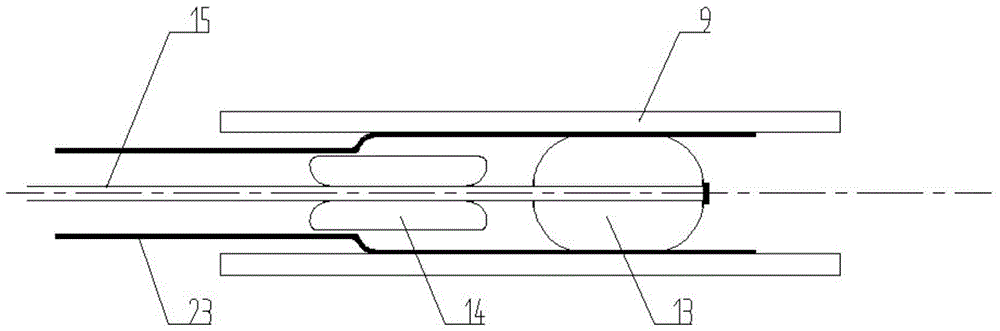

Production equipment and process for large-diameter biaxial-stretching PVC pipe fitting

ActiveCN104149354ARealize continuous productionEnhanced axial mechanical propertiesTubular articlesProduction linePipe fitting

The invention discloses production equipment and process for a large-diameter biaxial-stretching PVC pipe fitting. The equipment mainly comprises a tapered double-screw extruder, an extruder head, a vacuum sizing device A, a first traction device, a reheating device, a stretching and diameter expanding molding device, a vacuum sizing device B and a second traction device which are sequentially and linearly arrayed to form a production line; the stretching and diameter expanding molding device is composed of an inflation rod, an expansion bag, an expansion sizing mould and a shaping bag; each of the expansion bag and the shaping bag is of an annular bag-shaped structure; the expansion bag is continuously expanded and retracted under the action of the inflation rod; a pipe fitting to be expanded moves by a certain distance through the action of an outer ring circular-arc surface of the expansion bag when the expansion bag is expanded once, so that each point of the pipe fitting can be subjected to annular expansion; the stretching is generated in the axial direction of the pipe fitting through a stretching ratio between the first traction device and the second traction device. By adopting the production equipment and process, the continuous production of the diameter-expanded pipe fitting is successfully realized, the thermal contraction of the pipe fitting is small and the axial mechanical property can be enhanced.

Owner:BEIJING UNIV OF CHEM TECH

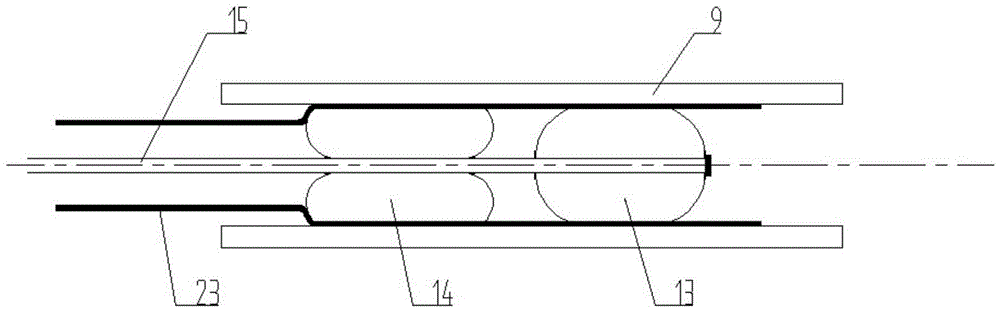

Composite diaphragm material and preparation method and application thereof

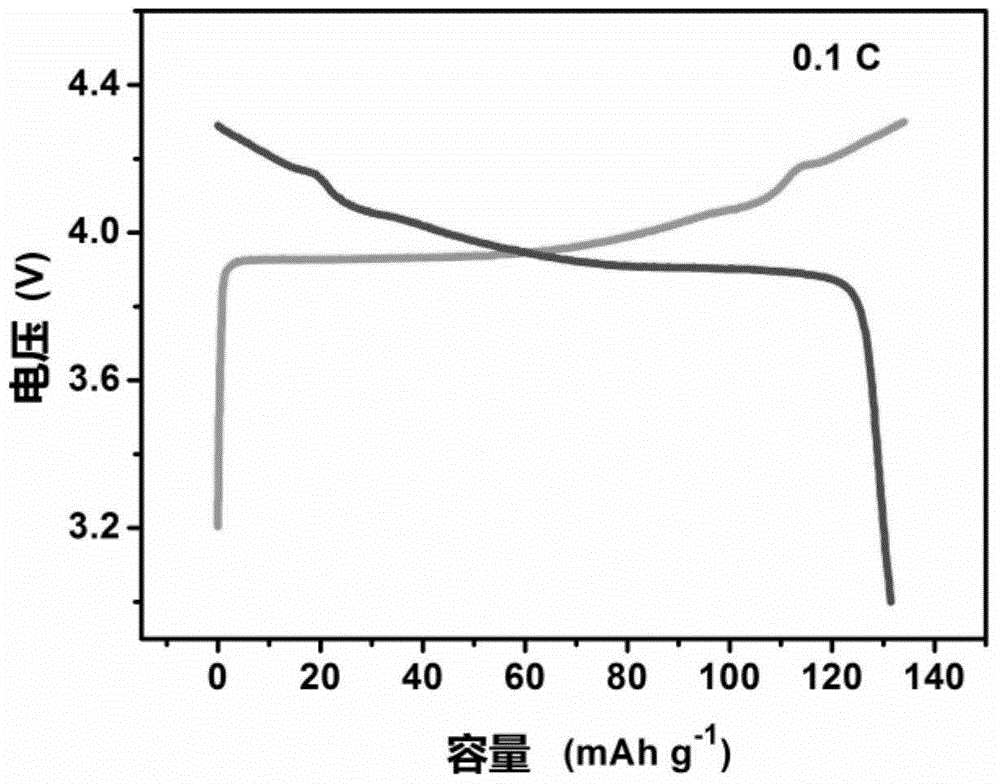

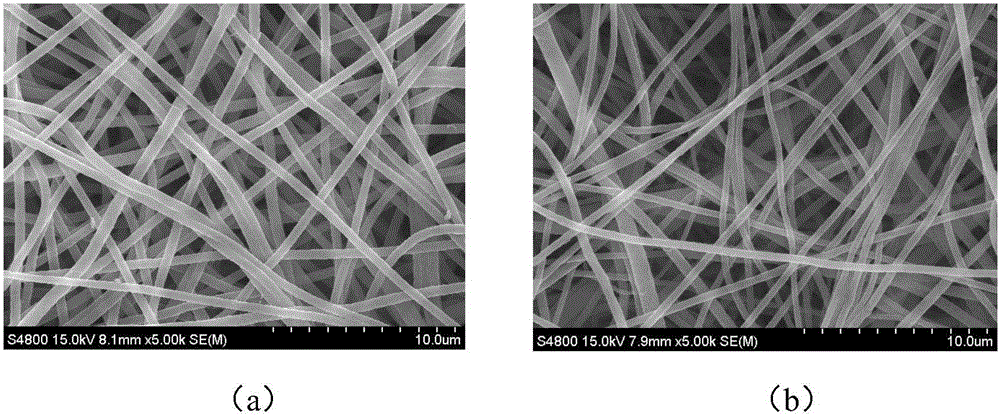

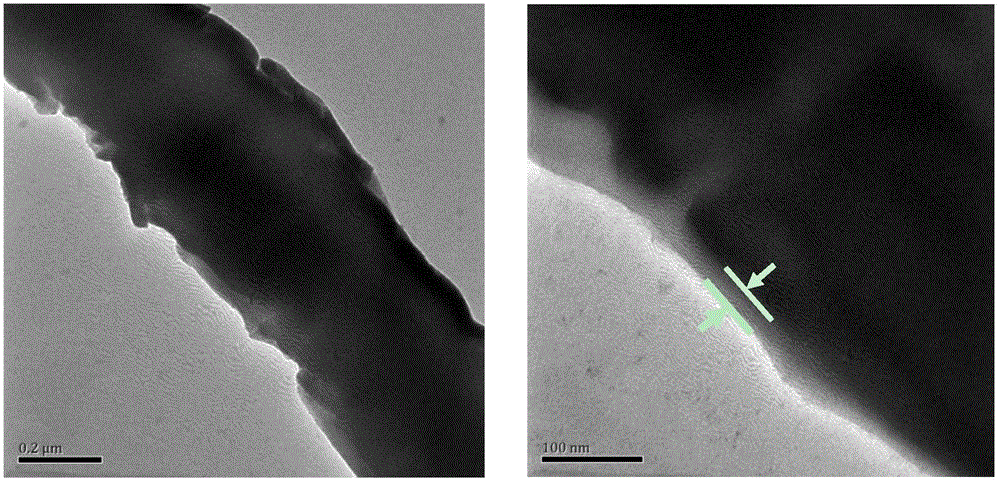

InactiveCN104409674AImproved thermal stability and mechanical strengthExcellent battery capacity and cycle performanceSecondary cellsCell component detailsLithium electrodePore diameter

The invention discloses a composite diaphragm material and a preparation method and application thereof. The composite diaphragm material comprises an inorganic layer and a porous polymeric membrane layer, wherein the inorganic layer is positioned on one side or two sides of the porous polymeric membrane layer; the inorganic layer is connected with the porous polymeric membrane layer through adhesive; the inorganic layer is made of fiber rod-like materials; the fiber rod-like materials are mutually stacked to form a plurality of pores with the average pore diameter of 0.05-1 micron; the porous polymeric membrane layer has the average pore diameter of 0.05-0.5 micron and the porosity of 30-60%. The composite diaphragm material can be used as a diaphragm of a secondary lithium ion battery; the lithium ion battery using the diaphragm material provided by the invention has excellent electrochemical performance and safety.

Owner:TSINGHUA UNIV +1

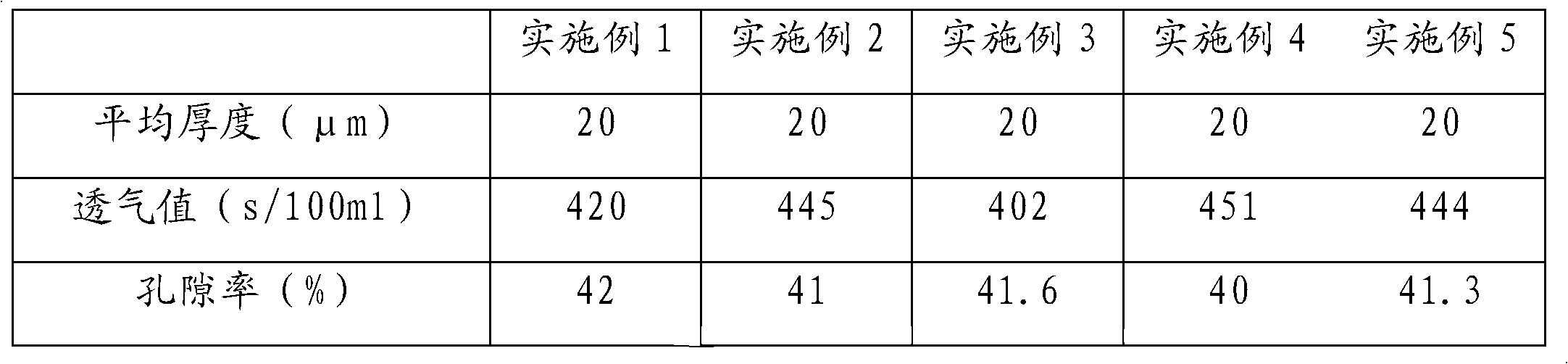

Nonwoven fabric ceramic separator, and preparation method and application thereof

InactiveCN106784539AImprove liquid absorption and retention capacityHigh porosityCell seperators/membranes/diaphragms/spacersSecondary cellsLayer thicknessNonwoven fabric

The invention provides a nonwoven fabric ceramic separator, and a preparation method and application thereof. The preparation method specifically comprises the following steps: preparing a nonwoven fabric fiber base membrane through an electrostatic spinning method; and performing atomic layer deposition on the surface through a plasma enhanced atomic layer deposition technology, so that inorganic matters are uniformly coated on the surface of the polymer fiber to form a core-shell structure taking the one-dimensional polymer fiber as the core and the inorganic matters as the shell. The nonwoven fabric ceramic separator is used in a secondary battery. The separator can be further endowed with a thermal shutdown function through a polymer layer compounding method. The nonwoven fabric ceramic separator obtained by the invention has high thermal shrinkage resistance, enhanced mechanical strength, small membrane ceramic layer thickness and favorable uniformity; and an assembled battery has high mass and volume specific energy and high safety. Thus, the separator provided by the invention can be used as a high safety separator material for lithium ion batteries and other secondary batteries.

Owner:XIAMEN UNIV

Polyolefin multilayer micro-porous membrane and preparation method thereof

ActiveCN102501419ALow closed cell temperatureHigh membrane rupture temperatureCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinSurface layer

The invention discloses a polyolefin multilayer micro-porous membrane and a preparation method thereof. The middle layer of the polyolefin multilayer micro-porous membrane is a polyethylene micro-porous membrane; both surface layers of the polyolefin multilayer micro-porous membrane are micro-porous membranes which respectively contain polypropylene and polyethylene with super-high molecular weight; the polyethylene of the middle layer has the molecular weight of 1*105 to 6*105; the polypropylene of the surface layers has the molecular weight of 1*105 to 1*106; and the polyethylene of the surface layers has the molecular weight of 5*105 to 5*106. The preparation method comprises the following steps: firstly, respectively fusing to mix the raw auxiliary material of the middle layer and the raw auxiliary materials of the surface layers; putting the raw auxiliary materials of the middle layer and the surface layers into a twin-screw extruder; extruding through a multilayer co-extrusion die head; cooling; and then, drawing to manufacture the membrane, extracting and shaping to obtain the polyolefin multilayer micro-porous membrane.

Owner:河南惠强新能源材料科技股份有限公司

Composite ceramic coating, lithium ion battery composite ceramic diaphragm and lithium ion battery

ActiveCN105428576AHigh mechanical strengthImprove the problem of overchargingSecondary cellsCell component detailsComposite ceramicCeramic coating

The invention belongs to the technical field of a lithium ion battery, and specifically to a composite ceramic coating layer; meanwhile, the invention relates to a lithium ion battery composite ceramic diaphragm using the coating and the lithium ion battery using the diaphragm. The ceramic coating comprises ceramic powder, inorganic carbonate and a binder, wherein the mass ratio of the ceramic powder to inorganic carbonate to binder is 0-0.5:0.1-1:0.02-0.1. According to the composite ceramic diaphragm using the coating, the mechanical strength of the diaphragm is improved, the thermal shrinkage of the diaphragm is reduced, and the problem of overcharging and abuse of the battery is solved; and meanwhile, the safety performance of the battery is improved without affecting the energy density of the battery.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

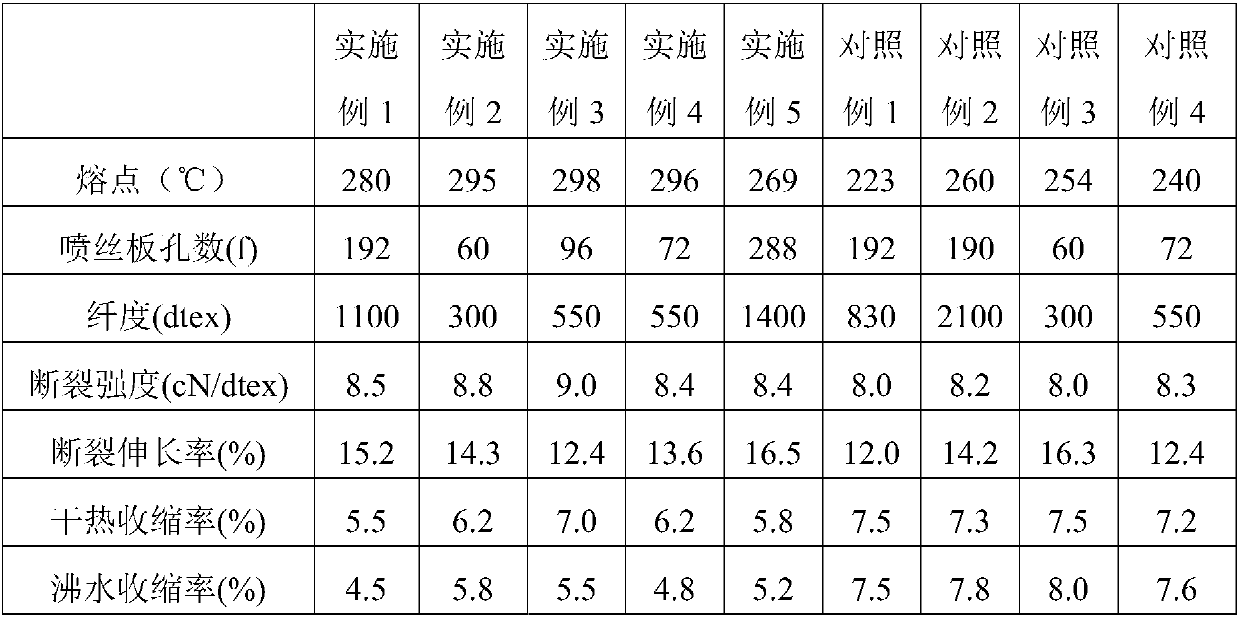

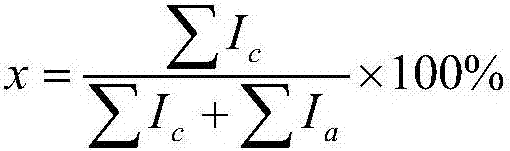

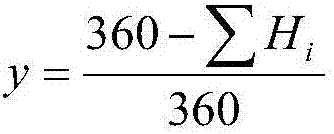

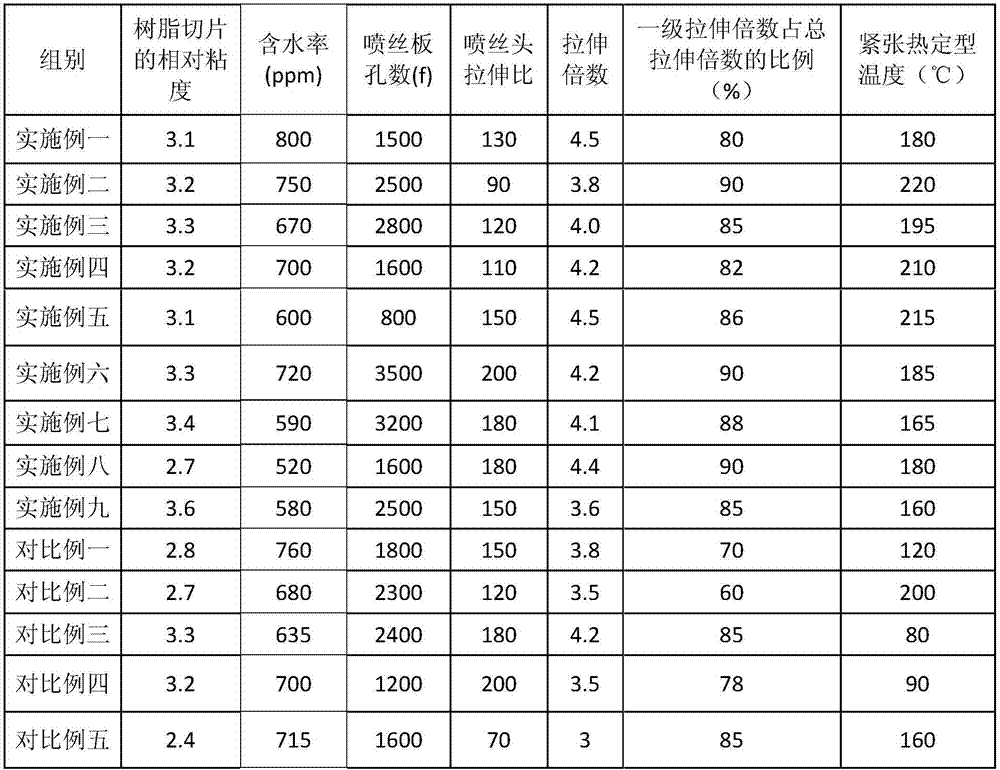

Copolyamide industrial yarn and preparation method thereof

PendingCN109930230AIncrease draft ratioHigh breaking strengthFilament/thread formingArtifical filament manufactureSolid phasesChemistry

The invention provides a copolyamide industrial yarn and a preparation method thereof. The copolyamide industrial yarn is prepared by polymerizing raw materials including a monomer, the monomer includes 1, 5-pentanediamine, a first dibasic acid and a second dibasic acid, wherein the first dibasic acid is terephthalic acid; the preparation method of the copolyamide industrial yarn comprises the following steps: 1) preparing the raw materials into a mixed solution; 2) polymerizing, granulating and solid-phase-tackifying the mixed solution to obtain tackifying copolyamide resin, and heating and melting the tackifying copolyamide resin to obtain tackifying copolyamide melt; 3) spinning the tackified copolyamide melt to obtain virgin yarn; 4) carrying out cooling, oiling, stretching and windingforming on the virgin silk to obtain the copolyamide industrial yarn. The copolyamide industrial yarn has good high temperature resistance and thermal stability.

Owner:CATHAY WUSU BIOMATERIAL CO LTD +2

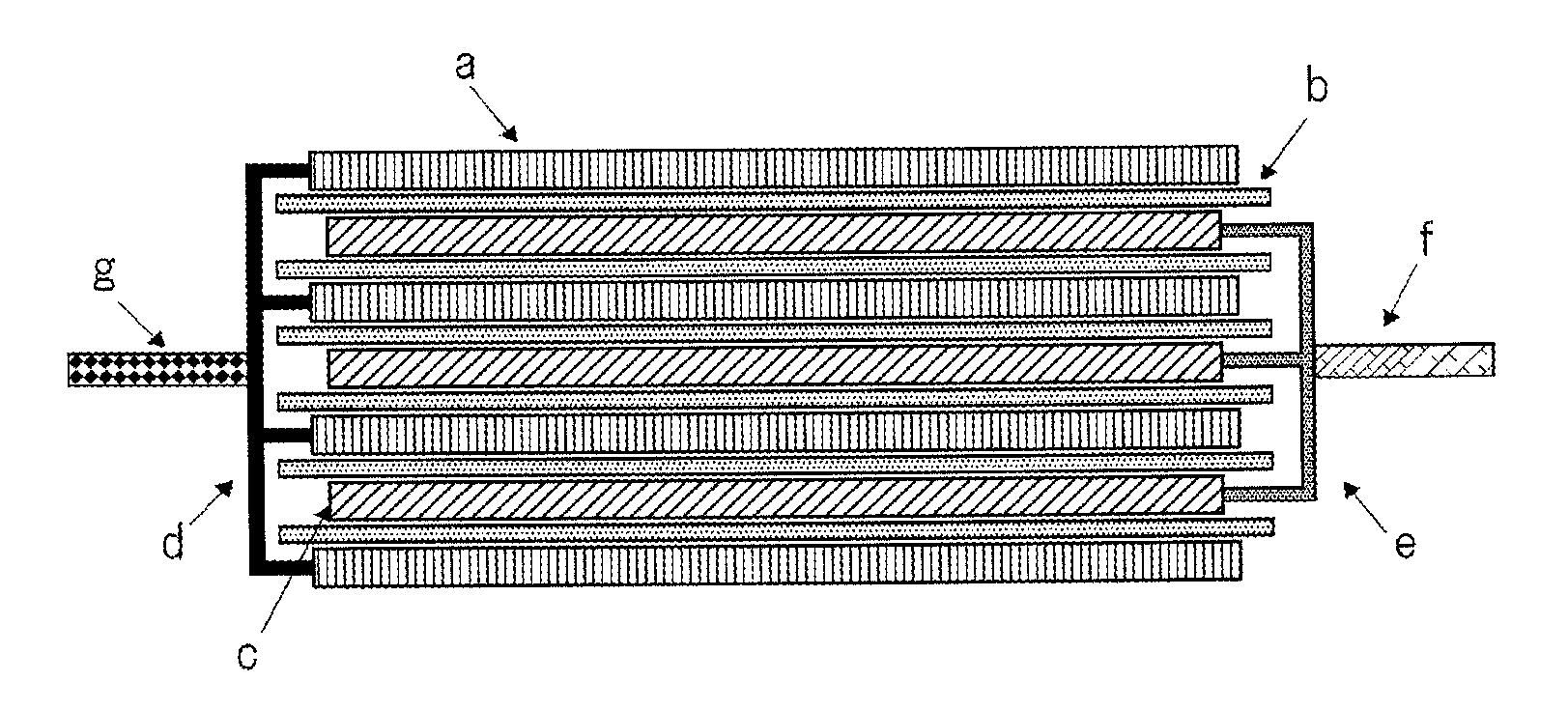

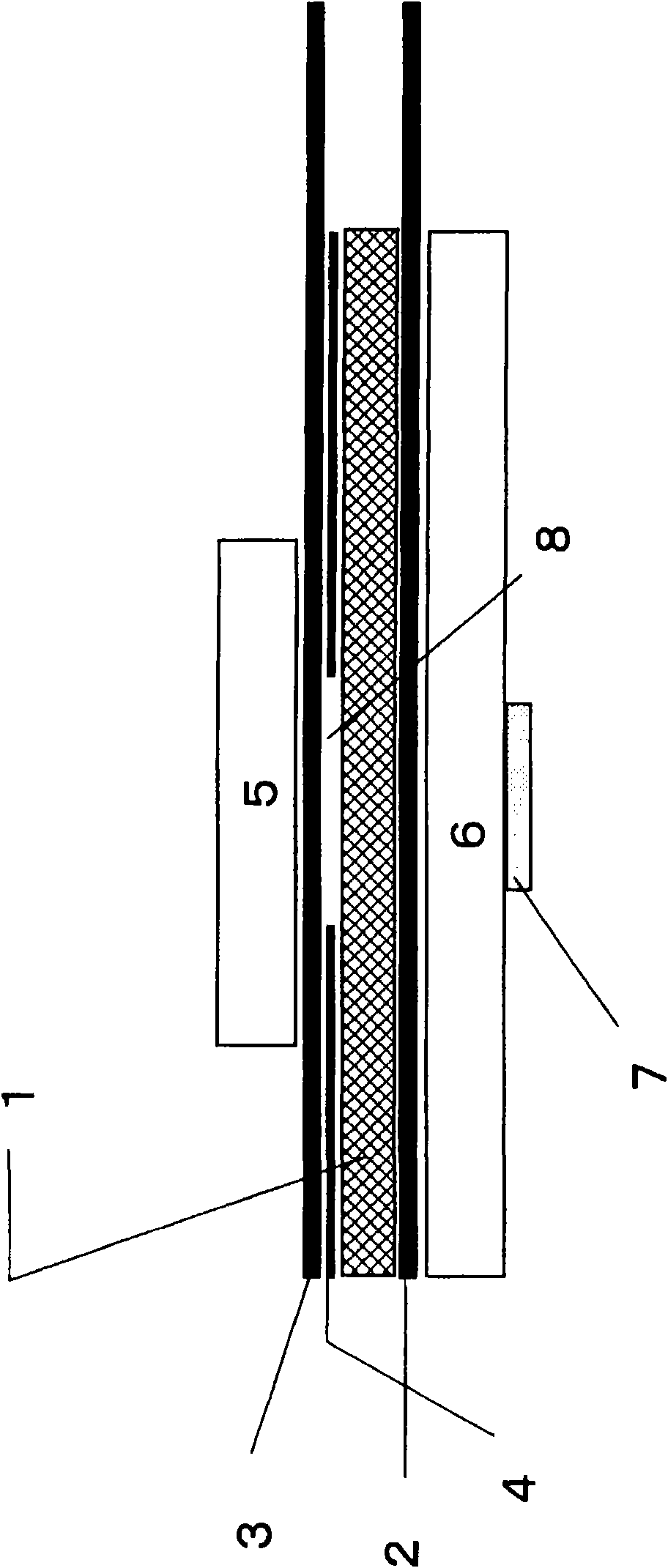

Lithium ion battery and combination electrode used for the same and production method thereof

ActiveCN101246958AGood compatibilityGood diaphragm wettingElectrode manufacturing processesSecondary cellsSolubilityHydrophilic monomer

The present invention relates to compound electrode slices applied in lithium ion battery and producing method thereof, which belongs to fields of battery production, in order to provide a new septum and cathode two-in-one electrode slices. The provided compound electrode slices is polymer colloid latex initiated, grafted and copolymerized by 1-5 portion initiator in aqueous solution containing 100 portion water-solubility polymer by 30-500 portion hydrophobic monomer and 0-200 portion hydrophilic monomer. Counted as that the solid content in the polymer colloid latex is 100%, the inorganic filler of 0-100% and the plasticizer of 20-100% are added, and the slurry is coated on the carbon cathode slice which is obtained by drying. The electrode slices has good heat stability and electrochemistry stability, super water absorptivity and rapid water absorption speed, and keeps higher water absorptivity in whole circle service life period. The battery has credible safety and circle service life, and the present invention provides a new thinking for lithium ion battery fields.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

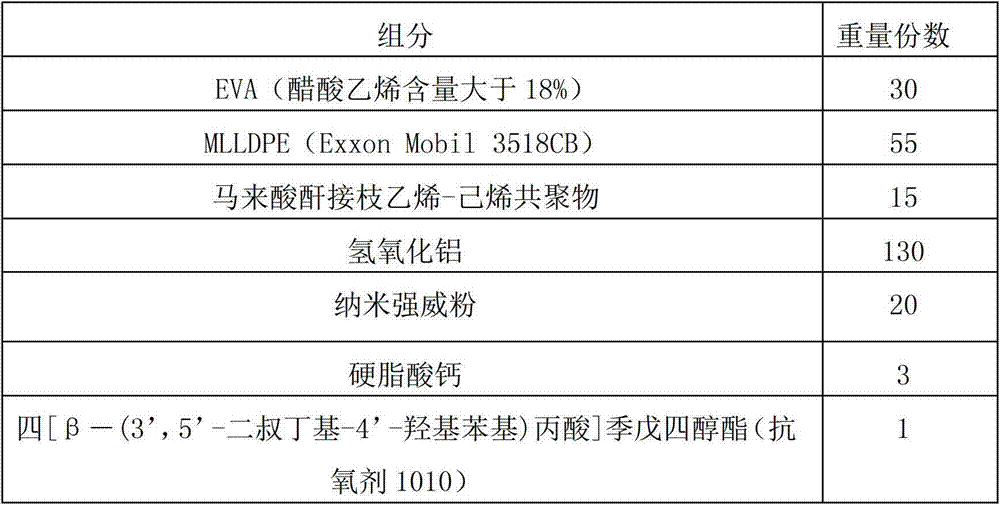

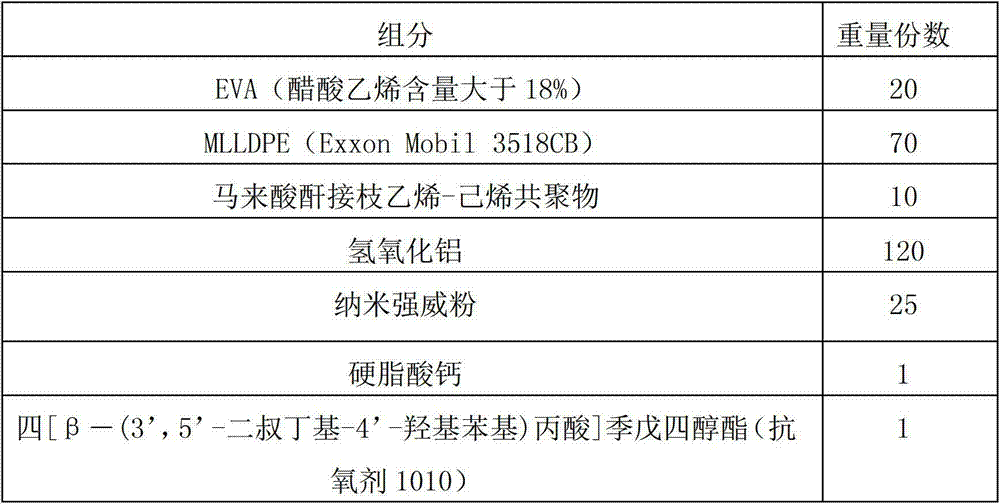

Nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and preparation thereof

ActiveCN103205053AImprove toughnessHold powder wellPlastic/resin/waxes insulatorsInsulated cablesPolyolefinAntioxidant

The invention relates to a cable material, and in particular relates to a nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and a preparation method thereof. The polyolefin cable material comprises the following components: EVA (Ethylene Vinyl-acetate Copolymer), MLLDPE (Linear Low-Density Polyethylene), an interfacial compatibilizer, aluminum hydroxide, nanometer strong micropowder, an antioxidant and a lubricant. The preparation method comprises the following steps of: evenly stirring the EVA and the MLLDPE as basic materials, the interfacial compatibilizer, the aluminum hydroxide, the nanometer strong micropowder, the antioxidant and the lubricant in a high-speed mixer; performing banburying in a banbury mixer at the temperature between 120 and 150 DEG C; extruding by using double screw rods; granulating by grinding and hot-cutting; conveying materials by using a cyclone separator; and screening by using a vibrating screen and packaging, thereby obtaining the finished nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material product. Compared with the common low-smoke halogen-free and flame-retardant polyolefin cable material, the polyolefin cable material provided by the invention has the effects that the thermal aging resistance is enhanced; the shrinkage performance of the product is improved greatly; and the problem that the low-smoke halogen-free polyolefin cable material is easy to shrink at the high temperature is solved.

Owner:JIANGSU LINRY NEW MSTAR TECH

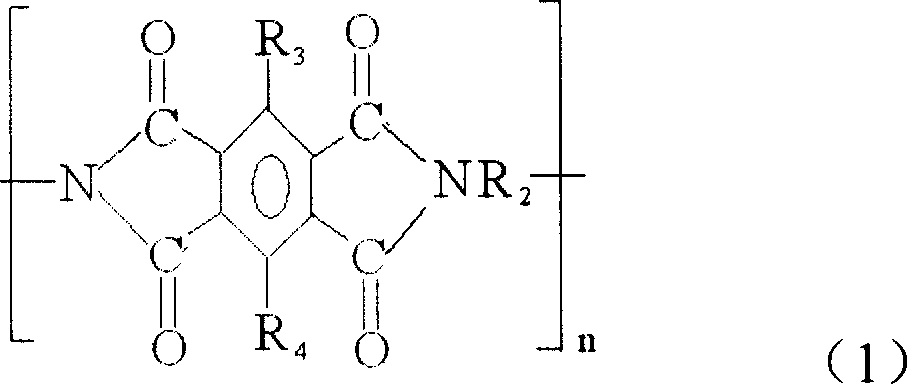

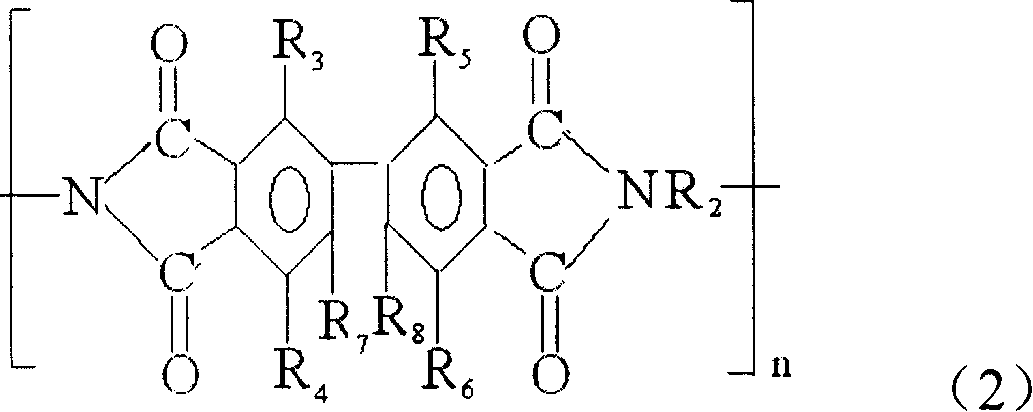

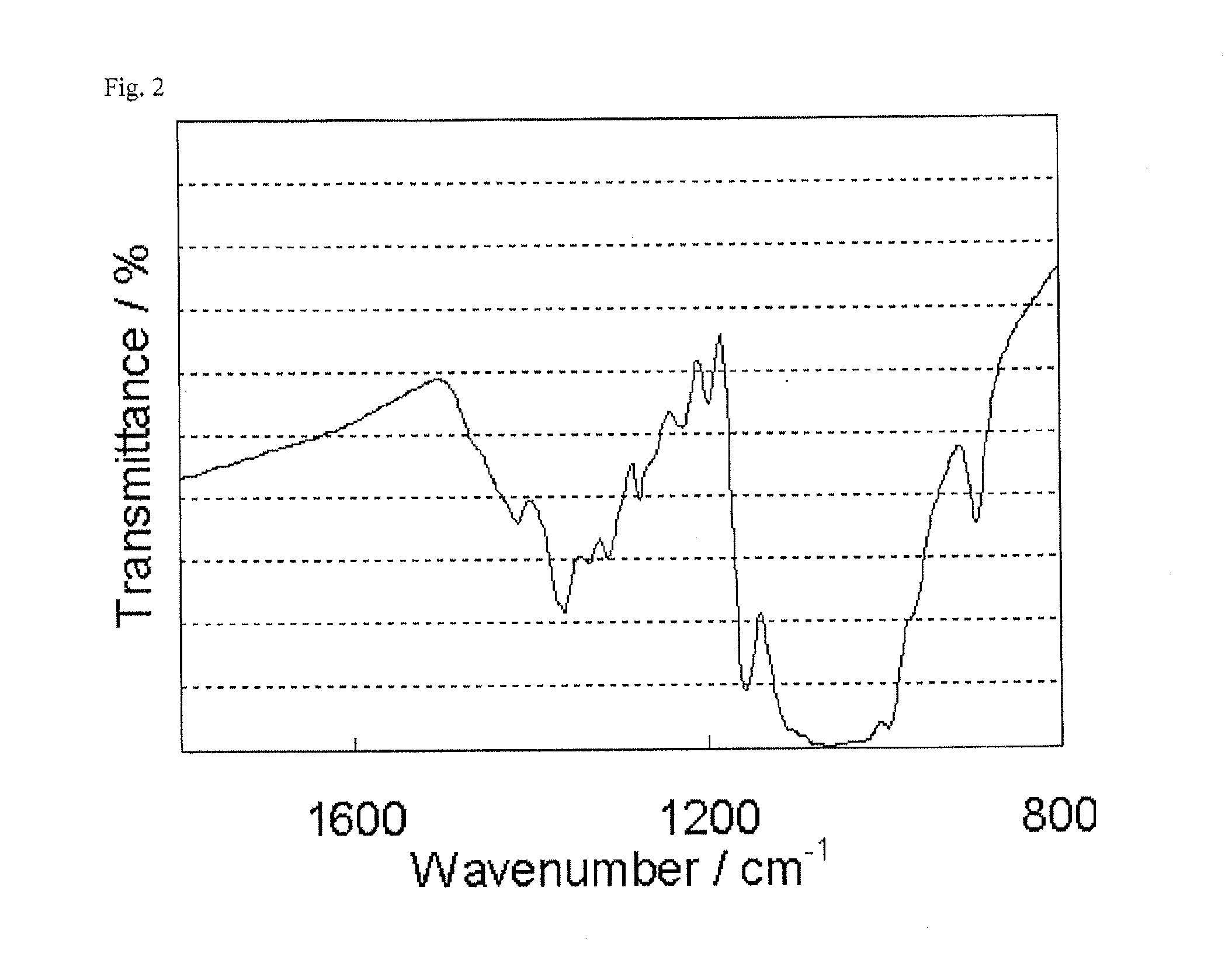

Separator for electronic component and method for producing the same

ActiveCN1661829AHigh mechanical strengthGood dimensional stabilityElectrolytic capacitorsPretreated surfacesVitrificationHeat resistance

The present invention provides an electronic component separator that allows for easy thickness reduction and also has excellent mechanical strength, dimensional stability and heat resistance. This electronic component separator contains in a porous film made of a synthetic resin with a glass transition temperature of 180° C. or above, filler grains having a melting point of 180° C. or above or virtually no melting point, and the electronic component separator is produced by way of applying onto a base a coating material comprising (a) a synthetic resin with a glass transition temperature of 180° C. or above, (b) filler grains having a melting point of 180° C. or above or virtually no melting point, (c) at least one good solvent capable of dissolving the synthetic resin, and (d) at least one poor solvent incapable of dissolving the synthetic resin, and then drying the coated base to form a porous film.

Owner:SUMITOMO CHEM CO LTD

Polyamide 5X short fiber as well as preparation method and application thereof

ActiveCN106958046AEmission reductionReduce the greenhouse effectSpinnerette packsArtificial filament heat treatmentFiberBreaking strength

The invention discloses a polyamide 5X short fiber, a preparation method and application thereof in preparing a sewing thread. The production raw material of the polyamide 5X short fiber at least includes 1,5-pentamethylene diamine and dicarboxylic acid or polyamide 5X acquired by polymerizing the monomers of 1,5-pentamethylene diamine and dicarboxylic acid. The breaking strength of the polyamide 5X short fiber is 6.0-10.0cN / dtex. The preparation method comprises the following steps: (1) polymerizing 1,5-pentamethylene diamine and dicarboxylic acid, thereby forming a polyamide 5X flux, or heating the polyamide 5X resin to molten state, thereby forming the polyamide 5X flux; (2) spinning the polyamide 5X flux, thereby forming a primary raw silk; and (3) treating the primary raw silk, thereby acquiring the polyamide 5X short fiber. The polyamide 5X short fiber has high strength, low elongation and low thermal contractility and especially can meet the requirement for the sewing thread.

Owner:CATHAY R&D CENT CO LTD +2

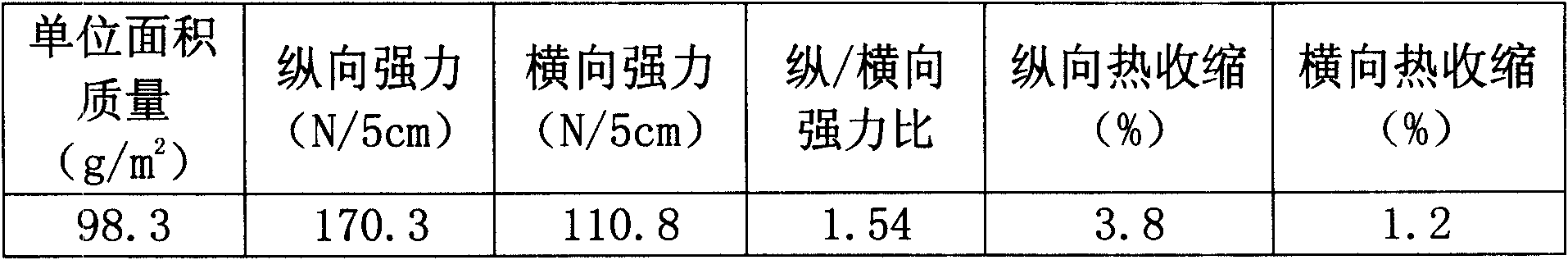

Polylactic acid non-weaving cloth with high strength and low thermal contraction and manufacture method thereof

InactiveCN101525812AHigh strengthSmall thermal shrinkageFilament/thread formingNon-woven fabricsYarnPolymer science

A polylactic acid non-weaving cloth with high strength and low thermal contraction is manufactured by adopting a method taking polylactic acid slices as raw materials, wherein the polylactic acid has the L polylactic acid not less than 95 percent, the L lactic acid monomer not more than 5 percent, the melting point not lower than 160 DEG C and the melt index being 20-60g / 10min; the quality of the manufactured non-weaving cloth at a unit area is 15-120g / m<2>, the breaking strength value in one direction (longitudinal direction) is not smaller than 1.5 times of the quality of the non-weaving cloth at the unit area, the breaking strength value in the other vertical direction (horizontal direction) is not smaller than 1.1 times of the quality of the non-weaving cloth at the unit area, the strength ratio in the longitudinal direction and the horizontal direction is smaller than 2, and the dry thermal contraction coefficient is 120 DEG C and is not larger than 5 percent in the 10min state. A high-speed airflow spray head is adopted to stretch to improve the degree of orientation of a continuous yarn so as to obtain enough fibre strength; and rolling mill line pressure higher than 100N / mm and roller temperature of 125-157 DEG C are adopted so as to obtain the optimal bond strength.

Owner:温州昌隆纺织科技有限公司 +1

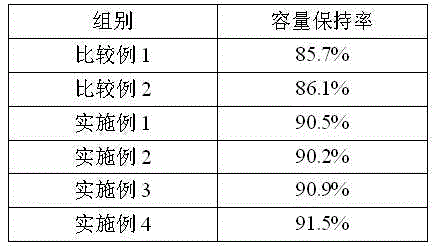

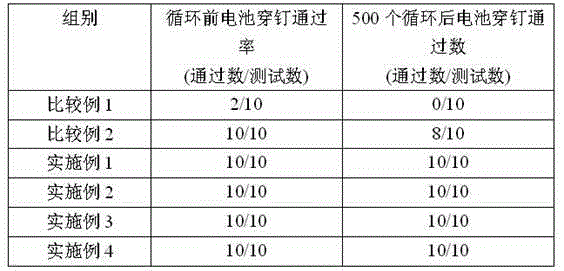

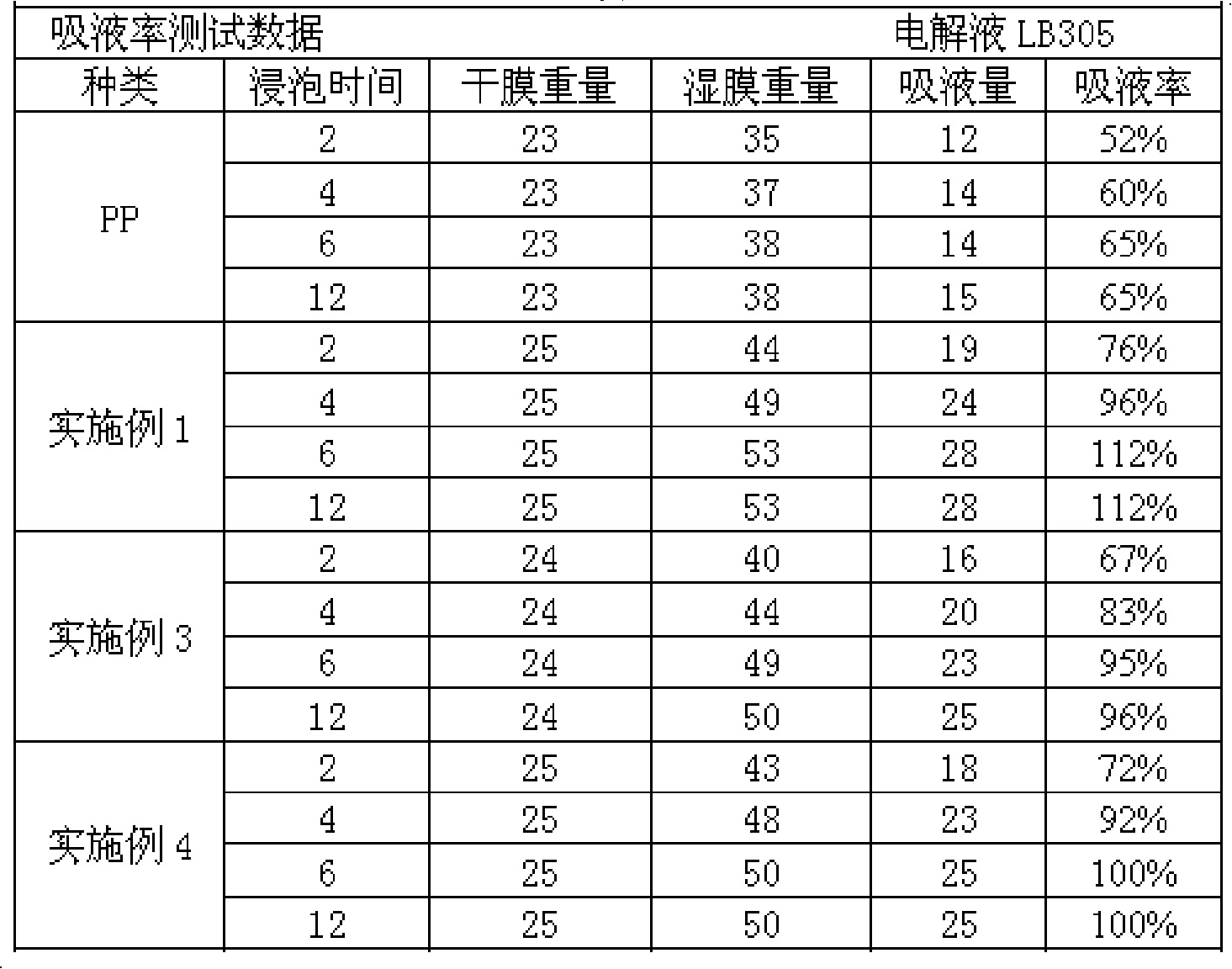

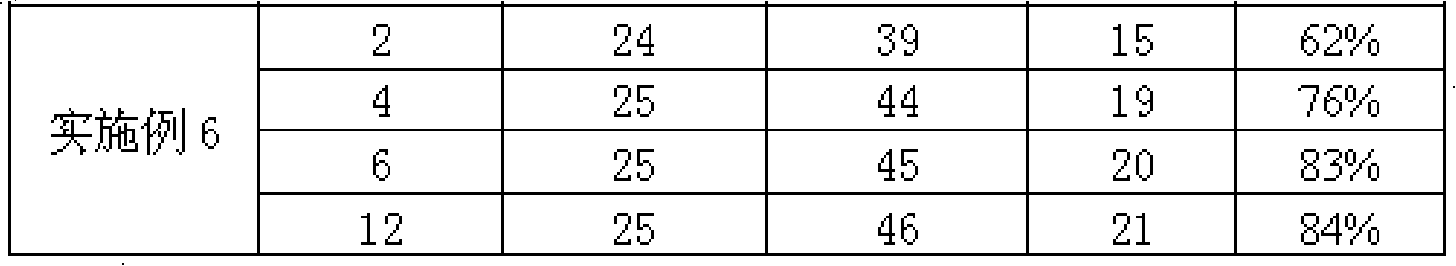

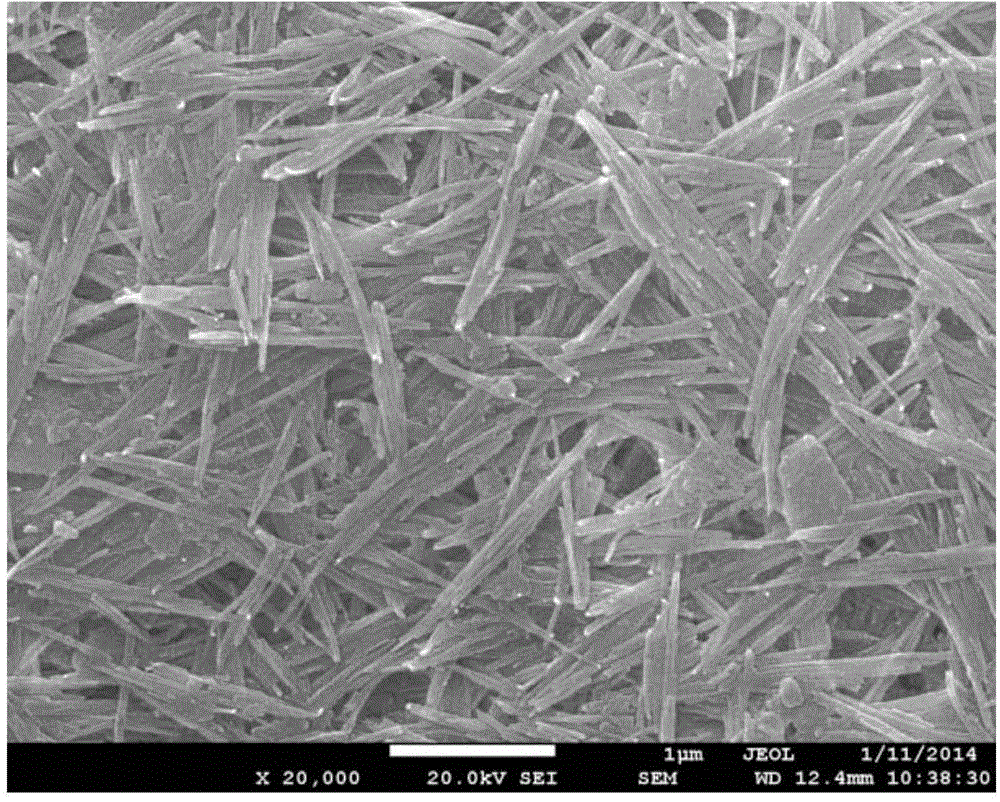

Polymer composite membrane as well as preparation method and lithium ion battery with same

InactiveCN107785519AImprove high temperature resistanceSmall thermal shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufacturePolymer sciencePolymer composites

The invention relates to the field of lithium ion batteries, discloses a polymer composite membrane as well as a preparation method thereof, and further discloses a lithium ion battery with the polymer composite membrane. The polymer composite membrane comprises a porous base membrane and a thermal-resistant fiber layer, wherein the surface of at least one side of the porous base membrane is covered with the thermal-resistant fiber layer; the thermal-resistant fiber layer is made of a material containing a first high polymer material and a second high polymer material simultaneously; the firsthigh polymer material is a thermal-resistant high polymer material of which the melting point is 180 DEG C or greater; the melting point of the second high polymer material is lower than that of thefirst high polymer material; the liquid absorption capacity of the second high polymer material in electrolyte of 25 DEG C is 40% or greater, with the error of + / -5%. Due to adoption of the first highpolymer material and the second high polymer material, the high temperature stability and the mechanical properties of the polymer composite membrane under high temperature conditions can be improved.

Owner:BYD CO LTD

Separator for electric storage device and electric storage device

InactiveUS20130330637A1Small thermal shrinkageSuppresses battery temperature riseHybrid capacitor separatorsNon-aqueous electrolyte accumulator electrodesPhosphateEngineering

The object of an exemplary embodiment of the invention is to provide a separator for an electric storage device which has small thermal shrinkage under high-temperature environment, and in which the increase of the battery temperature can be suppressed. An exemplary embodiment of the invention is a separator for an electric storage device, which comprises a cellulose derivative represented by a prescribed formula. The separator for an electric storage device can be obtained, for example, by treating a cellulose separator containing cellulose with a phosphate or a phosphite.

Owner:NEC CORP

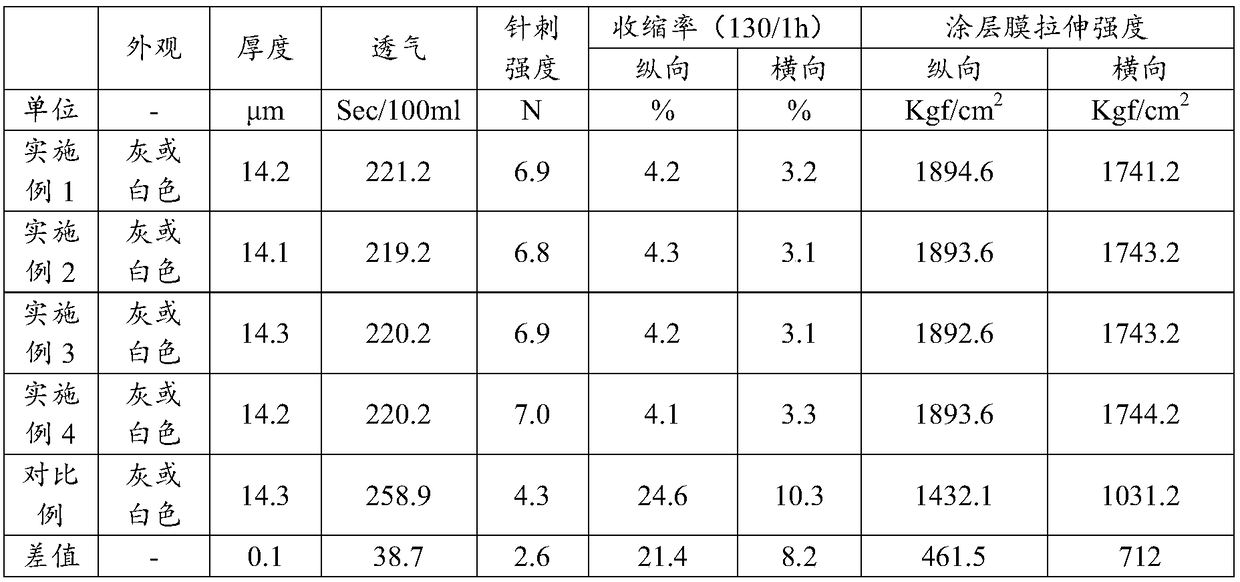

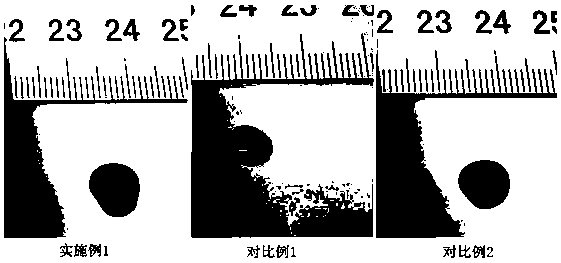

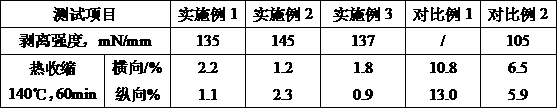

Aramid dissolved solution and preparation method of aramid dissolved solution as well as aramid membrane coating solution and production method of aramid membrane coating solution, and membrane

InactiveCN108864930AEasy to operateImprove heat shrinkageCell component detailsPolyamide coatingsOrganic solventFiltration

The invention relates to the technical field of coating, and particularly relates to an aramid dissolved solution and a preparation method of the aramid dissolved solution as well as an aramid membrane coating solution and a production method of the aramid membrane coating solution, and membrane. The production method of the aramid membrane coating solution comprises the following steps: adding apore-forming agent into the aramid dissolved solution; performing uniform stirring to obtain a first dispersion solution; adding ceramic material granules into an organic solvent to obtain the seconddispersion solution; uniformly mixing and stirring the first dispersion solution the second dispersion solution; performing filtration and discharging. The method has the advantages of simple preparation and strong feasibility. According to the method, dissolved meta-aramid is adopted, so that the cost is reduced, the original viscosity and property of the meta-aramid membrane coating solution arekept to the maximum limit, the performance of the aramid membrane coating solution is improved, a heat shrinkage ratio at 130 DEG C is reduced by 8 to 10 percent, the acupuncture strength is improvedby 4 to 5 percent, the air permeability is reduced by 5 to 8 percent, and the tensile strength is increased by 4 to 5 percent.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Preparation method of heat-resistant lithium battery diaphragm

ActiveCN108467503AImprove adhesionLess prone to dusting problemsFireproof paintsSecondary cellsWater basedAdhesive

The invention discloses a preparation method of a heat-resistant lithium battery diaphragm. The preparation method comprises the steps that an inorganic material and a dispersing agent are added intodeionized water, and the mixture is ground to obtain a uniform solution; then a suspension stabilizer, a defoaming agent, a wetting agent, a surfactant, a first adhesive and a second adhesive are added, low-speed dispersing is carried out, and water-based ceramic slurry is obtained; after a base diaphragm is coated with the slurry, the heat-resistant lithium battery diaphragm is obtained. The diaphragm has a relatively good liquid absorption rate, peel strength and thermal stability.

Owner:瑞固新能(上海)材料科技有限公司

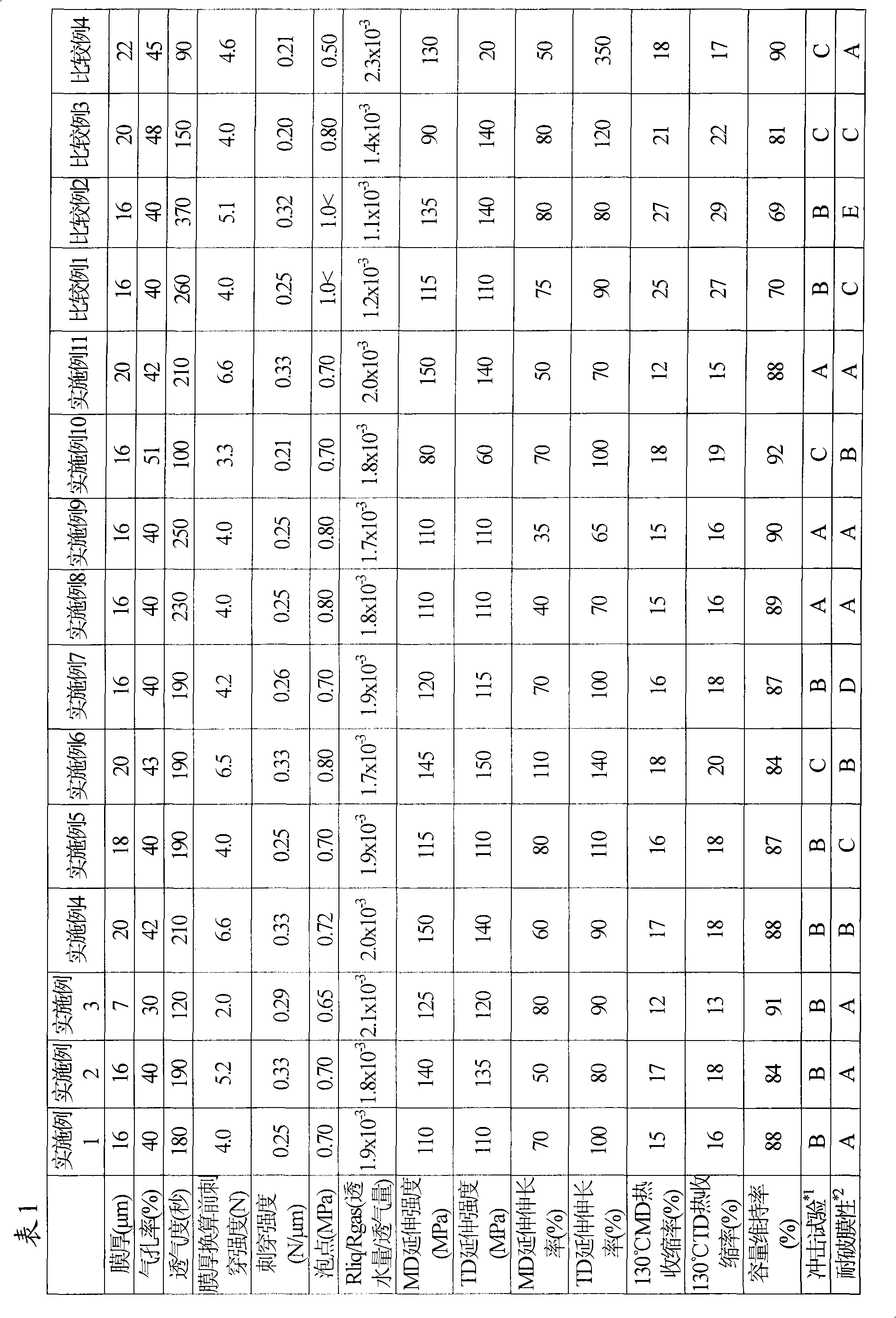

Polyolefin microporous membrane

ActiveCN101568575AExcellent strength and low heat shrinkageImprove battery characteristics and battery safetyLi-accumulatorsCell component detailsLarge porePolyolefin

Disclosed is a polyolefin microporous membrane having a bubble point of not more than 1 MPa, a tensile strength in the longitudinal direction of not less than 50 MPa, a tensile strength in the width direction of not less than 50 MPa, and a thermal shrinkage in the width direction at 130 DEG C of not more than 20%. This polyolefin microporous membrane is excellent in strength and low thermal shrinkage property, while having a large pore diameter.

Owner:ASAHI KASEI KK

Separator comprising a porous layer and method for producing said separator

ActiveCN104115306AHigh porosityGood dimensional stabilitySecondary cellsCell component detailsPorous layerLithium-ion battery

The invention relates to a separator for an electrochemical cell, preferably a lithium-ion battery, comprising a porous layer, which comprises at least one block copolymer having three or more polymer blocks and at least one aluminum oxide or aluminum hydroxide, to a lithium-ion battery having such a separator, and to a method for producing such a separator.

Owner:SIHL

Electrospinning technique-based ceramic diaphragm and preparation method thereof

InactiveCN106638007AHigh porosityThe overall thickness is thinSynthetic fibresSecondary cellsPorosityElectrospinning

The invention discloses an electrospinning technique-based ceramic diaphragm and a preparation method thereof. The preparation method comprises the steps of using a spinning nanofiber layer as a base membrane, and then coating / cast coating the base membrane with ceramic slurry or a ceramic precursor solution so as to obtain the final product. The ceramic diaphragm prepared by the method is high in porosity, thin in thickness and good in ion permeability; ceramic particles are introduced into the ceramic diaphragm, so that the thermal contraction of the ceramic diaphragm is greatly reduced, and the high temperature resistance of the ceramic diaphragm is improved.

Owner:烟台森森环保科技有限公司

Separator, battery using the same, and method for manufacturing separator

ActiveCN101339980AAvoid Secondary DefectsSmall thermal shrinkageOrganic electrolyte cellsSecondary cellsViscous liquidWater baths

The invention relates to a separator, a battery using the separator and a method for manufacturing the separator. The invention provides a separator comprising: a covering layer in which a fine framework of polyolefin resin is coated with a glass layer. The invention also provides a battery comprising a cathode, an anode, an electrolyte, and the separator having the covering layer in which the fine framework of polyolefin resin is coated with the glass layer. A method for manufacturing the separator is also provided, including the step of: coating a precursor containing viscous liquid productwhich contains only polysilazane compound or a mixture of viscous liquid product which contains only polysilazane compound with polycarbosilazane compound to the polyolefin resin, placing the precursor applied polyoleline resin in a water bath to dry, such that a fine framework of polyolefin resin is coated with the glass layer. The inventive proposal reduces heat contractibility of the separatorand acquires excellent electrolyte soakage performance without impairing ionic conductivity.

Owner:MURATA MFG CO LTD

Polymer composite film and preparation method thereof, and lithium ion battery comprising polymer composite film

InactiveCN107799703AImprove high temperature resistanceSmall thermal shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberElectrolytic agent

The invention discloses a polymer composite film and a preparation method thereof, and a lithium ion battery comprising the polymer composite film. The polymer composite film comprises a polymer basefilm, which comprises a first surface and a second surface, wherein the first surface and the second surface are oppositely arranged, the polymer composite film further comprises a first ceramic layer, a first heat-resistant fiber layer and a first adhesion layer, the first ceramic layer, the first heat-resistant fiber layer and the first adhesion layer are sequentially arranged on the first surface of the polymer base film from inside to outside, the materials of the first heat-resistant fiber layer simultaneously contain a first macromolecule material and a second macromolecule material, thefirst macromolecule material is a heat-resistant macromolecule material with a melting point of more than 180 DEG C, the melting point of the second macromolecule material is lower than the melting point of the first macromolecule material, the liquid absorption rate of the second macromolecule material in a 25 DEG C electrolyte is more than 40%, and the error is + / -5%. According to the present invention, by simultaneously using the first macromolecule material and the second macromolecule material, the high temperature stability and the mechanical property under the high temperature condition can be easily improved.

Owner:BYD CO LTD

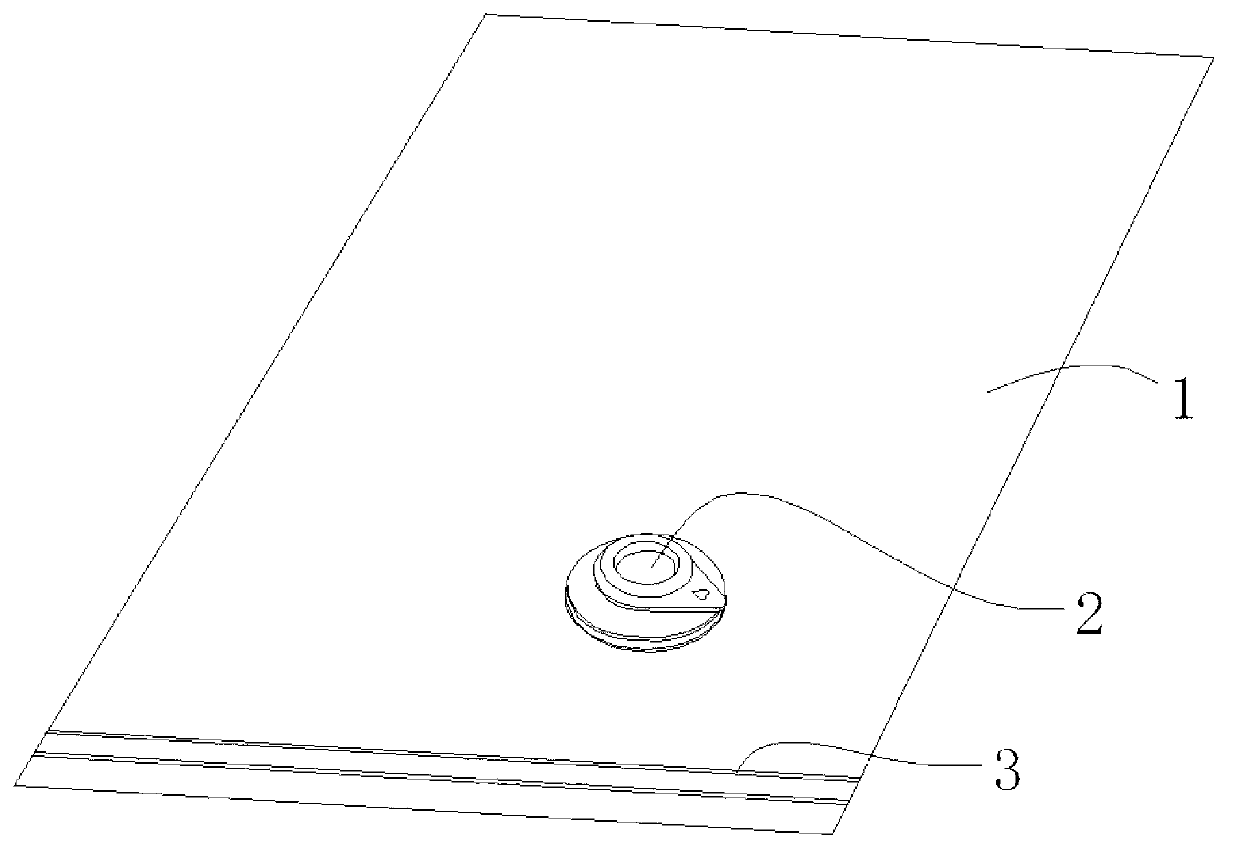

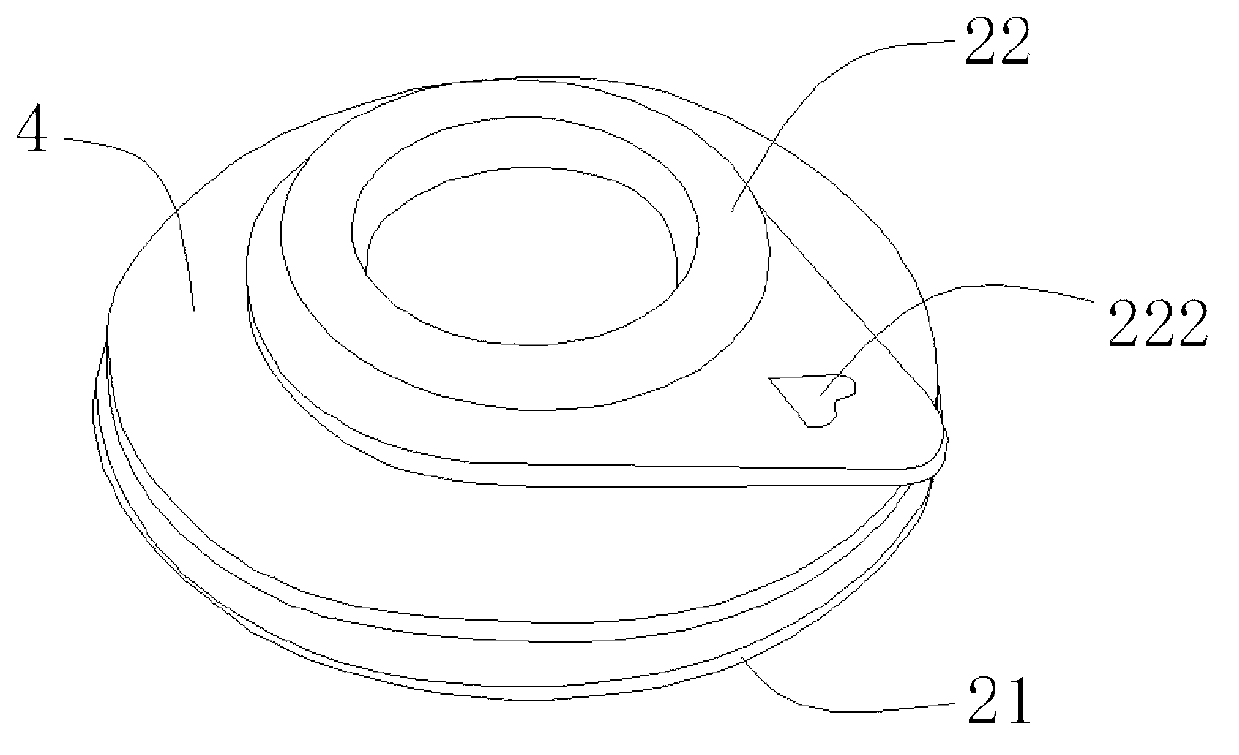

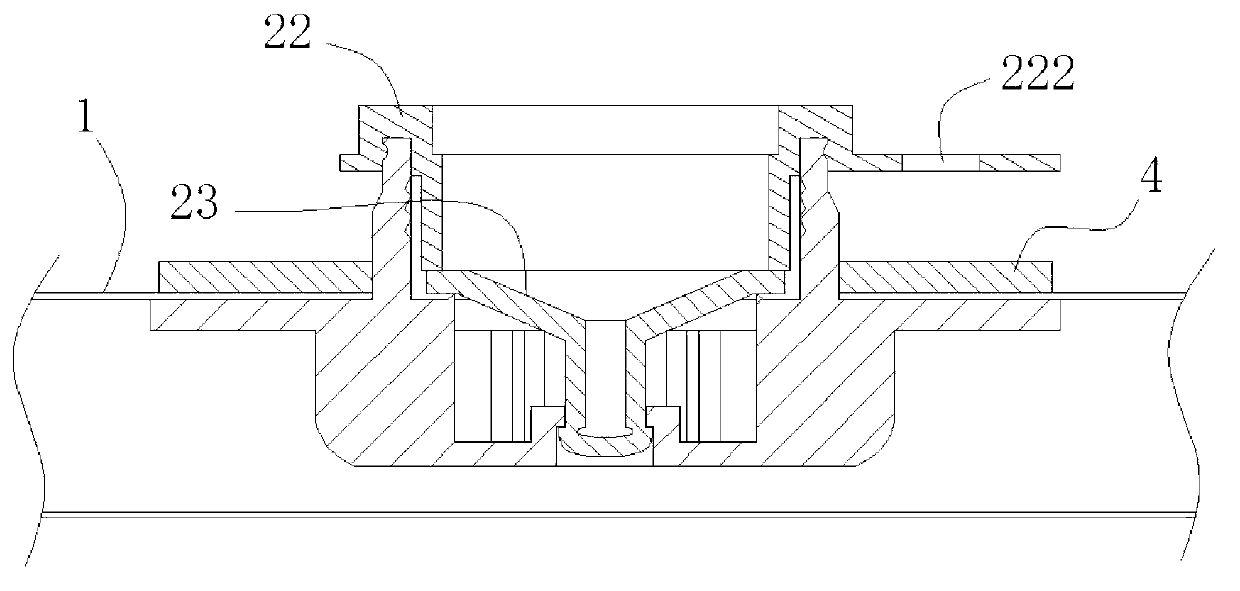

Vacuum bag manufacturing method and product of the same

The invention discloses a vacuum bag manufacturing method, and further discloses a product obtained by adopting the method. The vacuum bag manufacturing method and the product of the vacuum bag comprise a bag body and a vent valve. The vent valve comprises a valve seat, a valve cover and a cone-shaped soft plug. The method is easy in manufacturing procedure, easy to realize, and capable of being used for quickly manufacturing the vacuum bag product which is good in sealing effect and convenient to use. The vacuum bag product is ingenious and reasonable in structural design. The cone-shaped soft plug and an opening of an accommodating cavity are matched for sealing air, an operator just needs to cover the valve cover to ensure that the cone-shaped soft plug is tightly attached on the opening, and accordingly sealing effects are achieved. The valve cover is plugged out to ensure that air freely enters and leaves the bag body to bring convenience to air pumping and use. Furthermore, a flange is arranged on the opening to further strengthen sealing effects, and articles can be beneficially stored for a long period. A bag opening can be quickly opened or sealed through concave-convex seals. The vacuum bag manufacturing method and the product of the vacuum bag are convenient to use and simple and easy to operate, bring great convenience to the steps of taking and putting the articles and life of people, and facilitate wide promotion and applications.

Owner:广东树业环保包装有限公司

A kind of hydrophilic base cloth and its manufacturing method

InactiveCN102277690AHigh bonding strengthMeet high performance requirementsPaving reinforcementsNon-woven fabricsGramUltimate tensile strength

The invention discloses hydrophilic base fabric with high tensile strength and good water permeability. The hydrophilic-group fabric is characterized in that the gram weight per unit area is 100-280g / m<2>, the thickness is 0.4-1.0mm, the tensile strength is 4000-14000N / m, the tearing strength is 130-450N, and the vertical permeation coefficient is 0.1-1.0cm / s. The manufacturing method of the hydrophilic base fabric comprises the steps of: raw material processing, net forming, impregnating and bonding, drying and sizing. The product of the hydrophilic base fabric has the characteristics of high strength, good hydrophilcity, small thermal contractibility, easiness for impregnation and the like, has high bonding strength with modified asphalt, is easy for construction, and completely meets the requirements of high-grade highways on high performance of materials.

Owner:HUNAN NONWOVEN CNNC

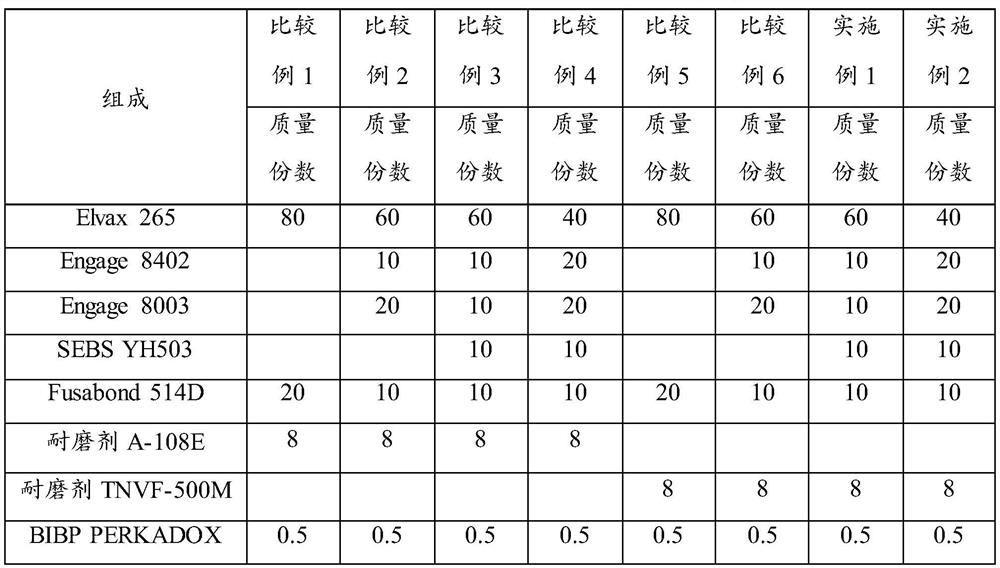

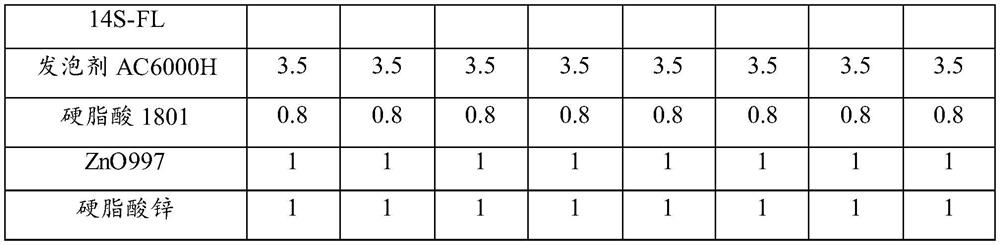

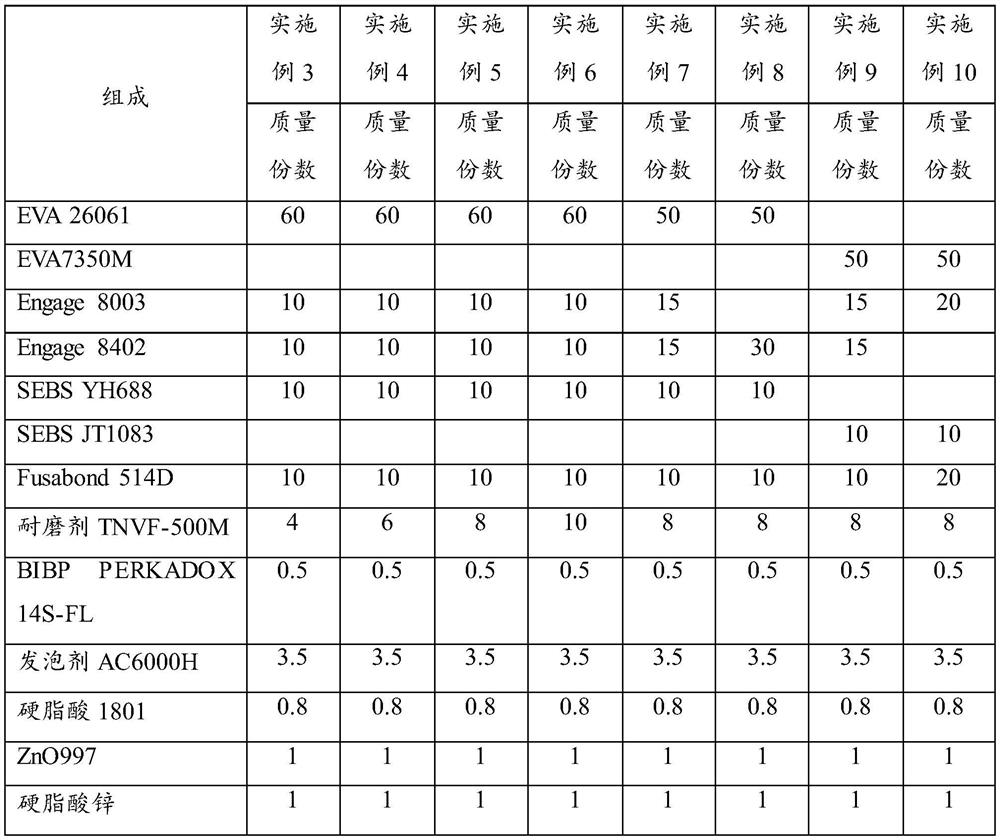

Lightweight, extremely-elastic and fatigue-resistant foam material and preparation method thereof

The invention provides a lightweight, extremely-elastic and fatigue-resistant foam material and a preparation method thereof. The foam material comprises 40-60 parts of EVA, 20-40 parts of POE, 5-20 parts of SEBS, 0-20 parts of an ethylene-methacrylic acid copolymer, 4-10 parts of a vinyl silicone oil wear-resistant agent, 0.5-0.7 part of a peroxide cross-linking agent, 3-4 parts of a foaming agent, 1 part of zinc oxide, 0.8 part of stearic acid and 1 part of zinc stearate. A polymer with high melt strength, a polymer with high molecular chain flexibility and a wear-resistant agent with a cross-linkable structure are introduced into the EVA, and the polymer with high melt strength improves the mechanical properties and fatigue resistance of the foam material and guarantees normal foaming of the material at a high rate; the resilience is improved by the macromolecular chain flexible polymer; and the wear-resistant agent improves the wear resistance, reduces the influence of the wear-resistant agent on the permanent compression deformation of the material, and reduces the thermal shrinkage of foaming through secondary compression molding, thereby obtaining the lightweight high-elasticity foaming material with favorable wear resistance and fatigue resistance.

Owner:ANTA CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com