Lightweight, extremely-elastic and fatigue-resistant foam material and preparation method thereof

A foaming material and fatigue technology, applied in the field of lightweight extremely elastic and fatigue-resistant foaming materials and their preparation, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

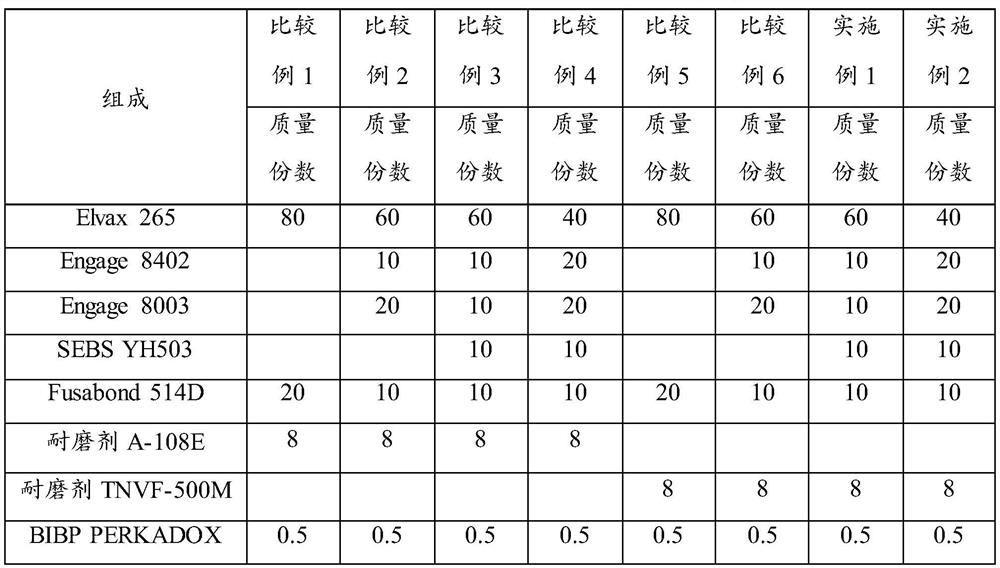

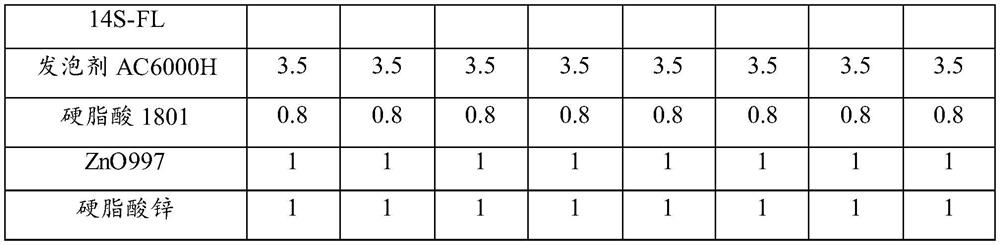

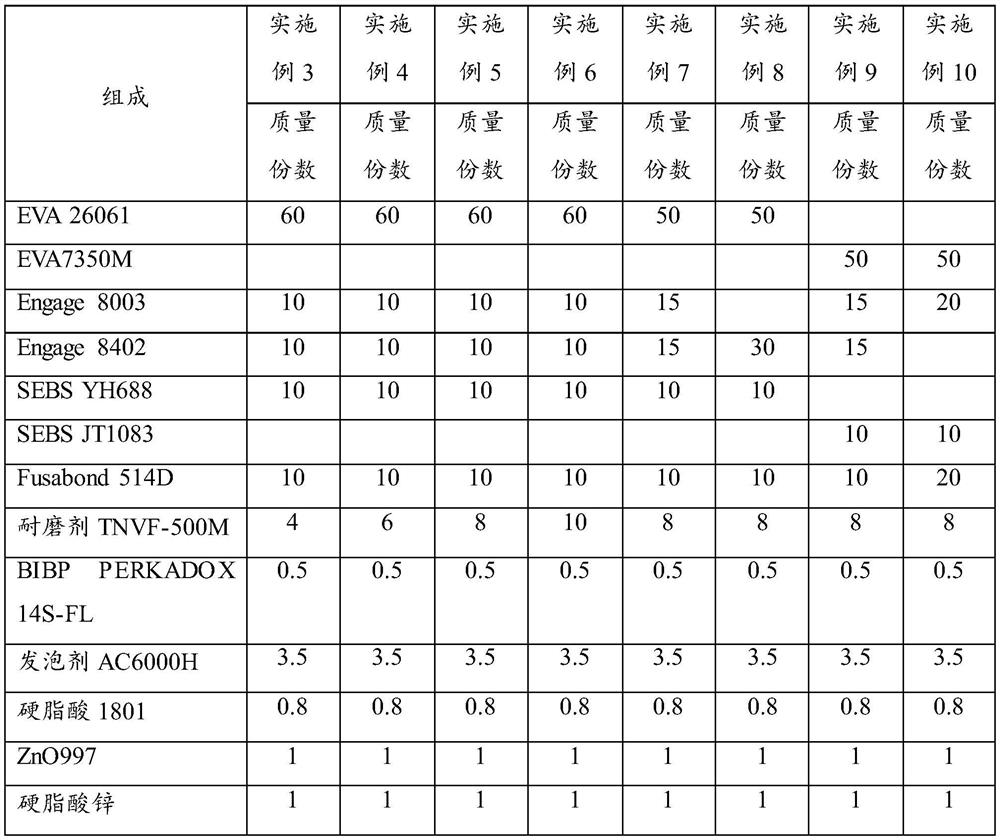

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a method for preparing a lightweight, extremely elastic and fatigue-resistant foaming material described in the above technical solution, comprising the following steps:

[0048] Mix ethylene-vinyl acetate copolymer, ethylene-octene random copolymer, SEBS and ethylene-methacrylic acid copolymer first, then add zinc oxide, stearic acid, zinc stearate and Vinyl silicone oil wear-resistant agent, then heat up to 85-95°C, add peroxide cross-linking agent and foaming agent, and wait until the temperature is raised to 100-105°C to obtain a mixture;

[0049] Granulating the mixed material to obtain pellets;

[0050] Vulcanize and foam the pellets at 172-178°C for 655-665 seconds to obtain a semi-finished product;

[0051] The semi-finished product is left to cool for 22-25 hours, then hot-pressed at 170-180° C. for 410-430 seconds, the compression ratio during hot-pressing is 1.5-1.6, and cooled to obtain a lightweight, extremely elastic and fat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com