Composite ceramic coating, lithium ion battery composite ceramic diaphragm and lithium ion battery

A technology of lithium-ion batteries and composite ceramics, which is applied in the field of composite ceramic coatings and lithium-ion battery composite ceramic diaphragms, can solve the problems of reducing battery energy density, increasing battery manufacturing costs, overcharging and overdischarging, and improving battery overcharging , Improve the safety performance of abuse and prevent overcharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

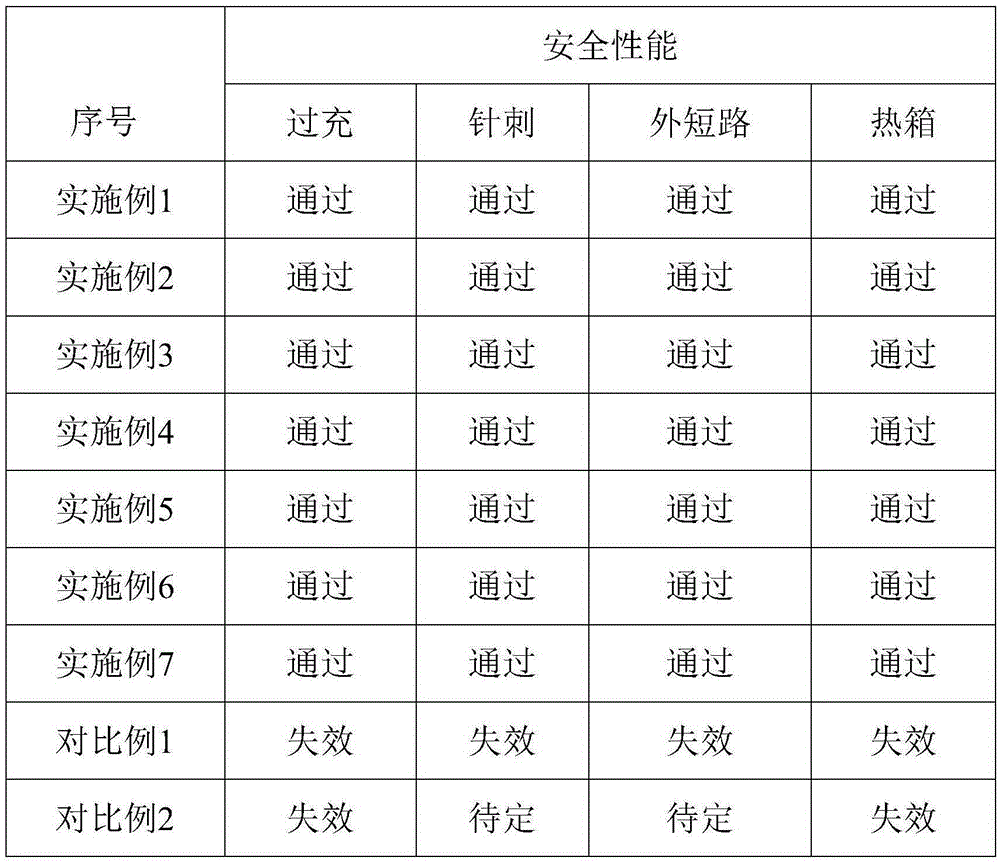

Examples

Embodiment 1

[0033] Preparation of positive electrode sheet: Mix nickel-cobalt lithium manganese oxide, conductive carbon, and binder (polyvinylidene fluoride) in N-methylpyrrolidone solvent at a mass ratio of 97:1.5:1.5 to make a positive electrode slurry, and then coat Clothed on aluminum foil and dried, then cold-pressed and slitting to make positive pole pieces.

[0034] Preparation of negative electrode sheet: Mix graphite, conductive carbon, dispersant (sodium carboxymethyl cellulose), and binder (styrene-butadiene rubber) in deionized water at a mass ratio of 95:1.5:2.0:1.5 to make negative electrode slurry Material, then coated on copper foil and dried, then cold pressed and slitting to make negative electrode sheet.

[0035] Preparation of ceramic diaphragm: Mix aluminum oxide, lithium carbonate, and sodium carboxymethyl cellulose in a mass ratio of 0.48:0.5:0.02, use deionized water as the dispersion medium, and prepare a slurry with a certain viscosity after high-speed stirring ...

Embodiment 2

[0039] The difference from Example 1 is that the preparation of the ceramic diaphragm: mix titanium dioxide, lithium bicarbonate, and sodium carboxyethyl cellulose in a mass ratio of 0.68:0.3:0.05, use deionized water as the dispersion medium, and stir at a high speed A slurry with a certain viscosity is prepared to obtain a composite ceramic coating, and the composite ceramic coating is coated on both sides of a PP base film with a thickness of 8um. The thickness of the composite ceramic coating is controlled at 4um, and then baked and cut into pieces. Ceramic separator for batteries.

[0040] The rest are the same as in Embodiment 1, and will not be repeated.

Embodiment 3

[0042]Different from Example 1, the preparation of the ceramic diaphragm: mix silicon dioxide, lithium carbonate, lithium bicarbonate, sodium carboxyethyl cellulose in a mass ratio of 0.28:0.35:0.35:0.1, and deionized water As a dispersion medium, a slurry with a certain viscosity is prepared by high-speed stirring to obtain a composite ceramic coating, and the composite ceramic coating is coated on one side of a PP / PP base film with a thickness of 10um, and the thickness of the composite ceramic coating is controlled at 8um. Then it is baked and cut into ceramic separators for batteries.

[0043] The rest are the same as in Embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com