Microporous polymer isolating film for Li-ion battery and method for producing the same

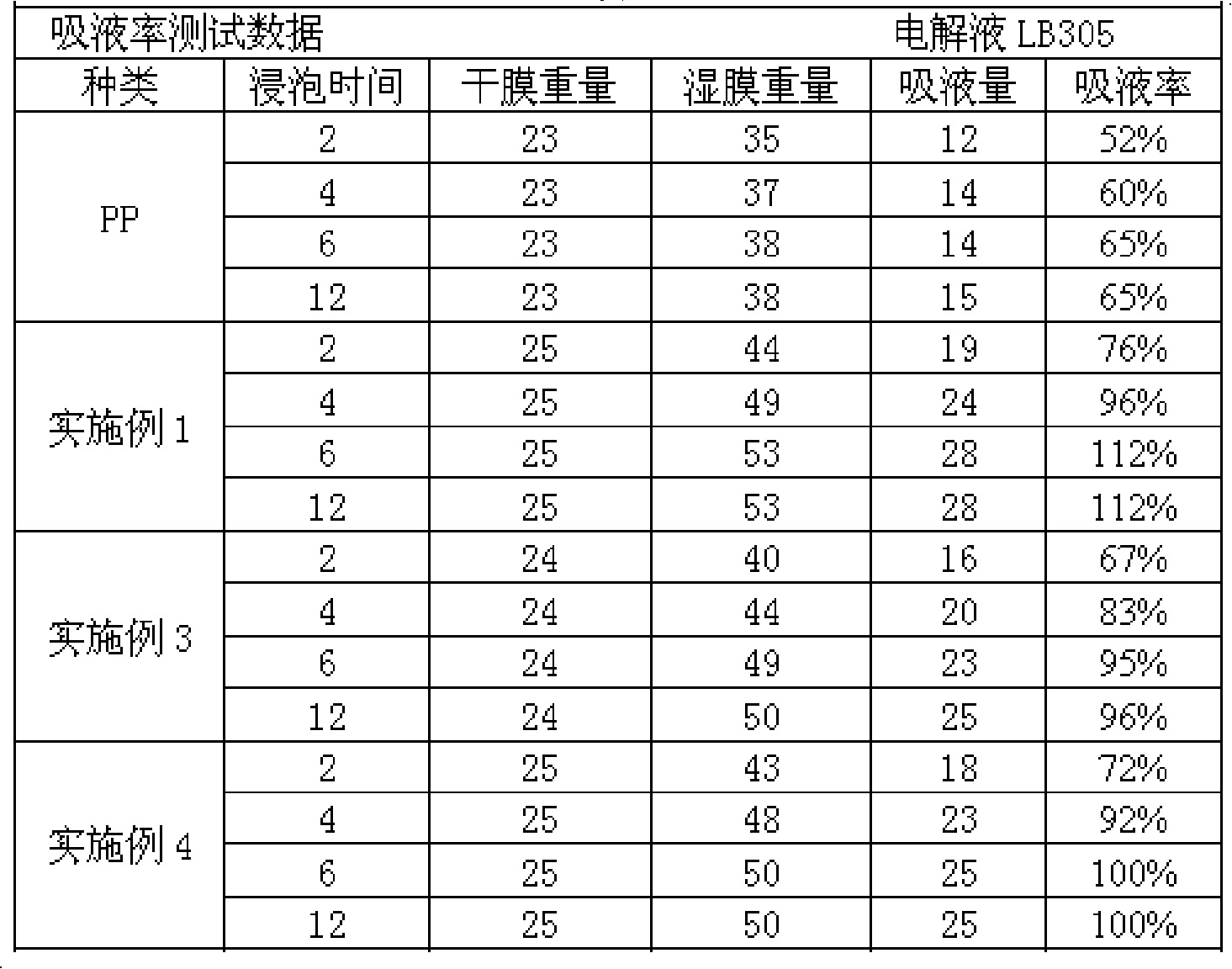

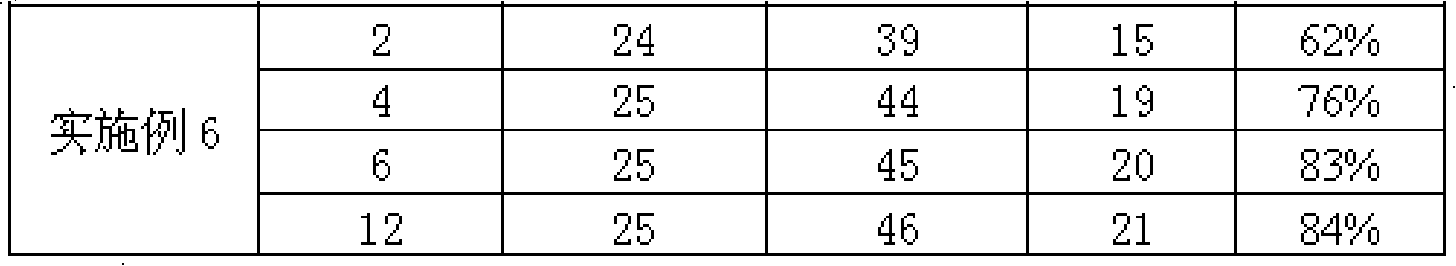

一种微孔聚合物、锂离子电池的技术,应用在二次电池、电池组零部件、非水电解质蓄电池等方向,能够解决膜片涂层凹凸不平、局部电压升高、电流分布不均等问题,达到吸液速度快、高吸液率、亲水性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Preparation of microporous polymer membrane of the present invention

[0037] Synthesis of the first step polymer colloidal emulsion

[0038] In this example, the hydrophilic polymer polyvinyl alcohol (PVA) 1750 and the lipophilic monomer vinyl acetate (VAC) / ethyl acrylate (EA) / acrylonitrile (AN) were grafted and copolymerized in the water phase to prepare Aqueous polymer emulsion for lithium battery diaphragm, its copolymer composition is PVA: VAC: EA: AN=10: 2: 2: 5 (weight ratio, the same below), the copolymer content is 17%, and the product is a white opaque emulsion .

[0039] The specific preparation method of the polymer emulsion is: in a four-port reaction vessel with condensed water, add 1000g of distilled water and 100g of polyvinyl alcohol (PVA) 1750; After 3 hours, when the material is transparent, it can be considered as complete dissolution, turn off the heating, and cool naturally to 55°C. Add 40g of a 1:1 blend of lipophilic monomer vinyl...

Embodiment 2

[0045] Example 2 Preparation of Microporous Polymer Diaphragm of the Present Invention

[0046] Synthesis of the first step polymer colloidal emulsion

[0047] The reaction steps are basically the same as in Example 1, except that the lipophilic monomer ethyl acrylate (EA) is replaced by acrylamide (AM) with good hydrophilicity, and its copolymer composition is PVA: VAC: AM: AN=10 :2:1:8.

[0048] The specific preparation method of the polymer emulsion is: all the monomers are added in a one-time feeding method, the material concentration is adjusted to about 13%, and the initiator is directly added, and the slurry quickly passes through the process of colorless-light blue-white milky, Faster than Example 1. After 12 hours of reaction, the material was discharged to obtain the polymer diaphragm emulsion for lithium batteries.

[0049] The second step slurry equipment

[0050] The proportion of the filler added is the same as in Example 1, and the materials are titanium dio...

Embodiment 3

[0053] Synthesis of the first step polymer colloidal emulsion

[0054] In this example, polyvinyl alcohol 1788 (PVA) is added with lipophilic monomer styrene (St) / butyl acrylate (Ba) / acrylonitrile (AN) to carry out ternary copolymerization in the aqueous phase to prepare a lithium battery separator The aqueous polymer emulsion, its copolymer composition is PVA: St: Ba: AN=10: 2: 4: 5 (weight ratio, the same below), the copolymer content is 17%, and the product is white opaque emulsion.

[0055] The polymer emulsion adopts step-by-step polymerization: in a four-port reaction vessel with condensed water, add 1000g of distilled water and 100g of polyvinyl alcohol (PVA) 1799, the reaction kettle is heated to 90 degrees, stirred and dissolved, and the speed is 100 rpm. After 3 hours, when the material is transparent, it can be considered that the dissolution is complete, turn off the heating, and cool naturally to the reaction temperature of 65°C. Add styrene (St) monomer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com