Composite diaphragm material and preparation method and application thereof

A composite diaphragm and film layer technology, applied in the field of materials, can solve problems such as easy clogging, loss of battery capacity and cycle life, and achieve low cost, improved battery capacity and cycle life, and high process stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

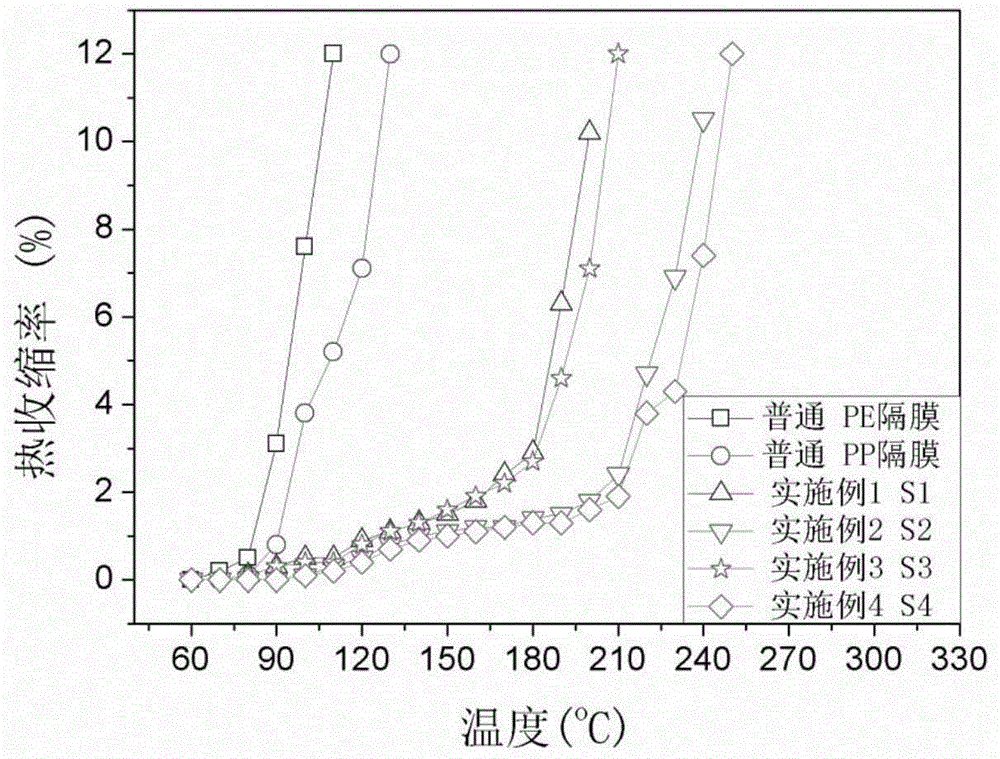

[0052] Embodiment 1, Al2O3 fiber composite diaphragm S1

[0053] 1) Preparation of fiber rod material:

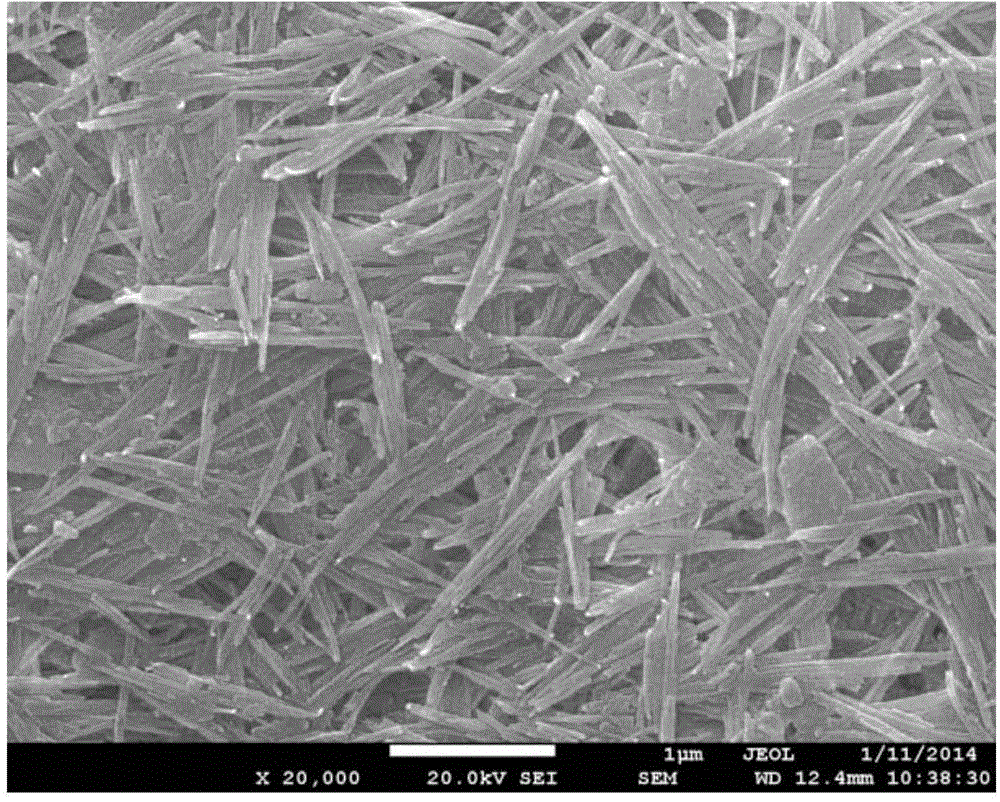

[0054] Dissolve 2.0g of aluminum nitrate in 20g of deionized water, then add 20g of polyvinyl alcohol aqueous solution with a concentration of 10% by mass, and stir thoroughly to obtain a precursor solution; add the above precursor solution into the syringe of the electrospinning equipment, The precursor composite fiber was obtained by electrospinning (spinning conditions: spinning voltage 30KV, extrusion speed 2.0ml / min). After repeating the above experiments several times, multiple precursor composite fibers were obtained. All the composite fibers were removed from the receiving plate, calcined in a medium-temperature furnace at 1000°C for 10 hours, and the aluminum oxide fibers collected were 50.5 g in total. The average length of the aluminum oxide fiber rod-shaped materials was 0.5 microns, and the 50 nanometers in diameter.

[0055] 2) Preparation of composite diap...

Embodiment 2

[0057] Embodiment 2, zirconia fiber composite diaphragm S2

[0058] 1) Preparation of fiber rod material:

[0059] Dissolve 2.0g of zirconium oxynitrate in 20g of deionized water, then add 20g of polyvinyl alcohol aqueous solution with a mass fraction of 10%, and stir thoroughly to obtain a precursor solution; add the above precursor solution into the syringe of the electrospinning equipment, and pass Electrospinning method to obtain precursor composite fiber (spinning conditions: spinning voltage 30KV, extrusion speed 2.0ml / min). After repeating the above experiments several times, multiple precursor composite fibers were obtained. All the composite fibers were removed from the receiving plate, calcined in a medium-temperature furnace at 1000° C. for 10 hours, and a total of 38.76 g of zirconium dioxide fibers were collected. The average length of the zirconia fiber rod-shaped material is 1.5 micrometers, and the average diameter is 300 nanometers.

[0060] 2) Preparation ...

Embodiment 3

[0062] Embodiment 3, natural mineral fiber composite diaphragm S3

[0063] 1) Preparation of fiber rod material:

[0064] Purified attapulgite clay fiber powder with a purity of 98% (purchased from Jiangsu Jiuchuan Nano Material Technology Co., Ltd.) was vacuum-dried to remove interlayer hydrates of attapulgite clay to obtain fiber rod-shaped materials. The average length of the fibrous rod-shaped material is 1 micrometer, and the average diameter is 50 nanometers.

[0065] 2) Preparation of composite diaphragm:

[0066] Weigh 500.0g of the obtained fiber rod-shaped material of step 1), 15.0g of the adhesive styrene-butadiene latex, and 10.0g of the dispersing agent polyethylene glycol (weight-average molecular weight is 4000), dissolve in 700g of water, and mix by high-speed stirring. In order to speed up the dispersing speed, ultrasonic assisted rapid dispersing is used. The obtained solution is coated on a commercial PE film with a thickness of 20 microns (the porous pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com