Preparation of zinc ion crosslinked core-shell acrylic acid ionomer emulsion and application of emulsion in producing indoor humidity-control paint

A core-shell acrylic and ionomer technology, applied in the field of polymer technology and functional coatings, to achieve the effect of improving indoor humidity, high mechanical strength and thermal stability, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

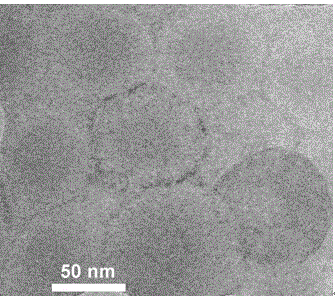

[0035] 1. Preparation of zinc ion crosslinked core-shell acrylic ionomer emulsion

[0036] (1) Preparation of styrene-acrylic copolymer core emulsion: Add 30 parts of distilled water, 5 parts of compound emulsifier (1 part of OP-10, 4 parts of sodium lauryl sulfate) and 1 part of potassium persulfate into a three-necked flask , stirred at 80°C for 20 min; then 1 part of initiator solution, 5 parts of methacrylic acid, and 15 parts of styrene were added dropwise to the reaction system within 1.5 h, and the polymerization reaction was carried out under stirring for 1 h to obtain the styrene-acrylic copolymer core Lotion;

[0037] (2) Preparation of core-shell acrylic ionomer emulsion: a solution of 20 parts of methacrylic acid, 10 parts of methyl methacrylate, 5 parts of butyl acrylate and 3 parts of potassium persulfate was added dropwise to the above core within 1.5 h. in the emulsion, and then polymerized for 1 h to obtain a core-shell acrylic ionomer emulsion;

[0038] (3) P...

Embodiment 2

[0042] 1. Preparation of zinc ion crosslinked core-shell acrylic ionomer emulsion

[0043] (1) Preparation of styrene-acrylic copolymer core emulsion: Add 25 parts of distilled water, 4 parts of compound emulsifier (2 parts of OP-10, 2 parts of sodium lauryl sulfate) and 0.5 parts of potassium persulfate into a three-necked flask , stirred at 90 ℃ for 20 min; then 1.5 parts of initiator solution, 5 parts of methacrylic acid, and 20 parts of styrene were added dropwise to the reaction system within 1.5 h, and the polymerization reaction was carried out under stirring for 1 h to obtain styrene-acrylic copolymer nuclei emulsion;

[0044] (2) Preparation of core-shell acrylic ionomer emulsion: a solution of 10 parts of methacrylic acid, 15 parts of methyl methacrylate, 10 parts of butyl acrylate and 2 parts of potassium persulfate was added dropwise to the above core within 2 h. in the emulsion, and then polymerized for 1 h to obtain a core-shell acrylic ionomer emulsion;

[004...

Embodiment 3

[0049] 1. Preparation of zinc ion crosslinked core-shell acrylic ionomer emulsion

[0050] (1) Preparation of styrene-acrylic copolymer core emulsion: Add 20 parts of distilled water, 5 parts of compound emulsifier (2.5 parts of OP-10, 2.5 parts of sodium lauryl sulfate) and 0.2 parts of potassium persulfate initiator solution into a three-necked flask , stirred at 80 ℃ for about 10 min, then 1.5 parts of potassium persulfate solution, 5 parts of methacrylic acid, and 10 parts of styrene were added dropwise to the reaction system within 1 h, and the polymerization reaction was carried out under stirring for 0.5 h to obtain Styrene-acrylic copolymer core emulsion;

[0051] (2) Preparation of core-shell acrylic ionomer emulsion: a solution of 15 parts of methacrylic acid, 20 parts of methyl methacrylate, 15 parts of butyl acrylate and 2.3 parts of potassium persulfate was added dropwise to the above core within 2 h. in the emulsion, and then polymerized for 1 h to obtain a core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com