Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

353 results about "Hard core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

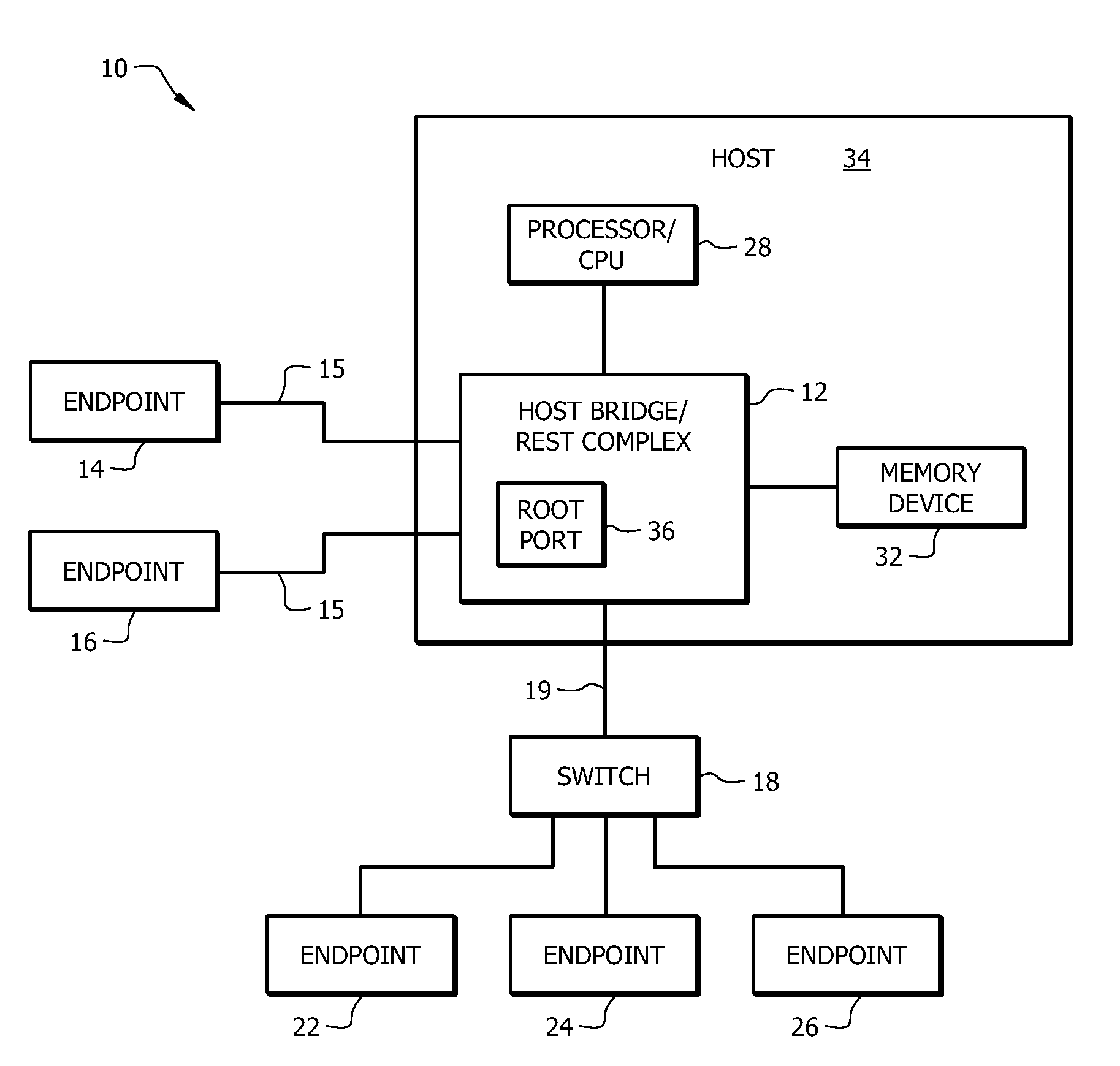

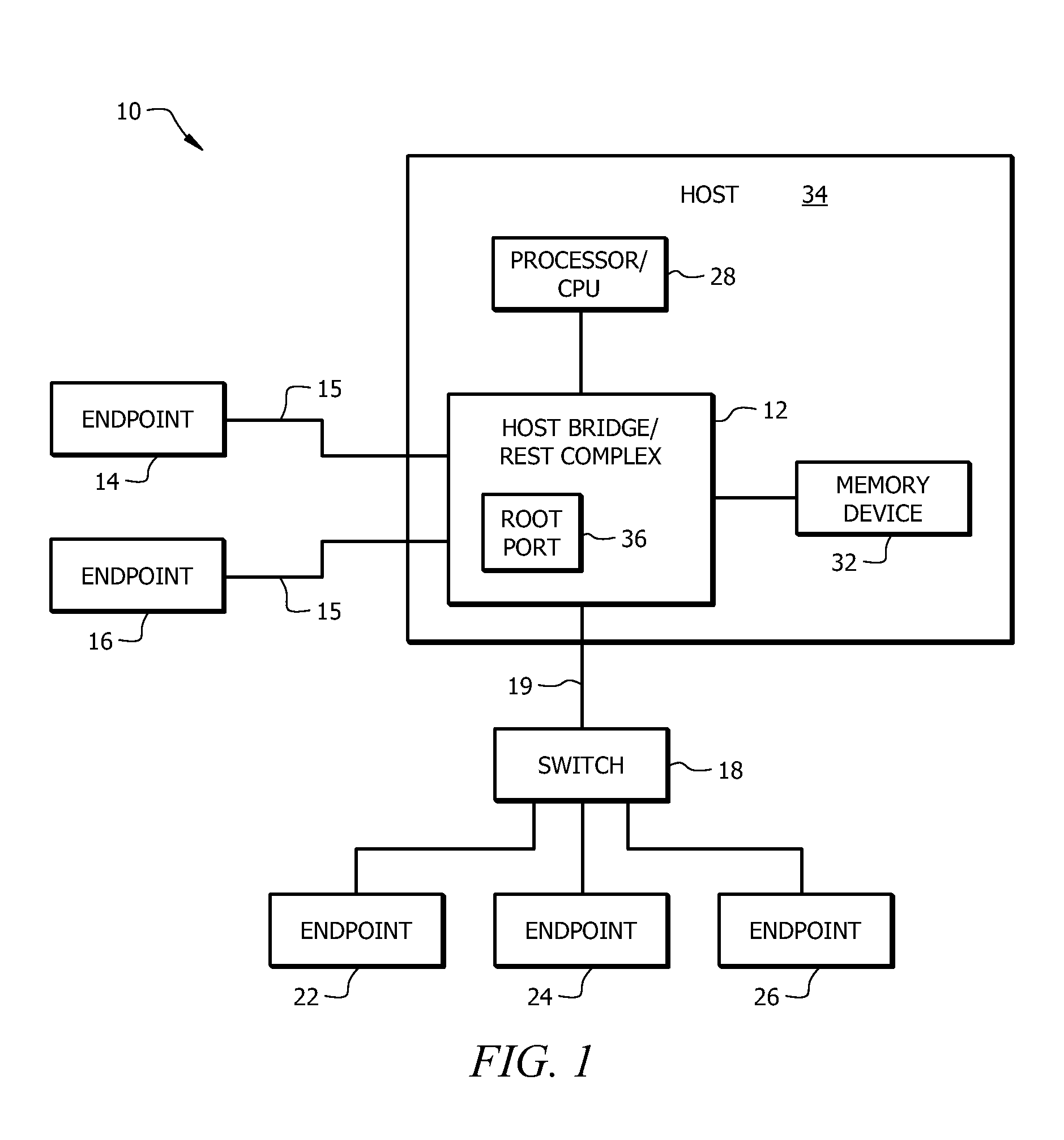

Apparatus and system having PCI root port and direct memory access device functionality

An apparatus and system having both PCI Root Port (RP) device and Direct Memory Access (DMA) End Point device functionality is disclosed. The apparatus is for use in an input / output (I / O) system interconnect module (IOSIM) device. A DMA / RP module includes a RP portion and one or more DMA / RP portions. The RP portion has one or more queue pipes and is configured to function as a standard PCIe Root Port device. Each of the DMA / RP portions includes DMA engines and DMA input and output channels, and is configured to behave more like an End Point device. The DMA / RP module also includes one or more PCIe hard core portions, an ICAM (I / O Caching Agent Module), and at least one PCIe service block (PSB). *The hard core portion couples the DMA / RP module and IOSIM device to an I / O device via a PCIe link, and the ICAM transitions data to a host memory device operating system.

Owner:CAVANAGH JR EDWARD T +3

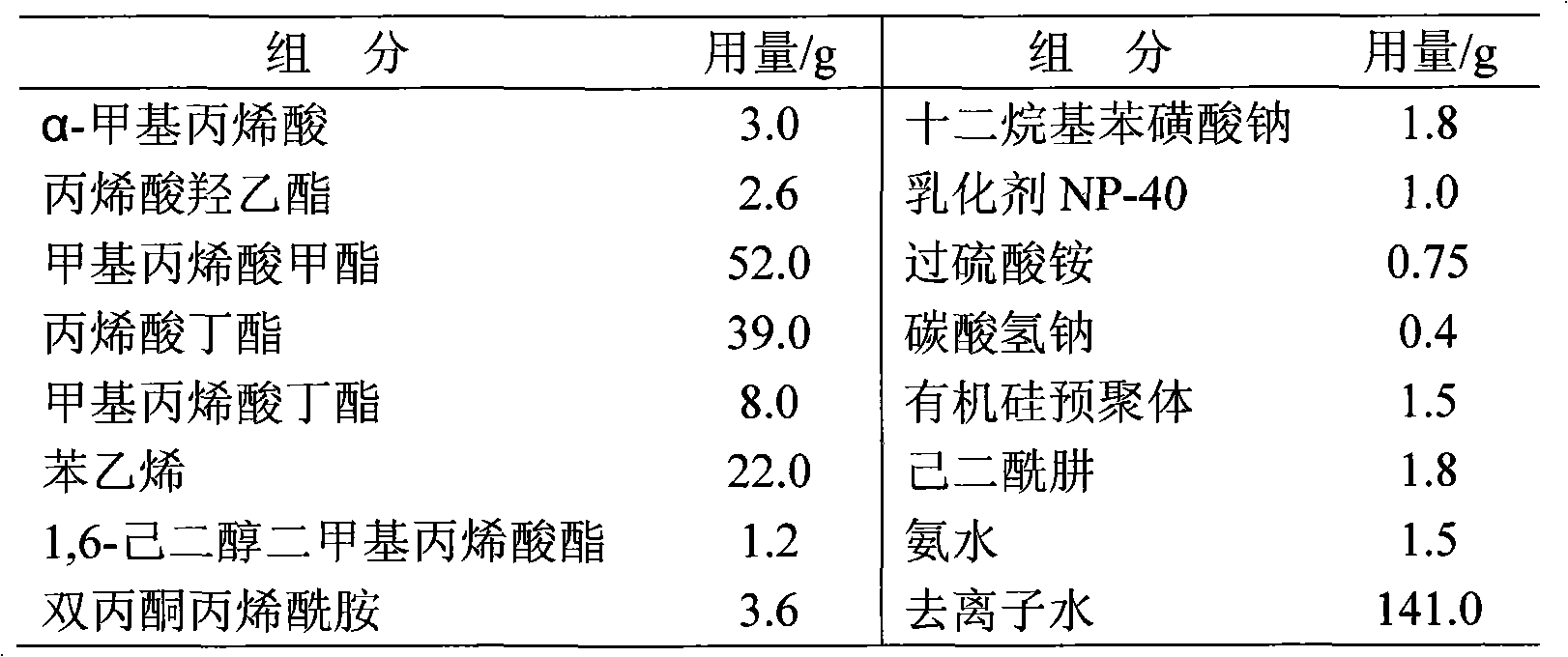

Preparation method for acrylic acid microemulsion with self-crosslinking core-shell structure

The invention provides a preparation method for an acrylic acid microemulsion with a self-crosslinking core-shell structure, which sequentially comprises the following steps of: emulsifying a seed microemulsion monomer in advance, preparing seed microemulsion and core-shell part microemulsion, emulsifying a core part microemulsion monomer in advance, and preparing the acrylic acid microemulsion with the self-crosslinking core-shell structure. In the preparation method for the acrylic acid microemulsion with the self-crosslinking core-shell structure, common self-crosslinking monomers are adopted for replacing expensive organo-siloxane monomers and fluoride-containing vinyl monomers, a polymerization technology is used for improving the performance of the emulsion, and therefore, the prepared acrylic acid microemulsion has low cost and can be widely used; the acrylic acid microemulsion with the self-crosslinking core-shell structure, prepared by the invention, has a soft-shell hard-core structure and a self-crosslinking characteristic; the average grain diameter of the microemulsion is 60-100nm; and the acrylic acid microemulsion with the self-crosslinking core-shell structure has good nanometer effects and good grinding performance when being used in aqueous woodware primers, and has advantages of good permeability and wettability to base materials, strong adhesive force, compactness in coating, good transparency, higher gloss and good smoothness.

Owner:东莞大宝化工制品有限公司

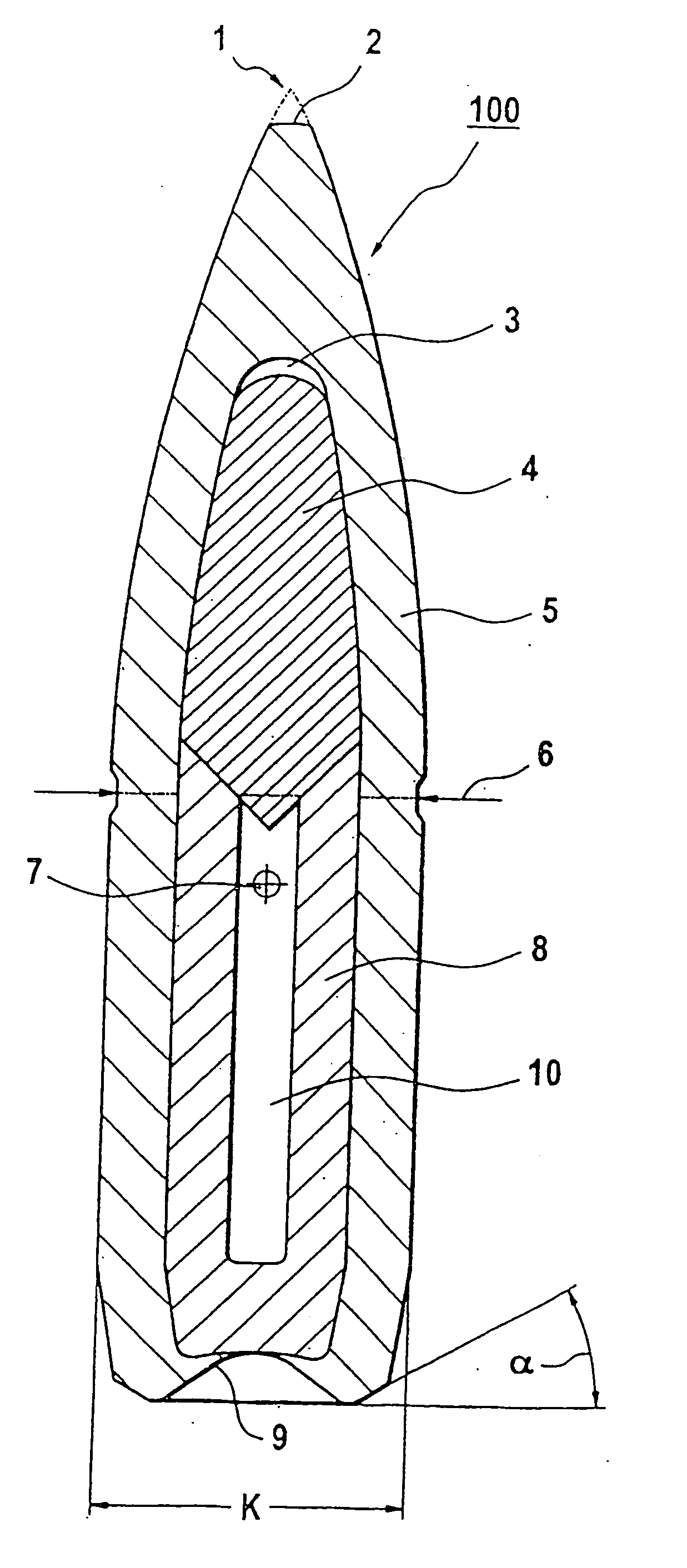

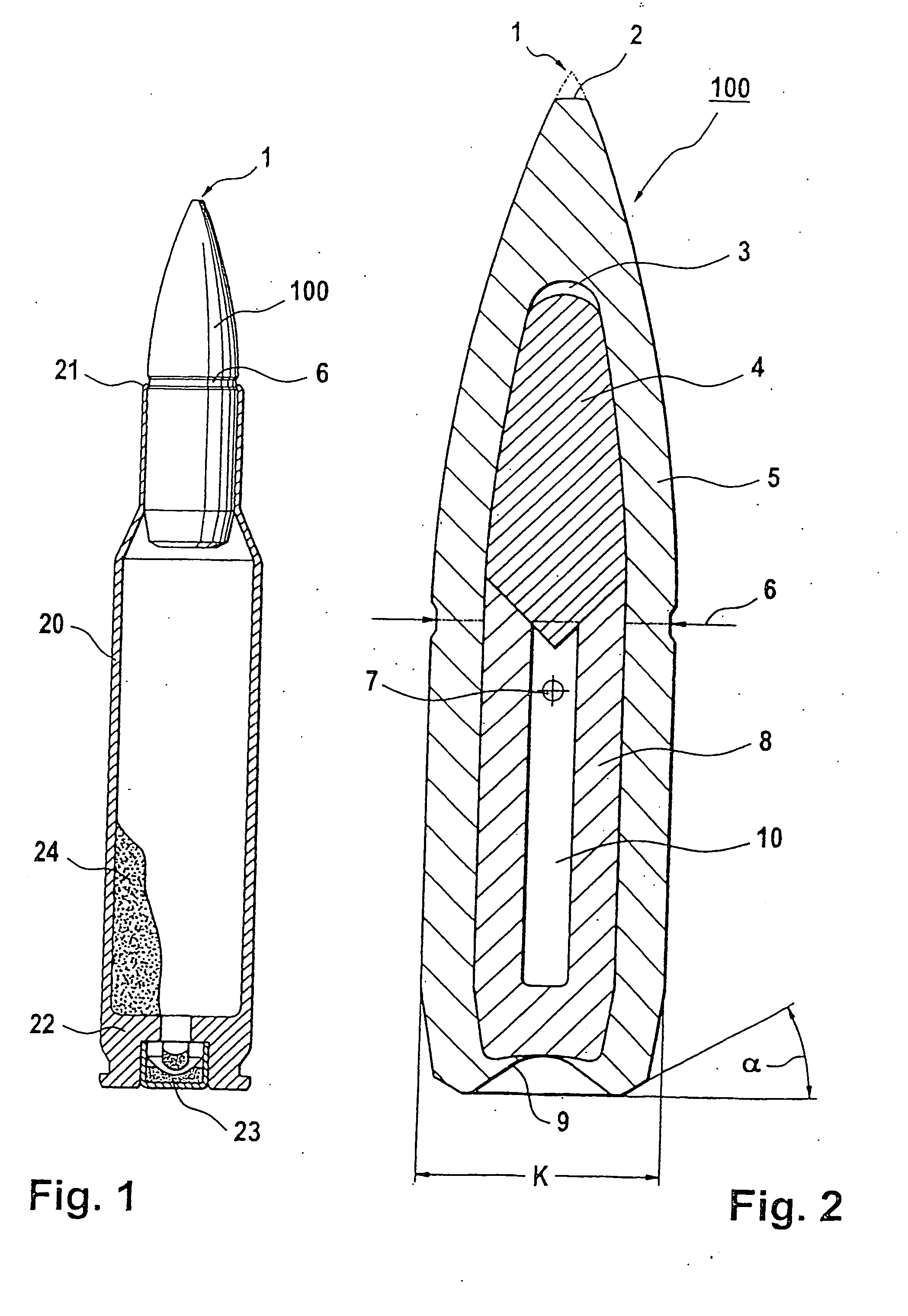

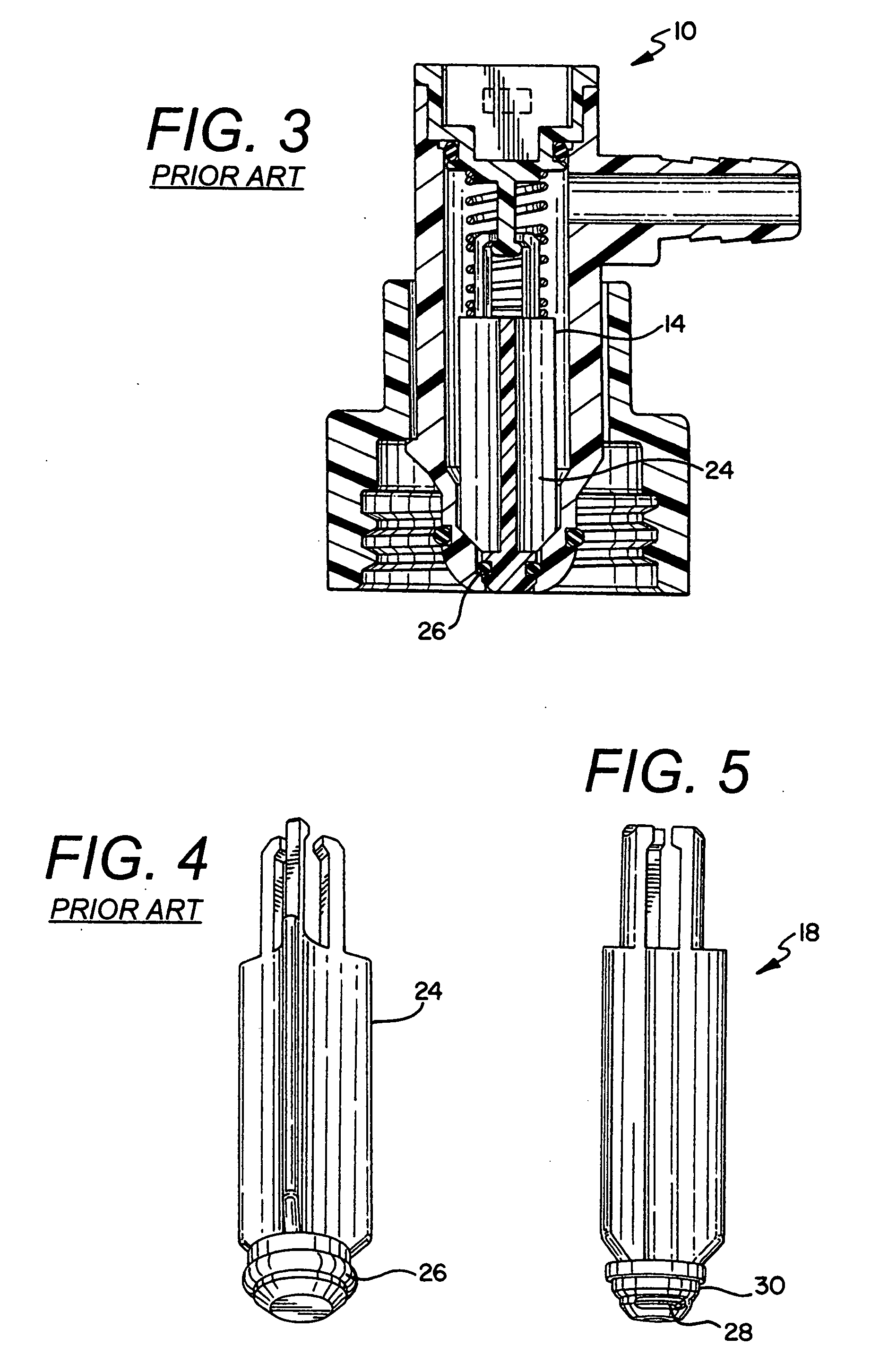

Lead-free projectile

ActiveUS20070204758A1Smooth connectionEasy to assembleAmmunition projectilesProjectilesEngineeringMechanical engineering

A small-bore projectile comprises a ductile outer jacket, a hard core, and a hollow jacket core. Kinetic energy of the projectile is substantially transmitted to the hard core when a target is hit such that said hard core penetrates the target. The outer jacket is supported by the jacket core that is located on the inside and mushrooms up into a deformed state upon impact without fragmenting. The projectile has good flying behavior and great final ballistic performance and can be produced in an entirely lead-free manner.

Owner:RUAG AMMOTEC GMBH

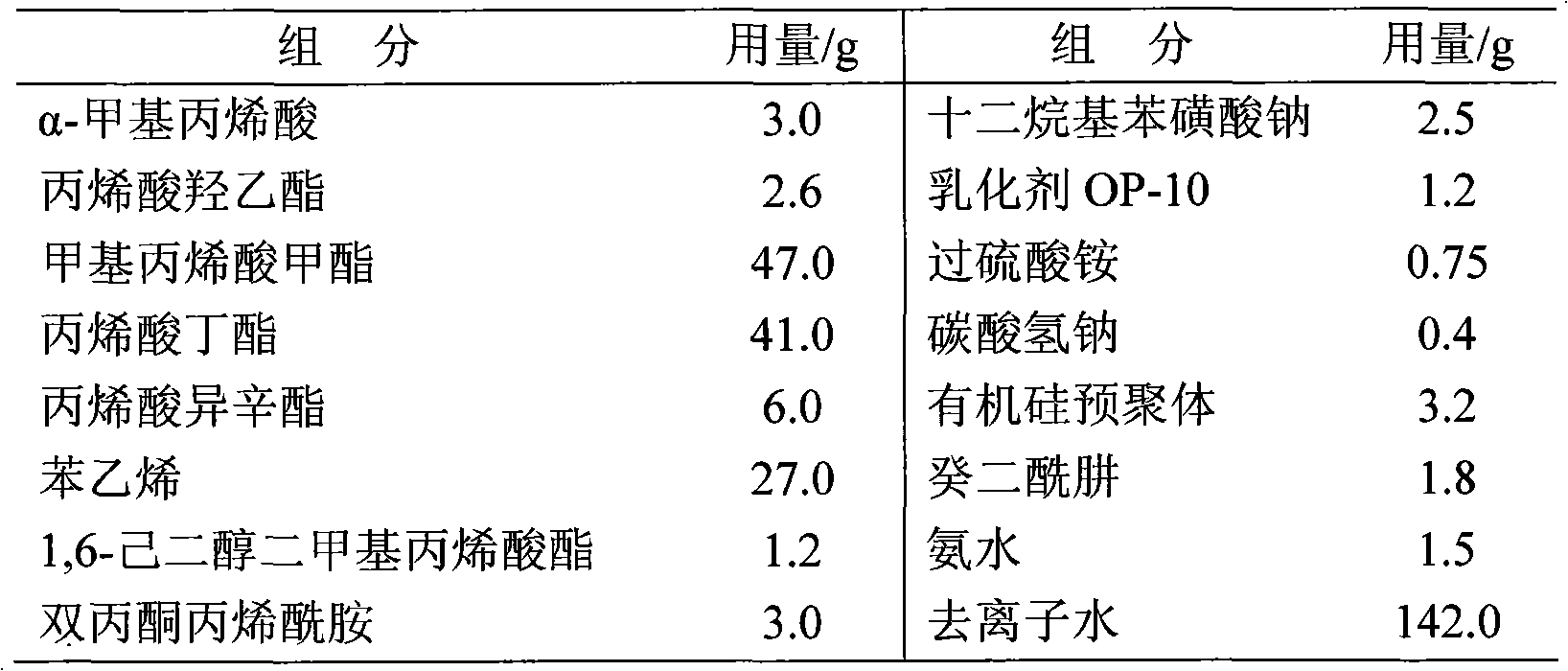

Organic silicon modified acrylic ester aqueous wood lacquer latex and synthesizing method thereof

The invention relates to an organic silicon modified acrylic ester aqueous wood lacquer latex and a synthesizing method thereof. The organic silicon modified acrylic ester latex has a three-layer nuclear shell structure latex particle with a hard core and a soft shell, can carry out self crosslinking at room temperature and has the particle diameter of 80-200nm, the solid content of 40-50 percentand the lowest film forming temperature of lower than 40 DEG C. The latex is prepared in such a way that a dicarbonyl compound containing double bonds and a (methyl) acrylic ester crosslinking monomercontaining double functionality or / and polyfunctionality, which can realize a room temperature crosslinking function are led in the polymerization process of acrylic ester nuclear shell latex, and anorganic silicon prepolymer is led in the outermost layer of the shell. The polymerization technology is simple and practical without gel generation in the polymerization process, and the storage stability of the latex can reach more than one year. The synthesized latex can generate an interpenetrating network structure and a self-layering structure during film formation. When the latex is appliedas aqueous wood lacquer, the pencil hardness of a lacquer film is larger than and equal to 2H, and the latex has favorable adhesive force, flexibility, scratch resistance, water resistance, oil resistance and fouling prevention.

Owner:DALIAN POLYTECHNIC UNIVERSITY

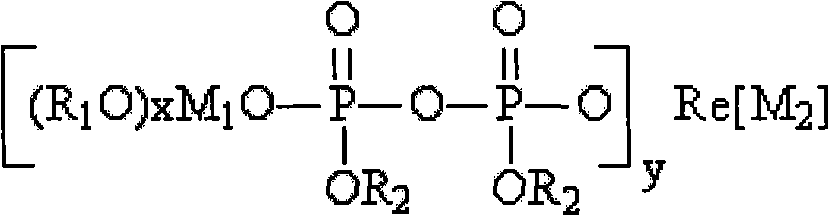

Water binding agent for lithium ionic cell electric pole material and preparation method thereof

ActiveCN101457131AStrong adhesionSufficient flexibility for processingElectrode manufacturing processesActive material electrodesLatex particleHigh voltage

The present invention relates to an aqueous binder used in lithium ionic cell electric pole material and the preparation method thereof, which belongs to lithium ionic cell electric pole material preparation field. The present invention aims to provide an aqueous binder for producing lithium ionic cell positive and negative plate with adjustable flexibility, and can meet all electric pole material aqueous binder requirements under various conditions of lithium ionic cell production and processing, storage and usage. The aqueouspolymer latex particle emulsion has an inside soft and outside hard core-shell structure with low polar polymer as core and high polar polymer as shell, and the solid content of the emulsion is 5-40 wt%, the mass percentage of low polar polymer is more than 0 and smaller than or equal to 95% in the core-shell structure. The lithium ionic cell produced according to the invention is provided with high capacity exertion of electroactive material, long battery periodic duty life and high voltage of discharge platform.

Owner:MEISHAN INDIGO TECH CO LTD

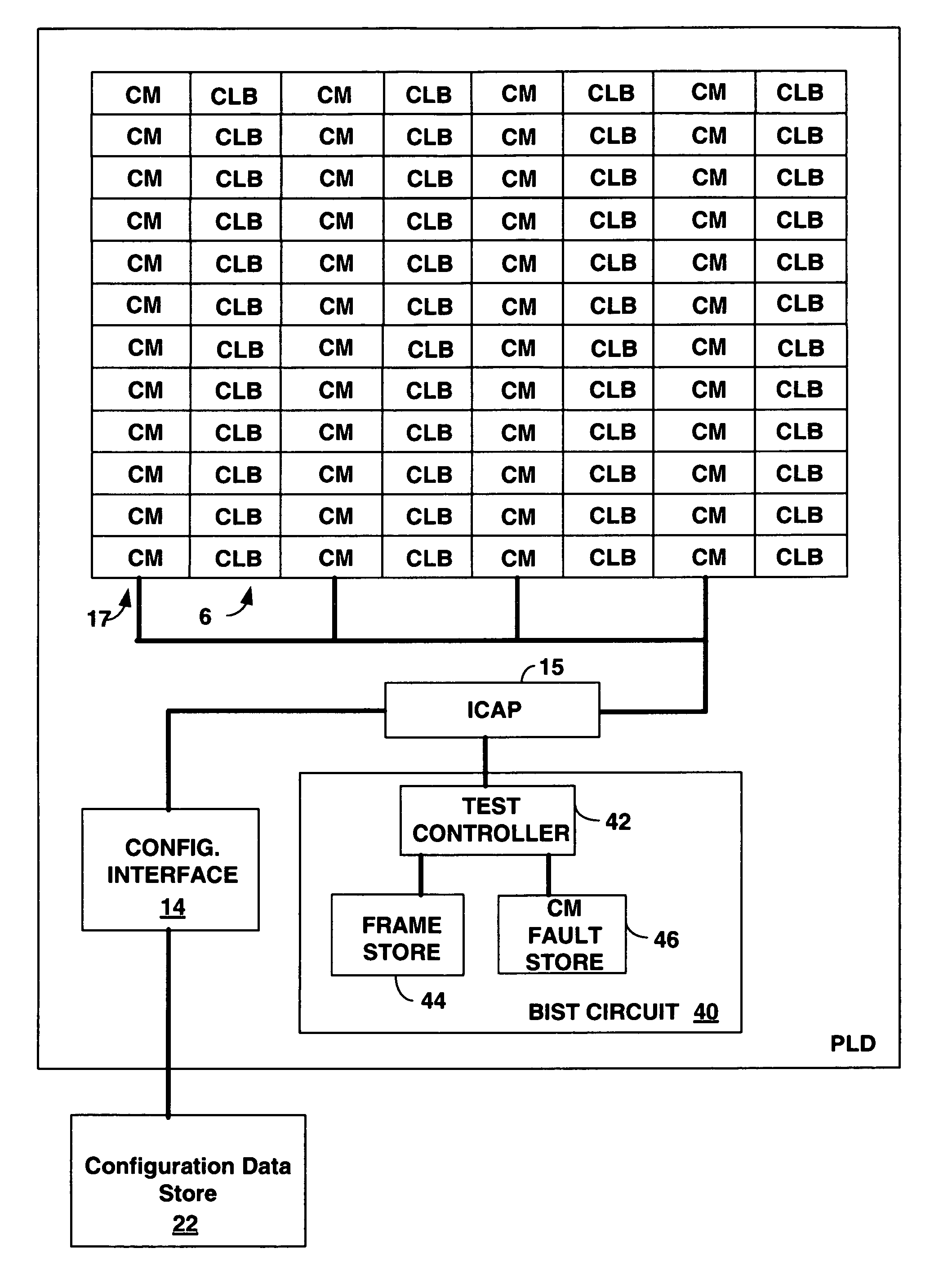

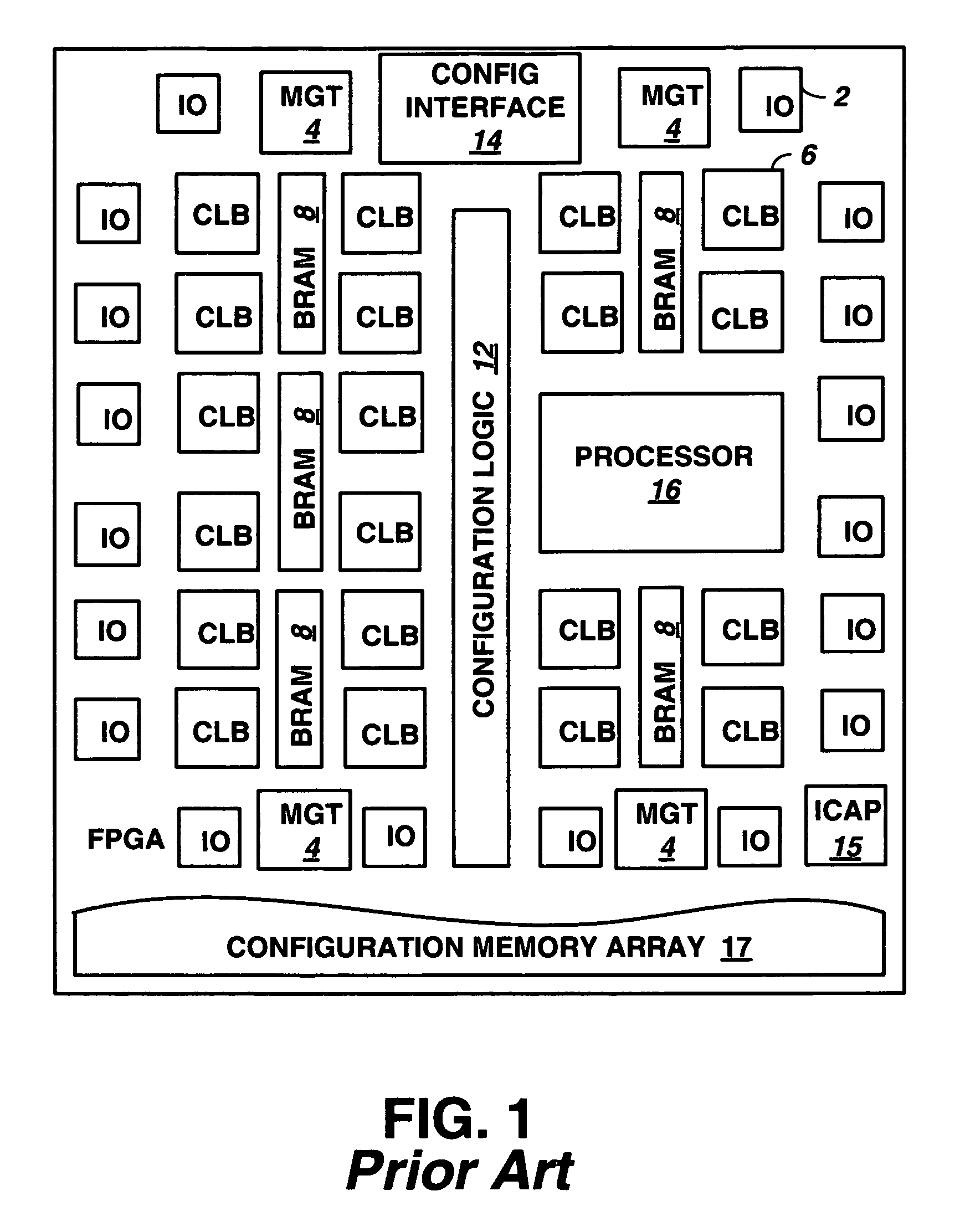

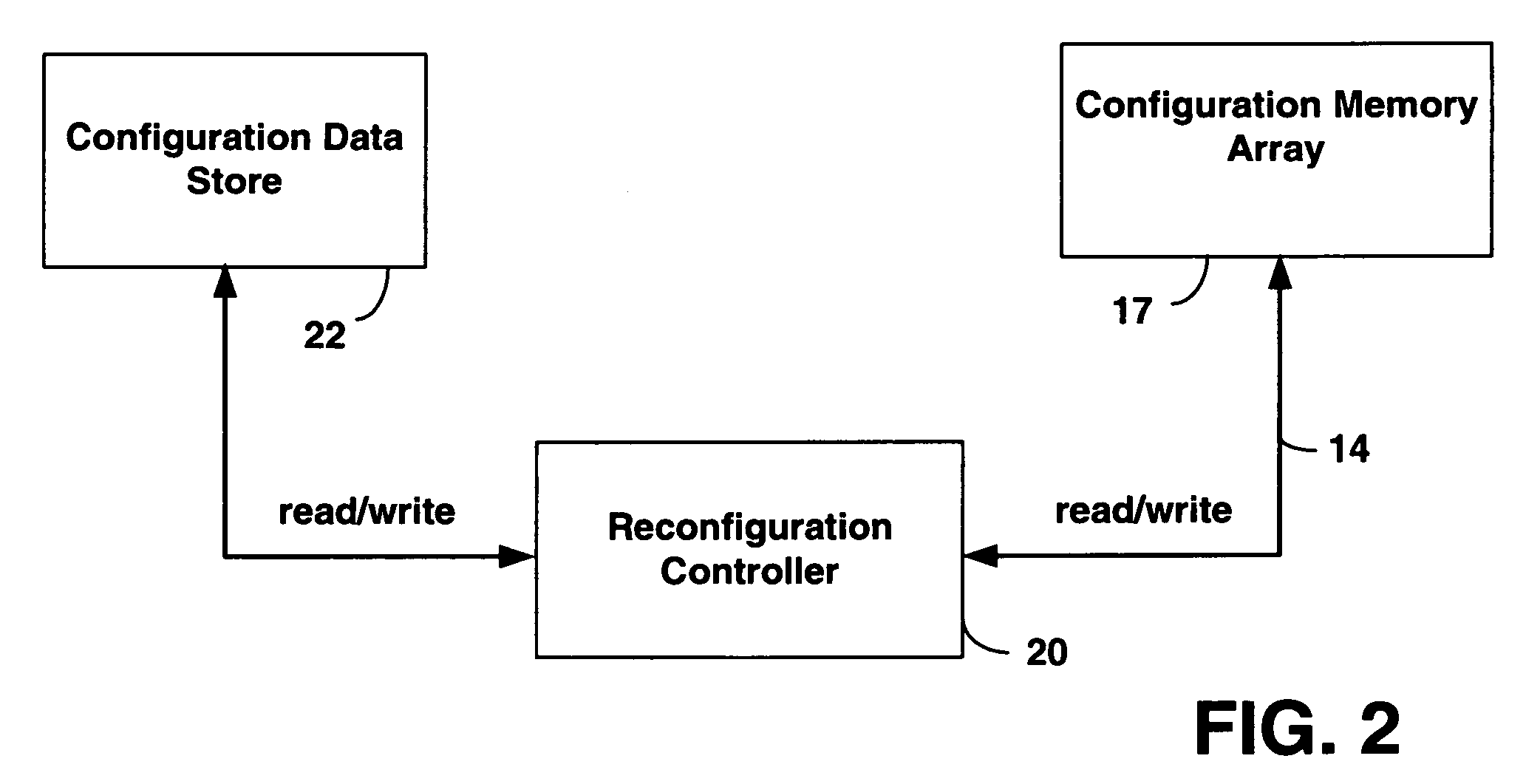

Total configuration memory cell validation built in self test (BIST) circuit

ActiveUS7409610B1Minimal circuitryElectronic circuit testingDigital storageElectricityProgrammable logic device

A built in self test (BIST) circuit is provided for a programmable logic device (PLD) constructed from fixed or hard core logic that includes circuitry to write recurring patterns of bits in the configuration memory in a frame by frame manner and read the cell state to enable the validation of every configuration bit at power up. The BIST circuitry can further be used to program the recurring patterns into the configuration memory, and then read frames of the configuration memory to detect the occurrence of single event upsets (SEU) that corrupt data in the configuration memory. The recurring patterns programmed do not require time consuming functional configuration of the PLD, and can be done in a production environment after power up without knowledge of how the PLD will later be configured. No soft logic is needed to form the BIST circuit, enabling 100% test coverage of the programmable configuration memory cells.

Owner:XILINX INC

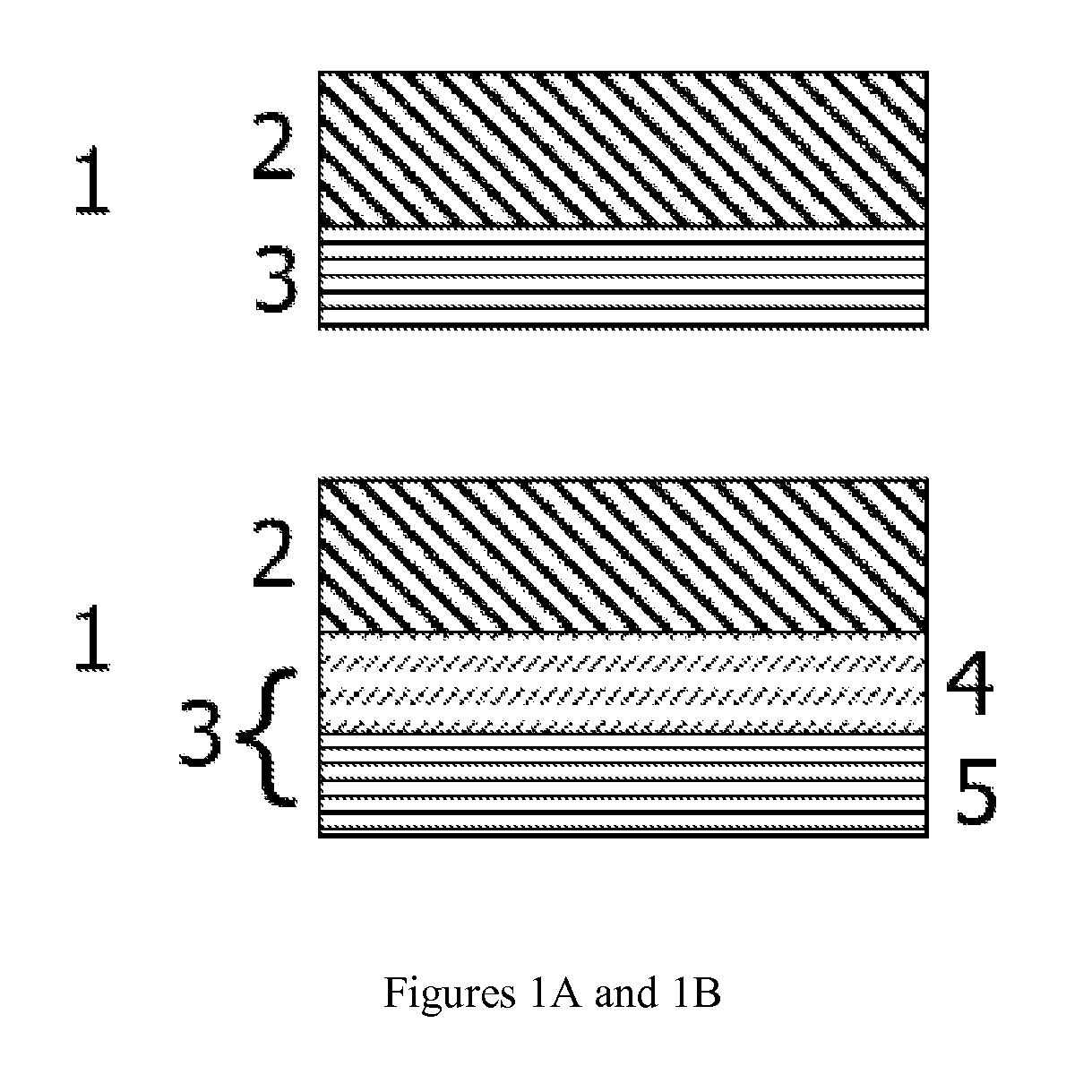

Waterproof membrane with good adhesion to concrete

ActiveUS20150231863A1Without diminishing adhesive capacityReduce adhesionFilm/foil adhesivesSynthetic resin layered productsPolymer dissolutionPremature aging

A waterproof membrane is described that includes a barrier layer and a functional layer. The functional layer can include a thermoplastic polymer that changes consistency under the influence of highly alkaline media, and an adhesive. The production and use of the membrane are also described. The functional layer of the membrane can be designed in the form of a film, a coating, or a nonwoven fabric. The fibers in the fabric can include a hard core that is surrounded by a polymer layer, is inert prior to coming into contact with liquid concrete and acts as a protective layer. Thus, the membrane is protected from premature aging and allows work to be performed with the seal in place. During the concreting process, i.e. when the functional layer comes into contact with liquid concrete, the polymer dissolves and thus allows the adhesive to bond to the concrete. The functional layer thus acts as an adhesive sealing compound and the seal is leakproof.

Owner:SIKA TECH AG

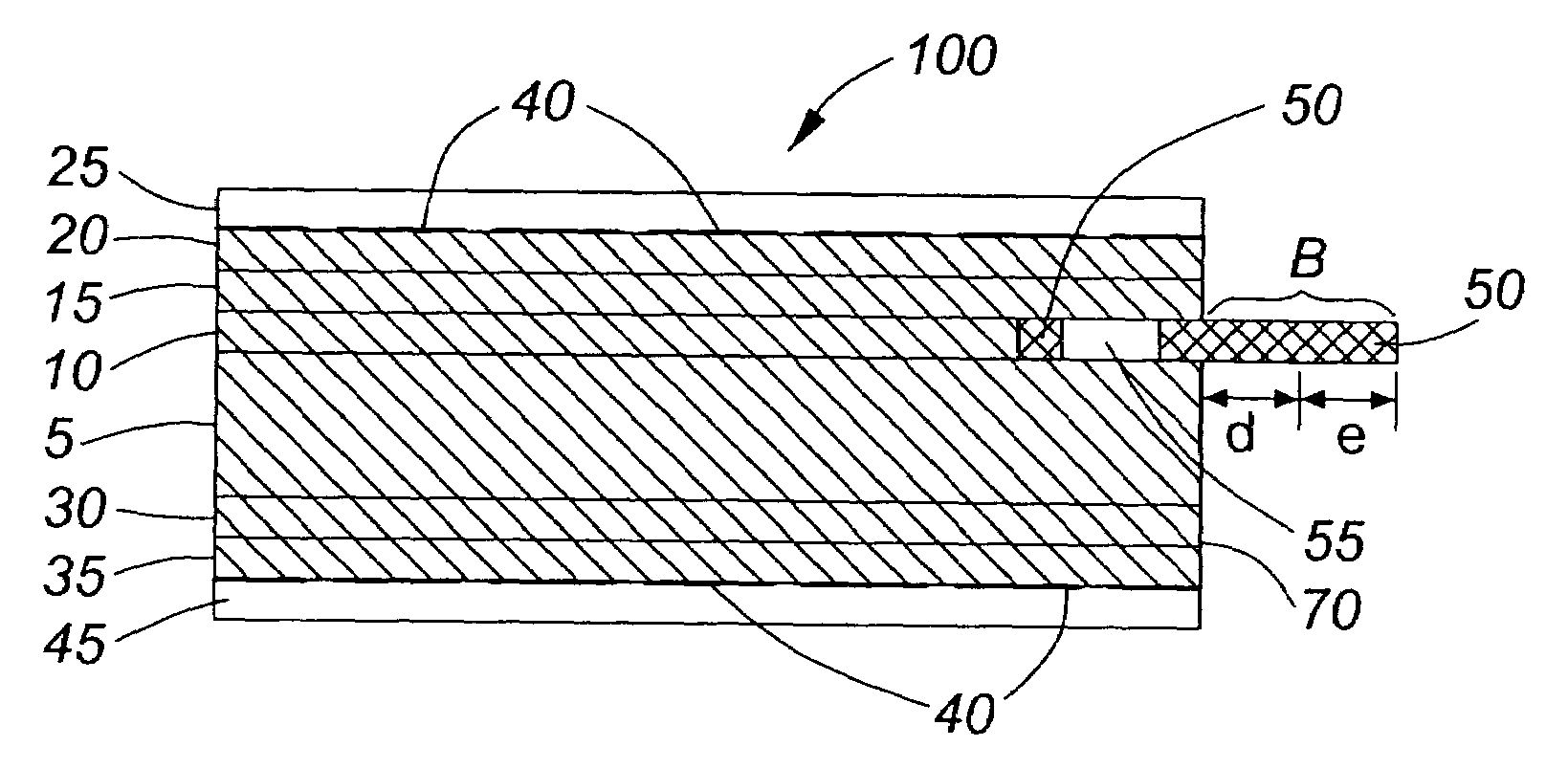

Laminate sheet for security booklets and method for making same

A hard laminate sheet for security booklets and method of making the same. The laminate sheet comprises at least two hard core layers (e.g. of polycarbonate) and a flexible component (e.g. nylon) there between and extending beyond an outer edge of the core layers to form a flexible band. The flexible component may be provided as an intermediate layer also comprising a hard component (e.g. of polycarbonate) juxtaposed with the flexible component and laminated to the adjacent core layers. The flexible component comprises a plurality of apertures within which material of the adjacent core layers is laminated together and affixes the flexible component to the laminate sheet. Additional hard core layers may be laminated to the core layers which sandwich the intermediate layer. Optionally, the laminate sheet may be used for a travel document (such as a passport) and may be laser engraved. Also, optionally, the laminate sheet may comprise a hard core inlay layer configured for containing a contactless integrated circuit chip and antenna or other electronic hardware.

Owner:CANADIAN BANK NOTE COMPANY

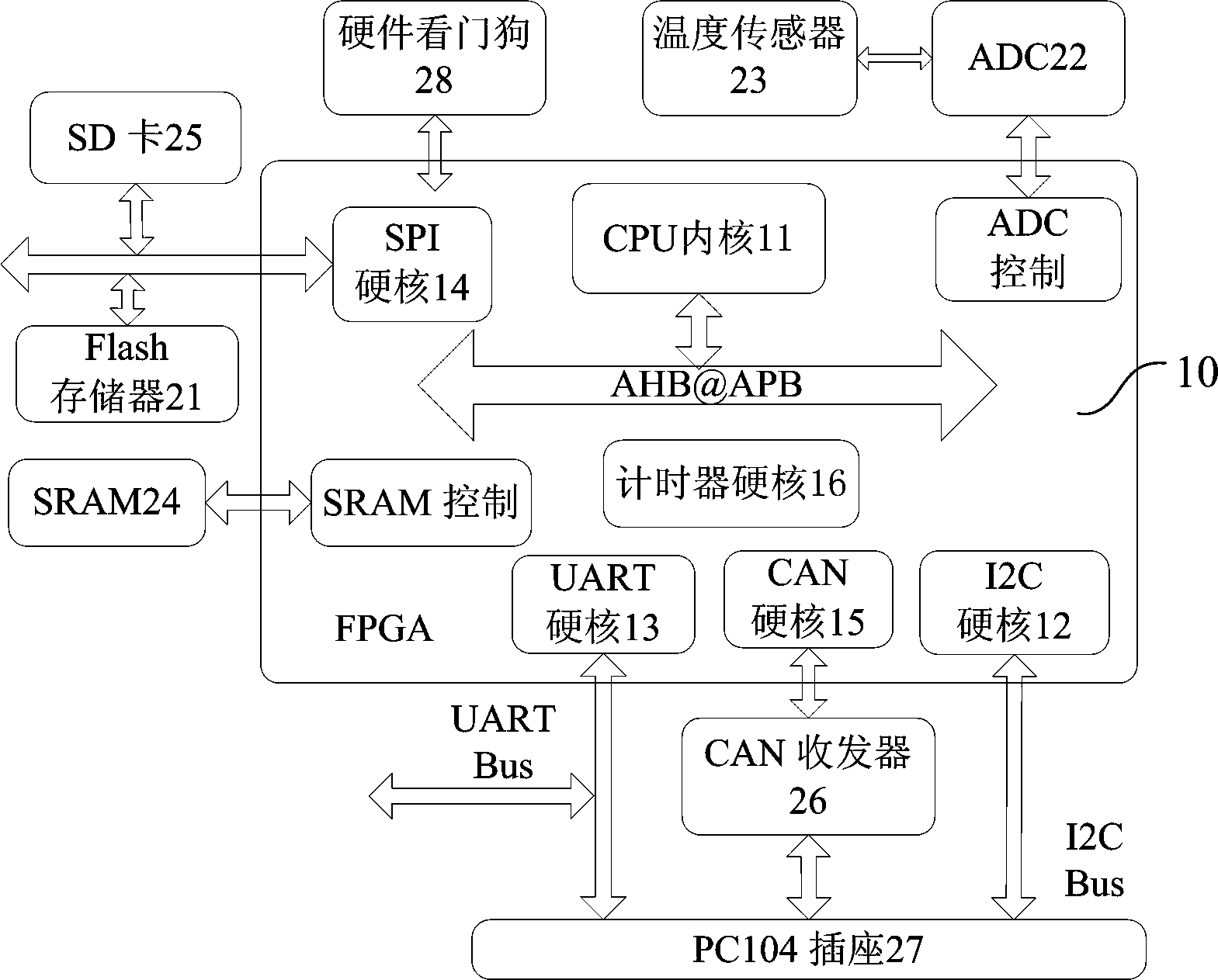

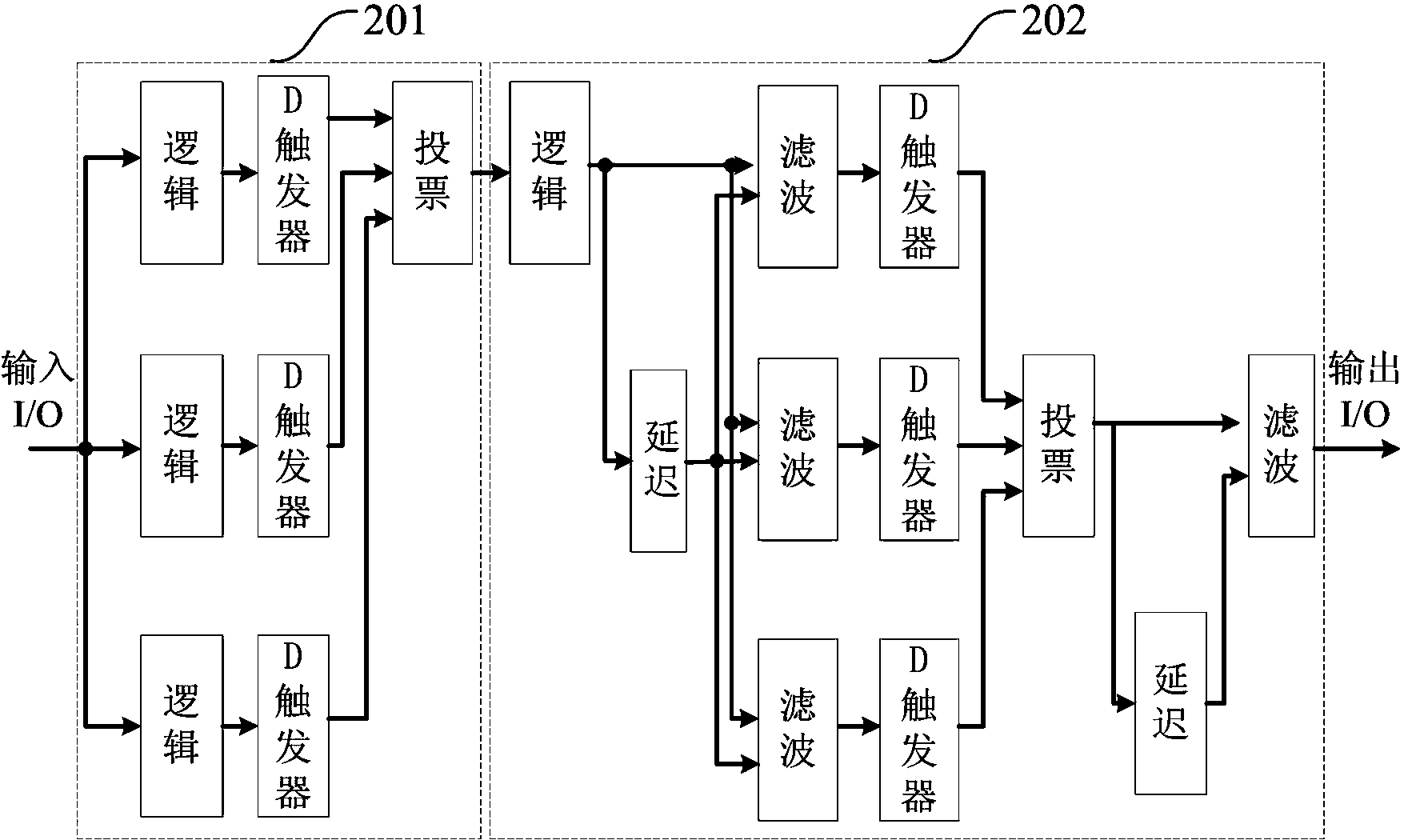

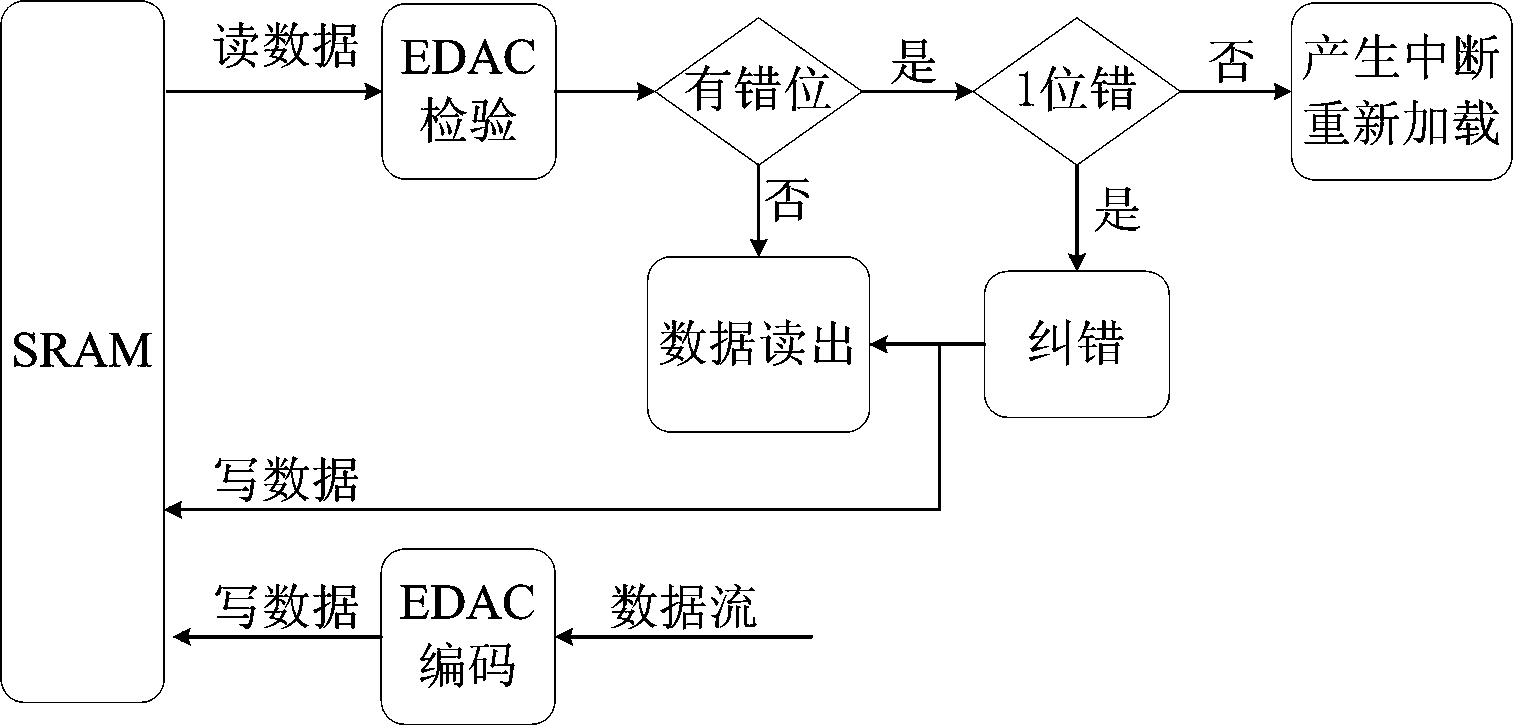

Embedded cubic star task computer based on FPGA (Field Programmable Gate Array) and reconstruction method thereof

ActiveCN104049687AFlexible useIncrease flexibilityDigital data processing detailsProgram loading/initiatingReconstruction methodData management

The invention provides an embedded cubic star task computer based on an FPGA (Field Programmable Gate Array). The computer comprises a processing chip, wherein the processing chip is integrated with an FPGA hard core, an FPGA logic unit and a CPU (Central Processing Unit) inner core; the FPGA hard core is used for communicating with a peripheral circuit and various subsystems of a cubic star; the FPGA logic unit is used for controlling the peripheral circuit and meanwhile timing the star task local time of the cubic star; the CPU inner core is used for performing whole star control algorithm implementation, whole star data management, gesture control algorithm implementation, control command dispatching and load data management on the cubic star. The embedded cubic star task computer has the advantages of flexibility in use, optimized performance, high integration level, low cost and high reliability.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

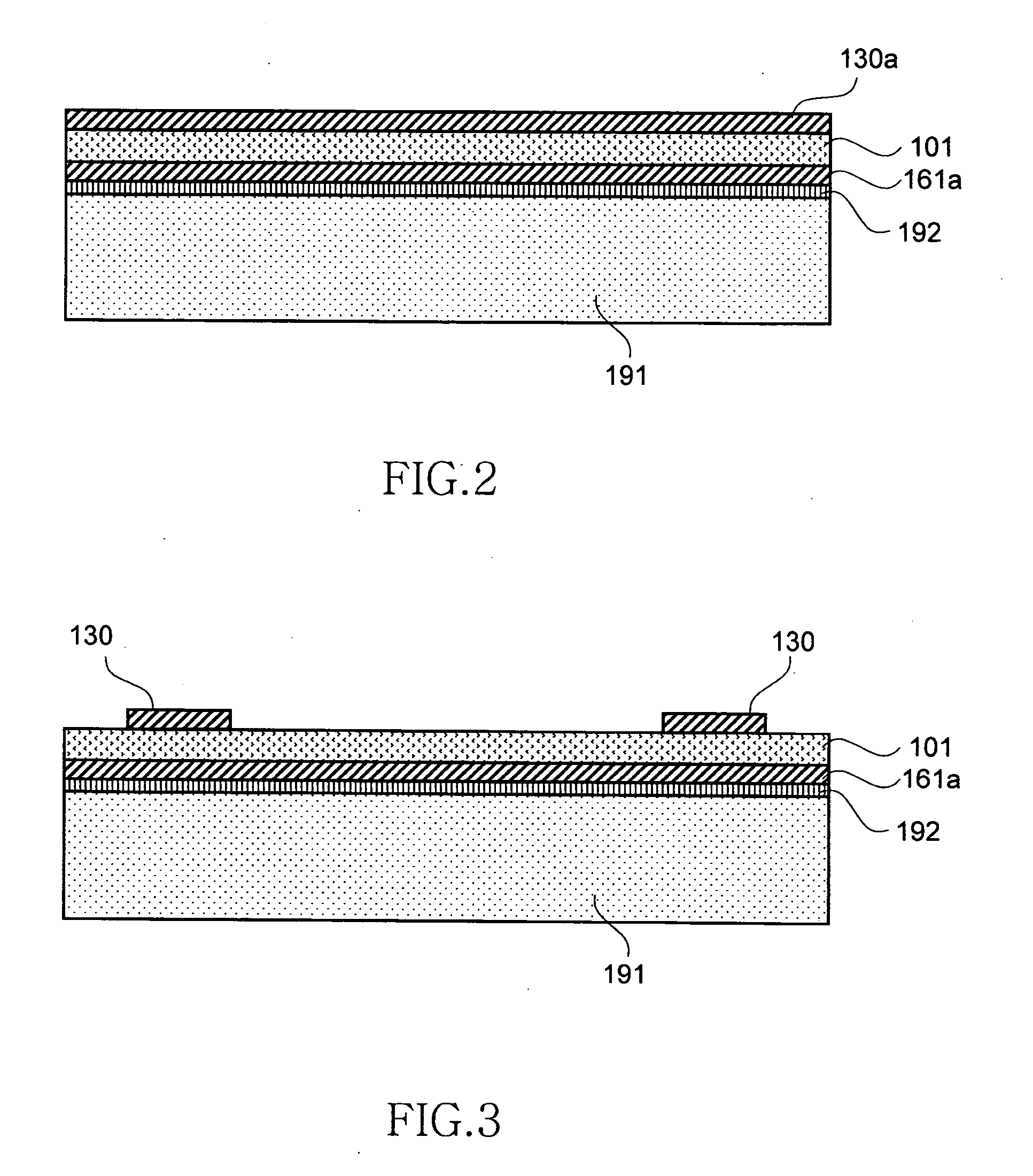

Multilayer circuit board and method for manufacturing the same

ActiveUS20070119541A1Small thicknessReliable productPrinted electric component incorporationSemiconductor/solid-state device detailsHard coreElectrical and Electronics engineering

A multilayer circuit board comprises core layers 101 and 102 made of a core material impregnated with resin, resin layers 111 and 112 interposed between the core layers 101 and 102, a wiring pattern 140 embedded in the resin layers 111 and 112. The core layers 101 and 102 have a thickness of 100 μm or smaller, whereby the entire board can significantly be thinned. Furthermore, the less strong resin layers 111 and 112 are interposed between the hard core layers 101 and 102, whereby the entire board has increased strength.

Owner:TDK CORPARATION

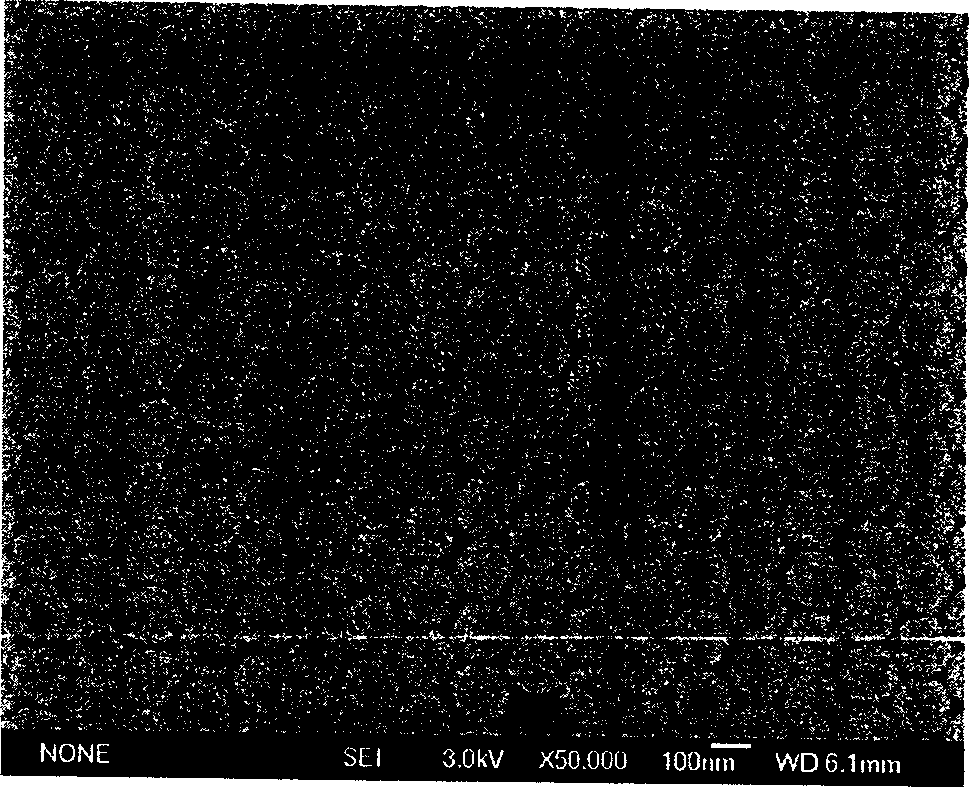

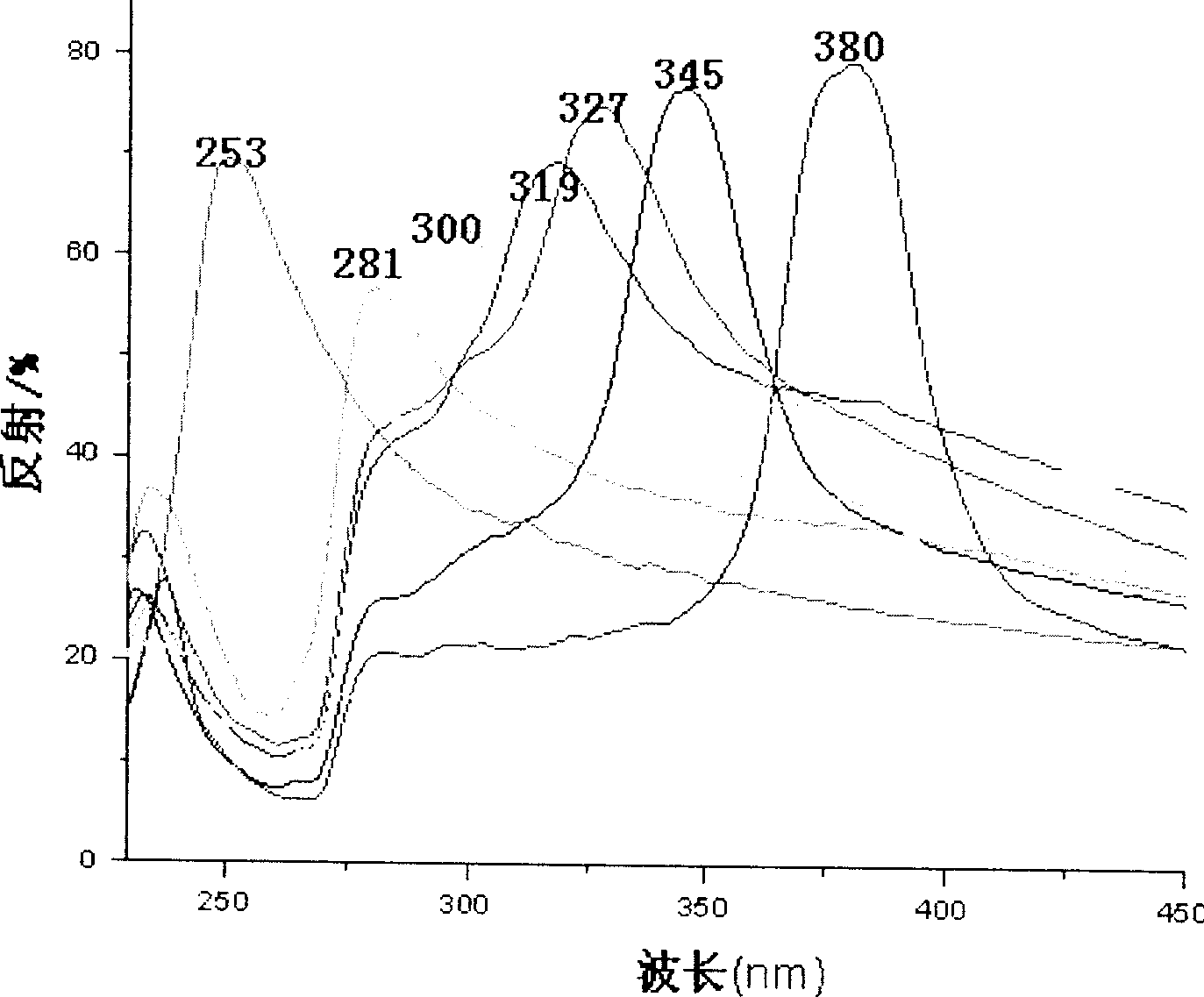

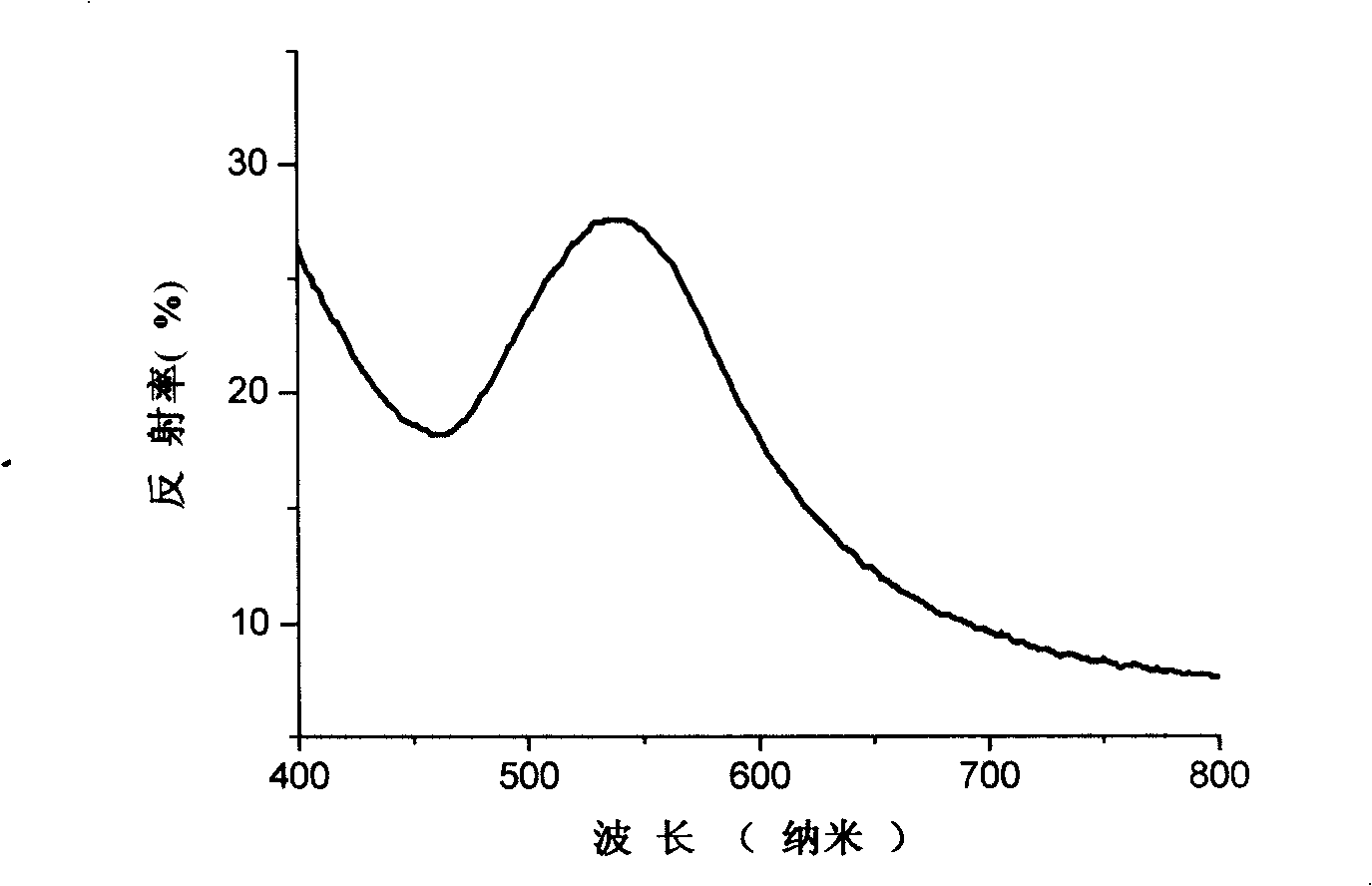

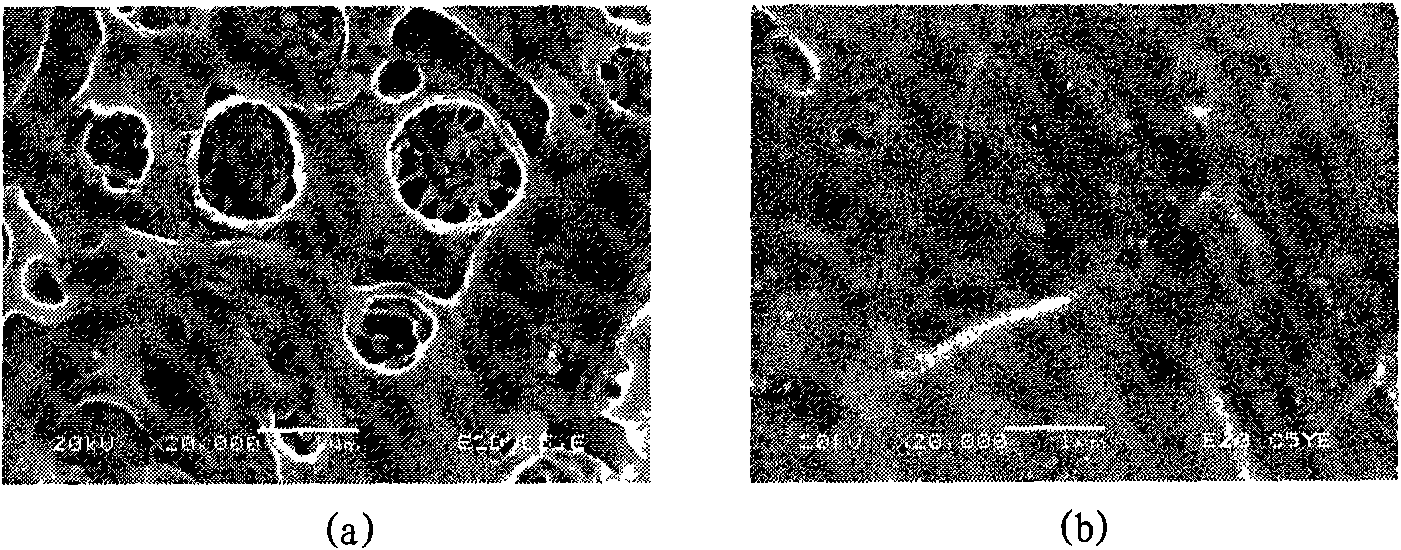

Photon crystal film of ultraviolet polymer colloid with photon band gap and its prepn and use

ActiveCN1887941AThe monodispersity index is smallThe size is easy to controlCosmetic preparationsToilet preparationsPhotonic bandgapLatex particle

The present invention relates to photo crystal film, and is especially one kind of colloidal photon crystal film and its preparation and application in ultraviolet preventing material or cosmetics material. The colloidal photon crystal film is prepared through coating monodispersed polymer latex in hard core-soft shell structure on flat substrate and volatilizing the dispersing liquid; the obtained monodispersed polymer latex particle has shell of 20-50 nm thickness, particle size of 100-160 nm and multiple dispersion index not greater than 0.005; and colloidal photon crystal film has photon band gap in the ultraviolet region of 200-400 nm. The colloidal photon crystal film is used as the ultraviolet preventing material in cosmetics, paint, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

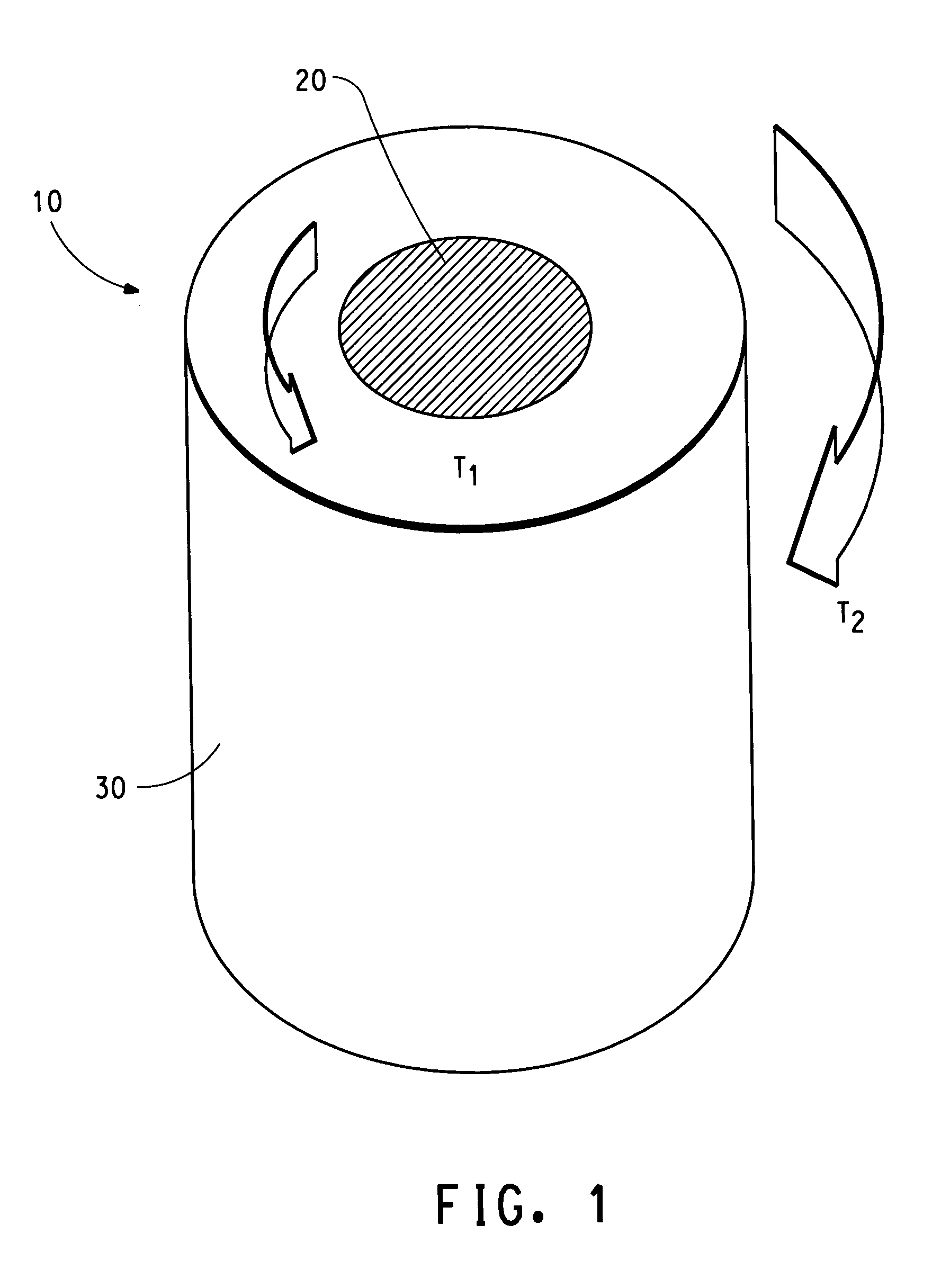

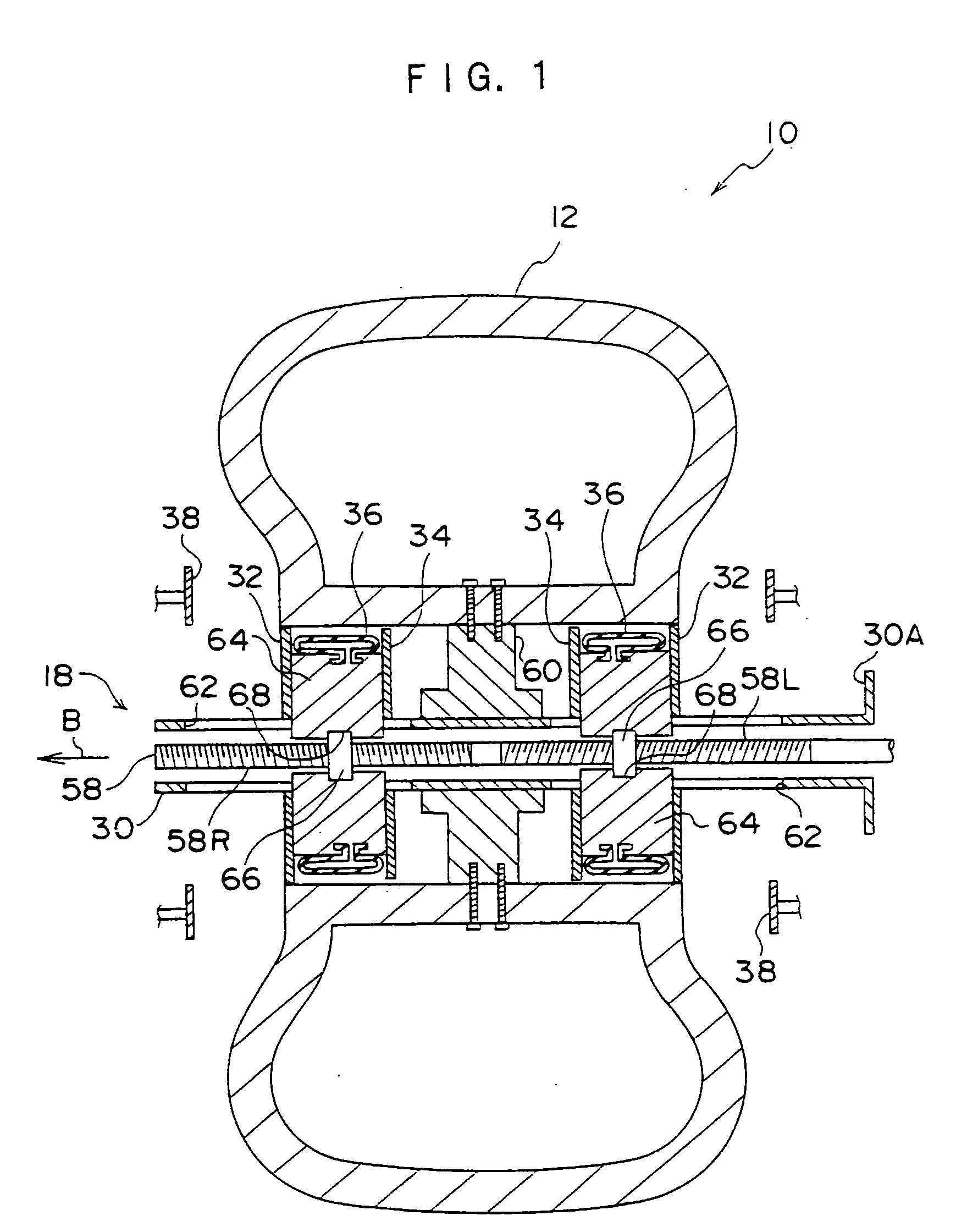

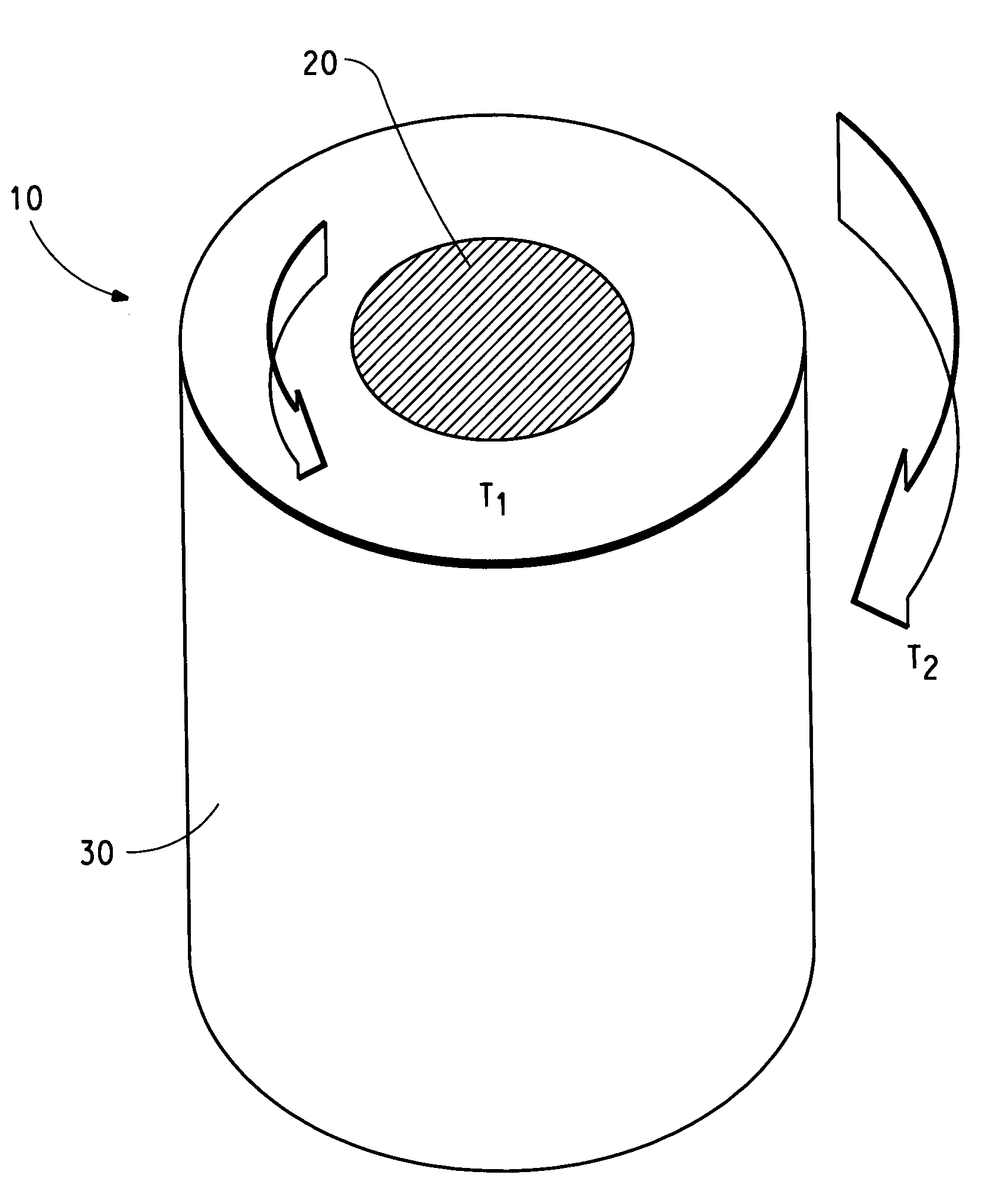

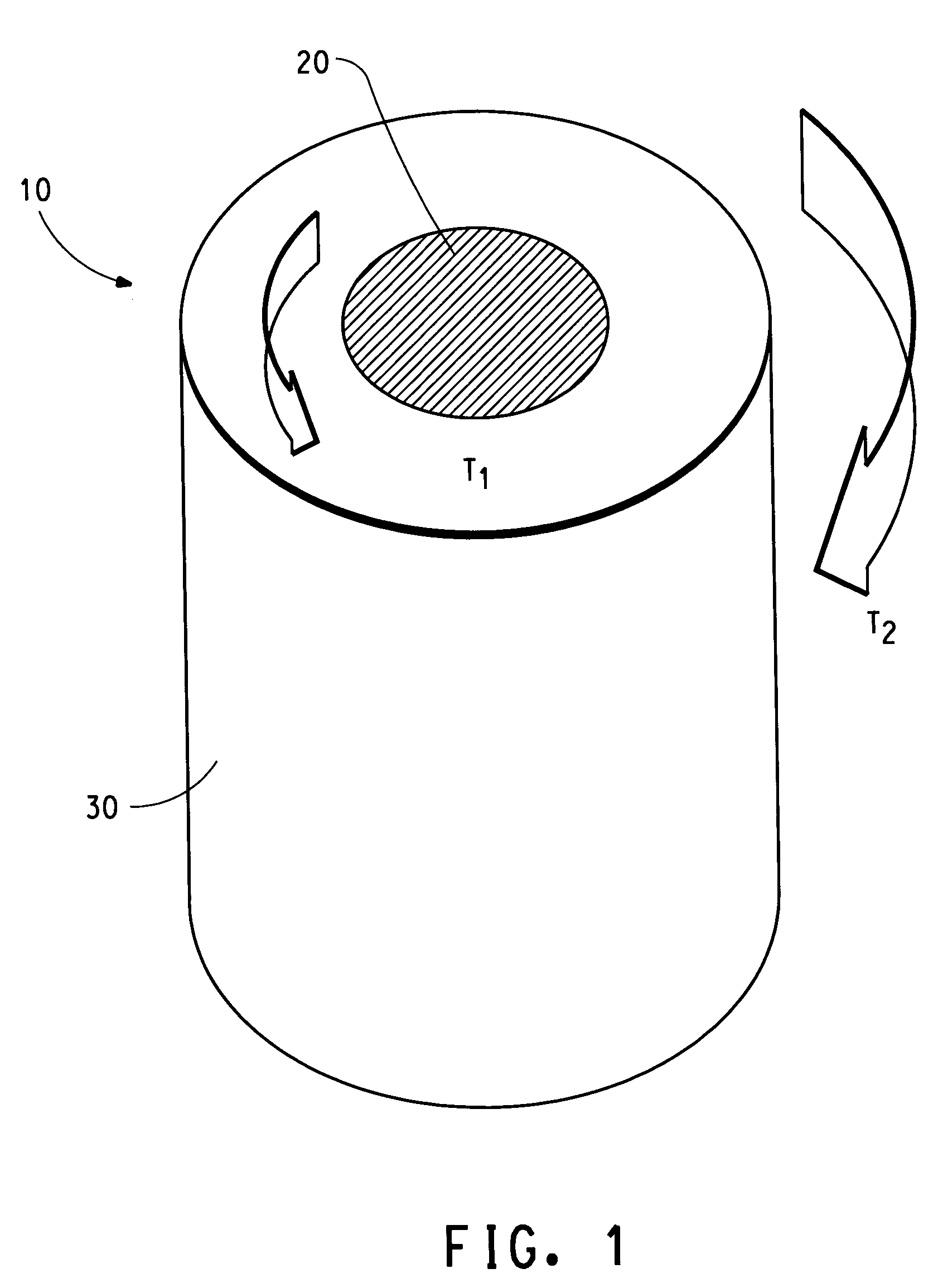

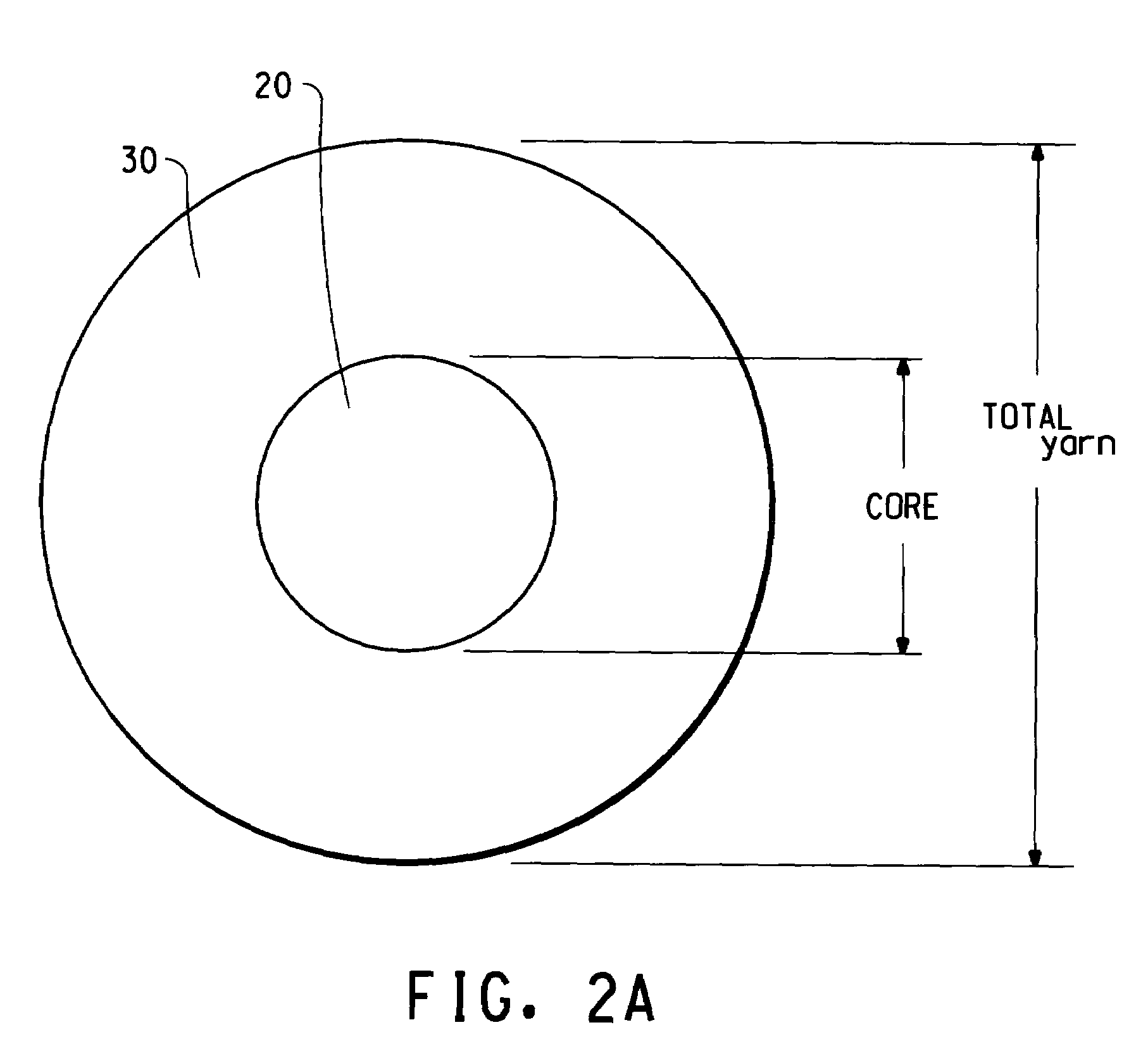

Composite twist core-spun yarn and method and device for its production

A substantially torqueless composite dual core-spun yarn (10) has a substantially inelastic central hard core (20) covered with a dual-spun fiber covering (30). The central hard core (20) has an elongation at break less than 50% and a Z or S twist, and the fiber covering (30) comprises fibers twisted on the core (20) with an S or Z twist opposite to that of the core. The opposite twists of the core (20) and of the covering (30) exert opposite and substantially equal torques. This yarn is produced by introducing two slivers (30A,30B) forming the covering (30) and a central (30) core in a spinning triangle (40). The core (20) is fed overtwisted S or Z and the slivers (30A,30B) have an opposite Z or S twist corresponding to about 30% to 70% of the twist of the fed overtwisted core (20) that detwists during spinning. The inelastic core (20) is fed at controlled speed to compensate for the angle of feed and to compensate for detwisting, and is guided into the spinning triangle (40) by a guide groove (52) in a feed roller (50).

Owner:DUPONT SAFETY & CONSTR INC

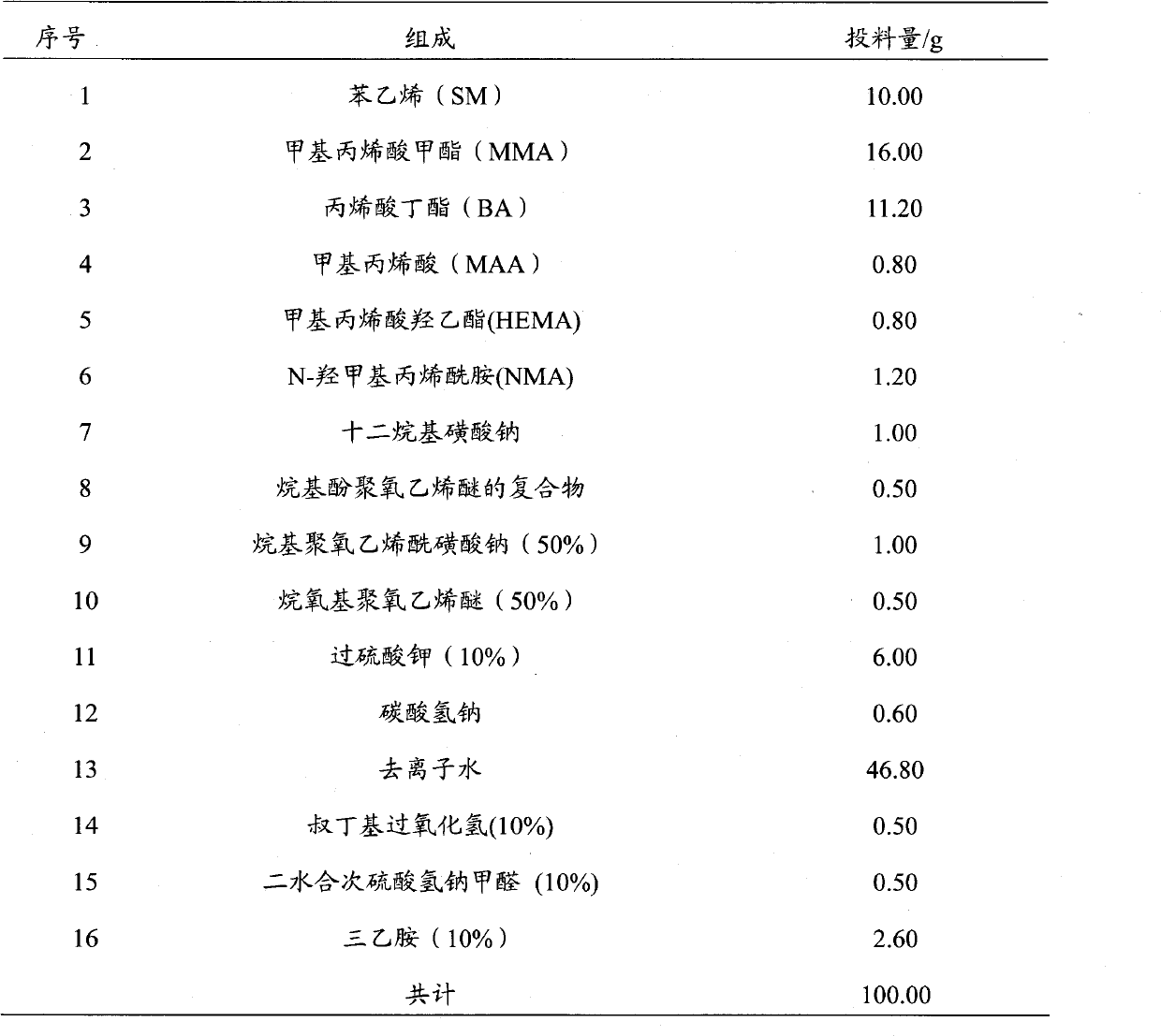

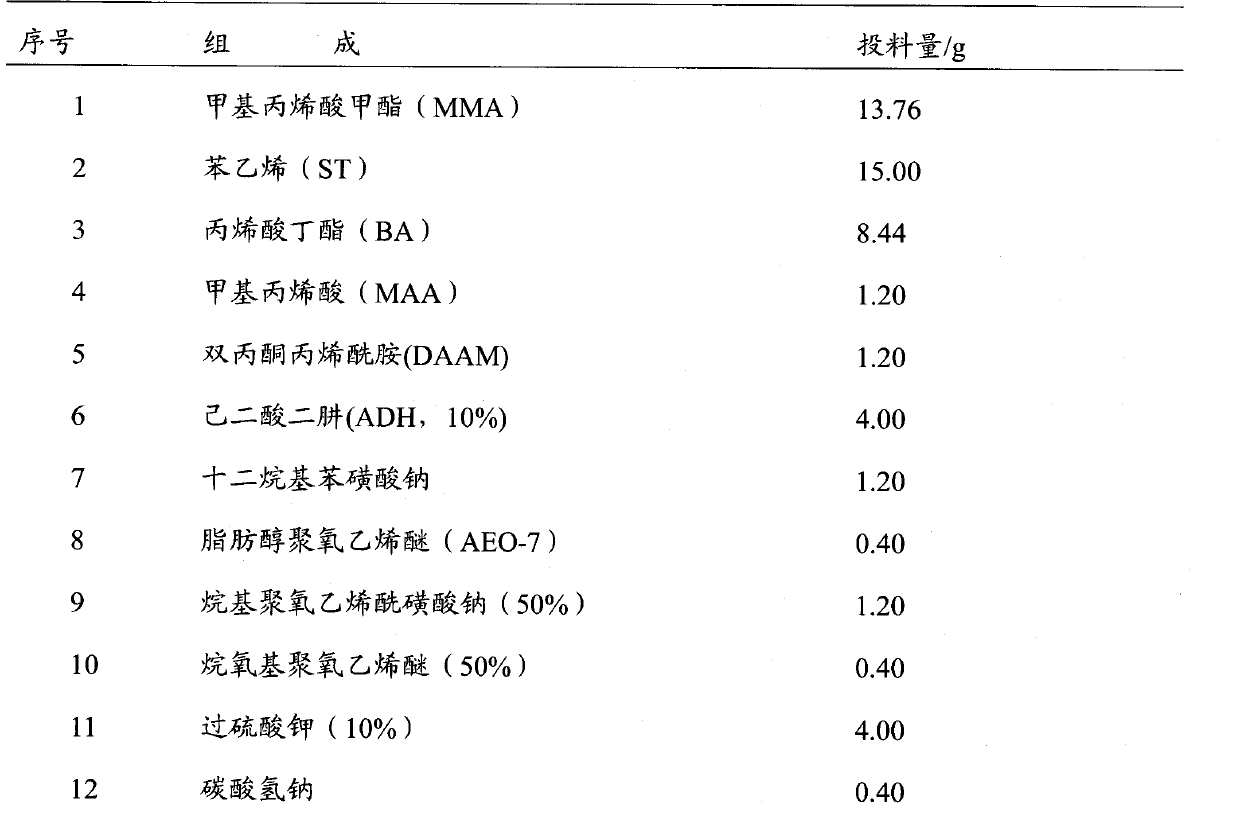

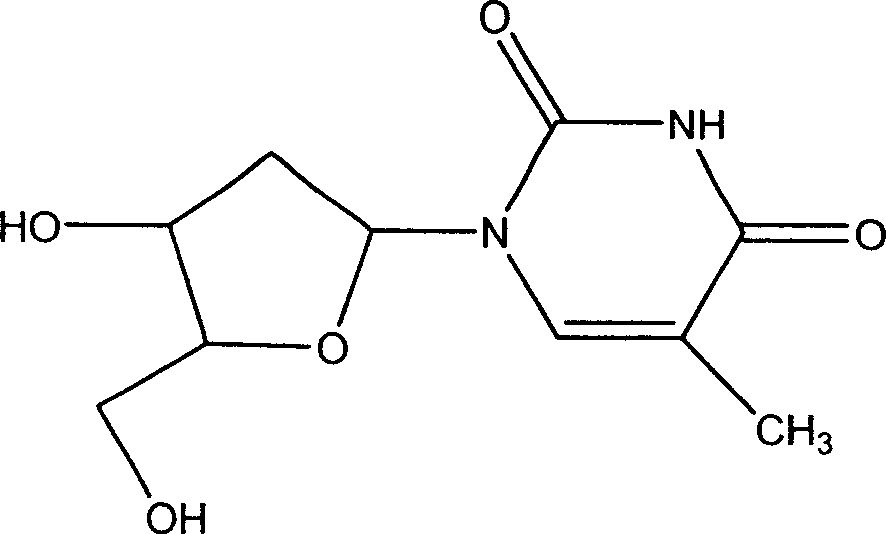

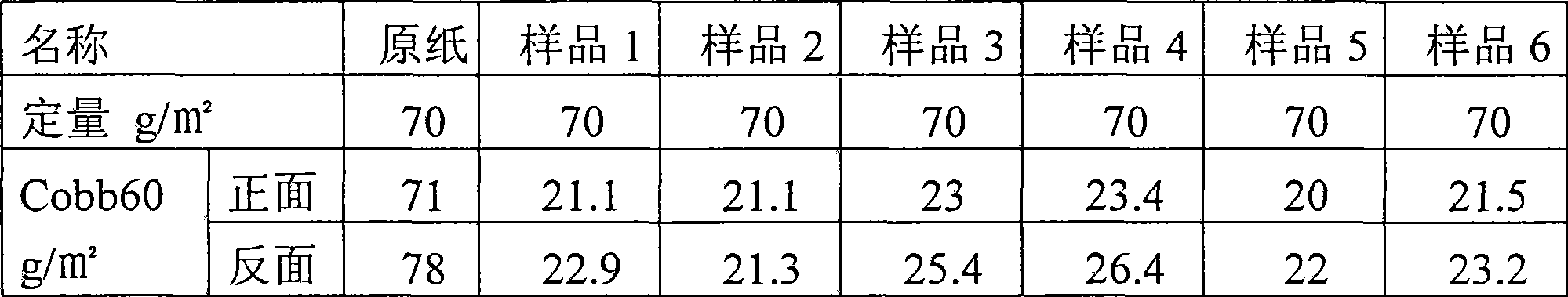

Styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and preparation method and application thereof

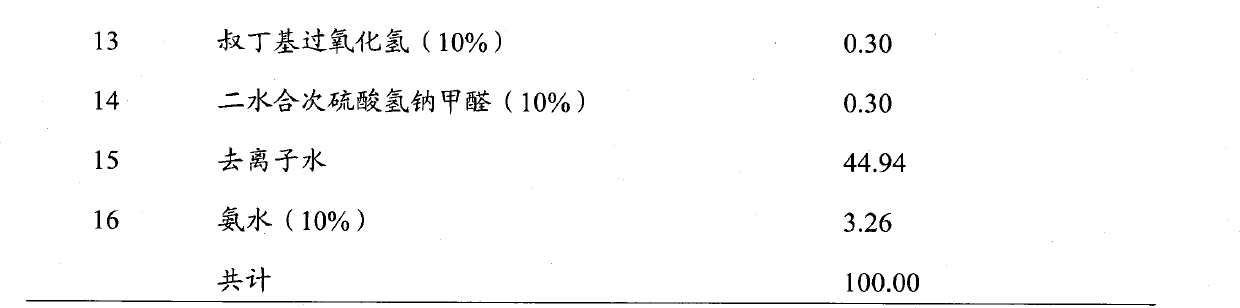

InactiveCN101544717AImprove water resistanceLarge particle sizeWater-repelling agents additionPaper/cardboardEmulsionOxidation-Reduction Agent

The invention discloses a styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and a preparation method and an application thereof. The preparation method comprises the following steps: adopting a seed emulsion method to synthesize core emulsion, dropping core pre-emulsified monomer solution and redox initiator into core the emulsion, controlling the dropping time, filtering the product of reaction by using a 250 mesh or 300 mesh sieve, discharging, and obtaining the microemulsion with hard core and soft core shell structure, wherein the microemulsion has a grain diameter of 20-100nm and the solid content of 40-48 percent. The surface sizing agent has the base characteristics of styrene-acrylic emulsion, good stability, core shell structure, small grain diameter, high solid content, and better gluing effect and can endow paper with better water resisting property and improve the surface property of the paper.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing polymer colloid photon crystal film by using spraying method

The invention belongs to the preparation and application technical field of a colloid photon crystal film, in particular relating to a method which adopts a spray coating method to realize simple, quick and large-area preparation of the polymer colloid photon crystal film. The method comprises the following steps that: monodisperse polymer latex particle with a hard nucleus-soft structure shell is dispersed in water at normal temperature; then, the obtained monodisperse polymer latex particle dispersion liquid is packed in a container with a common air spray gun; the spray gun is aimed at a selected leveled off base material to carry out spray coating; when the moisture in the monodisperse polymer latex particle is volatized under the action of gun body gas, a colloid photon crystal film is formed by the monodisperse polymer latex particle piling up on the surface of the base material in a face-centered cubic; and after a coated film is dried, a large area of polymer colloid photon crystal film with a photon band gap and in a visible region or an ultraviolet region can be obtained.

Owner:INST OF CHEM CHINESE ACAD OF SCI

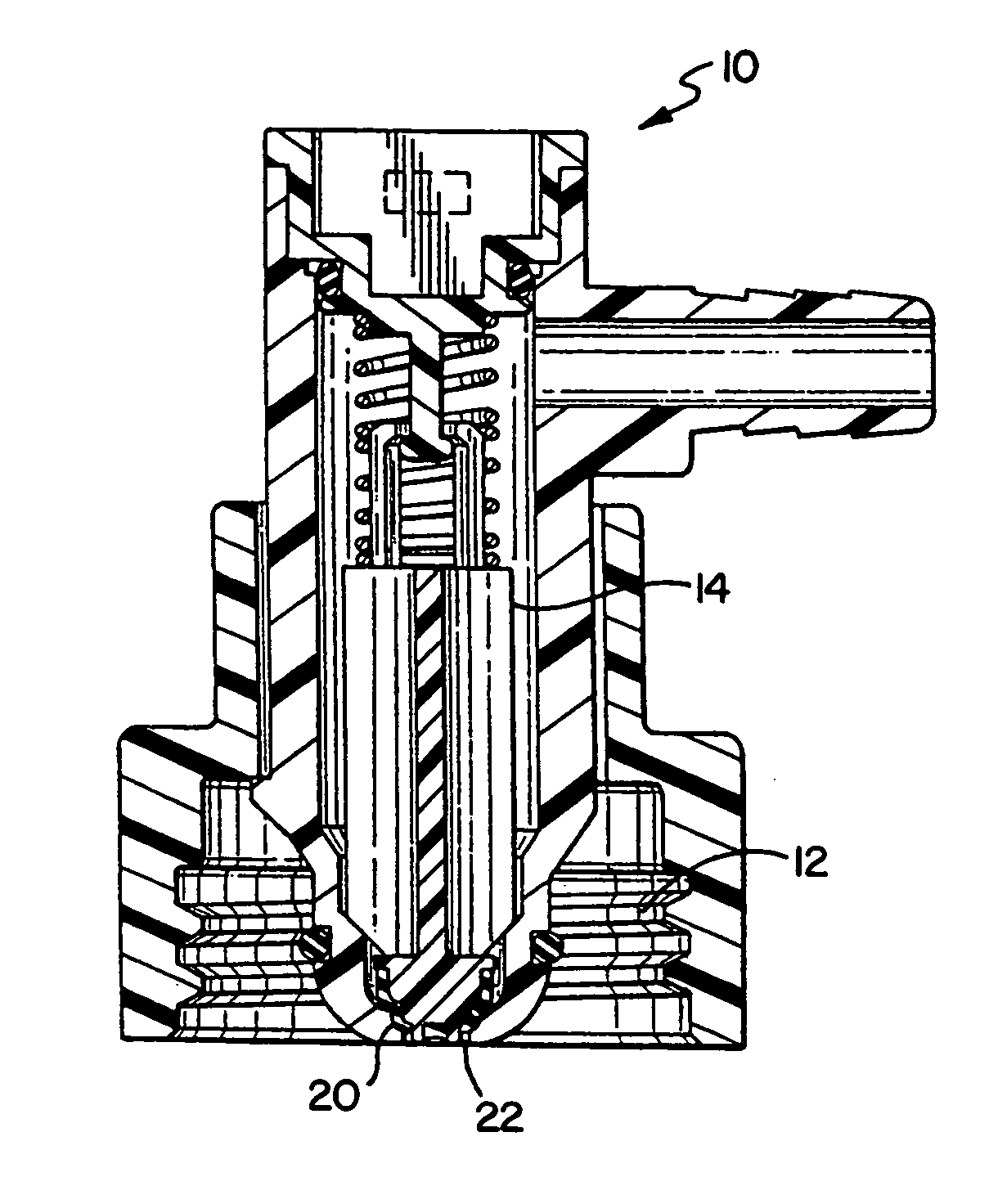

Valve for a fluid flow connector having an overmolded plunger

ActiveUS20070138423A1Reduce swellingCheck valvesJoints with fluid cut-off meansEngineeringVALVE PORT

A fluid flow connector and a method of manufacturing the same wherein the fluid flow connector utilizes a valve having a plunger which is made by overmolding a soft exterior to a hard core. The soft exterior being overmolded to the hard core by either insert or multi-shot methods. The method also including attaching the soft exterior to the hard core mechanically and / or by molecular bonding.

Owner:RAPAK INC

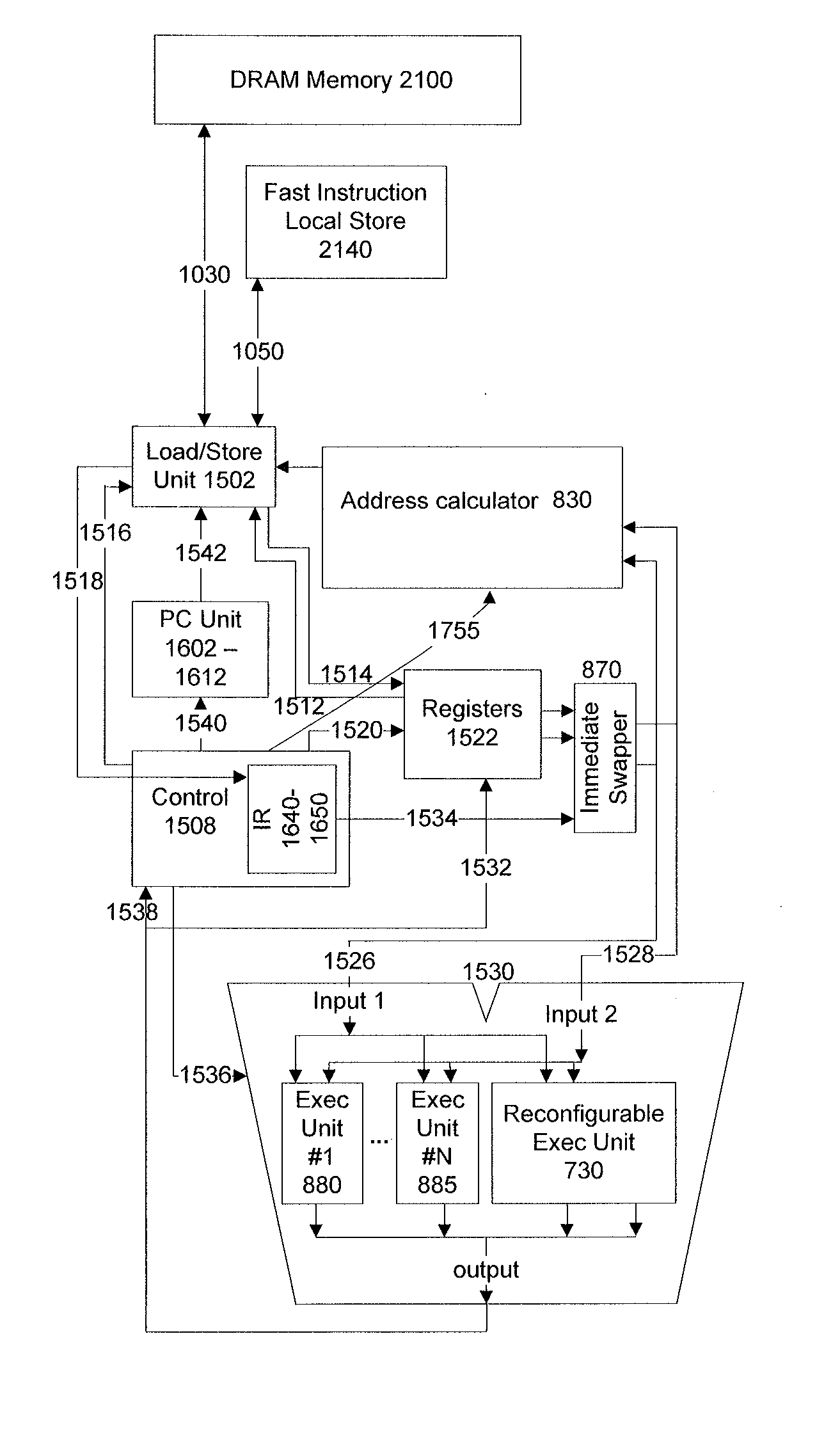

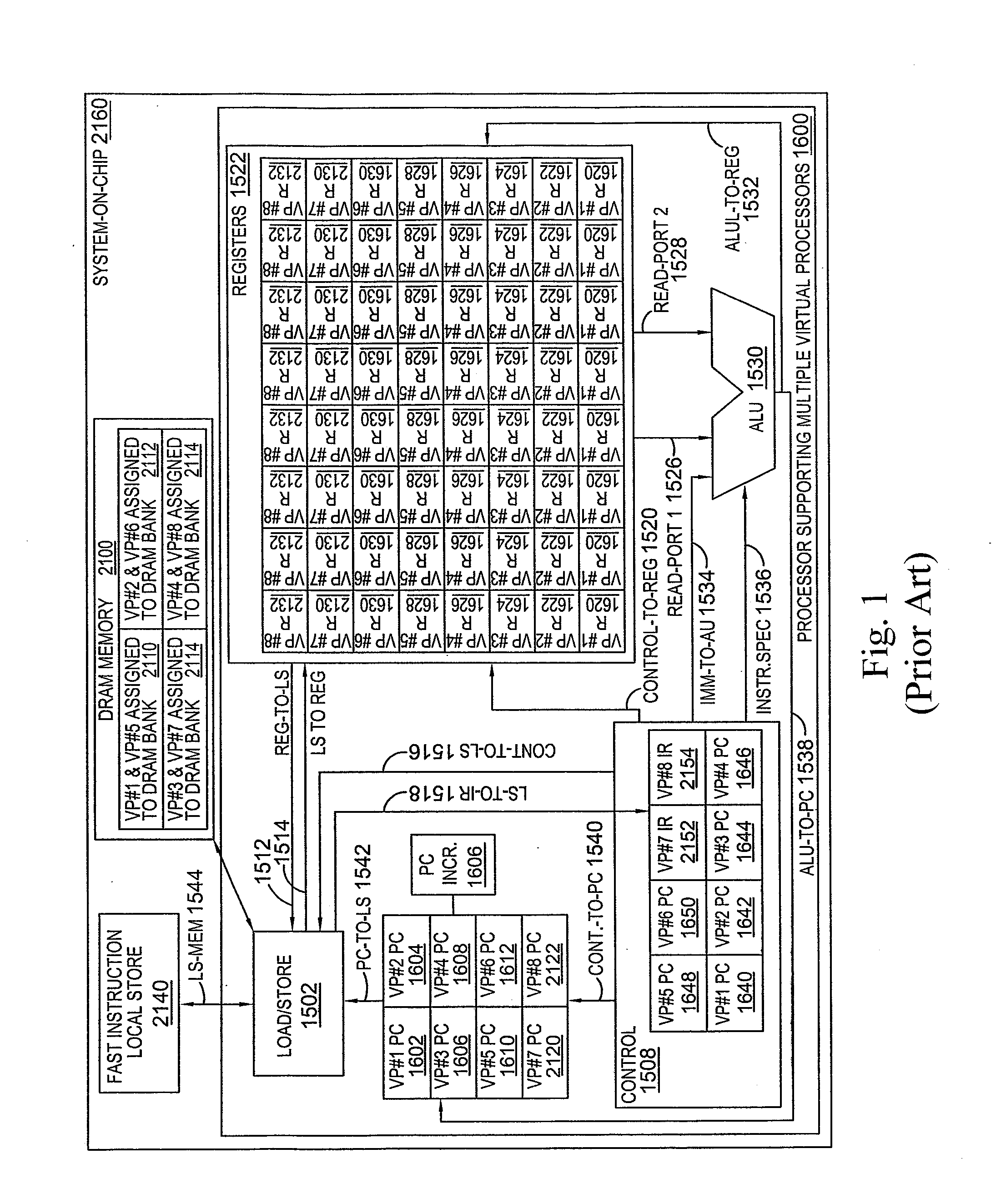

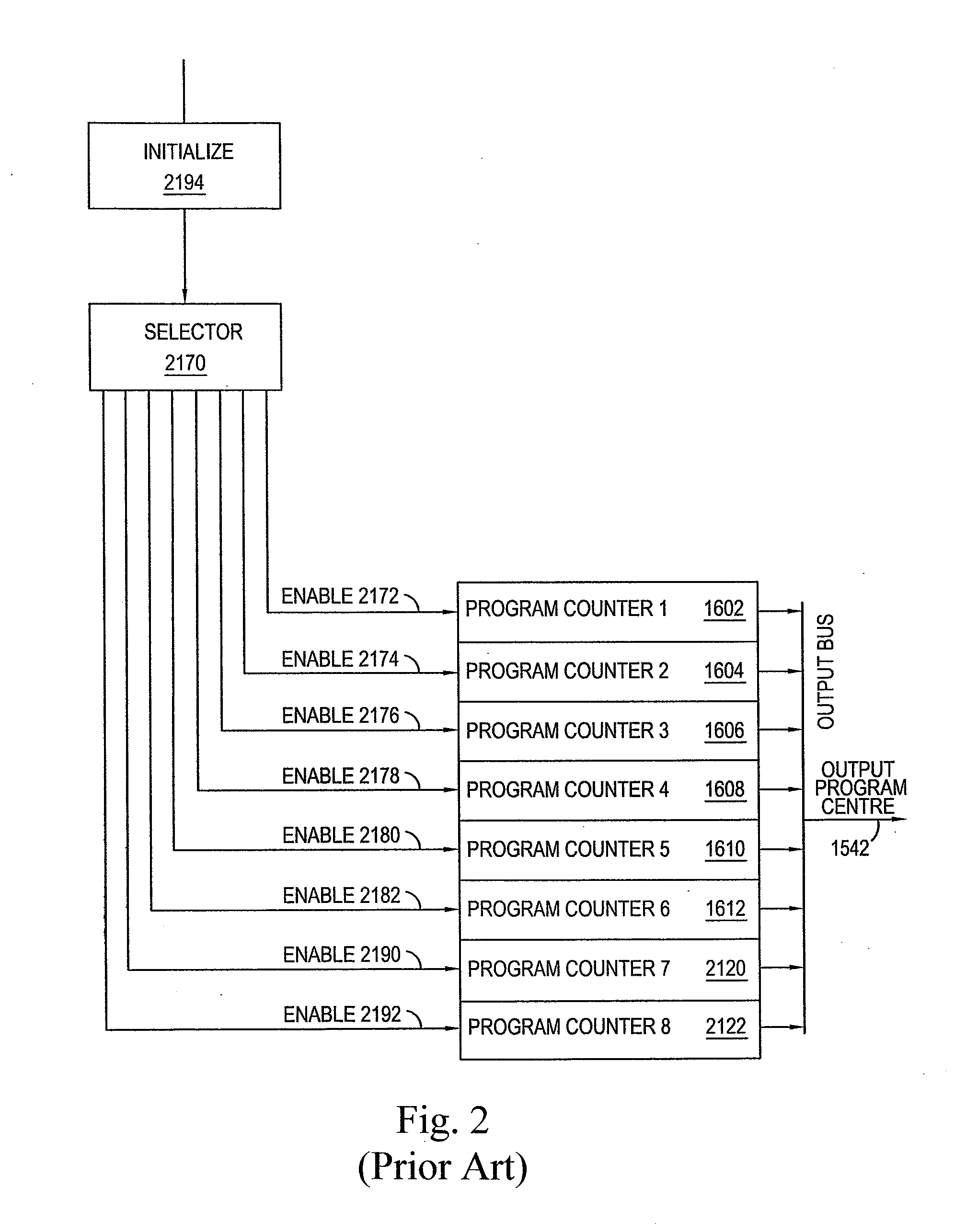

Integrated circuit having a hard core and a soft core

An integrated circuit (IC) is disclosed. The integrated circuit includes a non-reconfigurable multi-threaded processor core that implements a pipeline having n ordered stages, wherein n is an integer greater than 1. The multi-threaded processor core implements a default instruction set. The integrated circuit also includes reconfigurable hardware that implements n discrete pipeline stages of a reconfigurable execution unit. The n discrete pipeline stages of the reconfigurable execution unit are pipeline stages of the pipeline that is implemented by the multi-threaded processor core.

Owner:COGNITIVE ELECTRONICS INC

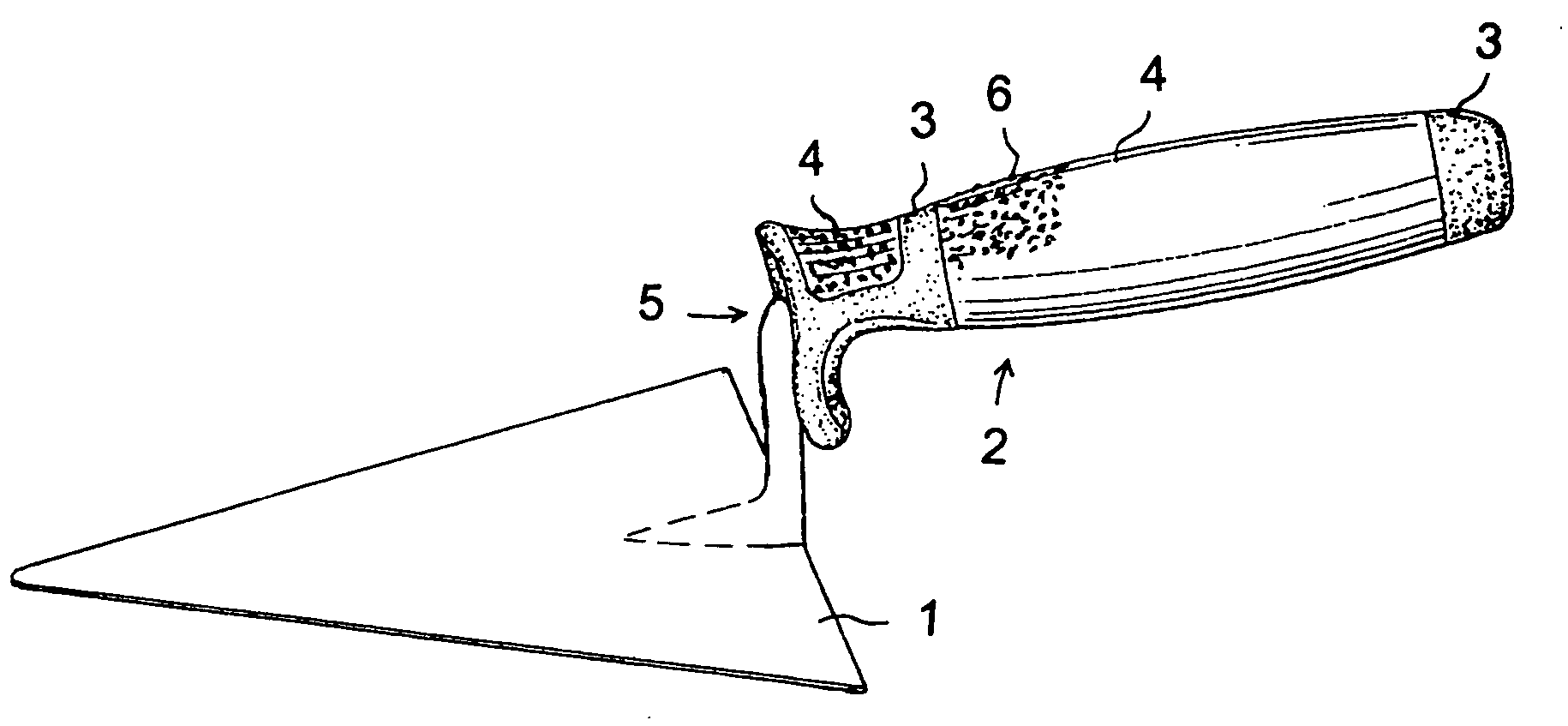

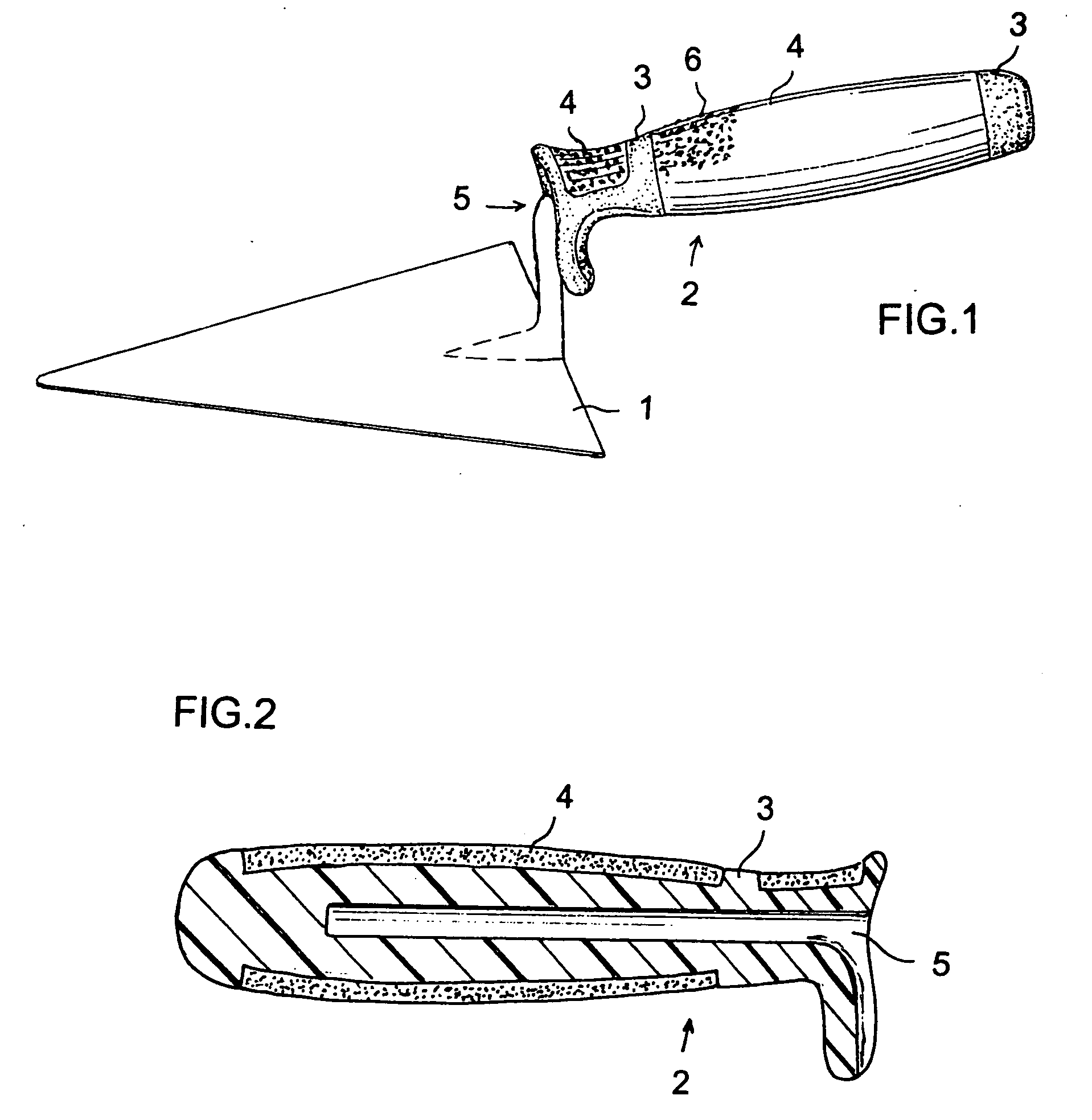

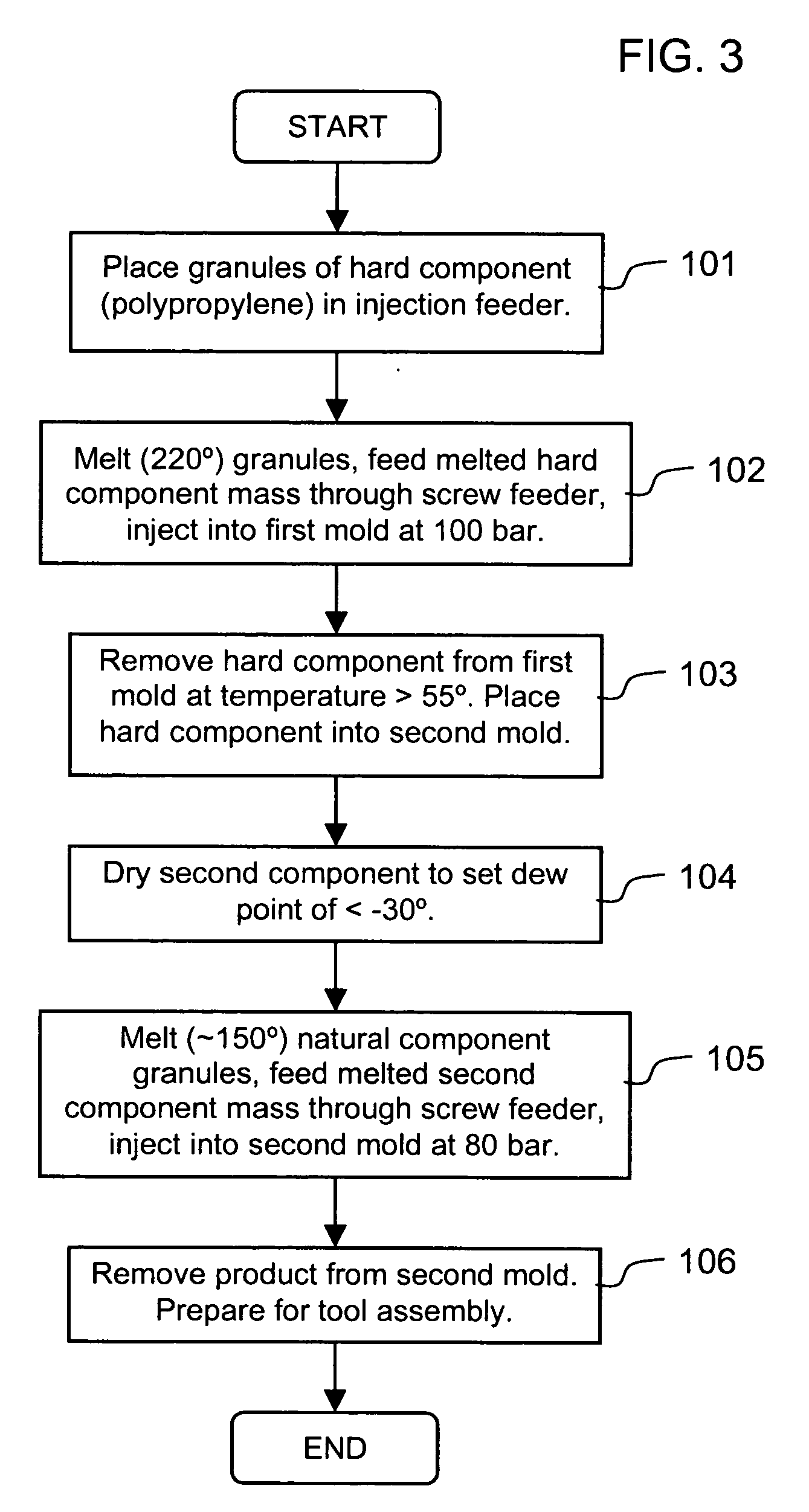

Two-component composite handle for a hand tool

InactiveUS20080014412A1Superior gripping characteristicImproved in of “ touchLayered productsDomestic articlesPlastic materialsSynthetic materials

A composite handle for a tool has a hard plastic material core and a softer grip cover with a natural component such as cork, cotton, flax, wood, or the like in a matrix of synthetic material. The two components are sequentially injection molded and a portion of the handle surface is formed by the soft grip cover and the remainder of the exterior surface is formed by the hard core. After the first injection shot, in which the hard plastic core is formed, the core is placed in a second mold and the temperature of the core is held at 55°-70° C. when the second shot is injected. The second component material with the natural component intimately distributed in the matrix of synthetic material may be injected at a temperature of up to approx. 220° C. and its final hardness is set by selectively mixing and adjusting the relative quantities of the natural component and the synthetic material.

Owner:ING JOHANN HORTNAGL WERKZEUGE M B H

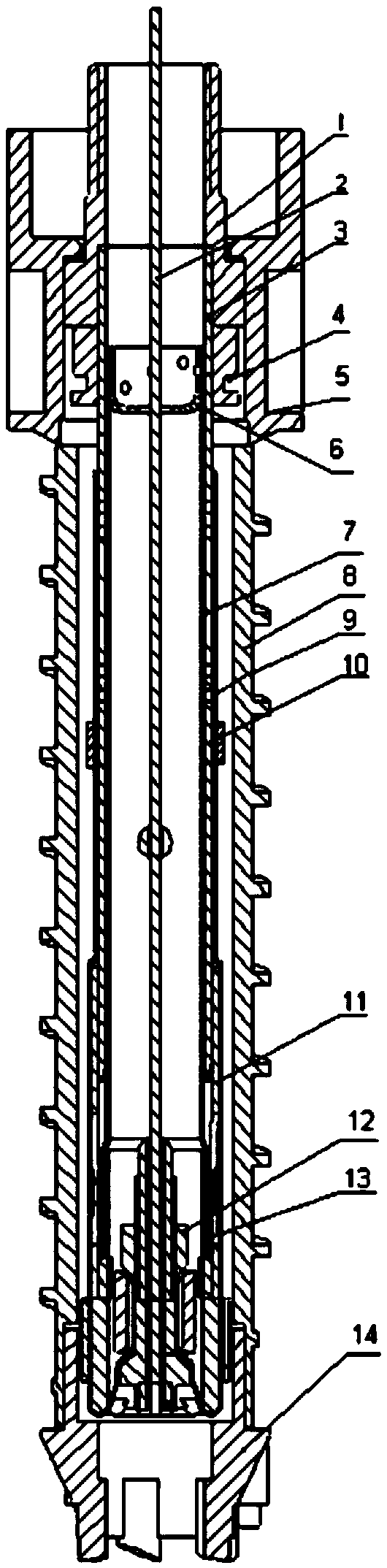

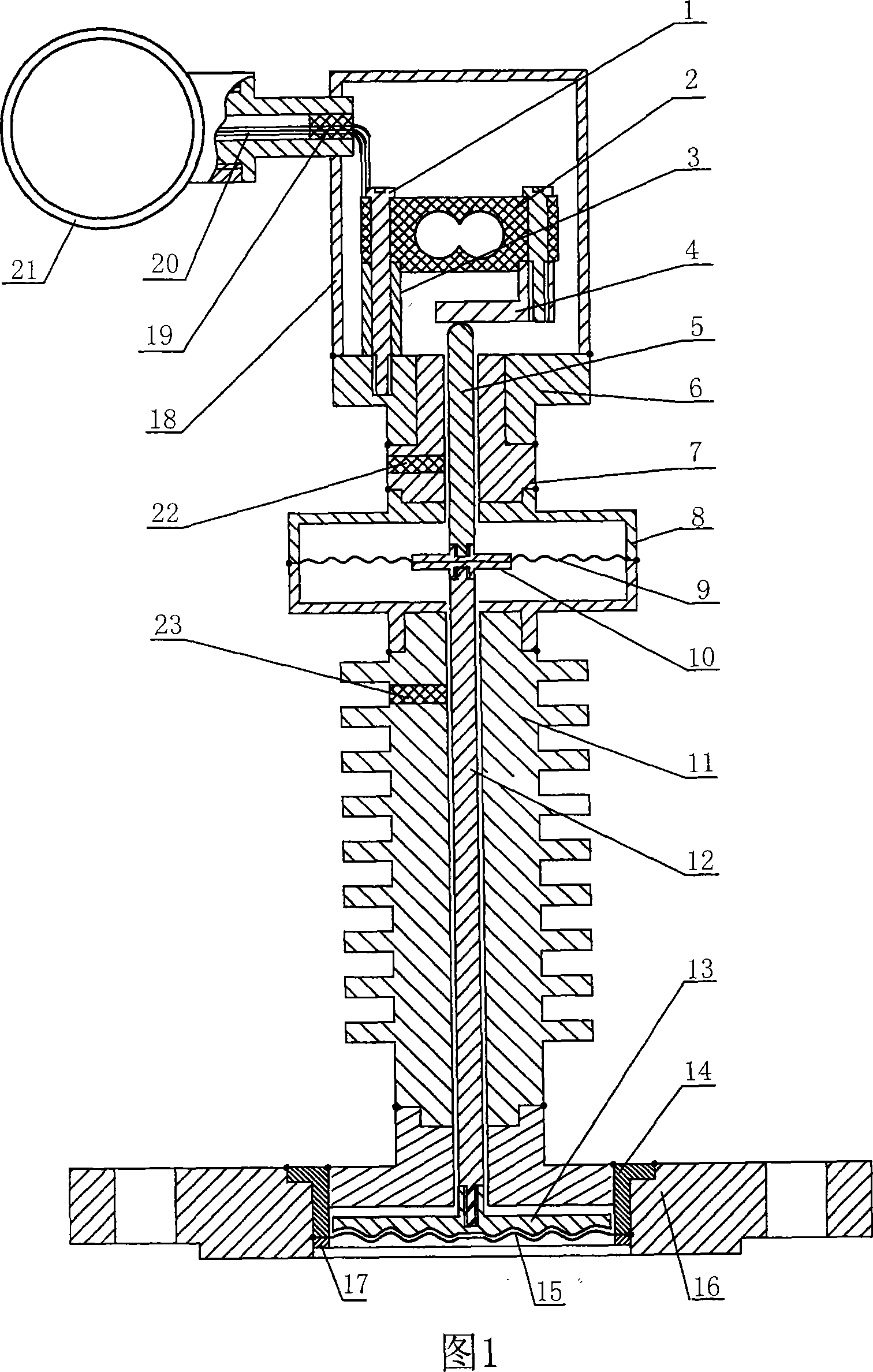

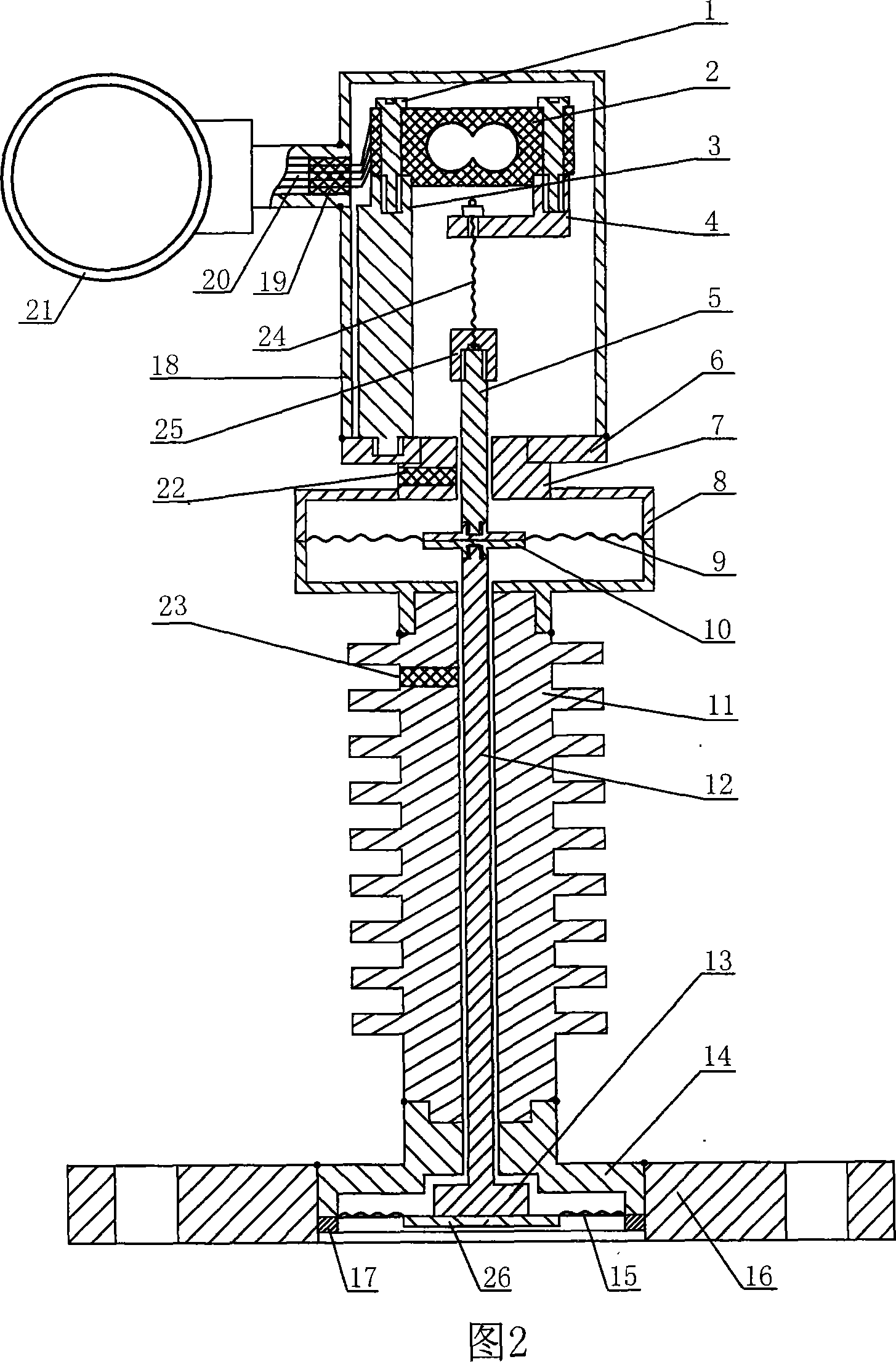

Built-in soft lunar soil sample sampling mechanism

ActiveCN105510078AGet raw scientific valueSave recycling spaceWithdrawing sample devicesLunar soilEngineering

The invention discloses a built-in soft lunar soil sample sampling mechanism. A core tube top joint, a core lifting stay rope, a core taking tube, a fixed ring, a drill rod sub, a spacing ring, a soft core-taking bag, a drill rod, a core taking belt, a guide ring, a core tube base joint, a pull head assembly, a sealer and a drill. The drill rod sub, the drill rod and the drill are fixedly connected to form a hollow drilling tool. The core tube top joint, the core taking tube and the core tube base joint form a hard core taking tube. The core tube base joint has an inner annular cavity structure. The soft core-taking bag is connected on the sealer, which is preplaced in the annular cavity of the core tube base joint. The spacing ring is installed on the soft core taking bag. The core taking belt passes through the guide ring to be fixedly connected on the pull head assembly. The sampling mechanism of the invention is simple and operates reliably, and can keep sequence information of deep lunar soil samples. The soft core taking bag for wrapping lunar soil samples can be used to realize in situ packaging, winding and recovering of deep lunar soil samples 2 m deep below the lunar surface, and recovery space is saved.

Owner:BEIJING SATELLITE MFG FACTORY

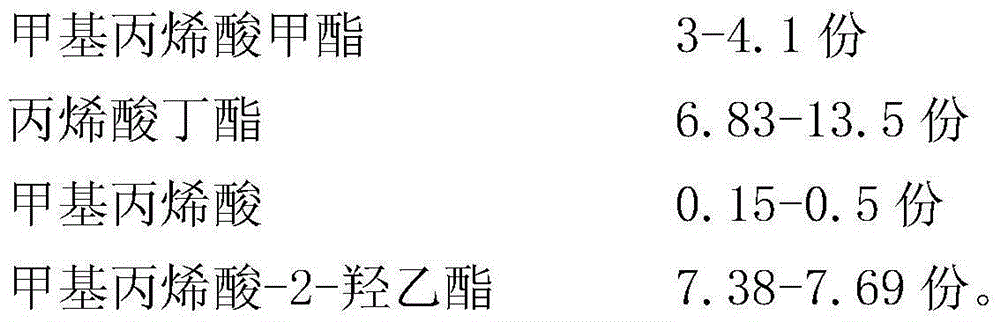

Polyacrylic woodware emulsion with core-shell bi-crosslinking structure and preparation method thereof

The invention relates to a polyacrylic woodware emulsion with a core-shell bi-crosslinking structure and a preparation method thereof. The polyacrylic woodware emulsion is prepared from the following components: methyl methacrylate, butyl methacrylate, methacrylic acid, a crosslinking monomer, butyl acrylate, methacrylic acid-2-hydroxy ethyl, diacetone acrylamide, adipic dihydrazide, an initiator, an emulsifier, and deionized water. Through molecular design of the polyacrylic emulsion with hard core and soft shell, the hard core provides the hardness and mechanical strength of a coating film and improves the stain resistance of a paint film, and the soft shell can improve the film-forming property of coating film, has no need for film-forming assistant, reduces VOC emission, and improves the low temperature resistance of the coating film. By means of the core-shell bi-crosslinking system, the hardness and water resistance of the paint film are improved.

Owner:SKSHU PAINT

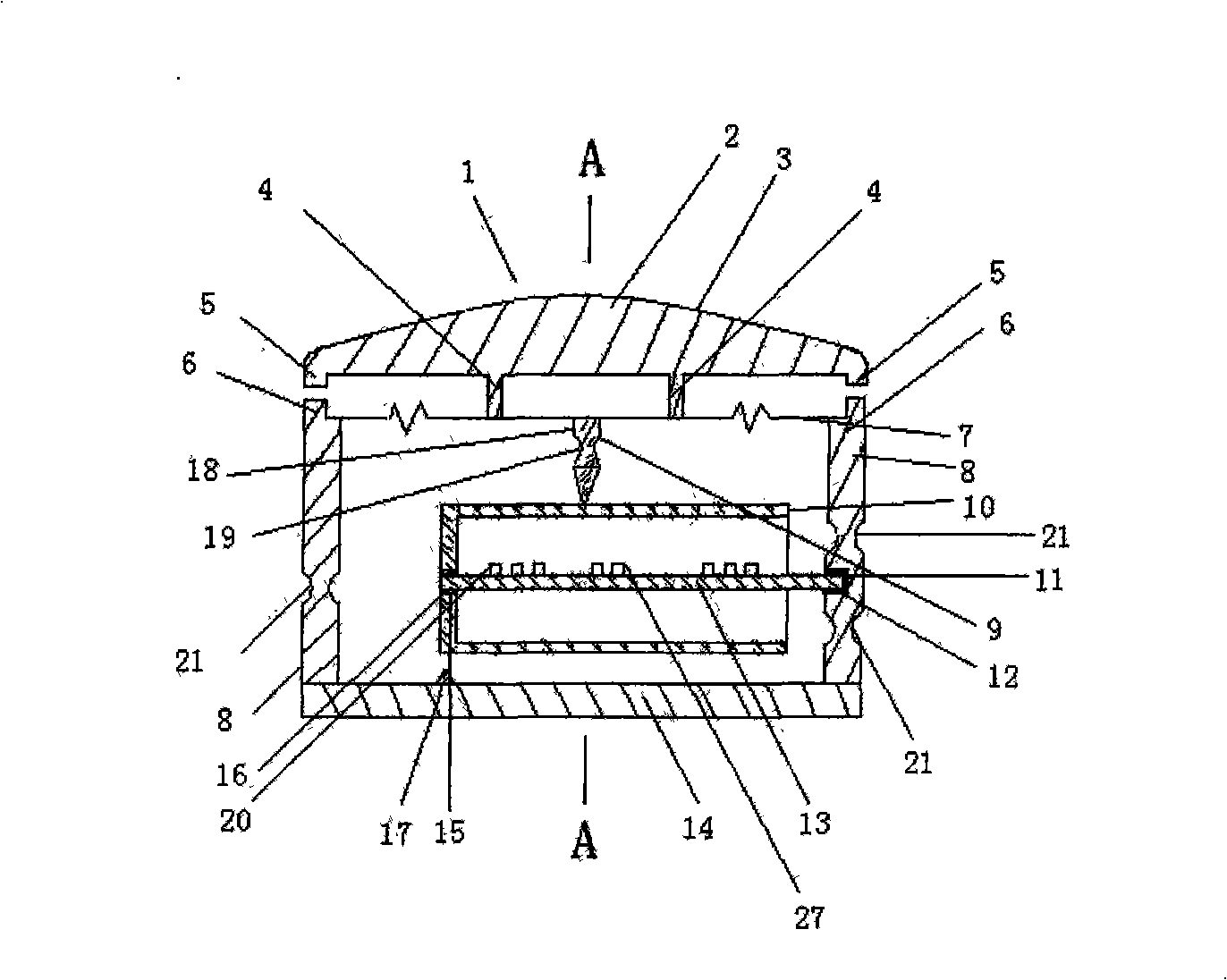

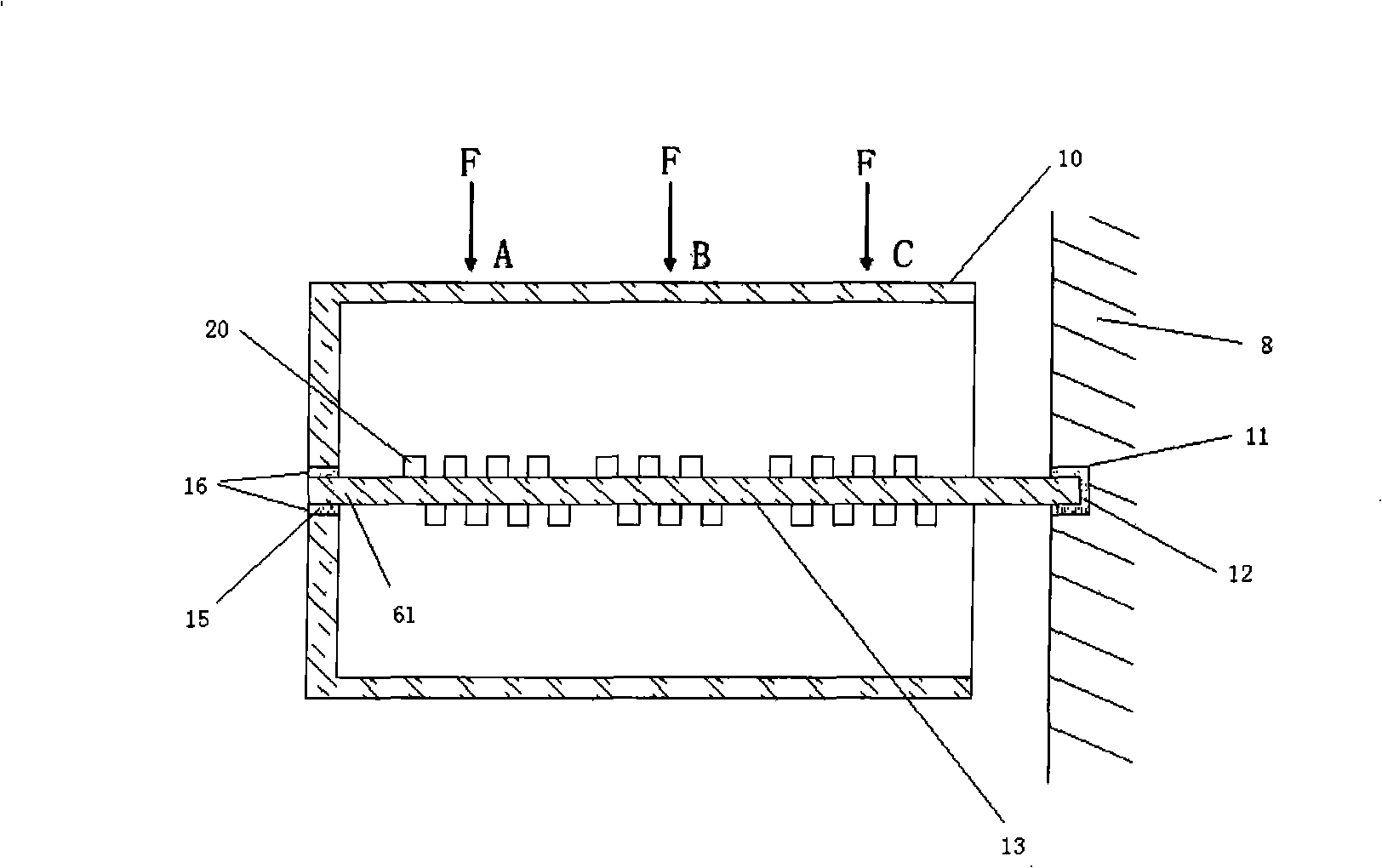

Sonic surface wave pressure sensor using composite mold

ActiveCN101354302AImprove long-term stabilityReduce oxidationFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesOvervoltageSurface acoustic wave

The invention relates to a surface acoustic wave pressure sensor adopting a compound die, which pertains to the technical field of sensors and comprises a mushroom pressurization cap, a hard-core ball shell pressure guiding metal diaphragm, a metal force guiding column, an overvoltage protective device, a metal shell side wall, a force guiding ejector disk, a force guiding cylinder, a quartz cantilever beam sensitive element, a bottom case and an overvoltage protective device, wherein, the hard-core ball shell pressure guiding metal diaphragm, the metal shell side wall and the bottom case form an air-tight container; the upper surface of the hard-core ball shell pressure guiding metal diaphragm is connected with the mushroom pressurization cap by the metal force guiding column, while the lower surface thereof is fixed with the force guiding ejector disk rigidly connected with the force guiding cylinder; the interior of the force guiding cylinder is provided with the quartz cantilever beam sensitive element; one end of the quartz cantilever beam sensitive element is connected with a blind hole end surface of the force guiding cylinder by glass powder, while the other end thereof is connected with a blind hole of the metal shell side wall by utilizing glass powder. The flexibility of the invention is 15 times higher than the conventional surface wave sensor, and the surface acoustic wave pressure sensor of the invention is suitable for the wireless monitoring of the tire pressure of carts.

Owner:SHANGHAI JIAO TONG UNIV

Impact resistant acrylic alloy

ActiveUS20120164364A1Reduced melt flow viscosityReduce melt viscositySynthetic resin layered productsWater/sewage treatment by flocculation/precipitationPolymer scienceHigh surface

The invention relates to an acrylic polymer, modified with one or more hard core core / shell impact modifier, which is blended with one or more low melt viscosity polymer. The alloy formed by the blend has good impact properties, good melt processability, high modulus, high surface hardness, and excellent resistance to chemical attack.

Owner:TRINSEO EURO GMBH

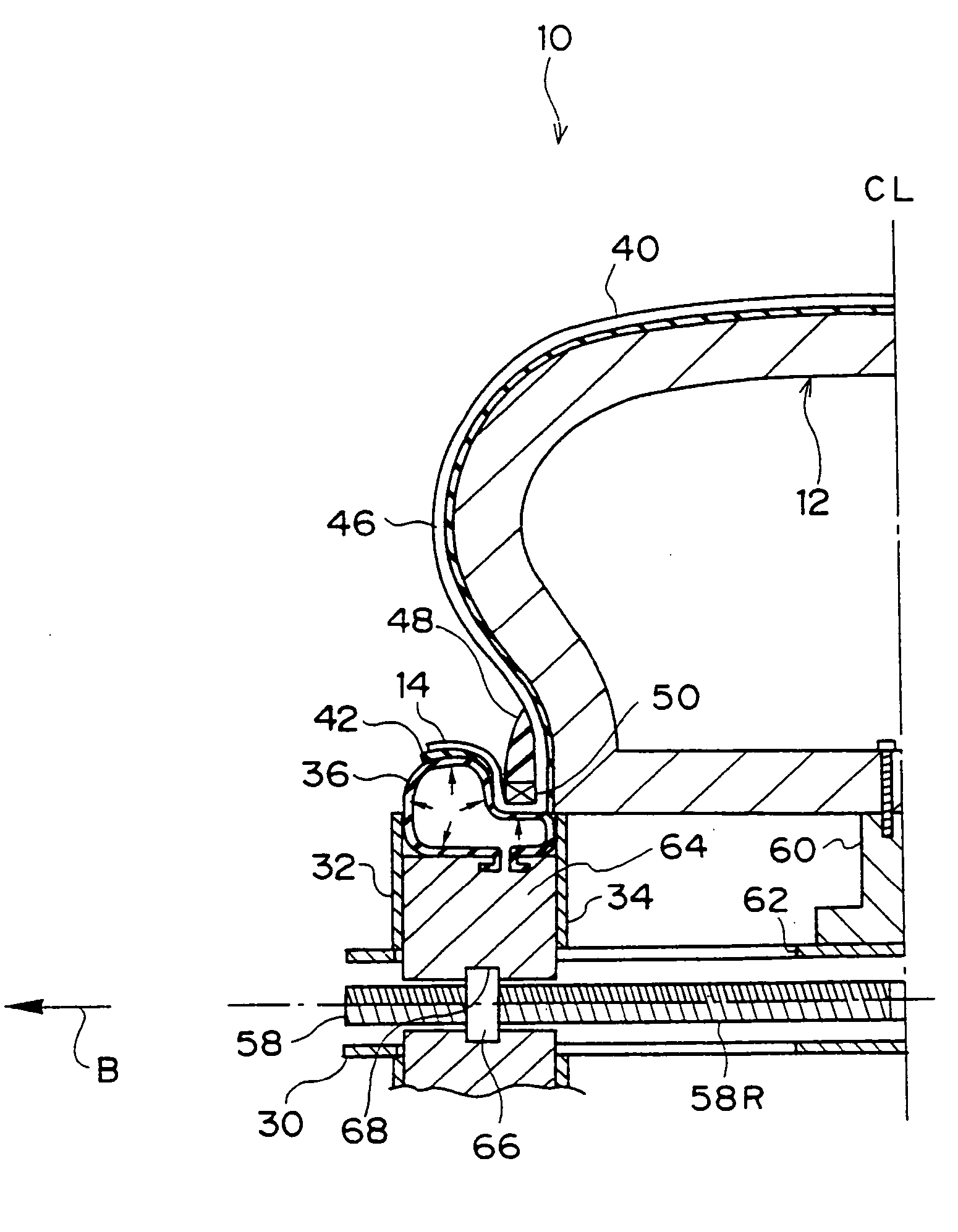

Tire manufacturing method, and green tire manufacturing equipment

Using a core manufacturing method, a green tire is obtained in which edge portions of a carcass ply are turned up at bead cores. An inner liner 40 is set on an external surface of a hard core 12, and a carcass 46 is formed thereon. A bladder 36 disposed inside the core is inflated, whereby edge portions of the carcass 46 can be turned up. Thereafter, conventionally known tire structural members such as a belt, a side tread and a top tread are set on, and a green tire is completed on the external surface of the hard core 12.

Owner:BRIDGESTONE CORP

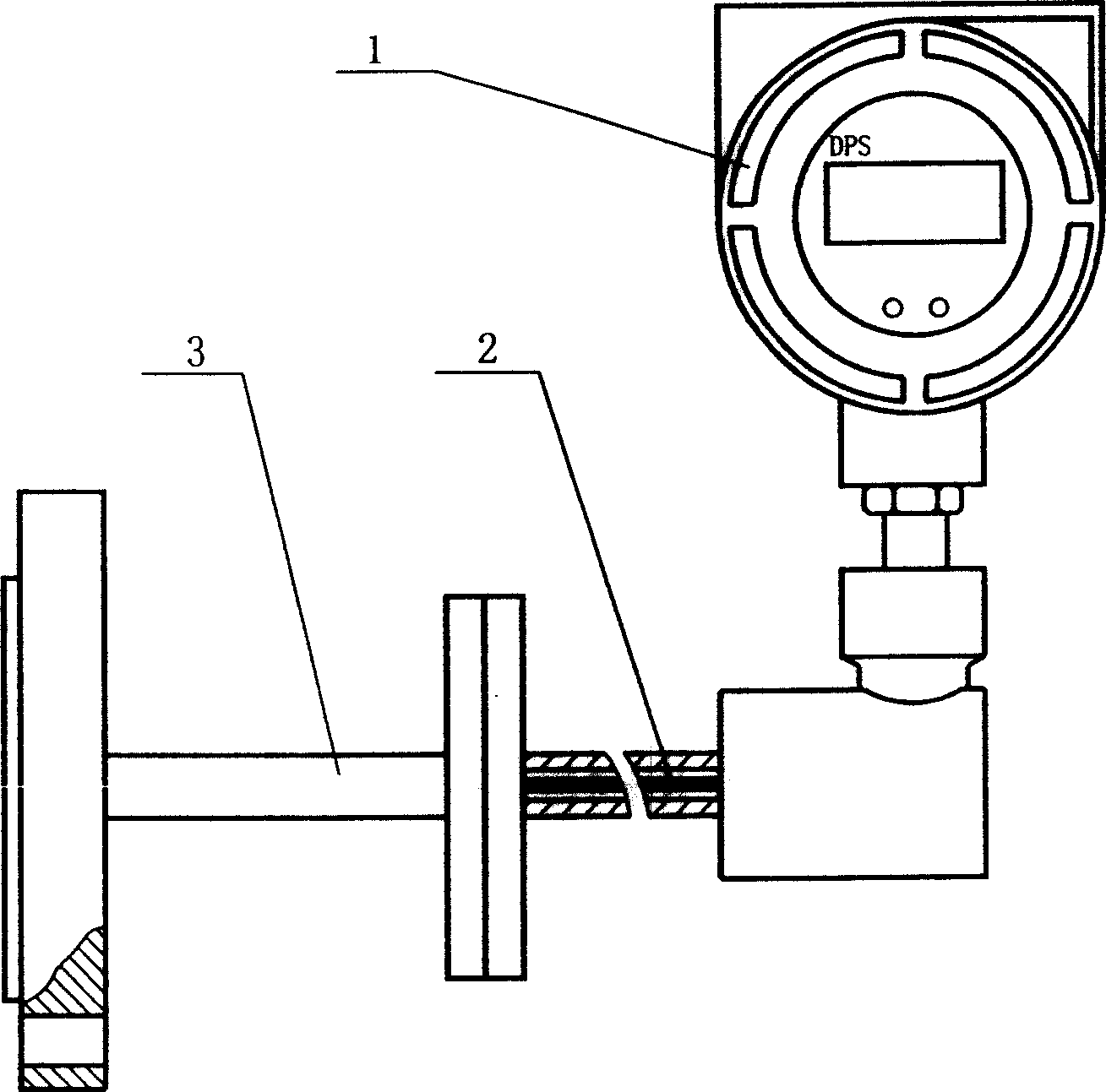

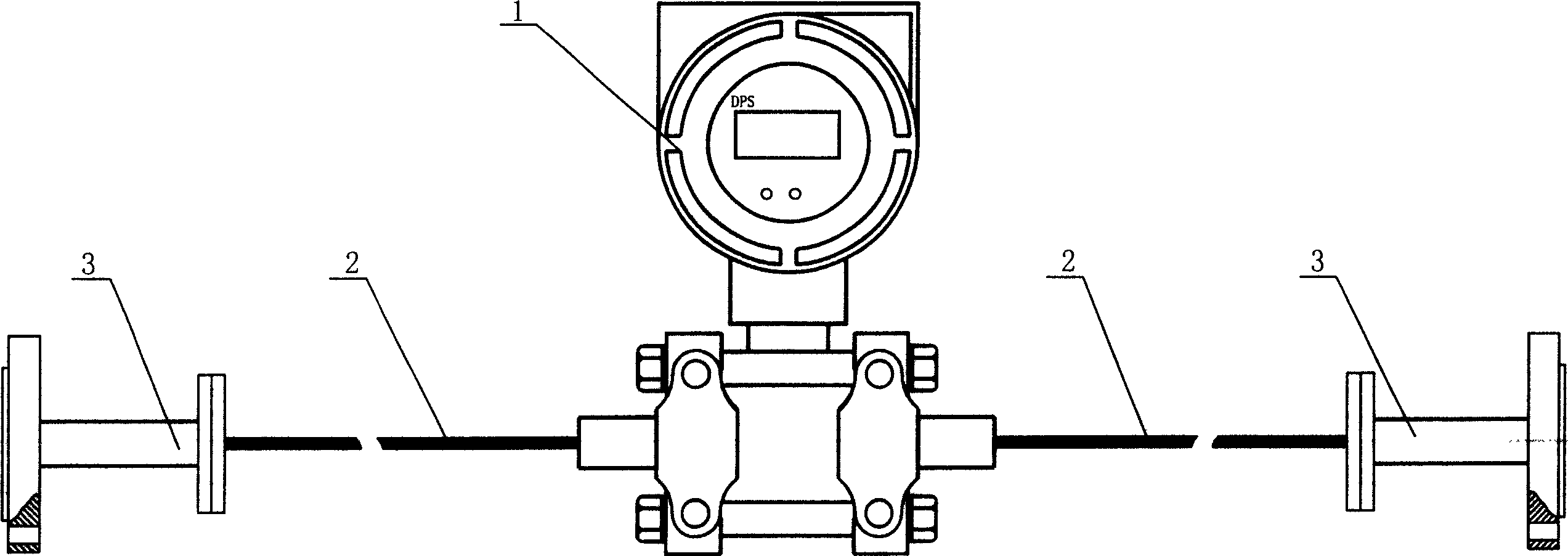

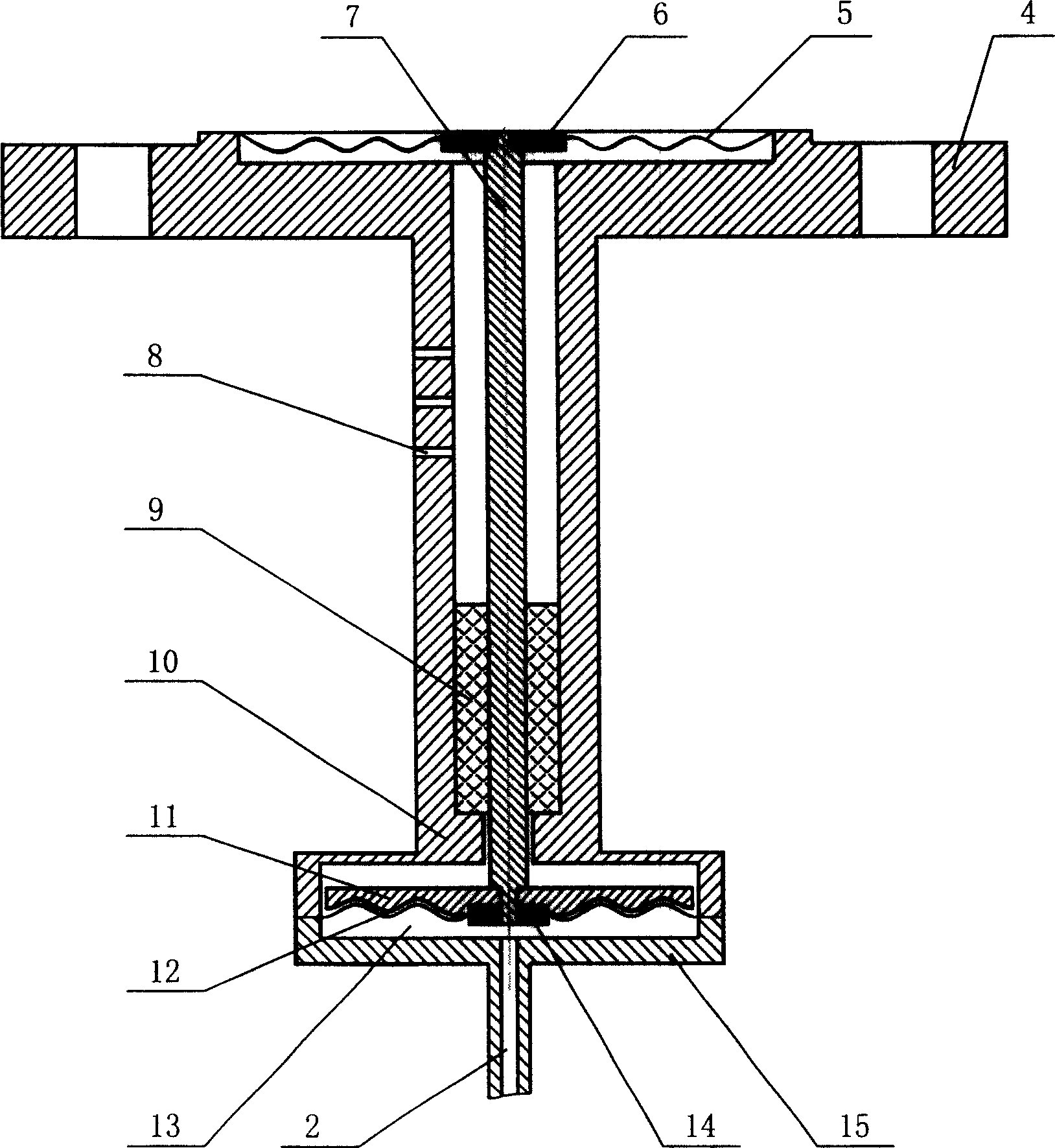

Telemetering high-temp pressure resistant / differential pressure sensor

InactiveCN1651891AReasonable structural designReasonable operationFluid pressure measurement by electric/magnetic elementsDifferential pressureTransducer

The present invention relates to a remote transferred high temperature resstant pressure / differential pressure transducer. Said invention includes the following components: transducer, measuring membrane, isolating diaphragm, membrane hard core, connecting flange, rigid stress bar and membrane box. Said invention also provides their connection mode, and said invented transducer can raise accuracy of measurement, and can prolong its service life.

Owner:SHENYANG SENSOR TECH INST

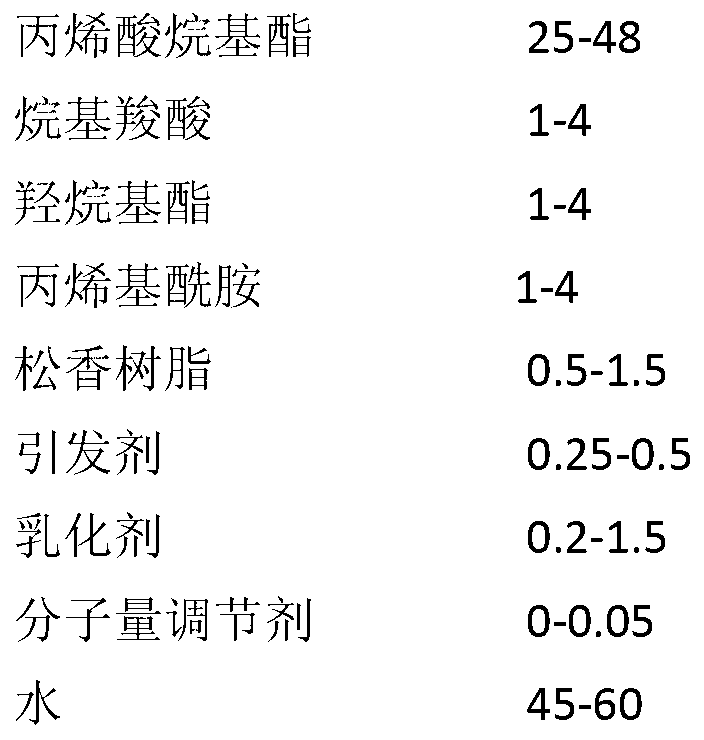

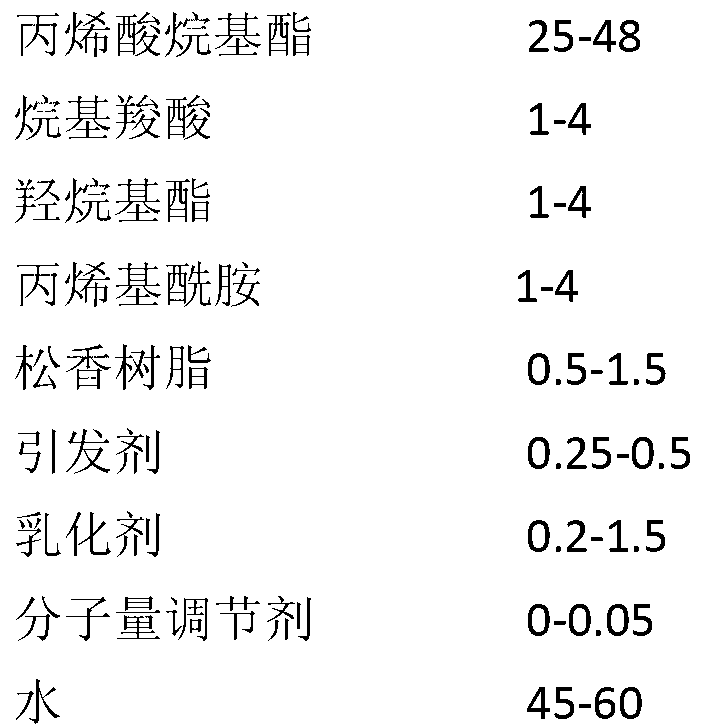

Frankincense-modified acrylate emulsion and its preparation method and use

The invention discloses a frankincense-modified acrylate emulsion and its preparation method and use. The frankincense-modified acrylate emulsion comprises, by mass, 25-48% of alkylacrylate, 1-4% of alkyl carboxylic acid, 1-4% of a hydroxyalkyl ester, 1-4% of acrylamide, 0.5-1.5% of rosin resin, 0.25-0.5% of an initiator, 0.2-1.5% of an emulsifier, 0-0.05% of a molecular weight conditioning agent and 5-60% of water. The invention also discloses PVC floor glue prepared from the frankincense-modified acrylate emulsion. The frankincense-modified acrylate emulsion has a hard-core soft-shell structure. The PVC floor glue prepared from the frankincense-modified acrylate emulsion has the advantages that through utilization of the tackifying resin and the hard-core soft-shell structure, base material wettability is improved; material adhesiveness is improved; initial adhesiveness is good; bonding strength is high; a film-forming assistant, a plasticizer and an antifreezing agent are avoided; and environmental friendliness is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Toughened and modified polyethylene terephthalate composite material and preparation method thereof

The invention provides a high-toughness polyethylene terephthalate (PET) composite material and a preparation method thereof. The composite material comprises a PET matrix, an elastic body, an inorganic nano material and a surface treating agent. The invention adopts a simple method to obtain a soft shell-hard core structure (sandbag structure) of an elastic body covered packing material so as to obtain the composite material with high toughness and high rigidity. The method achieves elastic body / nano calcium carbonate synergistic toughening of the polyethylene terephthalate, enlarges the application range, and reduces the cost of the material.

Owner:广东炜林纳新材料科技股份有限公司

Composite twist core-spun yarn and method and device for its production

A substantially torqueless composite dual core-spun yarn (10) has a substantially inelastic central hard core (20) covered with a dual-spun fiber covering (30). The central hard core (20) has an elongation at break less than 50% and a Z or S twist, and the fiber covering (30) comprises fibers twisted on the core (20) with an S or Z twist opposite to that of the core. The opposite twists of the core (20) and of the covering (30) exert opposite and substantially equal torques. This yarn is produced by introducing two slivers (30A,30B) forming the covering (30) and a central core in a spinning triangle (40). The core (20) is fed overtwisted S or Z and the slivers (30A,30B) have an opposite Z or S twist corresponding to about 30% to 70% of the twist of the fed overtwisted core (20) that detwists during spinning. The inelastic core (20) is fed at controlled speed to compensate for the angle of feed and to compensate for detwisting, and is guided into the spinning triangle (40) by a guide groove (52) in a feed roller (50).

Owner:DUPONT SAFETY & CONSTR INC

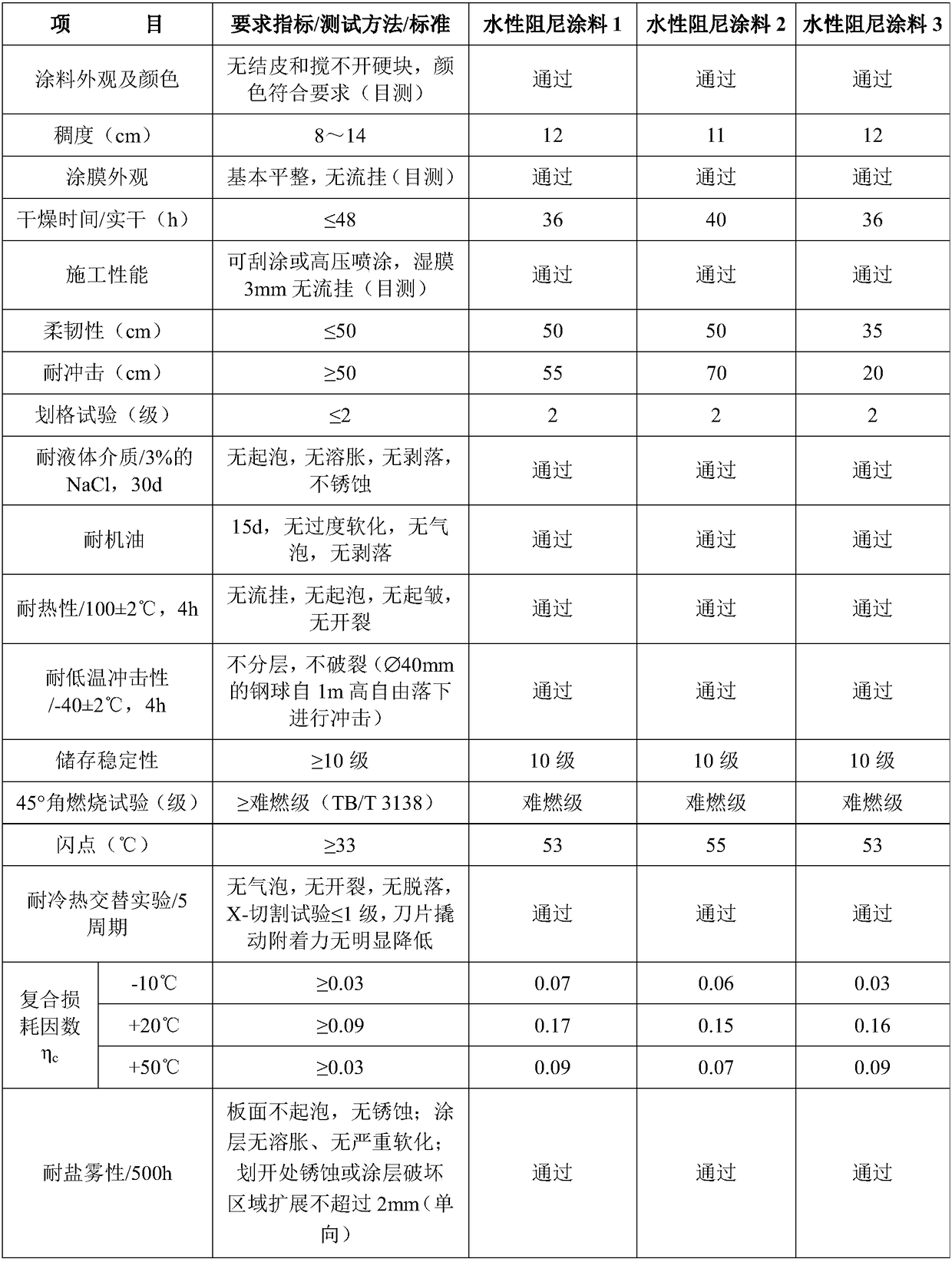

Hard-core and soft-shell type acrylic emulsion, and preparation method and application thereof

ActiveCN108129600ASimple preparation processWide damping temperature rangeCoatingsSodium bicarbonateEmulsion

The invention discloses a hard-core and soft-shell type acrylic emulsion, and a preparation method and an application thereof. The hard-core and soft-shell type acrylic emulsion is prepared from the following raw materials in parts by mass: 50 to 120 parts of a hard monomer, 60 to 150 parts of a soft monomer, 1 to 15 parts of a functional monomer, 1 to 5 parts of an emulsifier, 0.5 to 4 parts of sodium bicarbonate, 0.5 to 4 parts of an initiator, 4 to 7 parts of ammonia water and 100 to 200 parts of water. The hard-core and soft-shell type acrylic emulsion provided by the invention has simplepreparation process, and only needs reasonable adjustment of the addition ratio of the soft monomer to the hard monomer in the process of emulsion polymerization. The hard-core and soft-shell type acrylic emulsion provided by the invention can be used for waterborne damping coatings; the waterborne damping coating prepared from the hard-core and soft-shell type acrylic emulsion has wide damping temperature range; and the contradictions between high-temperature damping performance with impact resistance and flexibility of the coating can be well solved.

Owner:广州化工研究设计院有限公司 +1

Pressure converting to force pressure sensor/transmitter

InactiveCN101021445AEasy to manufactureLow costFluid pressure measurement using elastically-deformable gaugesForce measurementManufacturing cost reductionTransducer

A pressure sensor / transducer for transforming pressure to force contains force sensor and connecting element assembled by connecting module. Its technical features are: stressed block of connecting element is assembled on force sensor. Upper stress bar connecting with stressed block is jointed with lower vector bar by connecting hard-core and does advance and return movement along the internal cavity, which holds the two bars. Compressed aneroid of connecting element is fixed in adapting flange. Pressed body connecting the bottom end of lower vector bar is packaged in compressed aneroid by at least one corrugated diaphragm. It has more rational structural design and takes full advantages of sensor characteristics including simple construction, low cost and high precision etc. It can transform pressure to force in cooperation with connecting element, use force sensor with one measuring range to measure pressure with multi-range and complete measurement of plus-minus pressure under both high and low temperature, which reduce cost, improve measuring precision and extend application range greatly.

Owner:SHENYANG SENSOR TECH INST

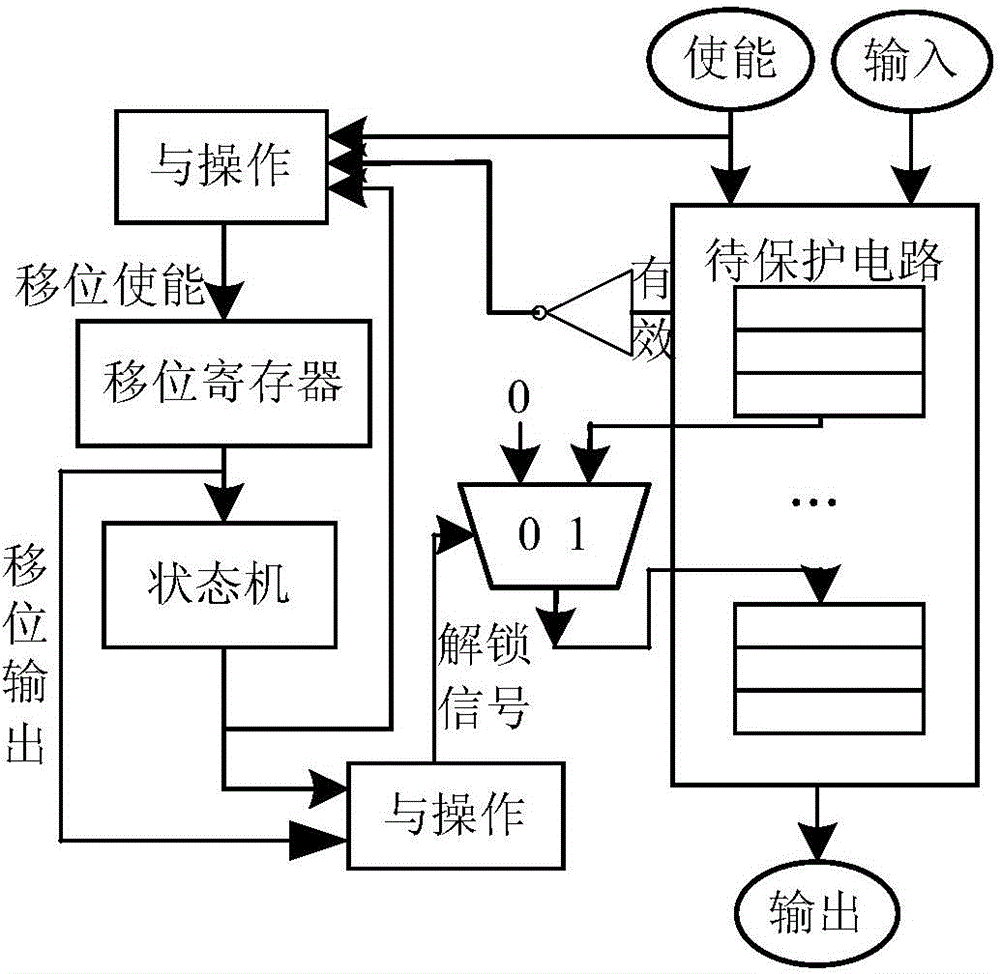

IP hard core intellectual property protection method and device based on path delay

InactiveCN104615952ADoes not affect running speedEasy to implementInternal/peripheral component protectionPath delayHard core

The invention relates to the field of integrated circuits and aims to provide an IP hard core intellectual property protection method and device based on path delay, wherein the IP hard core intellectual property protection method and device can be used for intellectual property protection of a timing sequence logic which can be applied to input and output and needs multiple delay periods. The IP hard core intellectual property protection method and device can effectively prevent various IP core theft problems, such as a brute force attack, a cleaning attack and reverse engineering. According to the technical scheme, the IP hard core intellectual property protection method based on the path delay comprises the following steps that 1, signals need to pass through a timing sequence logic path circuit of multiple time periods from input to output; 2, a protective path is designed; 3, a designed protective circuit comprises a shifting register, a finite state machine circuit and an interconnecting line, wherein the shifting register is used for storing an initialization secret key, the finite state machine circuit is used for secrete key checking, and the signal delay of the interconnecting line is adjustable; 4, the purpose of protecting a circuit IP is achieved by adjusting and controlling the input and output delay of the protective circuit and the protected circuit. The IP hard core intellectual property protection method and device based on the path delay are mainly applied to integrated circuits.

Owner:TIANJIN UNIV

A method for improving that alignment between a soft bonding plate layer and a hard bonding plate layer

ActiveCN108990317AHigh precisionImprove lamination qualityMultilayer circuit manufactureEngineeringExposure compensation

The invention discloses a method for improving the alignment between a soft bonding plate layer and a hard bonding plate layer, which comprises the following steps: manufacturing an inner layer circuit on a soft plate core plate; In the finished soft-hard bonding plate, the soft-board core plate comprises a soft-board area and a soft-hard bonding area; The coating film is pressed on the soft platearea of the soft plate core plate, and then the expansion and contraction coefficient of the soft plate core plate is measured. The inner layer circuit is fabricated on the hard board core board, andthe exposure compensation is carried out according to the expansion and contraction coefficient of the soft board core board when the inner layer circuit is fabricated. Using the same OPE punching machine to drill rivet holes at corresponding riveting positions on the soft plate core plate and the hard plate core plate respectively; Flexible and hard core plates are pre-laminated with non-flowingadhesive PP, riveted by rivets, and then compressed to produce plates. The method of the invention solves the deviation problem of the pressing counterpoint holes caused by pressing the covering film, improves the pressing quality of the soft-hard bonding plate, and reduces the deviation scrap rate of the soft-hard bonding plate layer.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com