Frankincense-modified acrylate emulsion and its preparation method and use

A technology of acrylate and rosin modification, which is applied in the direction of graft polymer adhesives, adhesive types, adhesives, etc. It can solve the problems of poor viscosity increasing effect and poor compatibility, and achieve low cost and good initial tack. Good, improve the effect of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

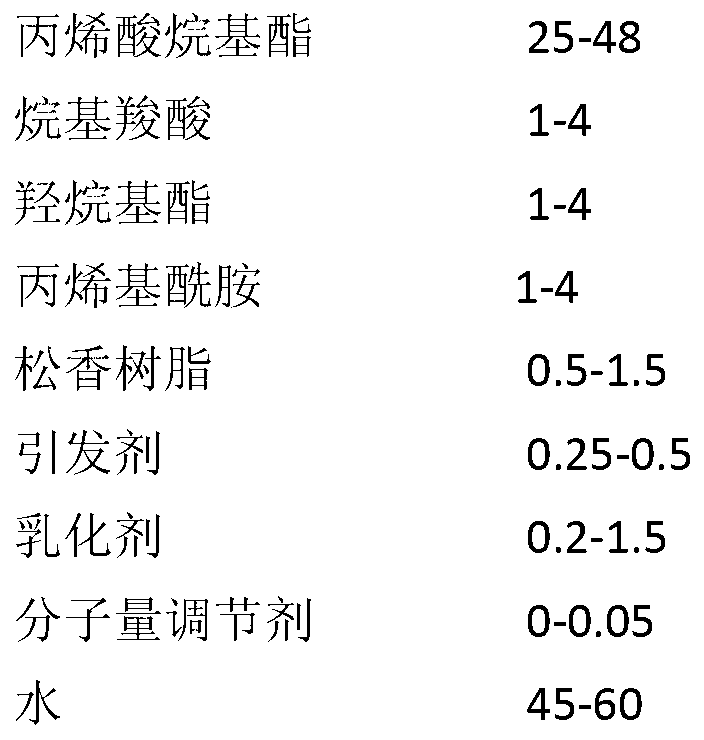

[0031] In the rosin modified acrylate emulsion, the proportioning ratio of each component by weight fraction is the following table 1:

[0032] Table 1 is the ratio table of each component weight fraction of rosin modified acrylate emulsion

[0033]

[0034] The preparation method of described rosin modified acrylate emulsion, the steps are as follows:

[0035] a. Take methyl acrylate, butyl acrylate, acrylic acid, hydroxyethyl acrylate, acrylamide, rosin resin and lauryl mercaptan according to the above ratio and mix them into the first mixed monomer and the second mixed monomer;

[0036] b. Preparation of seed emulsion: Add 60% deionized water, 40% emulsifier, and 30% initiator into the reaction kettle, stir for 10 minutes, raise the temperature to 75°C, and drop 5% of the mass within 15 minutes The first mixed monomers are kept for 30 minutes after the dropwise addition to obtain the seed emulsion.

[0037] c. In the seed emulsion, add the remaining first mixed monome...

Embodiment 2

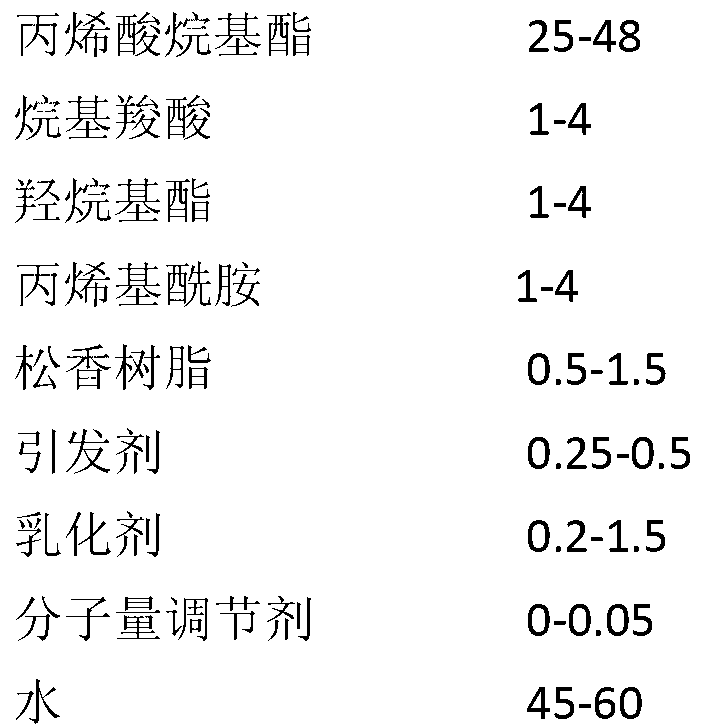

[0050] In the rosin-modified acrylate emulsion, the proportioning ratio of each component by weight fraction is the following table 4:

[0051] Table 4 is the weight ratio table of each component of rosin modified acrylate emulsion

[0052]

[0053] The preparation method of rosin modified acrylate emulsion, the steps are as follows:

[0054] a. Methyl acrylate, butyl acrylate, methacrylic acid, 3-hydroxypropyl acrylate, acrylamide, rosin resin and DTBP molecular weight regulator were mixed into the first mixed monomer and the second mixed monomer according to the above proportioning ratio. body;

[0055] b. Preparation of seed emulsion: Add 60% of deionized water, 60% of emulsifier, and 50% of initiator in the above ratio into the reaction kettle, stir for 10 minutes, raise the temperature to 80°C, and drop 5% of the mass within 15 minutes The first mixed monomers were added dropwise and then incubated for 30 minutes to obtain a seed emulsion.

[0056] c. In the seed e...

Embodiment 3

[0070] In the rosin-modified acrylate emulsion, the specific component distribution ratio of each component by weight is shown in Table 7 below:

[0071] Table 7 is the weight ratio table of each component of rosin modified acrylate emulsion

[0072]

[0073] The preparation method of rosin modified acrylate emulsion, the steps are as follows:

[0074] a. Take methyl acrylate, isooctyl acrylate, acrylic acid, 2-hydroxybutyl acrylate, methacrylamide and rosin resin according to the above ratio and mix them into the first mixed monomer and the second mixed monomer;

[0075] b. Preparation of seed emulsion: Add 60% deionized water, 55% emulsifier, and 45% initiator into the reaction kettle, stir for 10 minutes, raise the temperature to 78°C, and drop 5% of the mass within 15 minutes The first mixed monomers were incubated for 30 minutes after the dropwise addition to obtain the seed emulsion;

[0076] c. In the seed emulsion, add the remaining first mixed monomer and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com