Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

488results about How to "Good initial adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

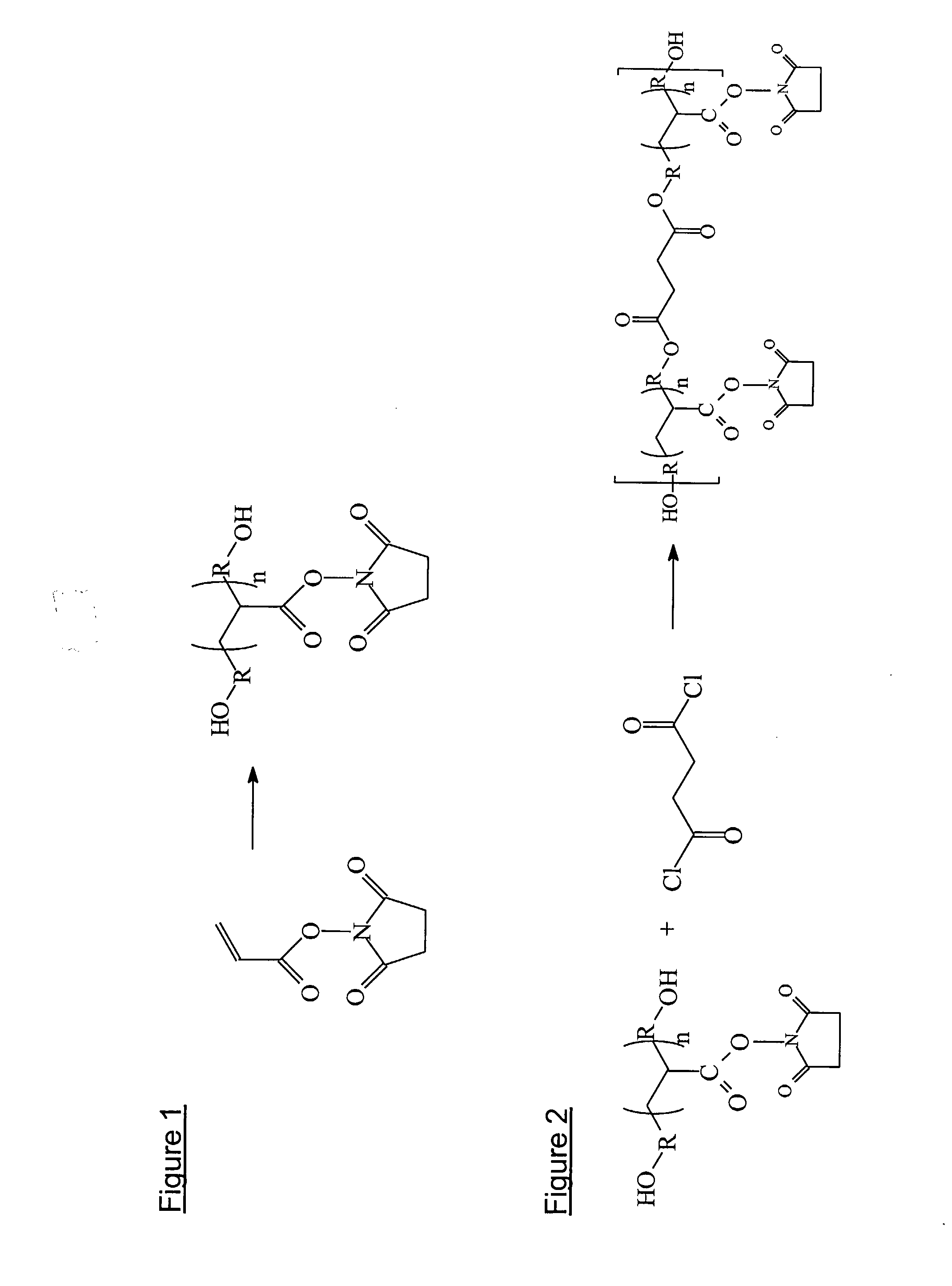

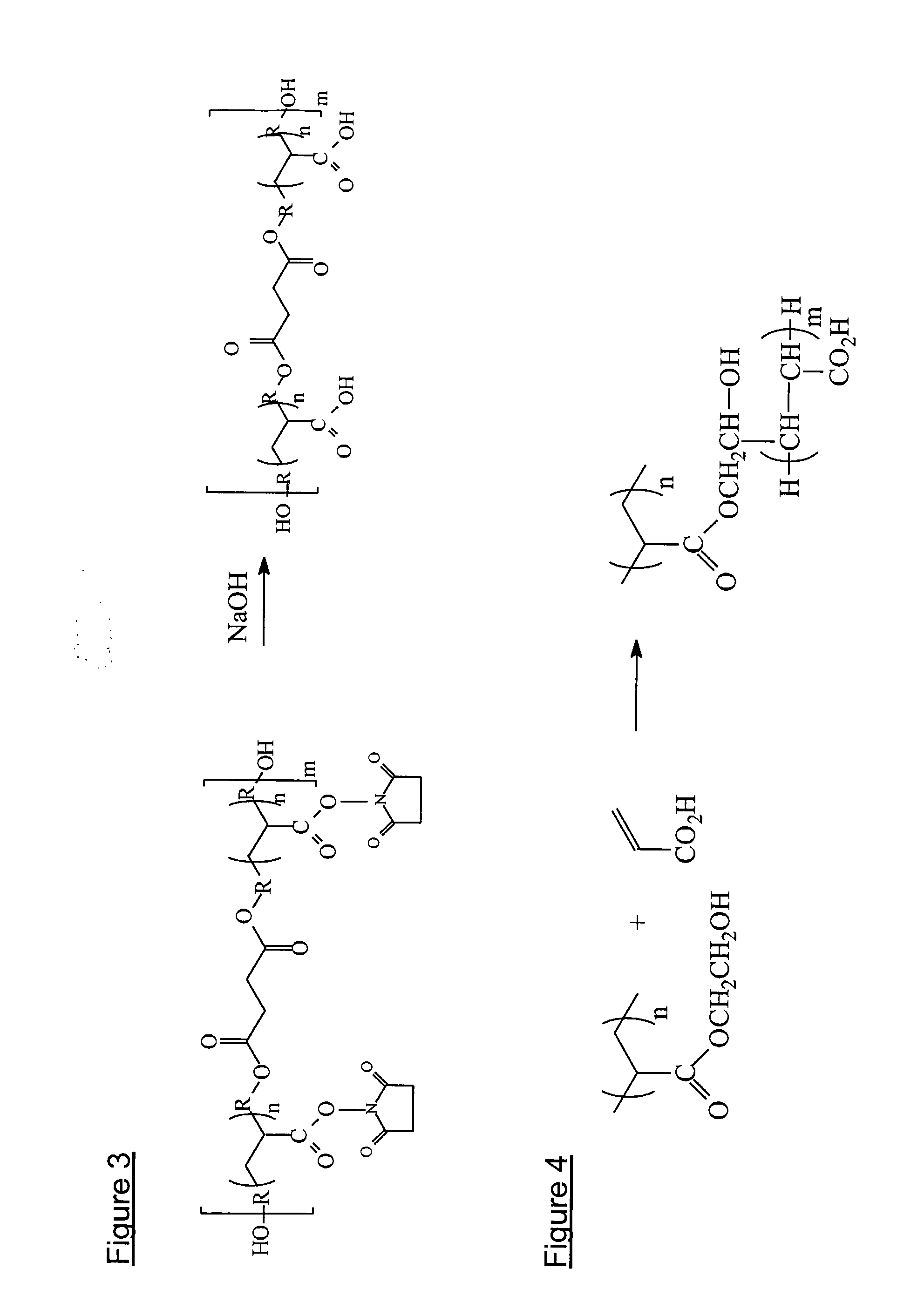

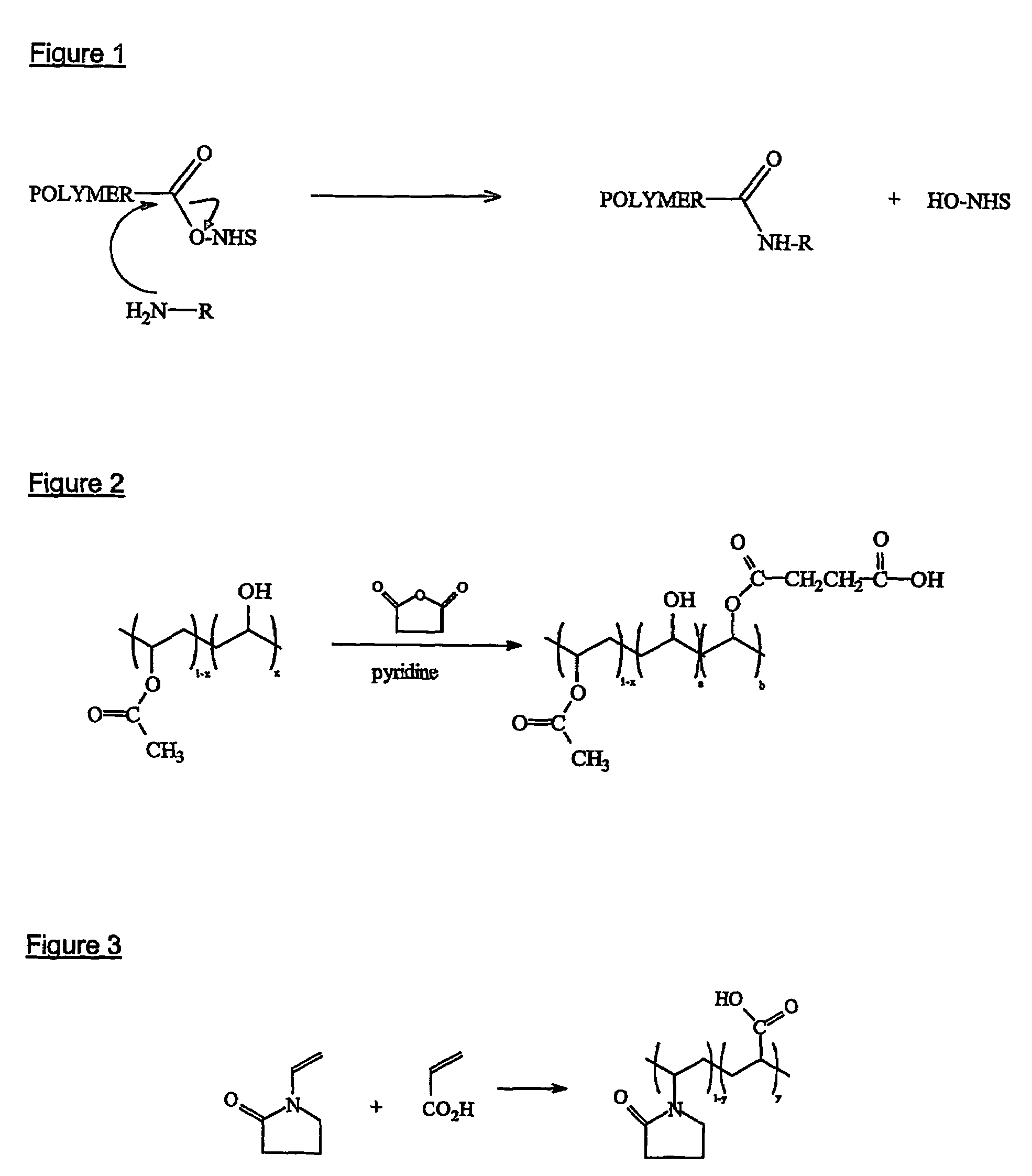

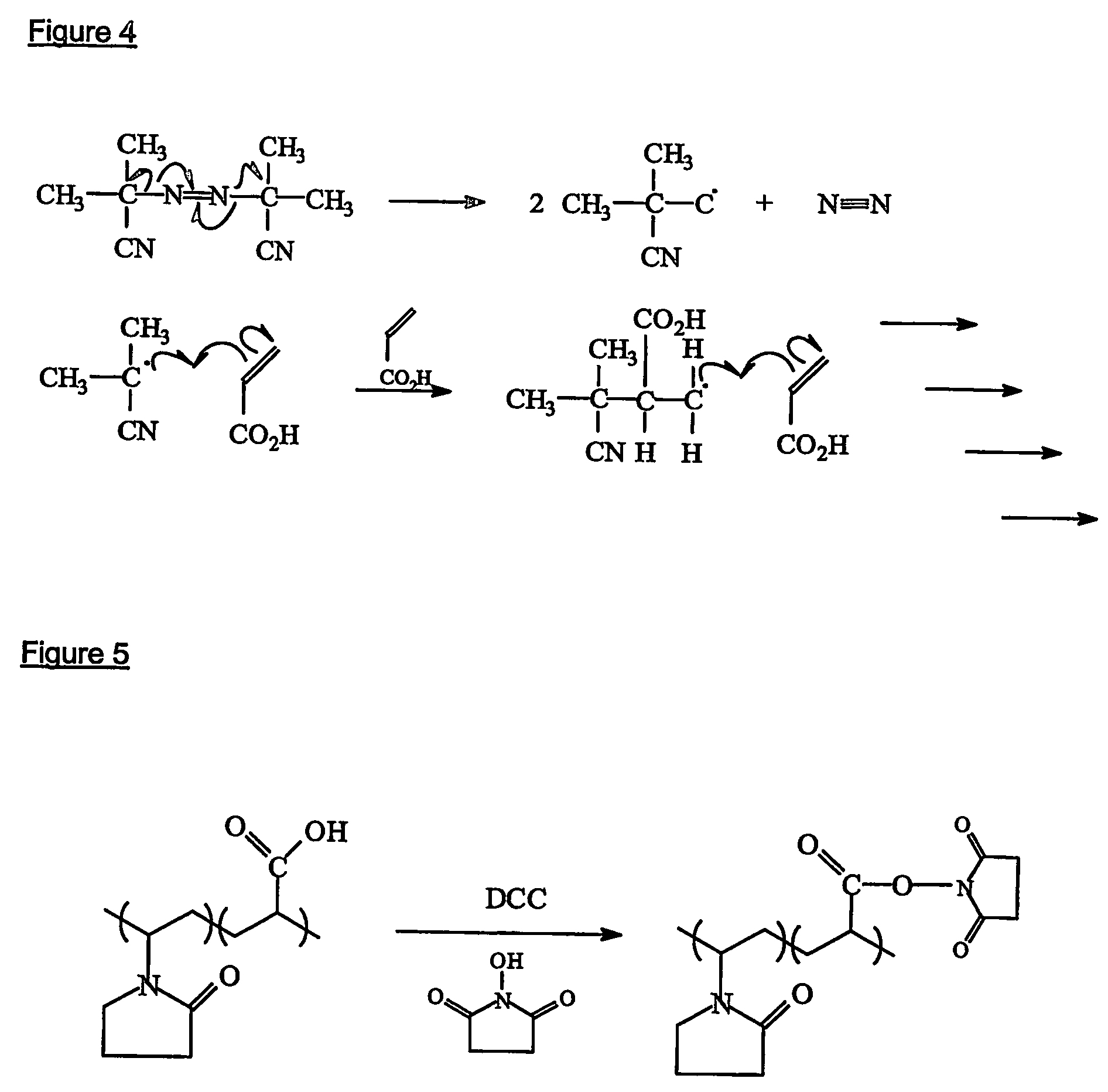

Tissue-adhesive formulations

InactiveUS20060105026A1Efficient use ofGood initial adhesionSurgical adhesivesAbsorbent padsParticulatesMedicine

A tissue-adhesive formulation consists of a naturally occurring or synthetic polymerisable and / or cross-linkable material in particulate form, the polymerisable and / or cross-linkable material being in admixture with particulate material comprising tissue-reactive functional groups. The formulation may be used in the preparation of a tissue-adhesive sheet, by applying the formulation to at least one side of a core of a naturally occurring or synthetic polymeric material.

Owner:TISSUEMED LTD

Tissue-Adhesive Materials

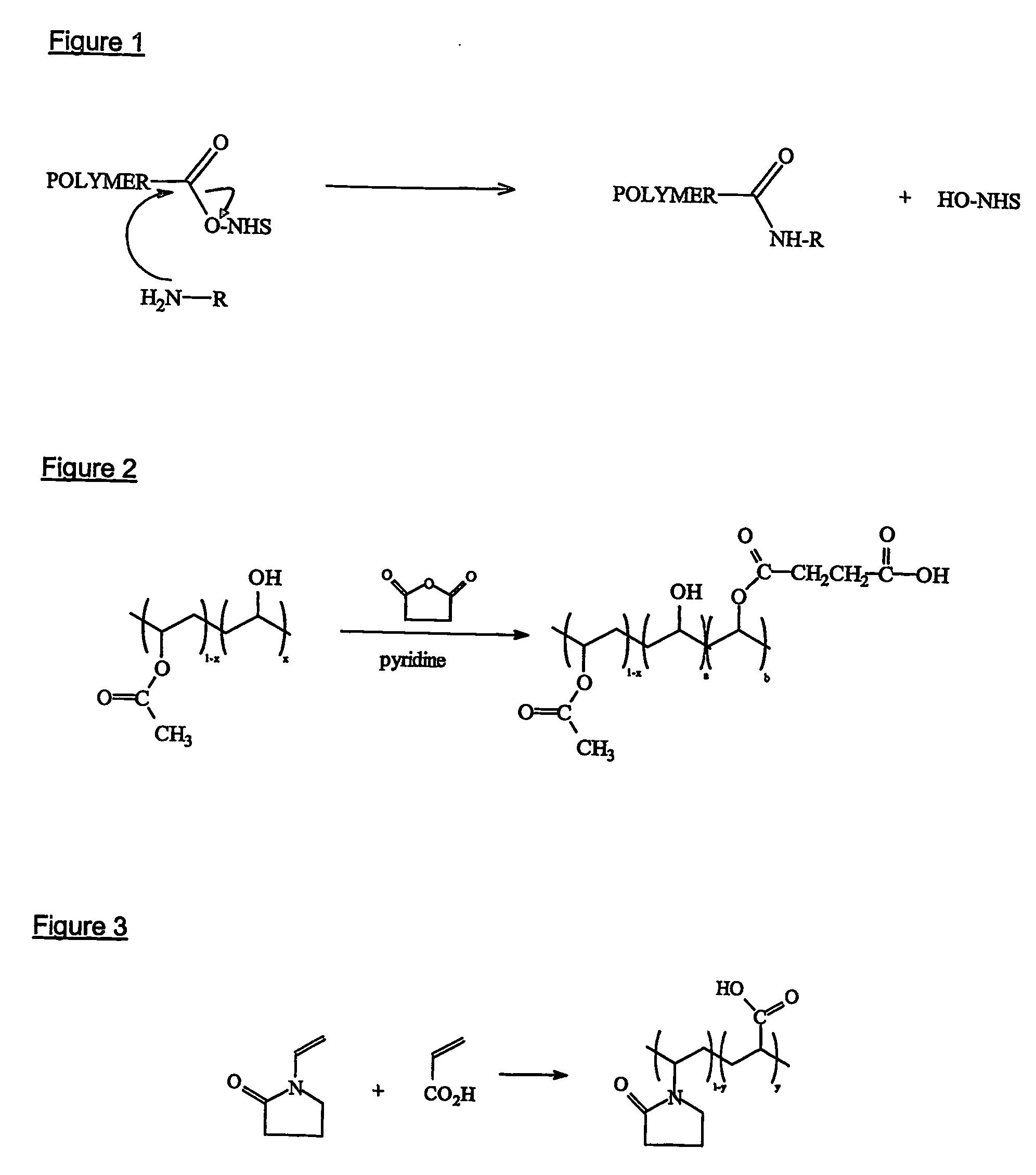

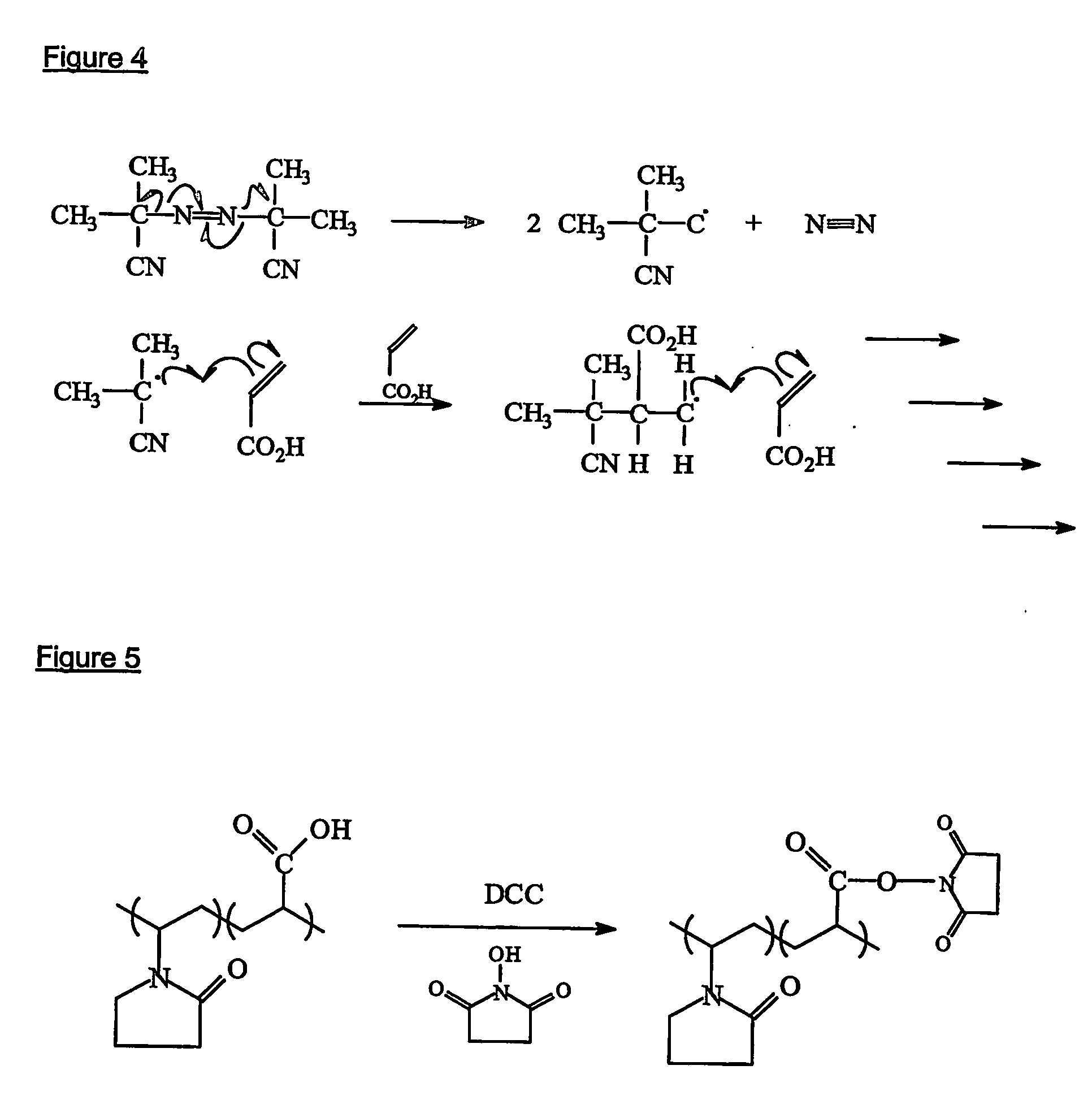

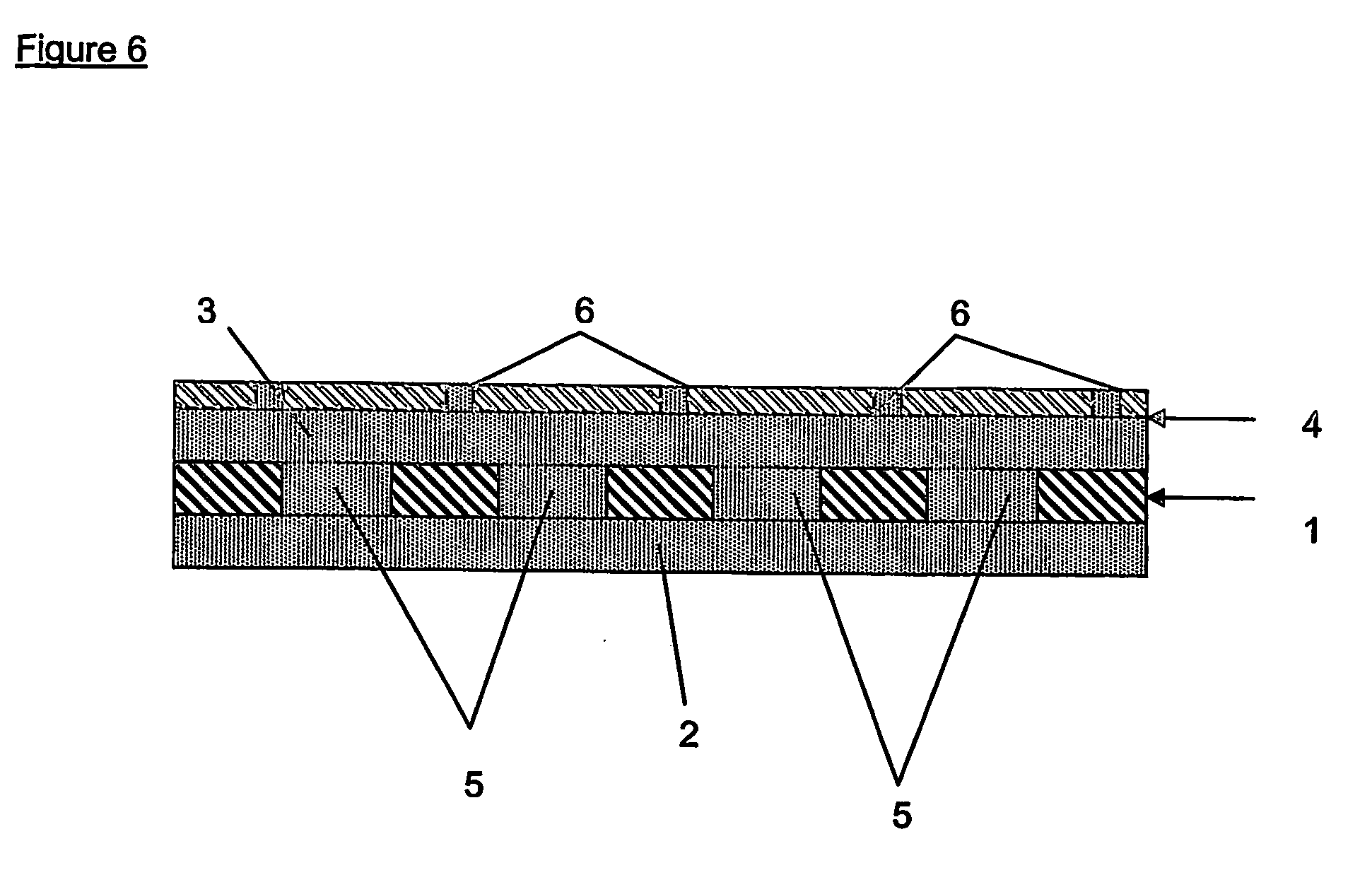

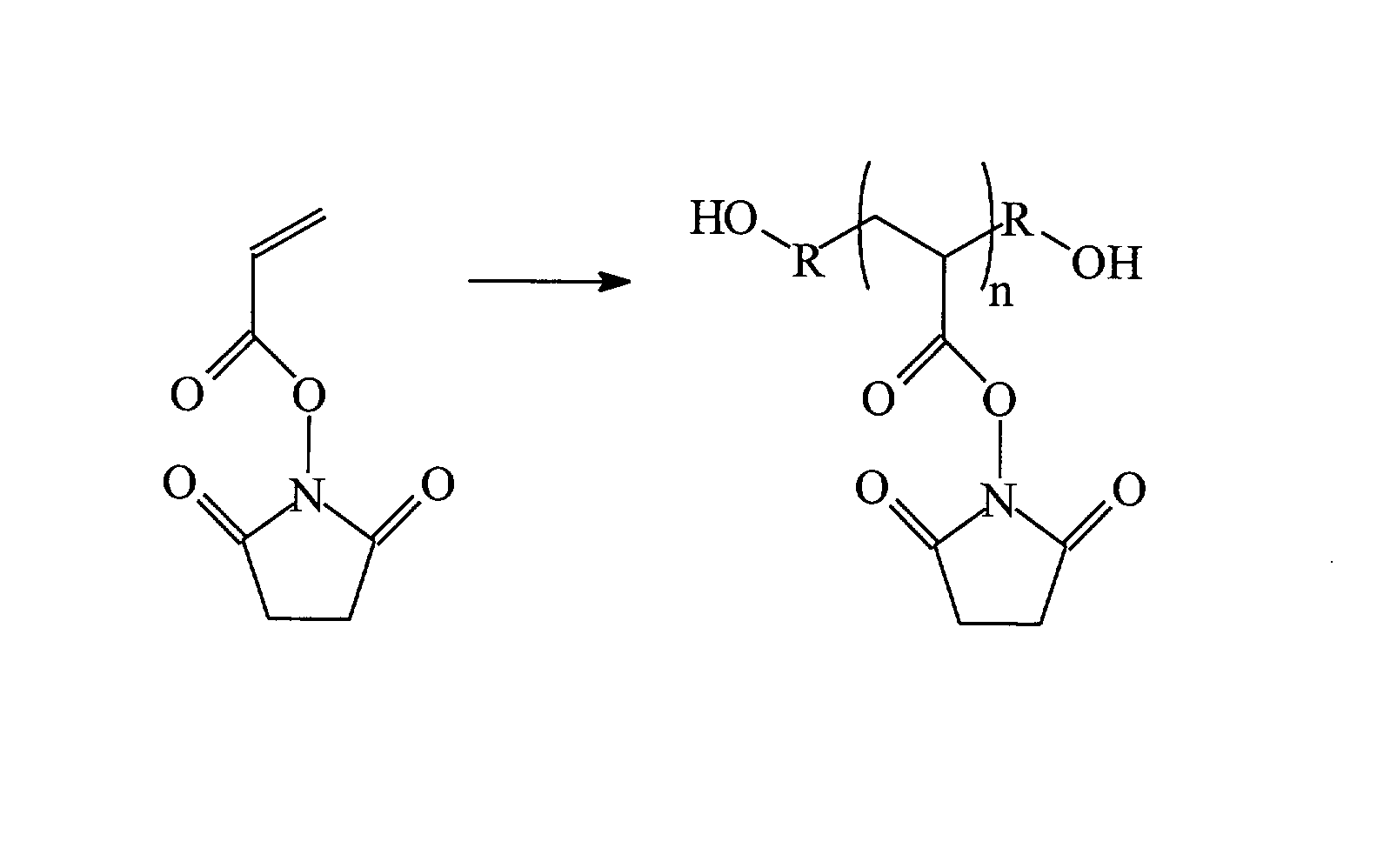

This invention related to a tissue-adhesive sheet comprising a homogeneous, preformed and cross-linked matrix formed from one or more polymers, and having at least one surface that, in use, is exposed, at least one of said one or more polymers being a synthetic polymer and having appendant functional groups of a first form, cross-linking of said matrix being via a proportion of said functional groups of the first form, and the remainder of said functional groups of the first form being free. The sheet is particularly useful as a tissue adhesive and sealant, and is intended for topical application to internal and external surfaces of the body for therapeutic reasons. The invention further relates to sheets comprising a scaffold material, three-dimensional articles formed from similar material to that of the sheet and to implantable medical devices coated with such material.

Owner:TISSUEMED LTD

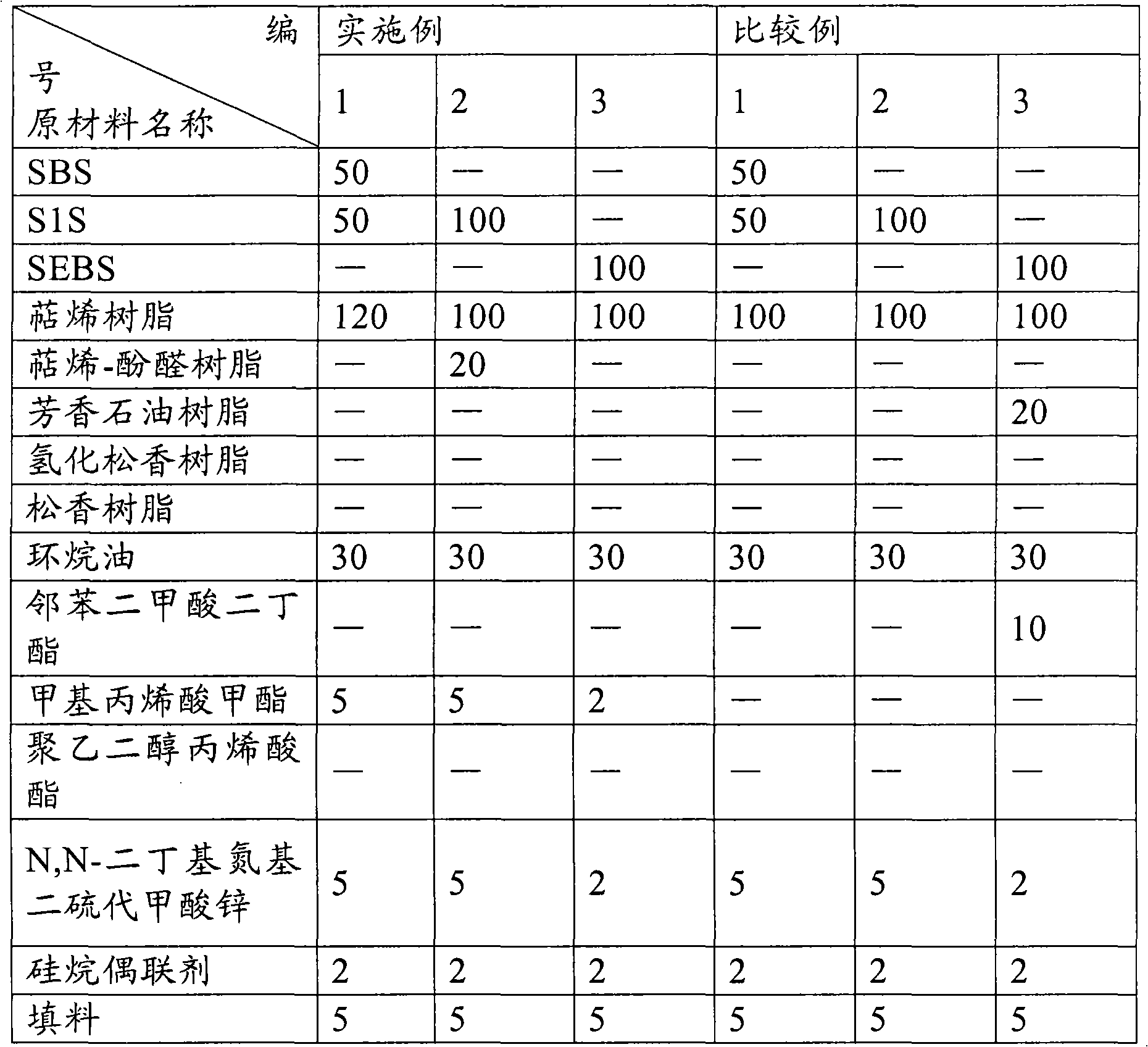

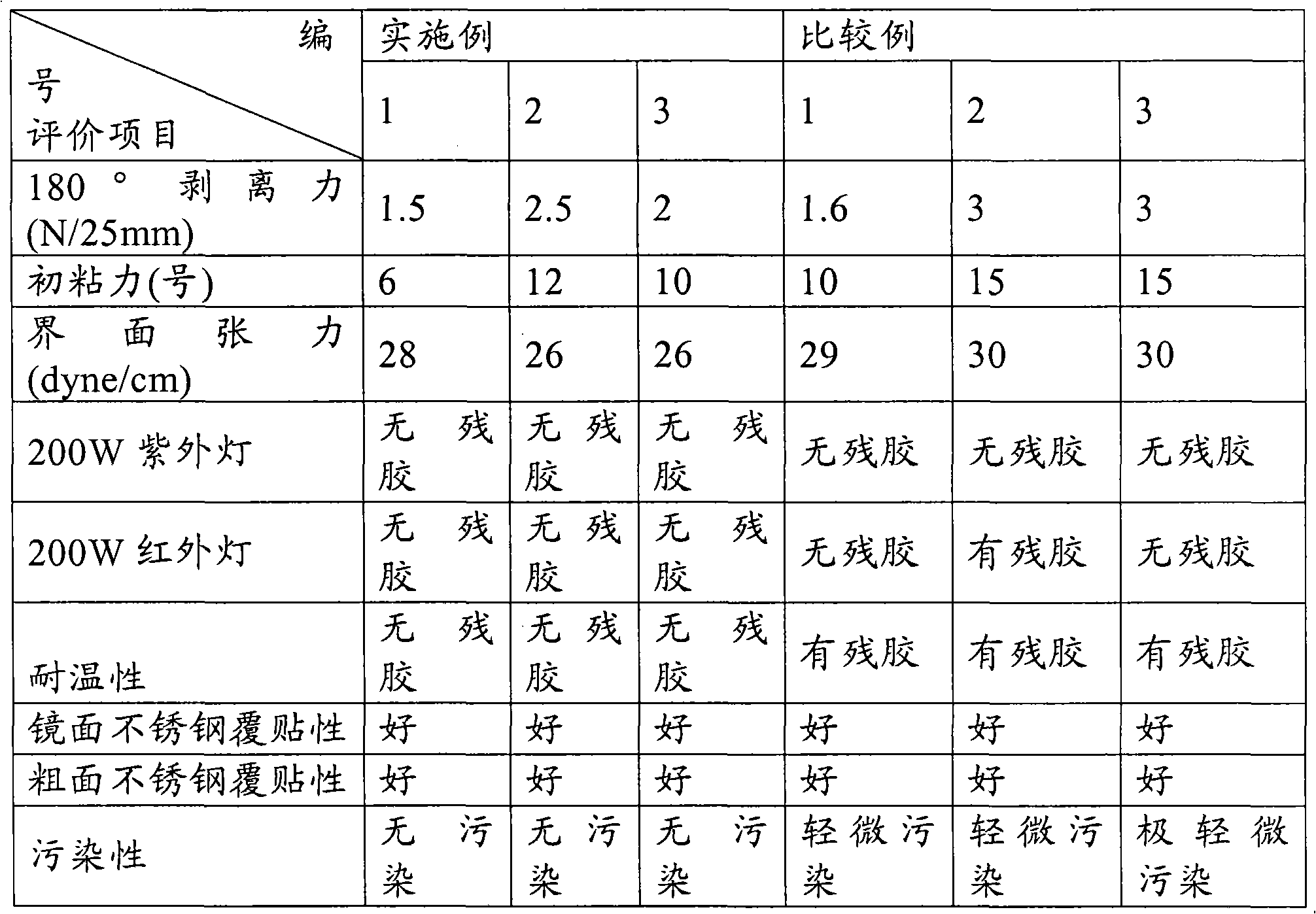

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

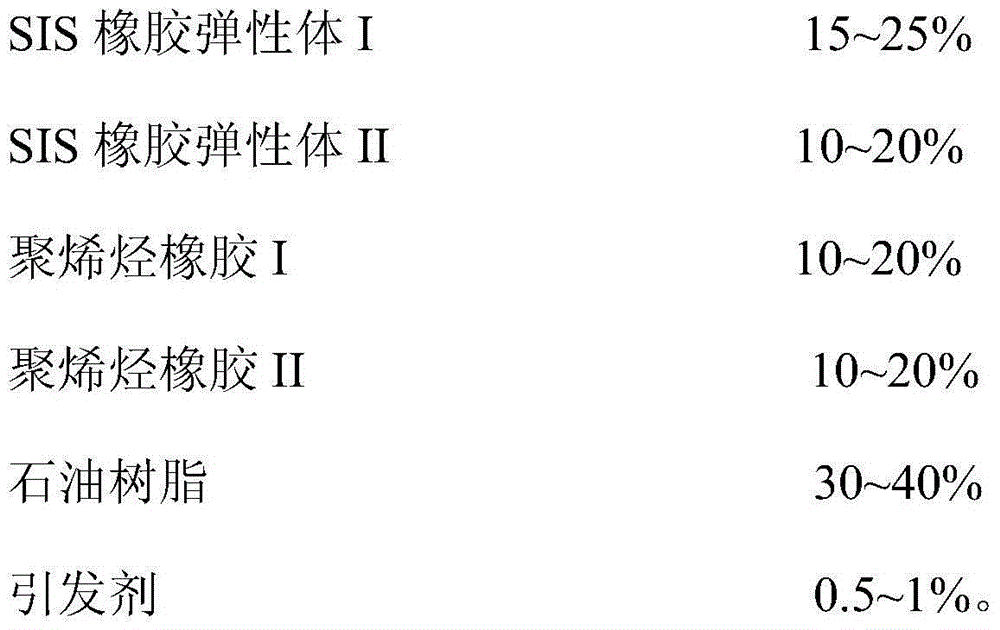

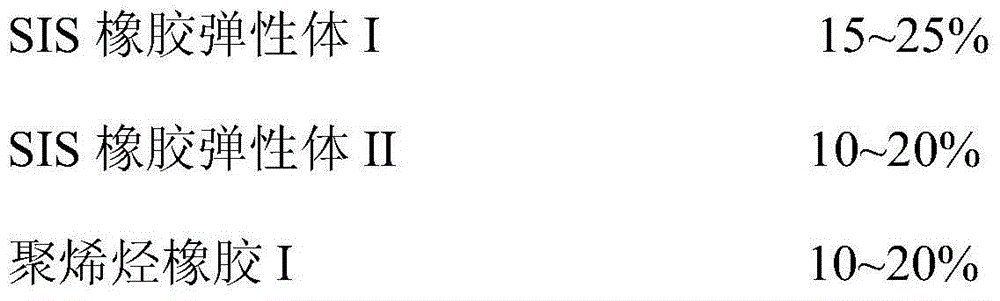

Reactive polymer waterproofing coiled material

ActiveCN101871248AHigh hardnessImprove cohesive strengthRoof covering using flexible materialsFilm/foil adhesivesCross-linkPolymer science

The invention discloses a reactive polymer waterproofing coiled material which comprises a fetal membrane layer, a reactive composite rubber layer and an anti-sticking isolation film layer; the reactive composite rubber layer is covered on the surface of the fetal membrane layer, and the anti-sticking isolation film layer is covered on the other surface of the reactive composite rubber layer; thereactive composite rubber comprises the following components in percentage by weight: 85.0 to 92.0 percent of SIS hot melt adhesive, 3.0 to 5.0 percent of talcum powder, 2.0 to 3.5 percent of composite ore powder, 1.0 to 2.5 percent of gaseous silica, 0.5 to 2.0 percent of silane coupling agent, and 0.5 to 2.0 percent of nano calcium carbonate. The waterproofing coiled material can have chemical cross-linking reaction and be cured with a cast-concrete matrix, fundamentally avoids 'watermoving between layer', and has the advantages of high strength, high toughness, aging resistance, long service life and the like.

Owner:KESHUN WATERPROOF TECH CO LTD

Hot-pressed veneer adhesive and preparation method thereof

ActiveCN102585736ALow costShort curing timeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveCarvacryl acetate

The invention discloses a hot-pressed veneer adhesive and a preparation method thereof. The hot-pressed veneer adhesive mainly comprises the following components: deionized water, polyvinyl alcohol, an emulsifier, an initiator, methacrylic acid, N-methylol acrylamide, vinyl acetate, a plasticizer, a buffering agent, cassava starch, borax, a dispersing agent, aqueous rosin, a defoaming agent and a corrosion inhibitor. When the hot-pressed veneer adhesive is prepared, the preparation method comprises the following steps of: firstly synthesizing a self-crosslinked polyvinyl acetate copolymerization modified emulsion, then adding 20-35% of raw cassava starch, a crosslinking agent, waterborne tackifying resin and other auxiliaries for mixing and finally preparing the hot-pressed veneer adhesive with excellent performances. Compared with a traditional urea resin veneer adhesive, the adhesive prepared by the invention has the advantages of convenience in use, low curing temperature, short curing time and no harm to an environment and a human body.

Owner:顶立新材料科技股份有限公司

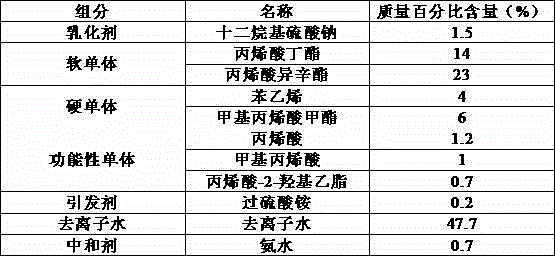

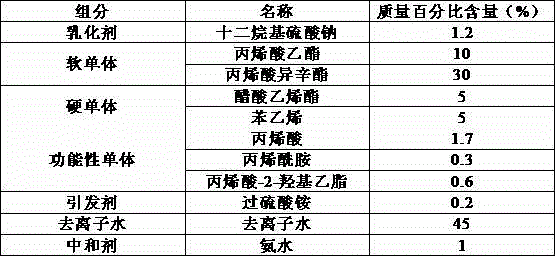

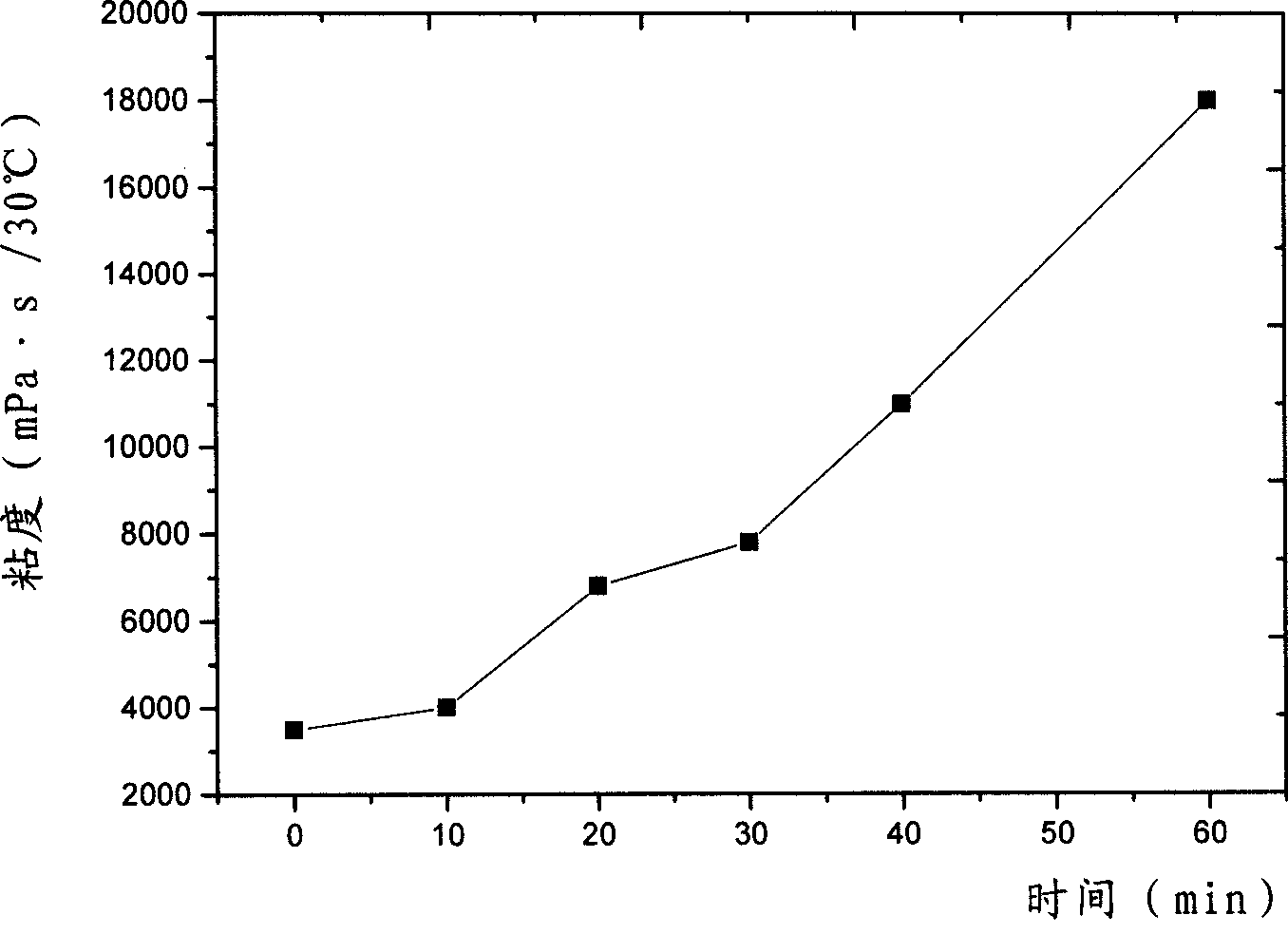

Adhesive emulsion for environment-friendly textile gilding printing paste and preparation method thereof

The invention discloses adhesive emulsion for environment-friendly textile gilding printing paste and a preparation method thereof. The emulsion consists of the following components in percentage by weight: 0.5-3% of emulsifier, 30-50% of soft monomer, 6-15% of hard monomer, 2-5% of functional monomer, 0.1-0.3% of initiator, 40-60% of deionized water and 0.5-2% of neutralizer. The adhesive is prepared into gilding paste and is used for bonding textile gilding foil; and the shortcomings of the products on the market of low net operability, hard handfeel, unsatisfactory firmness, easy color losing after washing, environmental pollution and the like are overcome. Through the invention, the prepared adhesive has excellent initial viscosity and sustained viscosity and good water resistance, and can realize good adhesive force against different textile fabrics; and meanwhile, the adhesive has good cohesion permanent viscosity, is environment-friendly without releasing toxic substances such as formaldehyde and the like, and does not contain the alkylphenol additives. The adhesive emulsion disclosed by the invention is suitable for the cold and hot gilding technology of manual or mechanical printing, is easy to operate, and has soft handfeel, no sand hole and high yield.

Owner:BAILIHE CHEM ZHONGSHAN

Modified water resistant low temperature white emulsoid

InactiveCN1377929AImprove water resistanceImprove low temperature resistanceMonocarboxylic acid ester polymer adhesivesChemical industryPolyvinyl acetate

The present invention relates to adhesive and discloses a kind of modified waterproof low temperature white emulsoid and its preparation. The modified waterproof low temperature white emulsoid is prepared by using polyvinyl acetate emulsion as base material, water solution of polyvinyl alcohol as emulsoid protector, ethylene-vinyl acetate emulsion as waterproof and low temperature modified and calcium carbonate as kaolin as adhesion intensifier. It has various specifications exceeding the chemical industry standard, excellent waterproof performance, good low temperature performance, simple production process, relatively lower cost and no toxicity and harm.

Owner:SHANGHAI UNIV OF ENG SCI

Adhesive for soft package compound and preparation method thereof

ActiveCN101544880AReduce contentReduce heat seal strengthPolyureas/polyurethane adhesivesChemical structurePolyester

The present invention discloses a macromolecule adhesive, particularly relates to an adhesive for a flexible package compound film and a preparation method thereof. The adhesive for a compound film includes a hydroxy polyester polymer component (A) and an isocyanate end capping prepolymer component (B), the preparation method is that firstly a polyester is synthesized by using a diatomic alcohol and a dibasic acid, a polyester is then synthesized by using a polyatomic alcohol and a dibasic acid, the polyester molecular mass is adjusted by selection and dosage proportion of the diatomic alcohol, the polyatomic alcohol and the dibasic acid chemical structure, so as to prepare the component (A); the diatomic alcohol reacts with a different isocyanate, and compose a isocyanate end capping prepolymer together with a biuret polymer of the isocyanate so as to prepare the component (B); the component (A) and the component (B) are mixed with each other at a certain proportionality to prepare a polyurethane adhesive for a double-component solvent-free type compound film. When using the adhesive, the coating amount of the adhesive is small, and a compound speed may arrive 300 m / min.

Owner:中山市康和化工有限公司

Double sticky tape for lithium battery and preparation method for double sticky tape

ActiveCN104610883AMeet the production process requirementsGuaranteed performanceMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesElectrochemical responseLithium-ion battery

The invention relates to a double sticky tape for a lithium battery. The double sticky tape comprises a first sealed hot-melting pressure-sensitive adhesive layer, a basic film layer, a second sealed hot-melting pressure-sensitive adhesive layer, a normal temperature cohesion-less sealed adhesive layer, and a two-sided silicon-free release film layer, which are sequentially connected from top to bottom, wherein one side of the double sticky tape for the lithium battery has the cohesiveness to an aluminium foil and a polyethylene film at normal temperature, and the other side is free of cohesiveness to the polyethylene side when the temperature is 80 DEG C or below, so that the double sticky tape meets the requirement on production technology of the lithium battery; the adhesive layers of the double sticky tape are free of release agent and other impurities, so that the purity of the adhesive layers can be kept; when the adhesive layers are immersed in electrolyte, the double sticky tape is still high in stability, good in corrosion resistance against the electrolyte and free of electrochemical reaction, so that the performance of the lithium battery can be maintained, and the service life of the lithium battery can be prolonged.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Hot-melt pressure-sensitive adhesive for polyethylene materials and preparation method thereof

ActiveCN102181248ASimple production processGood effectMineral oil hydrocarbon copolymer adhesivesRosin adhesivesPressure sensitiveChemistry

The invention discloses a hot-melt pressure-sensitive adhesive composition which is characterized by comprising the following components in percentage by weight: 20-30% of main body polymer, 30-40% of tackifier, 30-40% of plasticizer, 1-2% of antioxidant and 1-2% of light stabilizer. The invention also provides a preparation technique of the hot-melt pressure-sensitive adhesive composition. The hot-melt pressure-sensitive adhesive disclosed by the invention has the advantages of high cohesive force, favorable initial viscosity, high binding strength and high low-temperature flexibility, has favorable initial viscosity even in winter, can be used for binding solid materials, and especially has good effect for binding polyethylene materials.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Tissue-adhesive formulations

InactiveUS7727547B2Efficient use ofGood initial adhesionSurgical adhesivesAbsorbent padsMedicinePolymer

Owner:TISSUEMED LTD

Method for preparing multiple modified self-crosslinking aqueous polyurethane adhesive agent

InactiveCN101182406AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyCross-link

The invention discloses a preparation method of self cross-linking water-based polyurethane adhesive of multiple modifications. Polyisocyanate and oligomer polyol are added into a reaction device for reaction; then chain extender is added for reaction to prepare polyurethane prepolymer; then polyurethane prepolymer modified by rosin and epoxy resin is added to prepare modified polyurethane prepolymer; finally water is added into the modified polyurethane prepolymer and a high-speed disperser is used for dispersion; neutralizer and cross-linker are added to prepare the self cross-linking water-based polyurethane dispersoid of multiple modifications; thickening agent and defoamer are added into the dispersoid to prepare the modified polyurethane adhesive. The adhesive prepared in the invention has the rapid drying, good water resistance and high bond strength; the adhesive can meet the bonding requirements of vehicles and a plurality of other materials; the invention has the advantages of simple operation, simple process, short production cycle, low cost of operation and easiness of promotion and application.

Owner:SOUTH CHINA UNIV OF TECH

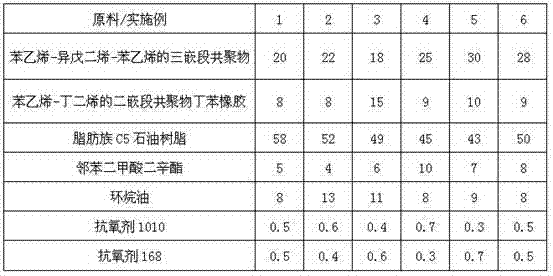

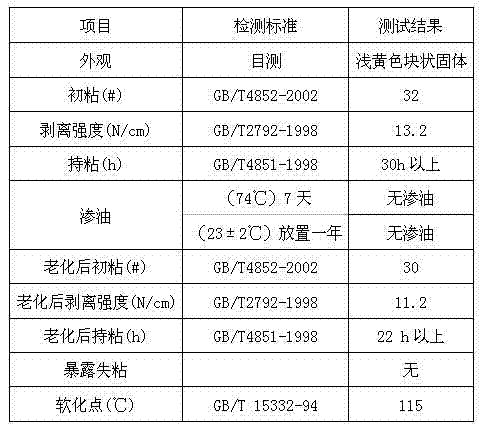

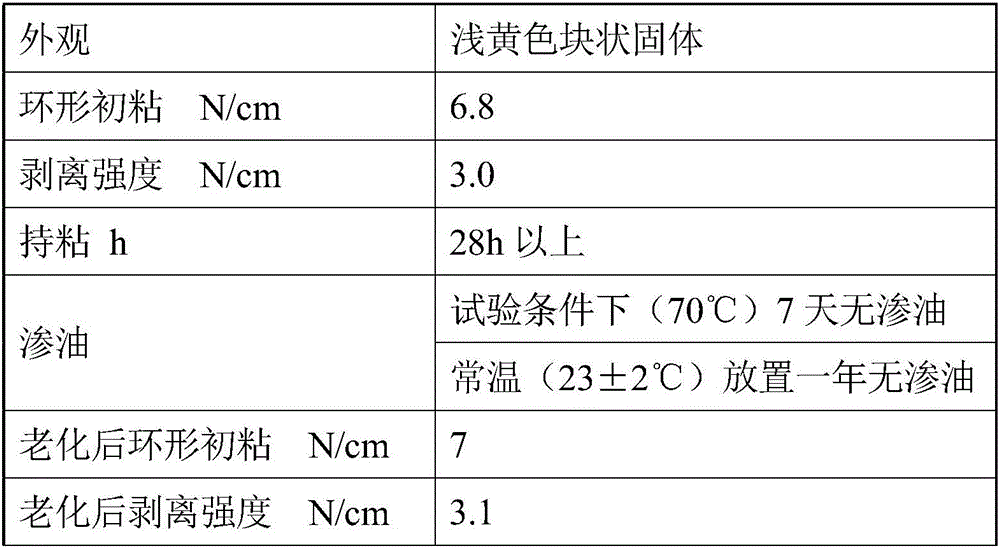

Hot melt pressure sensitive adhesive and preparation method thereof

ActiveCN102504735ASmall temperature changeGood initial adhesionMineral oil hydrocarbon copolymer adhesivesConjugated diene hydrocarbon adhesivesPlasticizerHot melt

The invention provides a hot melt pressure sensitive adhesive and a preparation method thereof, which solve the problems of improving initial tack, oil penetration and die cutting property, etc. The hot melt pressure sensitive adhesive comprises the following components by weight: 25-40 parts of matrix resin, 48-60 parts of tackifier, 12-22 parts of plasticizer and 0.6-1.2 part of a stabilizing agent, wherein the matrix resin comprises triblock copolymer of styrene-isoprene-styrene and diblock copolymer solution-polymerized styrene butadiene rubber of styrene-butadiene in a weight ratio of 1.2-3.1. The hot melt pressure sensitive adhesive provided by the invention has better initial tack, high peel strength and standard holding power; the hot melt pressure sensitive adhesive is free of oil penetration for seven days under heat temperature testing conditions and can be stored for one year at the normal temperature without oil penetration; the adhesive has better die cutting property; and the softening point reaches to 115 DEG C. The hot melt pressure sensitive adhesive of the invention can totally meet the requirement on fabricating back adhesive bags, labels and adhesive tapes.

Owner:河北方大新材料股份有限公司

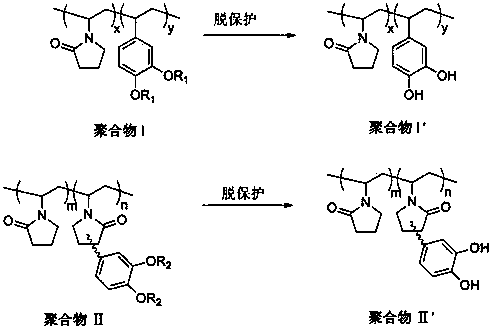

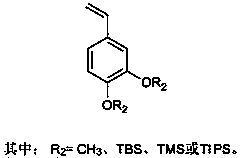

Preparation method for biomimetic mussel adhesive used for adhesion on wet surface and underwater curing

InactiveCN103965810AEfficient synthesisImprove bindingNon-macromolecular adhesive additivesPolymer scienceAttachment protein

The invention relates to a preparation method for a biomimetic mussel adhesive used for adhesion on a wet surface and underwater curing. The method is characterized in that the biomimetic mussel adhesive is composed of two components including A and B, wherein the component A is a methanol solution of a polymer containing catechol groups; the polymer containing catechol groups is obtained in the manner that N-vinyl pyrrolidone and a polymerizable catechol derivative monomer are subjected to free radical polymerization and further subjected to deprotection; the component B is a crosslinking curing agent. The method has the advantages as follows: 1, the synthetic method is simple and efficient, raw material and reagents used in the reaction process are low in price and easy to get, and amplification in the operation process and industrial production are facilitated; 2, the biomimetic mussel adhesive has certain biocompatibility and initial adhesion performance, can be used for adhesion on the wet surface and underwater curing, and has the bonding strength being over 1 MPa, so as to be applied to adhesion of human tissue and adhesion in the wet environment of commonly-used base material as well as adhesion under the water. According to the invention, perfect combination between synthetic macromolecule and natural mussel attachment proteins is successfully realized, the technical bottleneck about the current biomimetic mussel adhesive is expected to break through, and meanwhile, a new approach for shellfish-based development of biomimetic high polymer material is provided.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

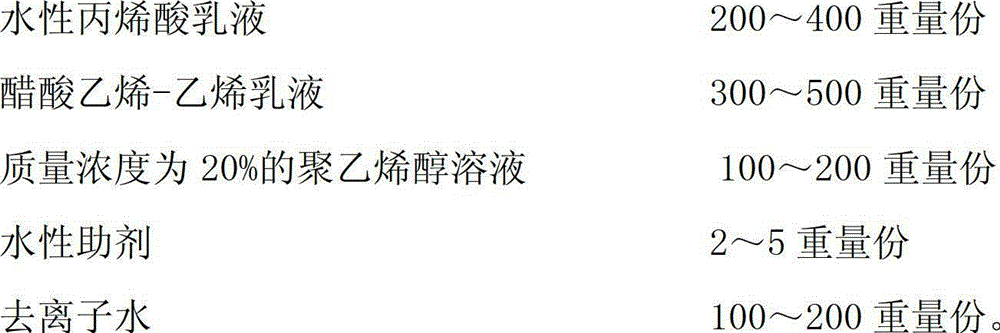

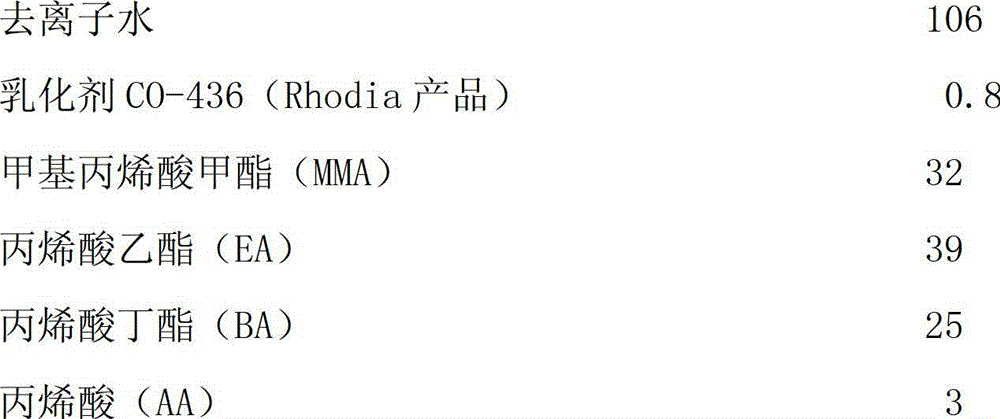

Water-based aluminium foil adhesive for cigarette packing and preparation method thereof

ActiveCN102977818AGood bonding performanceHigh peel strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerAluminium foil

The invention discloses a water-based aluminium foil adhesive for cigarette packing and a preparation method thereof and belongs to the field of adhesive preparation. The adhesive is composed of water-based acrylic emulsion, vinyl acetate-ethylene copolymer emulsion, a polyvinyl alcohol solution, water-based additives and deionized water. The adhesive has the advantages that both the economy of the vinyl acetate-ethylene emulsion and the excellent adhesive property of the water-based acrylic emulsion are provided, so that the peel strength is high in and the risk that aluminium foil paper products are delaminated is avoided; meanwhile, the copolymerization is carried out by adopting soft monomer based acrylic monomers, so that the initial adhesive force is good; acrylic acid functional monomers are adopted, so that the emulsion stability is enhanced and the final peel strength of the emulsion is greatly increased; the water-based acrylic emulsion is introduced, so that the water resistance is obviously increased, the freezing resistance is better than that of general vinyl acetate-ethylene copolymer emulsion and the use cost is much lower than that of general water-based acrylic emulsion; and residual vinyl acetate monomers and formaldehyde are removed through vacuumizing, so that the requirements of water-based adhesives for the cigarette packing are completely satisfied.

Owner:NANTONG GAOMENG NEW MATERIAL

Aqueous emulsion type nm adhesive for paper or plastics and its preparing process

InactiveCN1342735AImprove low temperature resistanceNo degumming phenomenonEster polymer adhesivesRosin adhesivesAdhesivePolyvinyl chloride

An emulsion-type paper-plastic adhesive is prepared from emulsion base material (40-70 wt.%), viscosity increaser (25-50) and nm inorganic powder (5-15). The emulsion base material contains butyl acrylate (25-60 wt. portions), vinyl acetate (20-50), acrylic acid (0-10), hydroxypropyl acrylate (5-15), PVA (2-8) ammonium persulfate (0.8-3.2), emulsifier OP-10 (0.3-3), sodium laurylsulfate (0.3-3) and water (80-207). Its advantages include no poison, excellent resistance to low temp., high temp and water, good adhesion, and fast drying.

Owner:SUN YAT SEN UNIV

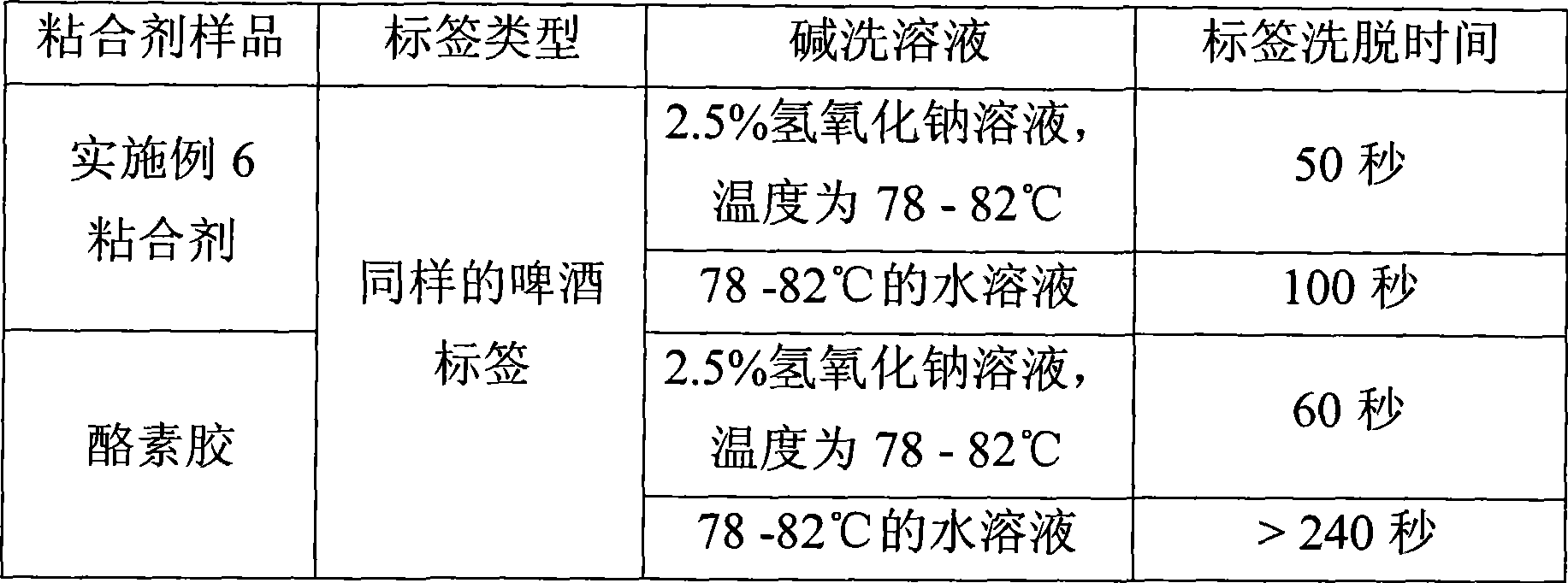

Adhesive, preparation and use thereof

InactiveCN101440269AGood initial adhesionLow freezing pointProtein waste adhesivesStarch adhesivesEnzymatic hydrolysisAdhesive

The invention provides an adhesive for labeling, which comprises 1 to 40 percent of animal glue, 0 to 45 percent of emulsion, 0 to 20 percent of starch, 5 to 40 percent of diluting agent, 0 to 10 percent of cross-linking agent, 0 to 5 percent of thickening agent, 0.001 to 2 percent of additive, and 20 to 50 percent of water. The adhesive has the advantages of good initial adhesion, low solidification point, good water resistance, strong enzyme hydrolysis resistant stability, elution in non-alkaline high temperature water and so on, well meets the requirements of improving production speed, improving the qualification rate of the production and recovering containers at present, and is particularly used for labeling beer bottles.

Owner:HENKEL KGAA

Room temperature self-crosslinking polyacrylate pressure-sensitive adhesive and preparation method and application thereof

InactiveCN104004477AReduce surface tensionSolve the \"chicken paw print\"StampsNon-macromolecular adhesive additivesFunctional monomerKetone

The invention belongs to the field of room temperature self-crosslinking materials, and discloses a room temperature self-crosslinking polyacrylate pressure-sensitive adhesive and a preparation method and application thereof. The method comprises the steps of preparing a pre-emulsion from 85-95 parts of acrylate soft monomer, 5-15 parts of hard monomer, 2-5 parts of functional monomer, 1.3-4 parts of emulgator and 30-55 parts of deionized water by mass fraction; then heating up the pre-emulsion, the deionized water, an initiator, the emulgator and a PH buffer agent for reaction; dripping a chain transfer agent, the pre-emulsion and an initiator solution when the emulsion shows blue light; adding ketone-containing carbonyl monomer, heating up together and reacting; then cooling down and regulating pH value to be 6.5-7.0; and adding hydrazide monomer, stirring and mixing uniformly, so as to obtain the room temperature self-crosslinking polyacrylate pressure-sensitive adhesive. The room temperature self-crosslinking polyacrylate pressure-sensitive adhesive prepared by the method has excellent indexes like excellent initial adhesive force, excellent persistent viscosity force and excellent peel strength, and can be used for preparing labels with good bond performance.

Owner:SOUTH CHINA UNIV OF TECH

Reactive hot melt adhesive

The invention is a reactive hot melt composition which has excellent adhesion and curing properties, and can be formulated into free-flowing pellets or beads, by using an ethylene-acrylic acid copolymer, and athylene-methacrylic acid copolymer, and / or an ethylene-acrylic acid methacrylic acid terpolymer as a component of the composition along with free radical crosslinking initiators. The incorporation of a foaming agent enables the production of compositions which are useful in space-filling applications, (i.e., as so-called "anti-flutter" compositions).

Owner:DOW GLOBAL TECH LLC +1

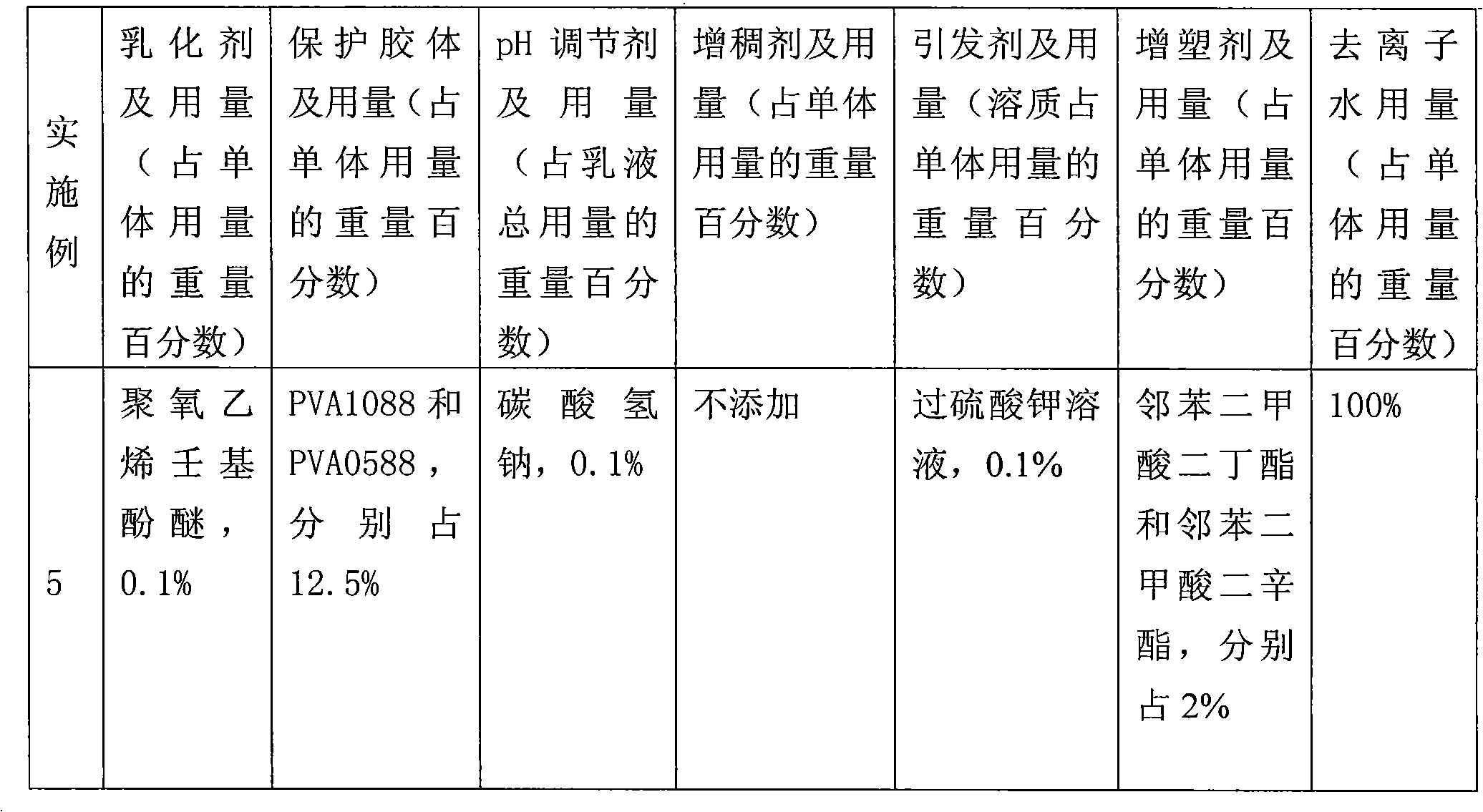

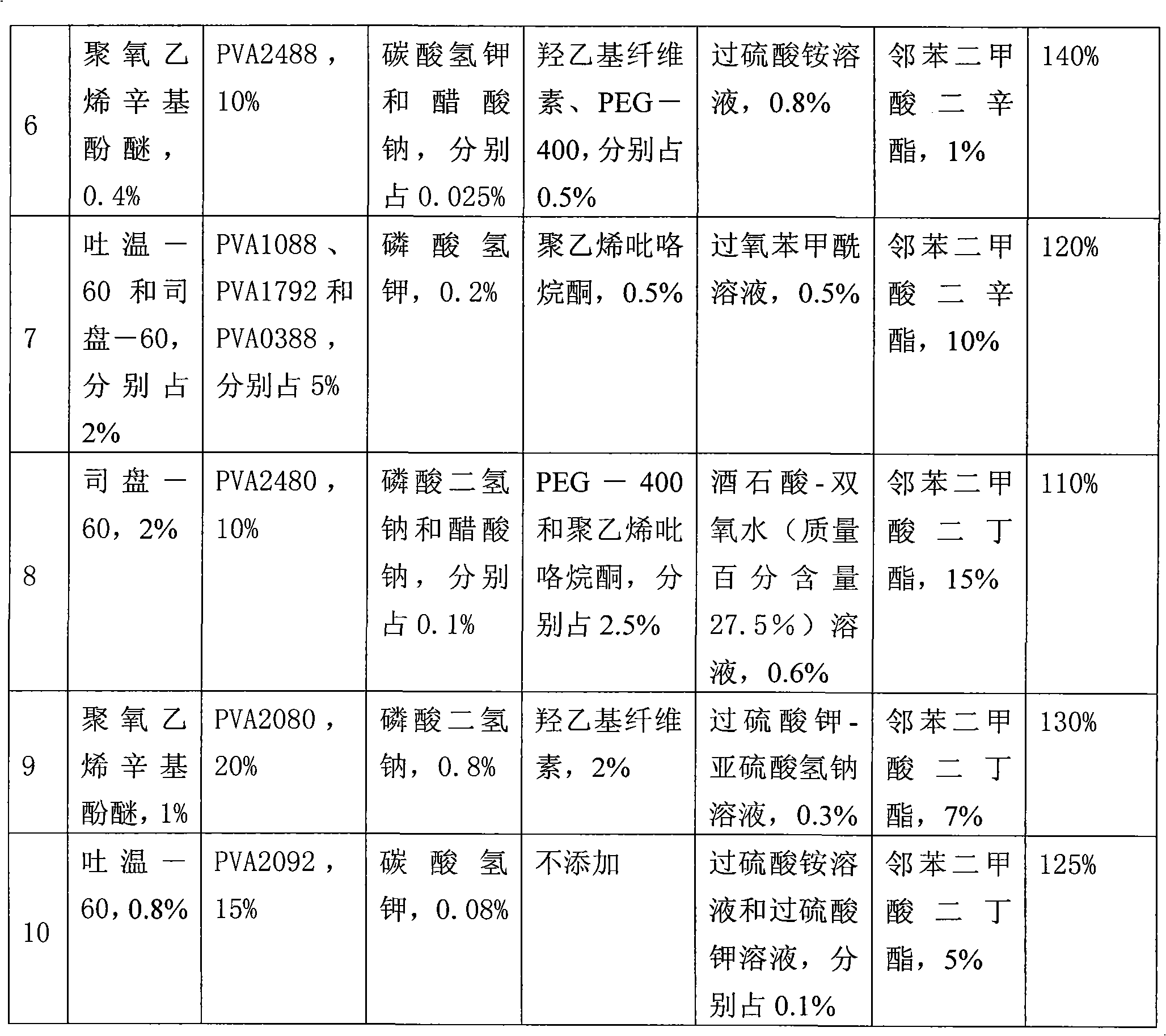

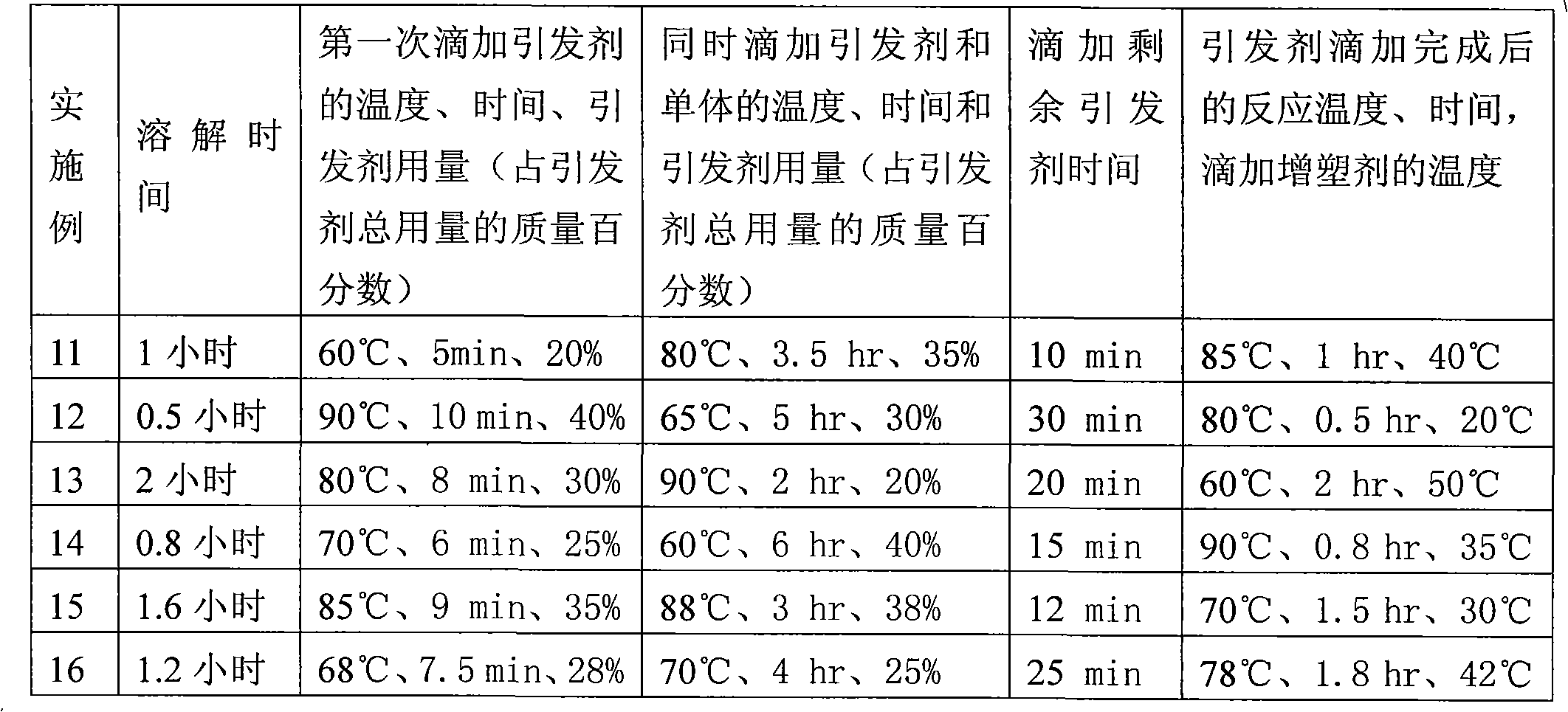

High viscosity polyvinyl acetate emulsion and preparation method thereof

ActiveCN102372885AHigh viscosity requirementsHigh strengthMonocarboxylic acid ester polymer adhesivesCelluloseMonomer

The invention relates to a high viscosity polyvinyl acetate emulsion. The high viscosity polyvinyl acetate emulsion is characterized in that: the emulsion is prepared from the following raw materials, wherein the raw materials comprise a vinyl acetate monomer, an emulsifying agent and protective colloid; the emulsifying agent is the non-ionic emulsifying agent, and the protective colloid is polyvinyl alcohol. According to the present invention, the viscosity of the high viscosity polyvinyl acetate emulsion exceeds 200000 mpa.s; after the high viscosity polyvinyl acetate emulsion is uniformly mixed with the cellulose and the filler, the resulting mixture is coated on the woodworking decorative sheet material, the coated material has advantages of good initial adhesion, no foaming, no cracking, high strength and the like; the high viscosity polyvinyl acetate emulsion of the present invention provides significant application effects for photo frame and other decorative industries with high emulsion viscosity requirements.

Owner:CHINA PETROCHEMICAL CORP +1

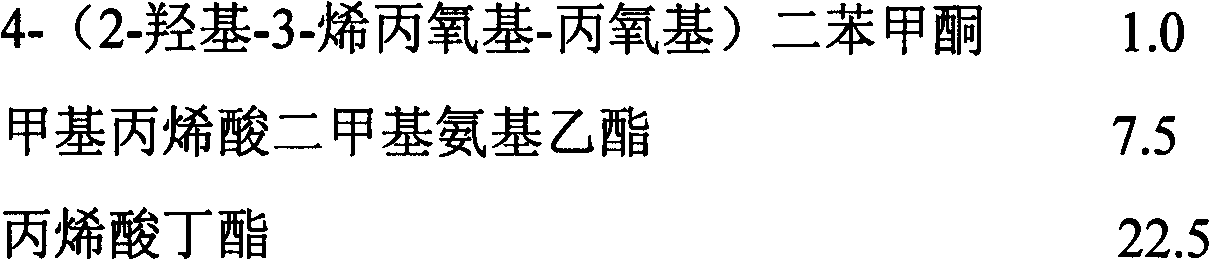

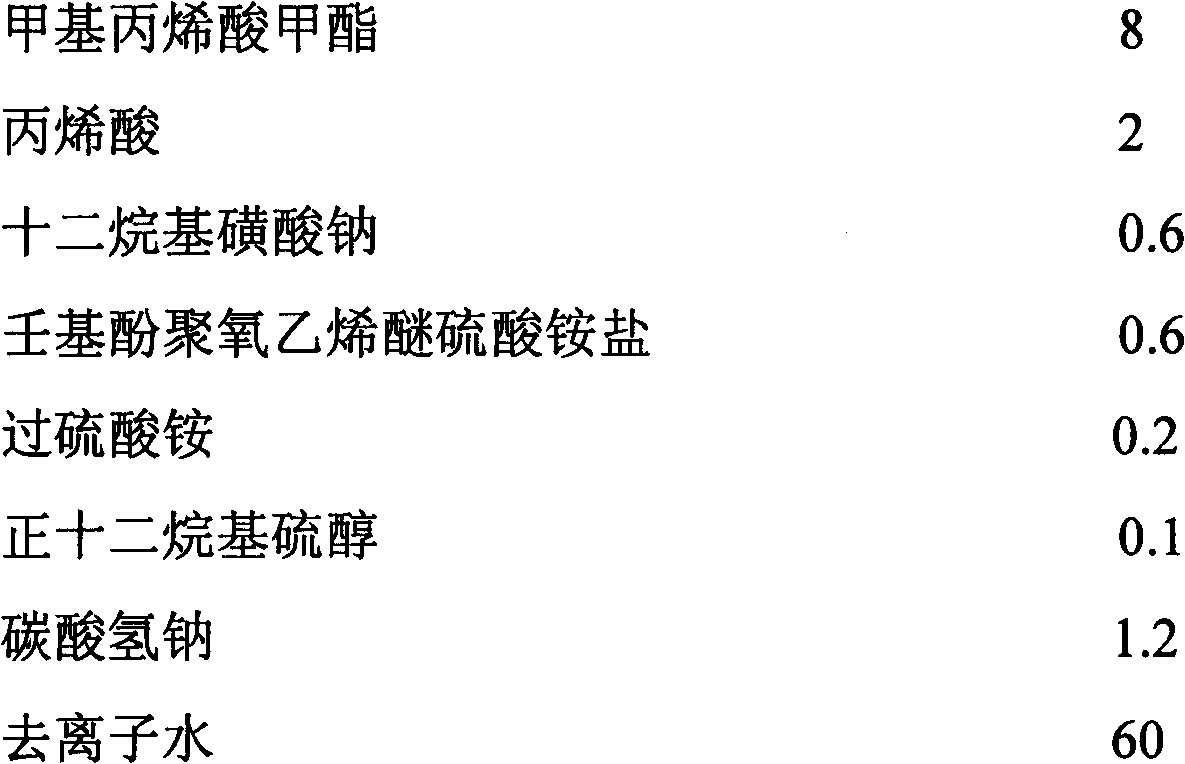

Single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive and synthetic method thereof as well as application thereof

InactiveCN102304333AStrong cohesionGood initial adhesionNitrile polymer adhesivesPretreated surfacesFunctional monomerEmulsion

The invention relates to a single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive and a synthetic method thereof as well as an application thereof; the emulsion pressure-sensitive adhesive is prepared from the following components in parts by weight through the thermal polymerization and synthesis of a free-radical emulsion: 0.02-4 of ultraviolet light active monomer, 2-20 of light crosslinking functional monomer, 15-40 of other single functionality monomer, 0.2-3 of emulsifying agent, 0.04-0.8 of initiator, 0.02-0.3 of chain transferagent, 0-2 of pH regulator and 50-80 of dispersed medium. The emulsion pressure-sensitive adhesive product is coated on a base material of a product to be coated; and after a solvent is volatile, thelight crosslinking is carried out on the coated product in an ultraviolet light curing device. Compared with the prior art, the single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive has the advantages of having stronger cohesive force, better initial adhesion and ideal persistent persistent adhesivity, containing no small molecular compounds, forming no toxic by-products, being capable of adapting to different application requirements, being stable in property and the like.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Method for preparing modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive

InactiveCN103435760AGood pressure sensitivityImprove water resistanceGraft polymer adhesivesEpoxyPolyurethane dispersion

The invention discloses a method for preparing a modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The method comprises the following steps: adding polyisocyanate and low polymer polyhydric alcohol into reaction equipment, further adding a hydrophilic chain extender to react to obtain a polyurethane prepolymer, subsequently adding acrylic ester containing hydroxyl and a modified epoxy resin so as to obtain the modified polyurethane prepolymer; further adding a neutralizer to neutralize, adding water, subsequently dispersing by using a high-speed dispersing machine so as to obtain a modified waterborne polyurethane dispersoid; uniformly dripping acrylate monomer, a modified rosin resin and an initiating agent so as to obtain a modified waterborne polyurethane dispersoid; further adding a defoaming agent, and finally adding a curing agent additionally so as to obtain the modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The pressure-sensitive adhesive prepared through the method is high in primary adhesion property, release force, adhesion lasting property and high-temperature adhesion lasting property; a high-temperature-resistant pressure-sensitive adhesive tape prepared from the adhesive can meet the requirements of automobile and electronic industries. According to the invention, the preparation process is simple, the production period is short and the operation cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous polyurethane adhesive and preparation method thereof

InactiveCN102516920AStrong initial adhesionImprove stabilityPolyureas/polyurethane adhesivesDiamineIon

The invention discloses an aqueous polyurethane adhesive and a preparation method thereof. The aqueous polyurethane adhesive comprises, by weight, 100 parts of polyester polyol, 30 parts of isocyanate, 7-8 parts of auxiliary agent and the balance of deionized water. The preparation method comprises steps of: dehydrating polyester polyol, adding isocyanate, dimethylolpropionic acid, trimethylol propane and N-methyl pyrrolidone and adding dropwise a catalyst to obtain a performed polymer; then adding acetone and triethylamine for neutralization into salt; dispersing the mixture into deionized water with high speed shearing and carrying out emulsification; adding ethene diamine for chain extension and steaming out acetone with reduced pressure. The method of the invention has a simple technology, is practical and employs self-made aromatic polyurethane polyol; an R value, namely a value of NCO / OH is controlled at 1.4, and an addition of the DMPA is 3.5%; and the prepared aqueous polyurethane adhesive has strong Initial adhesion and good stability.

Owner:东莞市山力高分子材料科研有限公司

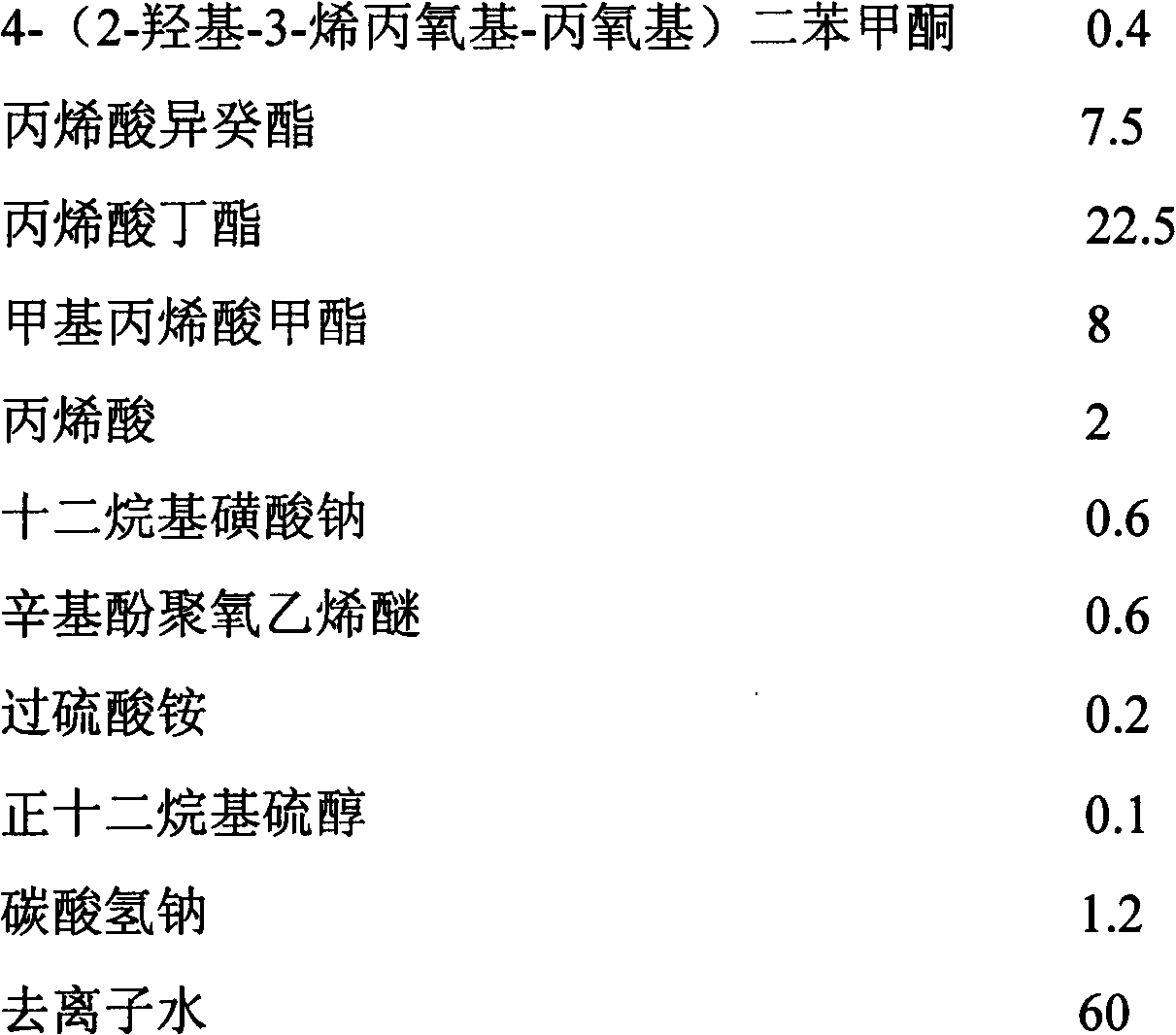

Adhesive tape used for solar cell assembly and preparation method thereof

InactiveCN102816536AGood adhesionGood initial tackFilm/foil adhesivesEster polymer adhesivesAmmonium sulfateEmulsion

The invention relates to a double-sided adhesive tape, and specifically relates to the double-sided adhesive tape used for a solar cell assembly and a preparation method thereof. The double-sided adhesive tape comprises a substrate, an adhesive, a backlining and backlining glue, wherein the adhesive mainly comprises the following components of, by weight, 0.5-1 part of ammonium sulfate, 5-10 parts of methyl methacrylate, 55-65 parts of butyl acrylate, 20-30 parts of hydroxymethyl acrylamide, 1-2 parts of a composite emulsifier, 60-70 parts of a tackifying resin, 0.2-0.8 part of acrylic acid, 1-2 parts of hydroethyl methacrylate, 1-1.5 parts of 2-acrylamide-2-methylpro panesulfonic acid and 1-3 parts of 3-(methacryloxy)propyltrimethoxysilane. The preparation method comprises the steps of firstly pre-preparing a high-strength organosilicone and acrylate co-polymeric emulsion pressure-sensitive adhesive; and then performing operations of double roll reverse coating, drying, compositing, transferring and the like with a B-50 multifunctional coating machine, wherein both the font side and the back side of the backlining of the substrate are already coated by a layer of low-adhesivity backlining glue.

Owner:SUZHOU DATONG ADVANCED MATERIAL

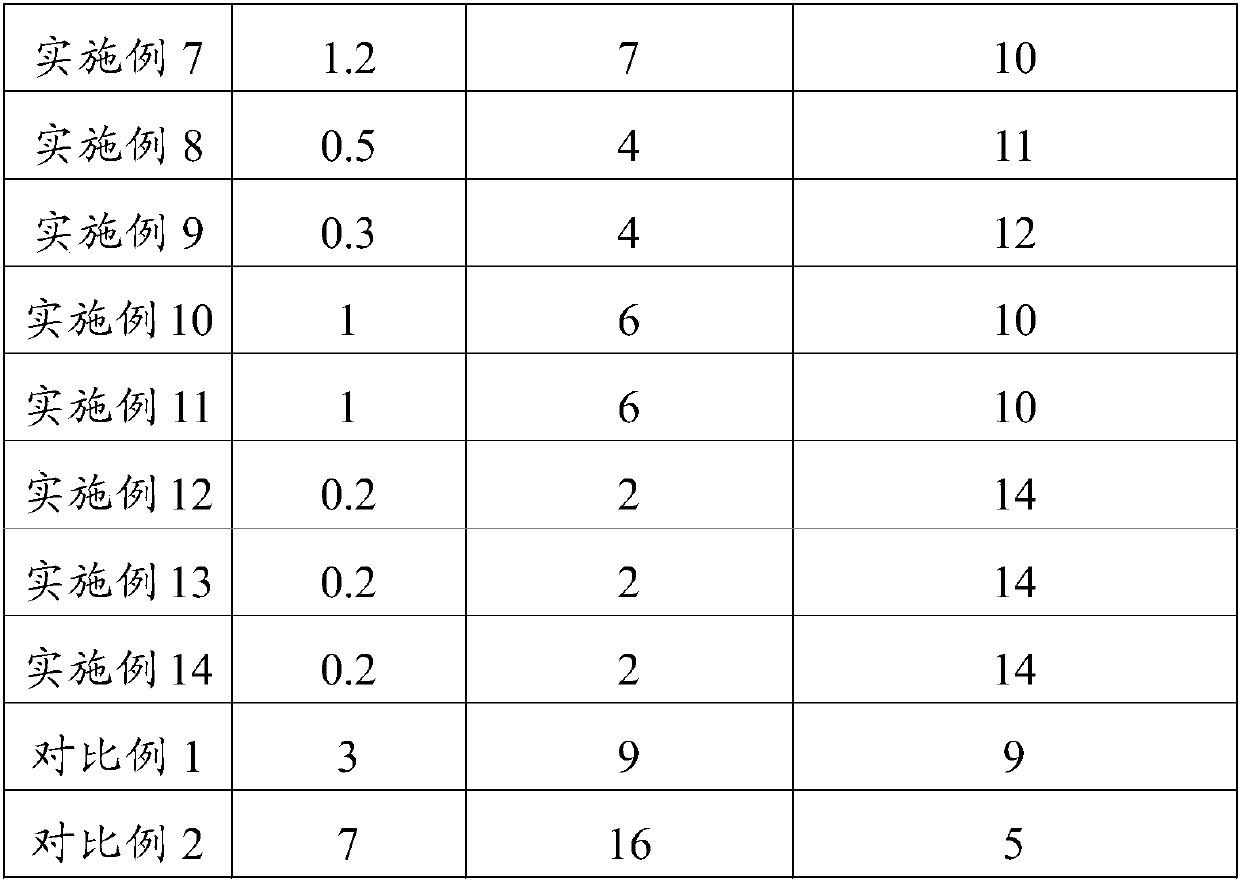

Soundproof floor mat

ActiveCN103774833AAvoid noiseReduce noiseNon-macromolecular adhesive additivesFlooring insulationsQuality of lifeEngineering

The invention relates to an article for daily life such as a floor mat, in particular to a soundproof floor mat, which comprises a first moisture-proof film, an all-open cell foam material or softwood layer and a closed cell foam material layer, wherein the first moisture-proof film layer is arranged in a bottom layer; the all-open cell foam material or softwood layer is arranged in a middle layer, and is positioned on the first moisture-proof film layer; the closed cell foam material layer is arranged in an upper layer, and is positioned on the all-open cell foam material or softwood layer. According to the soundproof floor mat, the advantages of a closed cell foam material, softwood and an all-open cell foam material in sound insulation and noise reduction are integrated, and the soundproof floor mat is laid under a floorboard by a multilayer composite technology, so that the shortcomings of each material are effectively overcome, high-frequency and low-frequency noise can be eliminated to effectively realize sound insulation and noise reduction, noise between floors is effectively lowered, 80 percent of impact sounds (knocking noise produced by high heels or other hard objects) from upper floors can be reduced and remarkably improved, and the quality of life is improved; due to the adoption of a three-layer structure, the foot-feel can be improved, and the floorboard can be protected.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

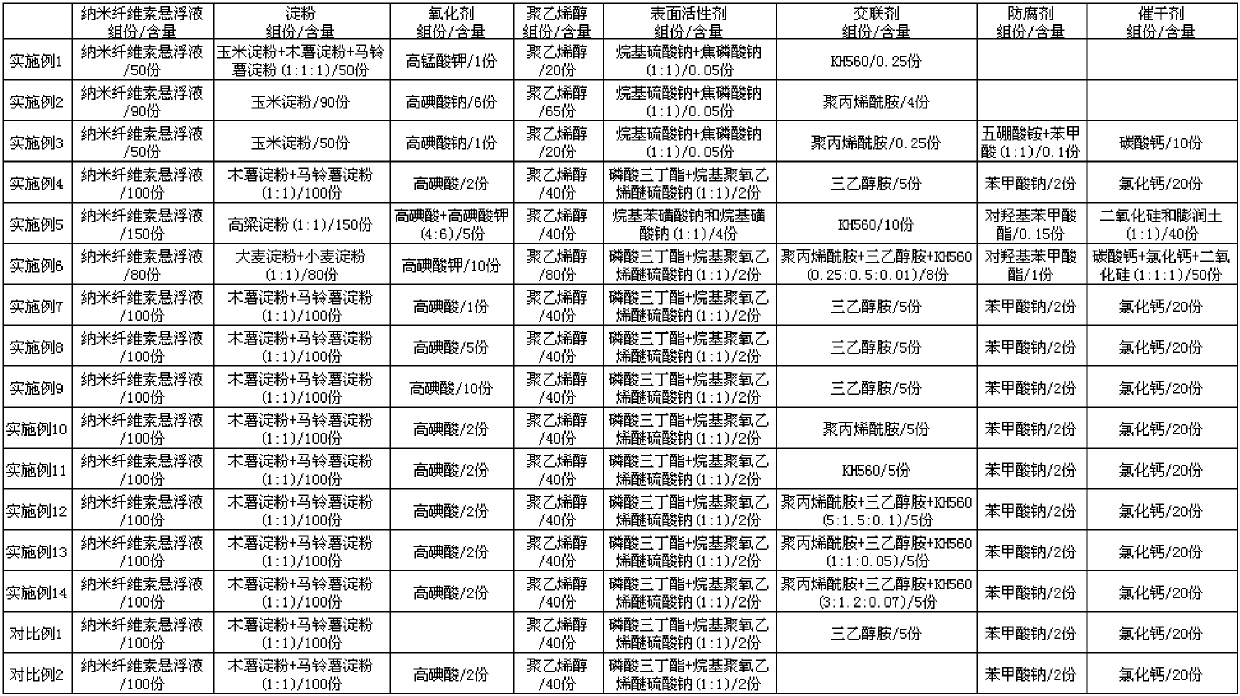

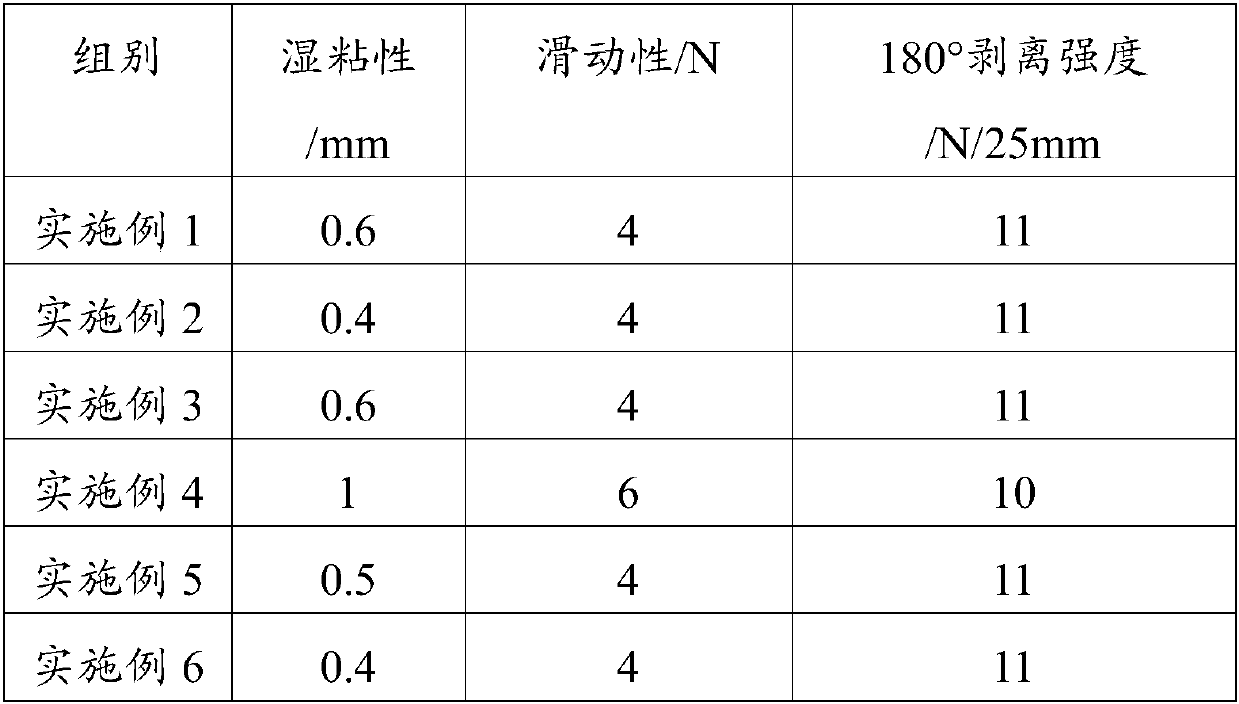

Starch adhesive and preparation method thereof

ActiveCN107779122AImprove water resistanceGood storage stabilityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveSolvent

The application provides a starch adhesive. The starch adhesive is prepared from the following components in parts by weight: 50 to 150 parts of nanocellulose suspension, 50 to 150 parts of starch, 1to 10 parts of an oxidant, 20 to 80 parts of polyvinyl alcohol, 0.01 to 5 parts of a surfactant and 0.25 to 10 parts of a crosslinking agent. The starch adhesive has good properties including good waterproof performance, good storage stability, excellent initial adhesion, great adhesion, good flowability and good coagulation resistance. The application further provides a preparation method of thestarch adhesive. The preparation method comprises the following steps: (1) preparing the nanocellulose suspension, preparing a polyvinyl alcohol solution and preparing a dialdehyde starch solution; and (2) mixing the dialdehyde starch solution, the nanocellulose suspension, the polyvinyl alcohol solution and the crosslinking agent and stirring and reacting with certain pH value and temperature toprepare the starch adhesive. According to the method provided by the invention, starch and waste paper products are used as raw materials, aldehyde substances are not added in a reaction process and water is used as a solvent; and a production technology and a product have an environment-friendly property and all the raw materials can react sufficiently.

Owner:GUANGDONG YULAN GRP

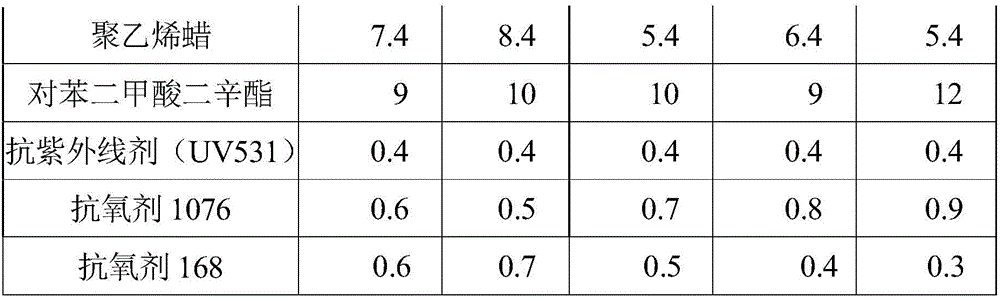

Removable hot-melt pressure-sensitive adhesive and preparation method

ActiveCN106318292AExcellent adhesionImprove retentionNon-macromolecular adhesive additivesFilm/foil adhesivesEnvironmental resistanceUltraviolet

The invention relates to a removable hot-melt pressure-sensitive adhesive and belongs to the technical field of adhesives. The pressure-sensitive adhesive is prepared from raw materials in parts by mass as follows: 35-45 parts of matrix resin, namely, a styrene-isoprene-styrene triblock copolymer, 30-40 parts of a tackifier, namely, C5 petroleum resin, 8-13 parts of a softener, namely, dioctyl terephthalate, 3-8 parts of a peel strength modifier, namely, polyethylene wax, 7-15 parts of a viscosity modifier, namely, liquid petroleum resin, 0.6-1.4 parts of an antioxidant and 0.4 parts of an ultraviolet absorbent. An adhesive tape prepared from the pressure-sensitive adhesive can be peeled and pasted repeatedly, and the adhesive cannot be transferred after the pressure-sensitive adhesive is pasted with paper, PE films, PP films and the like. The pressure-sensitive adhesive meets the environmental protection requirement of European Union REACH and RoHS on the basis of detection of specialized agencies and can completely meet the requirement of production of sealing labels, labels and removable adhesive bags.

Owner:河北方大新材料股份有限公司

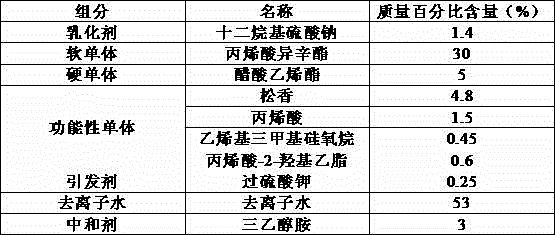

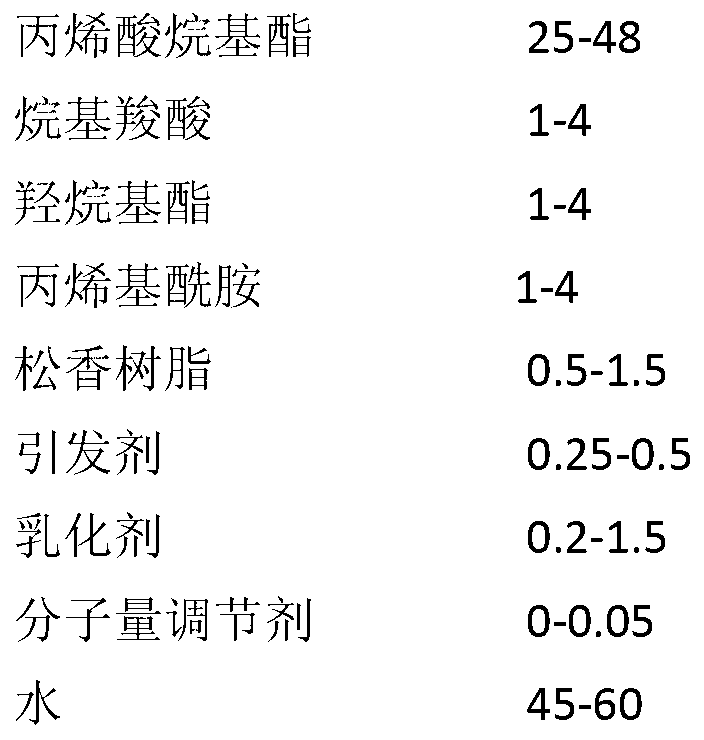

Frankincense-modified acrylate emulsion and its preparation method and use

The invention discloses a frankincense-modified acrylate emulsion and its preparation method and use. The frankincense-modified acrylate emulsion comprises, by mass, 25-48% of alkylacrylate, 1-4% of alkyl carboxylic acid, 1-4% of a hydroxyalkyl ester, 1-4% of acrylamide, 0.5-1.5% of rosin resin, 0.25-0.5% of an initiator, 0.2-1.5% of an emulsifier, 0-0.05% of a molecular weight conditioning agent and 5-60% of water. The invention also discloses PVC floor glue prepared from the frankincense-modified acrylate emulsion. The frankincense-modified acrylate emulsion has a hard-core soft-shell structure. The PVC floor glue prepared from the frankincense-modified acrylate emulsion has the advantages that through utilization of the tackifying resin and the hard-core soft-shell structure, base material wettability is improved; material adhesiveness is improved; initial adhesiveness is good; bonding strength is high; a film-forming assistant, a plasticizer and an antifreezing agent are avoided; and environmental friendliness is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Medical polyacrylate pressure-sensitive adhesive with high adhesion performance

ActiveCN105219316AGood adhesionHigh molecular weightEster polymer adhesivesCross-linkPolymer science

The invention relates to a medical polyacrylate pressure-sensitive adhesive with high adhesion performance. The medical polyacrylate pressure-sensitive adhesive comprises soft monomers, hard monomers, functional monomers, initiators, cross-linking agents and solvents. The glass-transition temperature of the soft monomers ranges from -65 DEG C to -60 DEG C. The cross-linking agents are isocyanate-group-containing compounds generated through the reaction between polyisocyanates and polyhydroxy compounds. The weight-average molecular weight of the pressure-sensitive adhesive ranges from 80*10<4> g / mol to 140*10<4> g / mol. The molecular weight distribution of the pressure-sensitive adhesive ranges from 10 to 25. In the preparing process of the pressure-sensitive adhesive, temperature and the reaction sequence and the adding quantity of the reaction materials are gradually controlled, and the product with the high molecular weight and the wide molecular weight distribution is obtained. The product can be used for the medical and health field.

Owner:四川厚生天佐药业有限公司

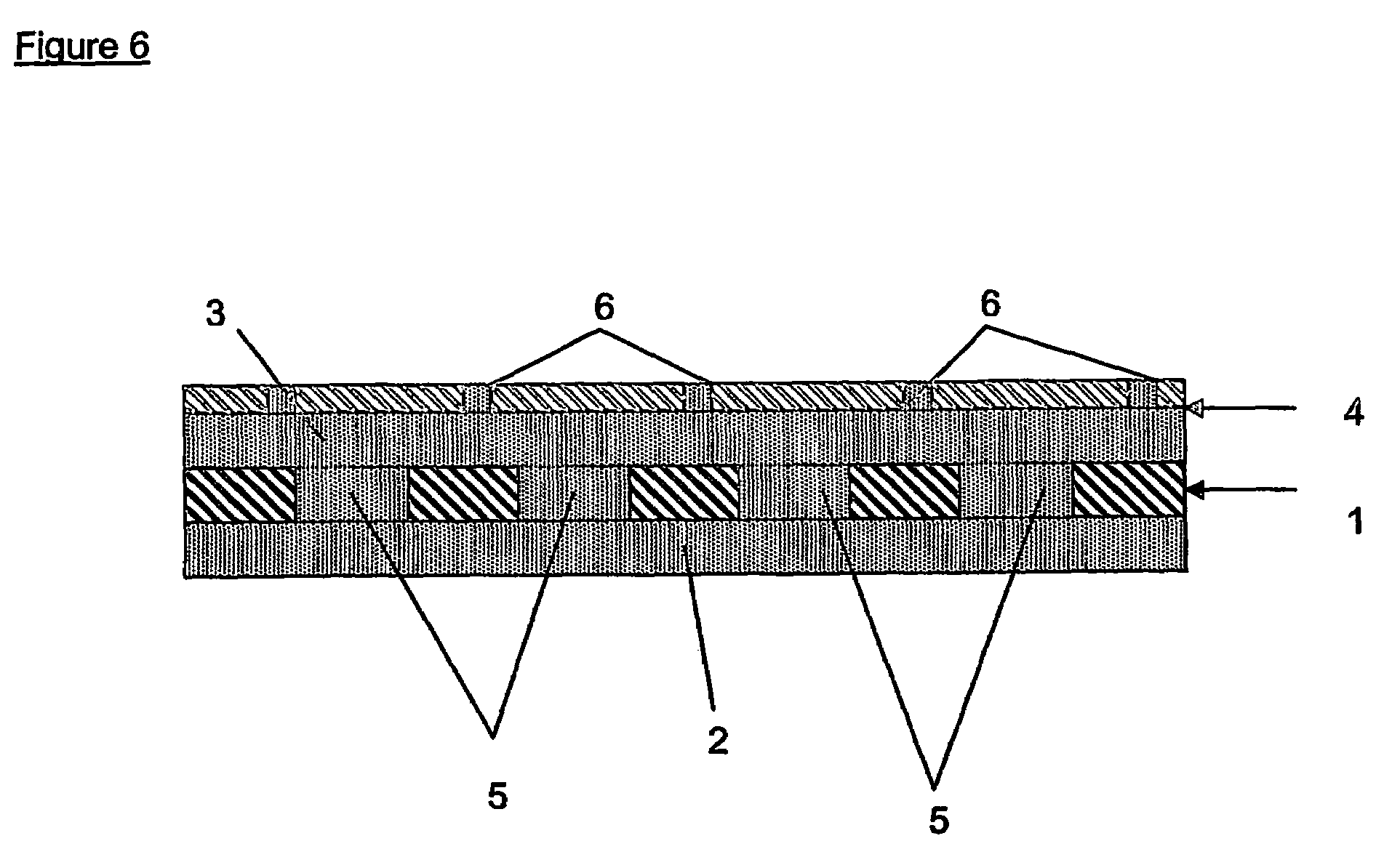

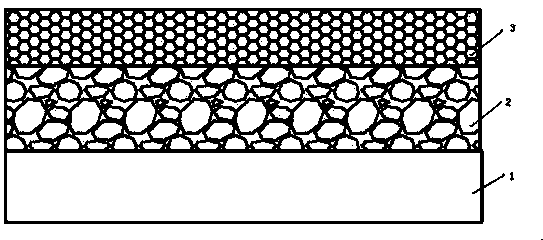

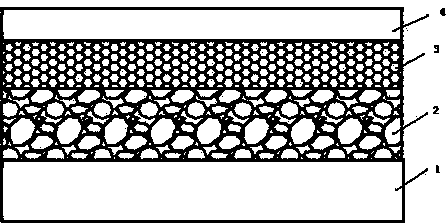

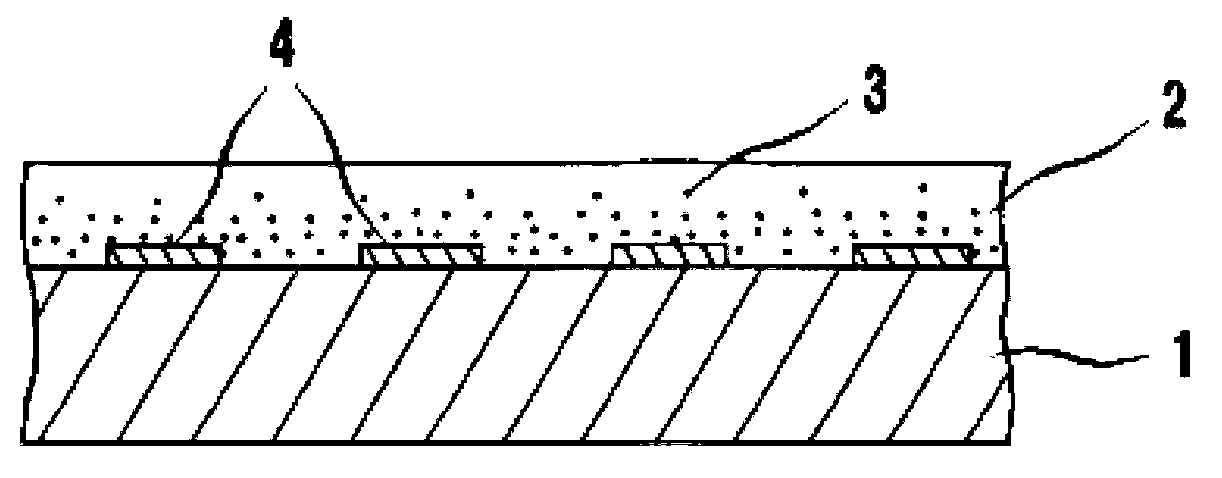

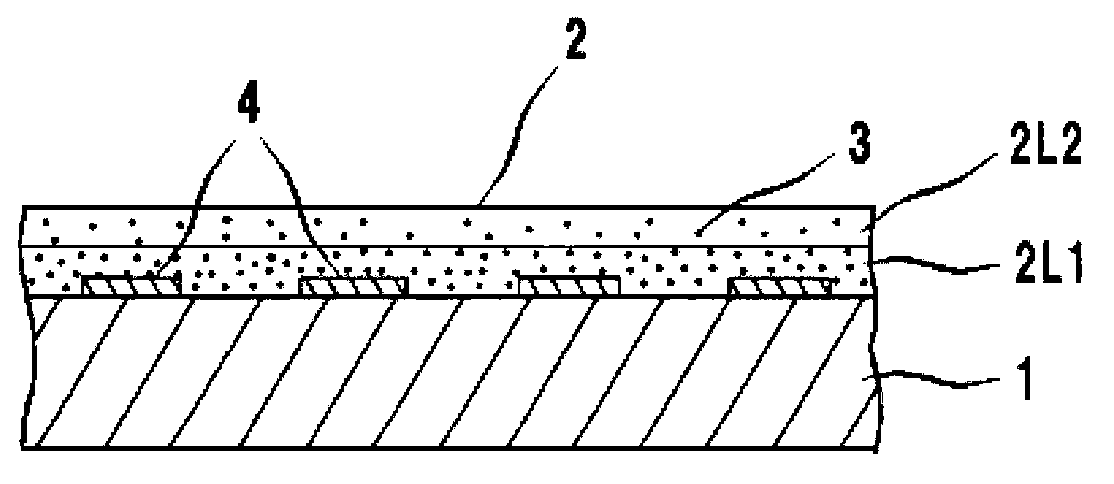

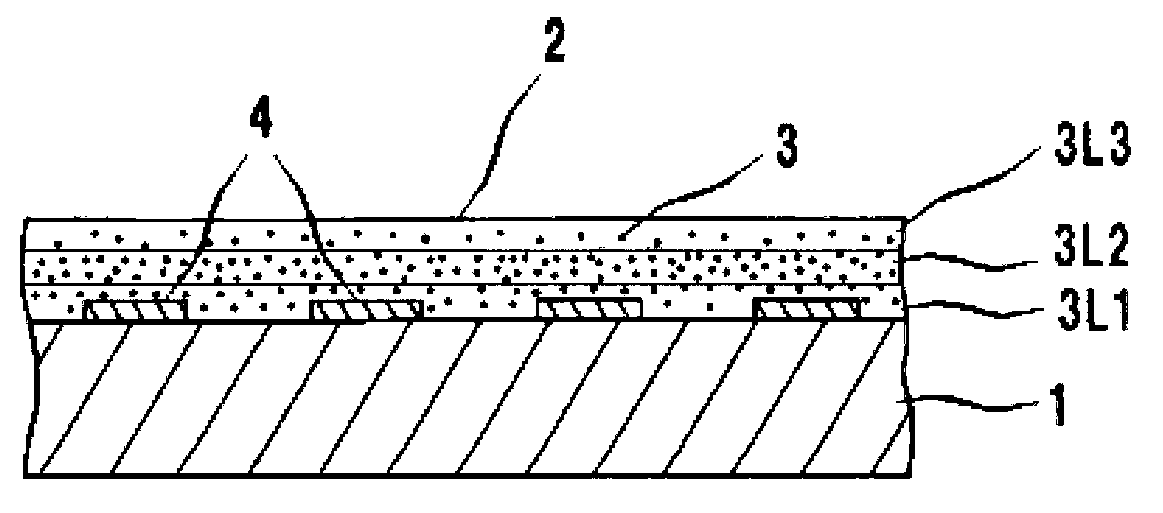

Layered structure and light-sensitive dry film used in same

ActiveCN102763036AImprove reliabilityLow coefficient of linear thermal expansionPrinted circuit aspectsSemiconductor/solid-state device manufacturingResistInsulation layer

Provided is a layered structure that has, at least, a substrate (1) and a light-sensitive resin layer or cured coating layer (2), containing an inorganic filler (3), formed on top of the substrate. In the light-sensitive resin layer or cured coating layer, the proportion of the inorganic filler is lower in a surface region opposite the substrate than in other regions, making it possible to keep the coefficient of linear thermal expansion of the entire light-sensitive resin layer or cured coating layer as low as possible while also avoiding losses in resolution and achieving excellent adhesion to an underfill resin section or a molded resin section. Preferably, the light-sensitive resin layer or cured coating layer comprises at least two layers having different inorganic filler proportions, and the surface-side light-sensitive resin layer or cured coating layer opposite the substrate has a lower inorganic filler proportion than the other layer(s). A light-sensitive dry film containing the abovementioned light-sensitive resin layer is suitable for use as an interlayer resin insulation layer or a solder resist in a printed circuit board.

Owner:TAIYO HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com