Water-based aluminium foil adhesive for cigarette packing and preparation method thereof

An adhesive, water-based technology, applied in the direction of adhesives, ester copolymer adhesives, unsaturated alcohol copolymer adhesives, etc., can solve the problem of residual formaldehyde in vinyl acetate monomer, performance degradation, poor adhesion, etc. Problems, to avoid the risk of delamination, improve the peel strength, excellent bonding performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

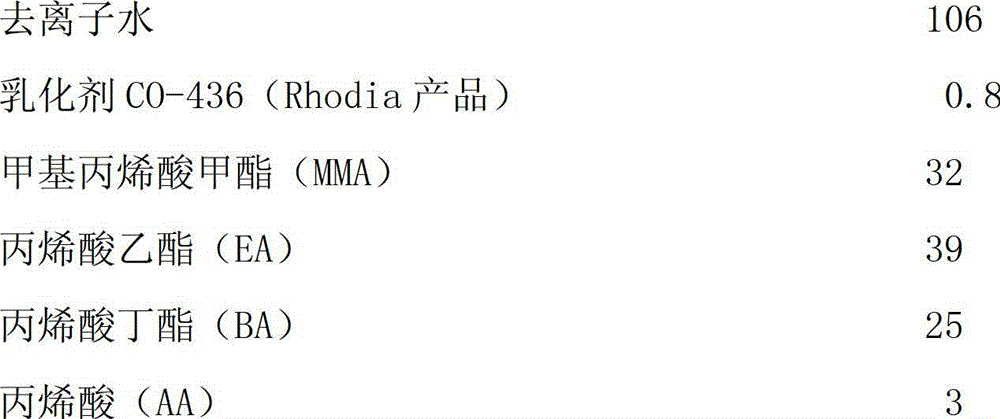

[0022] The embodiment of the present invention provides a method for preparing the above-mentioned water-based aluminum foil adhesive for cigarette packaging, comprising the following steps:

[0023] Get water-based acrylic acid emulsion, vinyl acetate-ethylene emulsion, mass concentration by formula of the present invention and be the raw materials of 20% polyvinyl alcohol solution, water-based auxiliary agent and deionized water;

[0024] At 70°C, put the vinyl acetate-ethylene emulsion in the raw material into the water-based acrylic emulsion prepared in the polymerization kettle, and stir for 25-35 minutes;

[0025] Add the prepared polyvinyl alcohol solution with a mass concentration of 20% to the mixed emulsion in the above polymerization kettle, and stir for 25 to 35 minutes;

[0026] Raise the temperature of the polymerization kettle to 82-84°C, vacuumize, the vacuum degree is -0.03--0.04MPa, keep it for 60 minutes, and keep stirring; then lower the temperature to belo...

Embodiment 1

[0041] This embodiment provides a water-based aluminum foil adhesive for cigarette packaging, the preparation method of which is as follows:

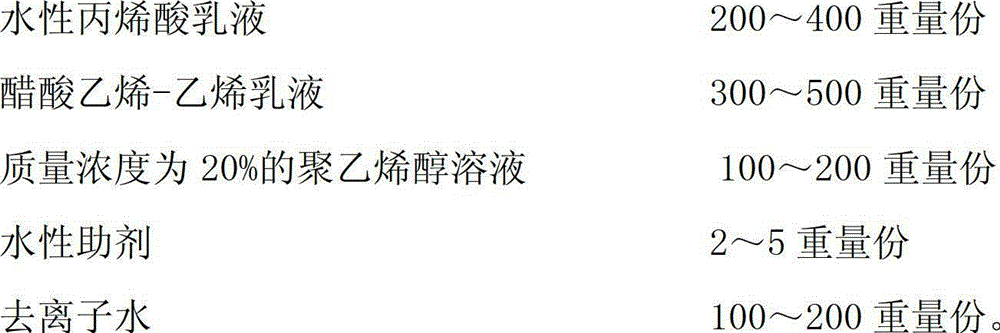

[0042] (1) Raw material formula for the preparation of water-based acrylic emulsion (parts by weight, the same below):

[0043]

[0044]

[0045] (2) VAE emulsion:

[0046] BJ-706 (product of Beijing Organic Chemical Factory) 450

[0047] (3) PVA solution:

[0048] Deionized water 144

[0049] PVA2088 (product of Beijing Organic Chemical Factory) 36

[0050] (4) Water-based additives:

[0051] Defoamer 8034A (Cognis product) 1.8

[0052] Preservative Kathon (Rohm and Haas product) 1.2

[0053] (5) Deionized water 170

[0054] Preparation steps:

[0055] (1) Preparation of water-based acrylic emulsion: using the conventional pre-emulsification seed emulsion polymerization method, first put 40wt% deionized water, emulsifier and all monomers into the pre-emulsification tank, stir and emulsify to obtain the pre-emulsion; then ...

Embodiment 2

[0060] This embodiment provides a water-based aluminum foil adhesive for cigarette packaging, the preparation method of which is as follows:

[0061] (1) Raw material formula for the preparation of water-based acrylic emulsion (parts by weight, the same below):

[0062]

[0063] (2) VAE emulsion:

[0064] Celvolit 143 (Celanese product) 400

[0065] (3) PVA solution:

[0066] Deionized water 128

[0067] PVA2099 (product of Beijing Organic Chemical Factory) 32

[0068] (4) Water-based additives:

[0069] Defoamer AD01 (Air Chemicals) 1.4

[0070] Preservative Kathon (Rohm and Haas product) 1.8

[0071] (5) Deionized water 140

[0072] Preparation steps:

[0073] (1) Preparation of water-based acrylic emulsion: using the conventional pre-emulsification seed emulsion polymerization method, first put 42wt% deionized water, emulsifier and all monomers into the pre-emulsification tank, stir and emulsify to obtain the pre-emulsion; then polymerize Put 48wt% deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com