Hot melt pressure sensitive adhesive and preparation method thereof

A technology of hot-melt pressure-sensitive adhesive and styrene-butadiene rubber, which is applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., and can solve problems such as short sticking time, reduced production efficiency, and low softening point , to achieve the effect of small system temperature change, good mixing uniformity and excellent die-cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

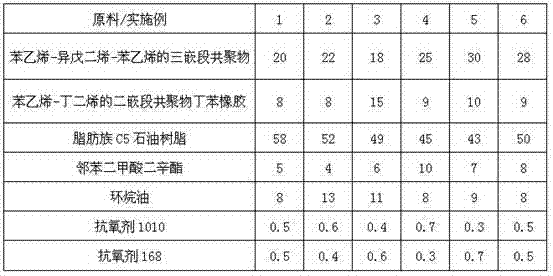

[0025] The present invention will be described in further detail below in combination with specific embodiments.

[0026] The hot-melt pressure-sensitive adhesive of the present invention is composed of matrix resin, tackifier, plasticizer and stabilizer according to a certain proportion. At present, the main matrix resin used in hot-melt pressure-sensitive adhesives is ethylene-vinyl acetate copolymer (EVA) or styrene-butadiene-styrene triblock elastomeric copolymer (SBS). Styrene-isoprene-styrene triblock copolymer (SIS) has the properties of vulcanized rubber at room temperature, has plasticity at high temperature, and has good processability; the excellent performance of SIS is its unique It is determined by the morphology and structure. It can be seen from the electron microscope that SIS has a two-phase structure. When the mass fraction of styrene is lower than 30%, it will form a constrained component-microdomain, which plays a role of "vulcanization" in the continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com