Single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive and synthetic method thereof as well as application thereof

An acrylate, ultraviolet light technology, used in ester copolymer adhesives, acid copolymer adhesives, nitrile copolymer adhesives, etc., can solve the problem of limited development space, strong odor, easy yellowing of coating films, etc. problem, to achieve the effect of strong cohesion, good initial viscosity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

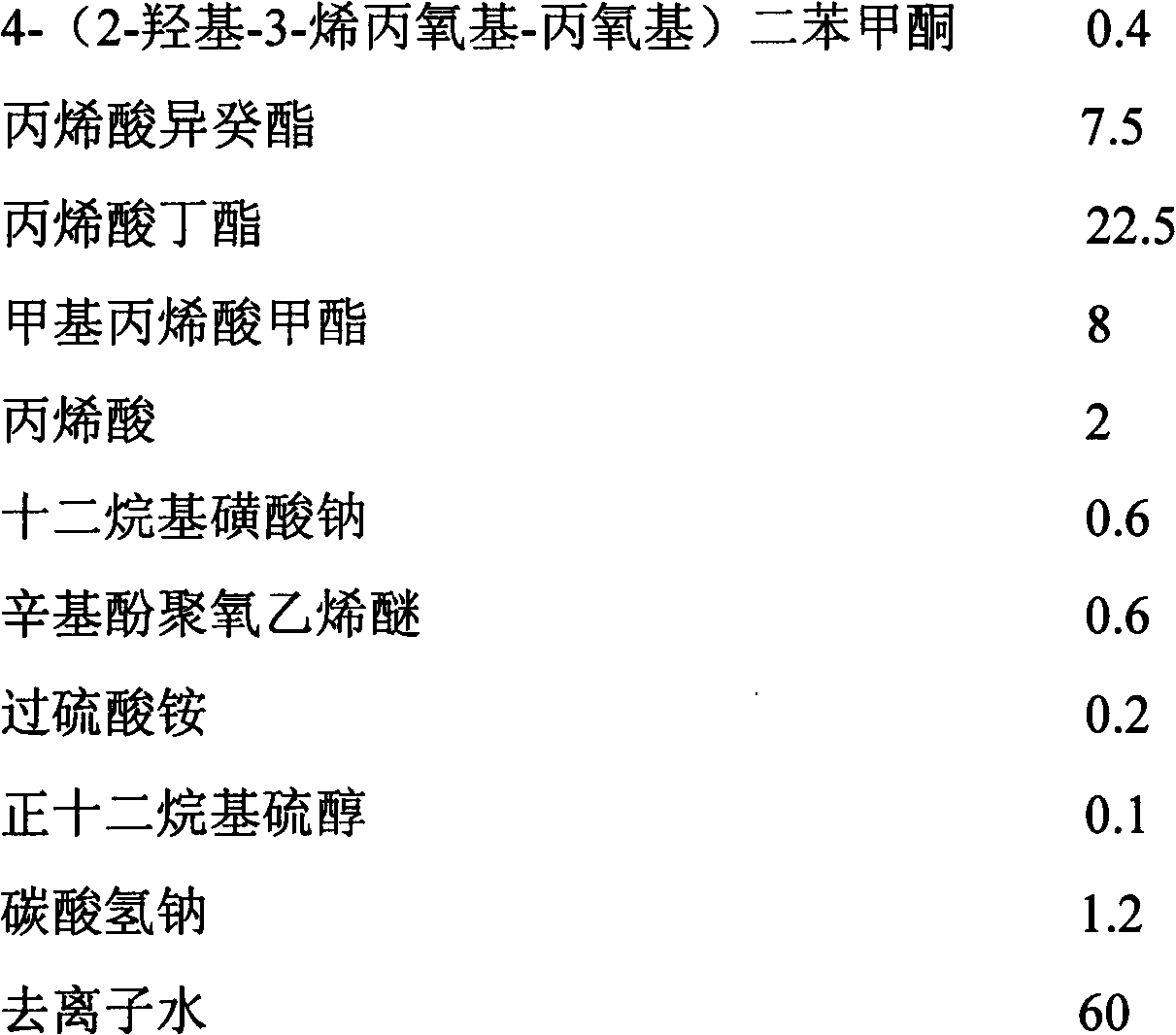

[0048] The single-component UV self-crosslinking acrylate copolymer emulsion pressure-sensitive adhesive of this embodiment is synthesized from the following components (parts by weight):

[0049]

[0050] The specific synthesis process is as follows: Put UV-active monomers, photo-crosslinking functional monomers, other monofunctional monomers, emulsifiers, chain transfer agents and part of the dispersion medium into the reaction kettle and stir at room temperature for 30 minutes to obtain a pre-emulsion; Put 10wt% of the pre-emulsion, 20wt% of the initiator, the pH regulator and the rest of the dispersion medium into another reaction kettle, stir and react at 85°C for 1h, so that the seed emulsion polymerization occurs; add 1 drop of Add the remaining pre-emulsion dropwise at a speed of 5 s, add the remaining initiator dropwise at a speed of 1 drop / min, finish adding the pre-emulsion in 2 hours, and drop the initiator in 2.5 hours; finish adding the pre-emulsion and initiat...

Embodiment 2

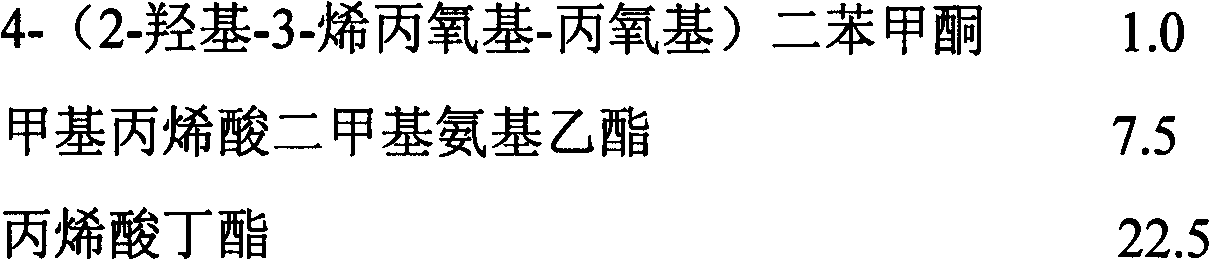

[0053] The single-component UV self-crosslinking acrylate copolymer emulsion pressure-sensitive adhesive of this embodiment is synthesized from the following components (parts by weight):

[0054]

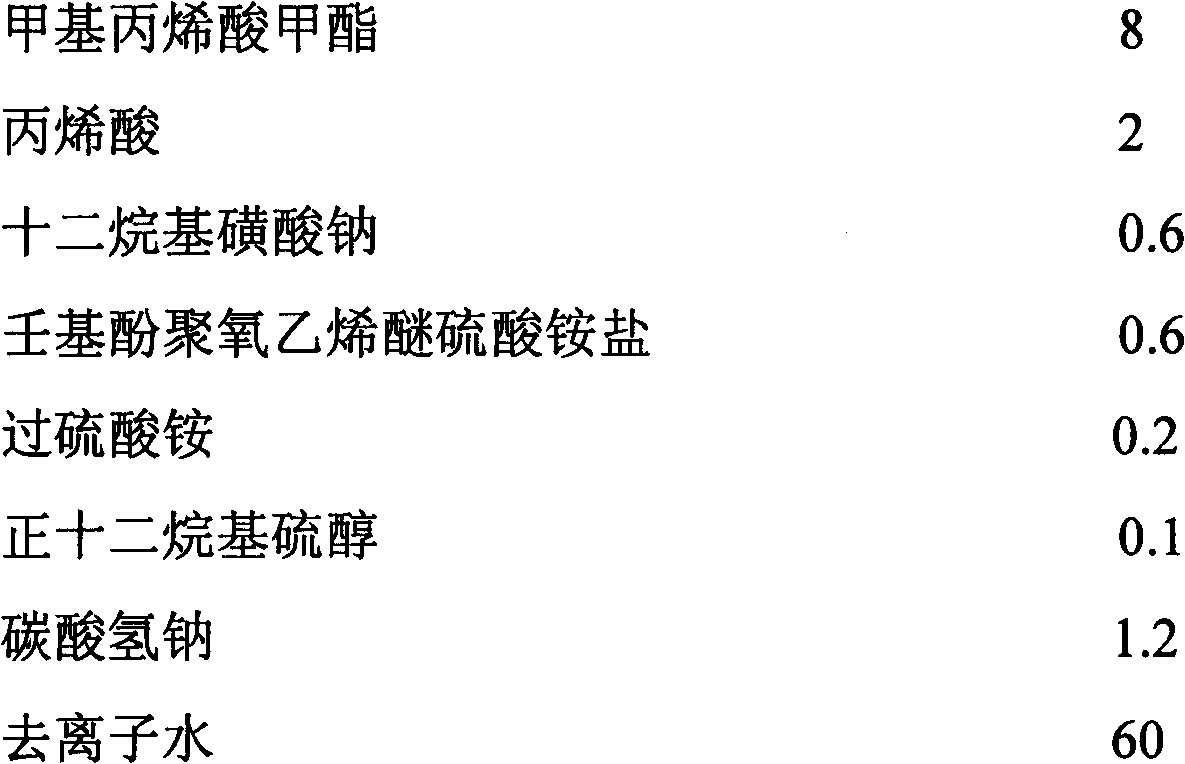

[0055]

[0056] Synthetic process is identical with embodiment 1. The obtained single-component UV self-crosslinking type acrylate copolymer pressure-sensitive adhesive emulsion is coated on the substrate, and after the solvent is evaporated, light crosslinking is carried out in a UV curing device. The irradiation energy of UV self-crosslinking is 500mJ. After testing, the cross-linking degree of the pressure-sensitive adhesive layer after ultraviolet light irradiation is 96%; the initial tack of the pressure-sensitive adhesive tape is 12 (ball number), the stickiness is greater than 72 hours, and the 180° peel strength is 2.1N / 25mm.

Embodiment 3

[0058] The single-component UV self-crosslinking acrylate copolymer emulsion pressure-sensitive adhesive of this embodiment is synthesized from the following components (parts by weight):

[0059]

[0060] Synthetic process is identical with embodiment 1. The obtained single-component UV self-crosslinking type acrylate copolymer pressure-sensitive adhesive emulsion is coated on the substrate, and after the solvent is evaporated, light crosslinking is carried out in a UV curing device. The irradiation energy of UV self-crosslinking is 500mJ. After testing, the cross-linking degree of the pressure-sensitive adhesive layer after ultraviolet irradiation is 82%; the initial tack of the pressure-sensitive adhesive tape is 15 (ball number), the stickiness is greater than 72 hours, and the 180° peel strength is 2.8N / 25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com