Pressure-sensitive adhesive sheet for dicing and dicing method

A technology for adhesive sheets and slices, applied in the direction of film/sheet adhesives, adhesive types, ester copolymer adhesives, etc., to achieve the effect of reducing adhesive strength, saving energy, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

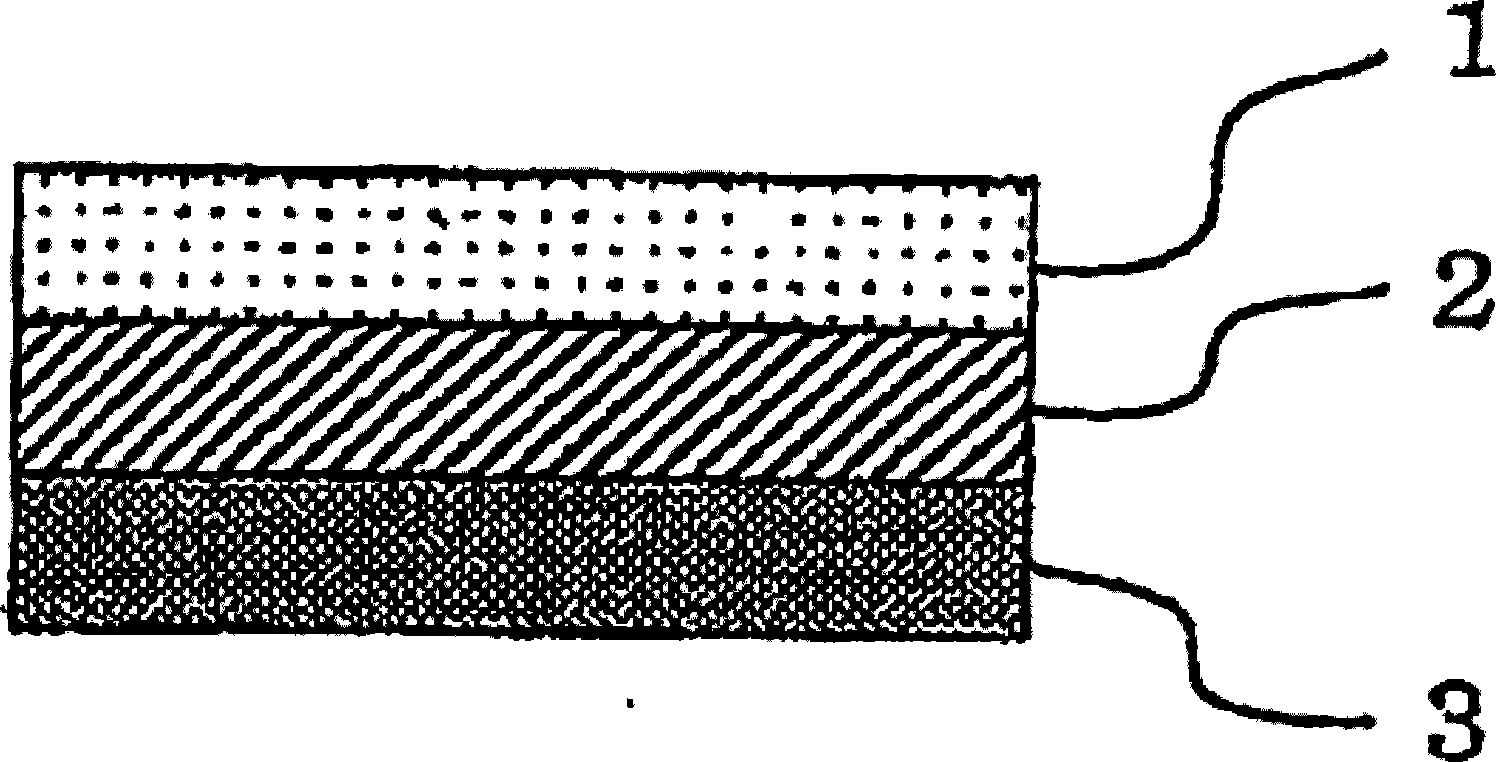

Image

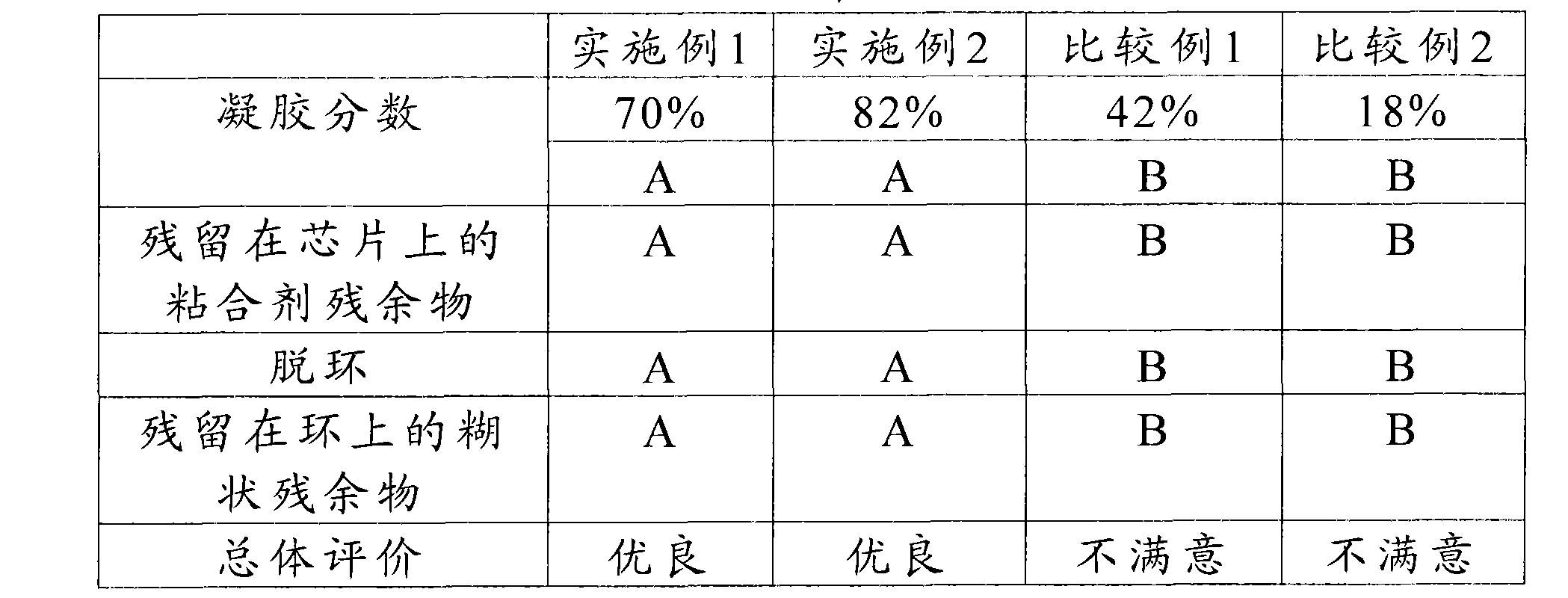

Examples

Embodiment 1

[0068] A 70 μm thick film made of linear low density polyethylene was used as a substrate. One side of the film was corona treated.

[0069] Also, 60 parts by weight of methyl acrylate, 30 parts by weight of 2-ethylhexyl acrylate, and 10 parts by weight of 2-hydroxyethyl acrylate were mixed to prepare a monomer solution.

[0070] Nitrogen is introduced into the reactor equipped with nitrogen introduction pipe, thermometer and stirrer, then add 400g ethyl acetate, 60g methyl acrylate, 30g 2-ethylhexyl acrylate, 10g acrylic acid and 0.2g AIBN ( azobisisobutyronitrile), and stirred at 60°C for 24 hours. Thereafter, the whole was cooled to room temperature to obtain an acrylic copolymer solution 1 containing an acrylic copolymer (weight average molecular weight: 600,000).

[0071] To the above-mentioned acrylic copolymer solution 1 were added 40 parts by weight of an ultraviolet curable oligomer (viscosity at 25°C: 10 Pa·sec) obtained by reacting pentaerythritol triacrylate and ...

Embodiment 2

[0074] Acrylic copolymer solution 2 comprising an acrylic copolymer having a carbon-carbon double bond at the terminal and having a weight average molecular weight of 600,000 was obtained by adding 12 parts by weight of 2-methacryloxyethylene Isocyanate was added to the same acrylic copolymer solution 1 as in Example 1, and they were reacted to introduce NCO groups into 90% OH groups at the end of 2-hydroxyethyl acrylate side chains in the copolymer.

[0075] Then, to this acrylic copolymer solution 2, 20 parts by weight of an ultraviolet curable oligomer (viscosity at 25°C: 10 Pa·sec) obtained by reacting pentaerythritol triacrylate and diisocyanate in equal amounts, 2 parts by weight Parts of photopolymerization initiator (trade name "Irgacure 651", manufactured by Ciba Specialty Chemicals Co.) and 3 parts by weight of polyisocyanate compound (trade name "Coronate L", manufactured by Nippon Polyurethane Co., Ltd.), thereby obtaining ultraviolet curing Type acrylic adhesive s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com