Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduced bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

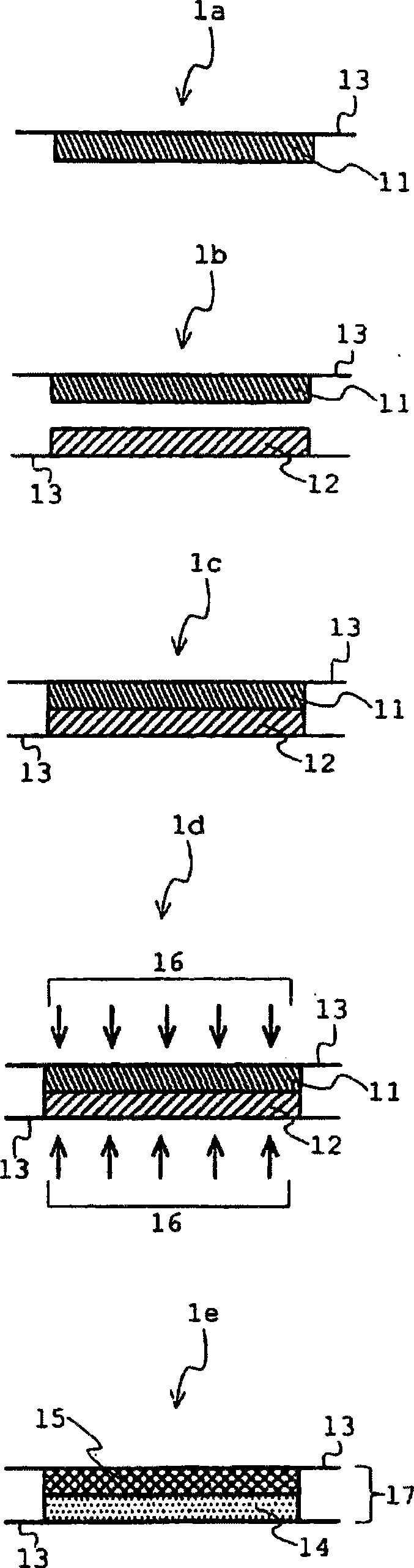

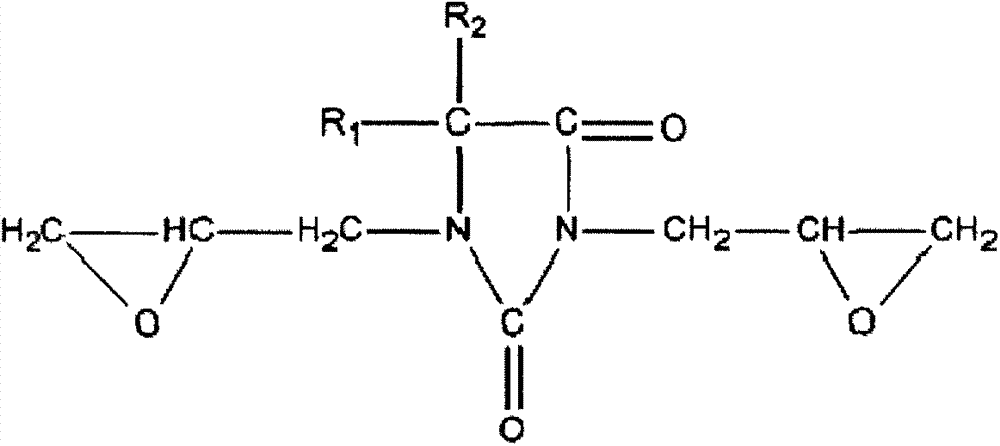

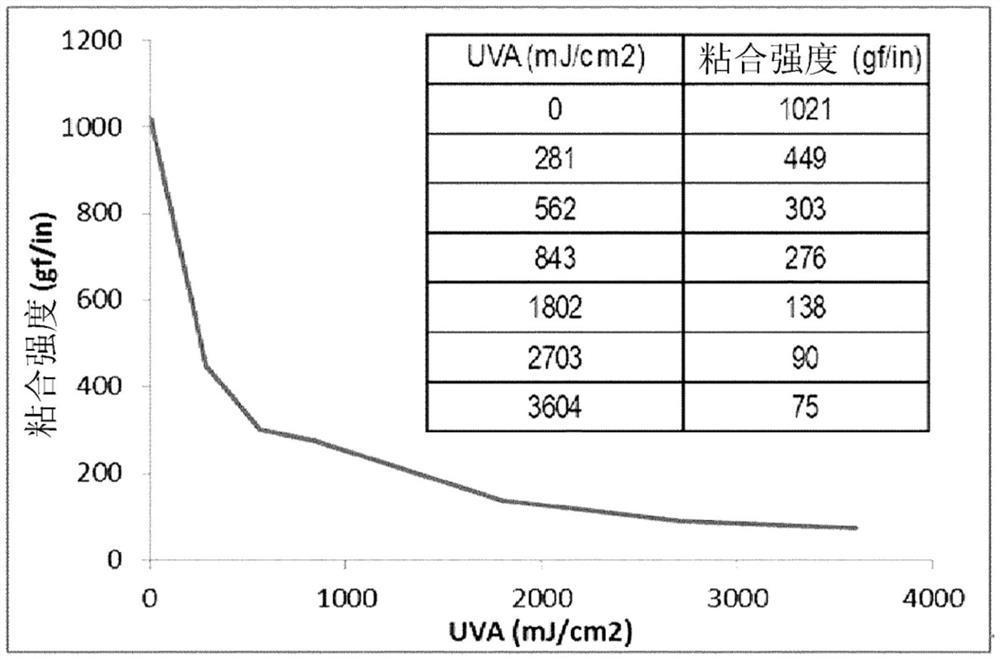

Removable pressure-sensitive adhesive composition and pressure-sensitive adhesive tape or sheet

ActiveCN101195734AEasy to removeReduced bond strengthSolid-state devicesSemiconductor/solid-state device manufacturingAcrylic polymerPolymer

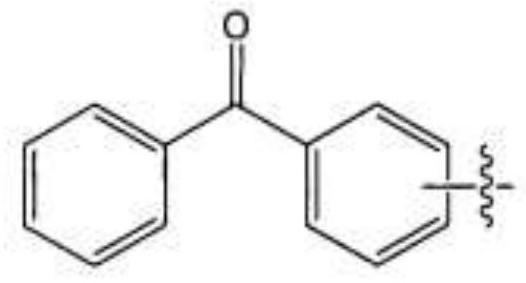

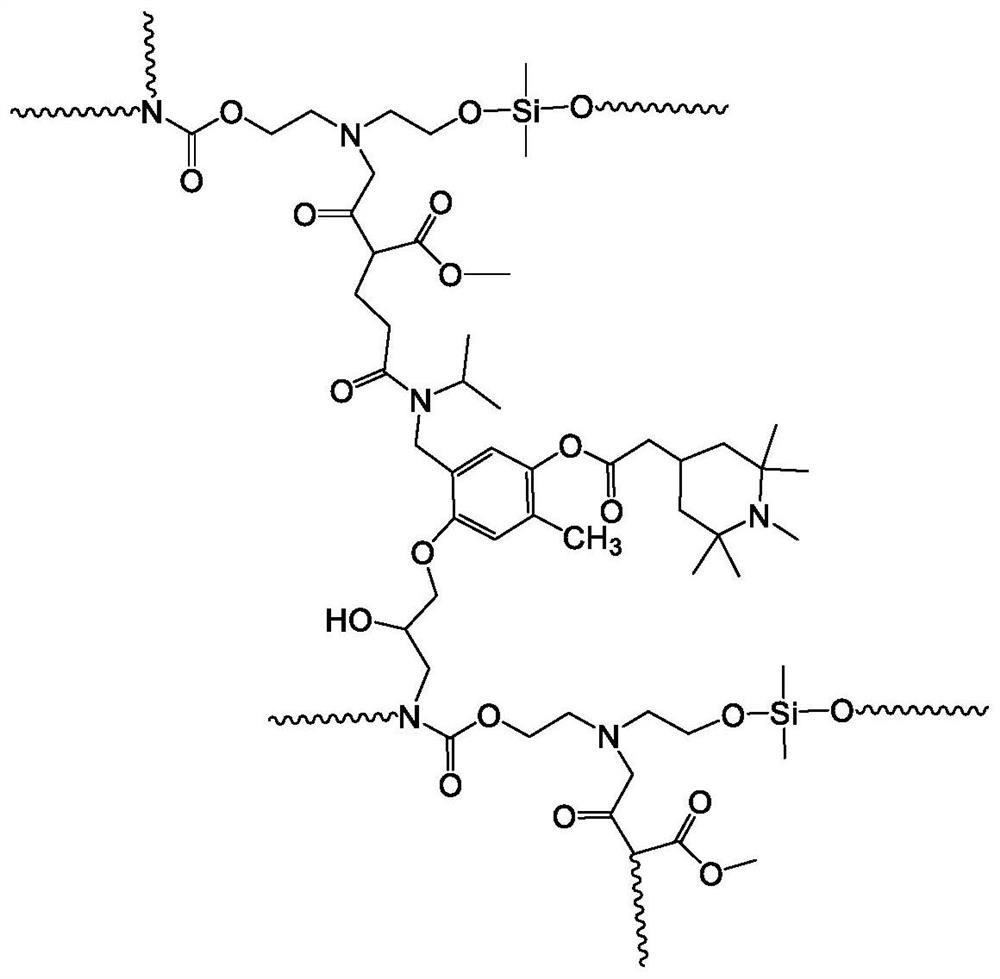

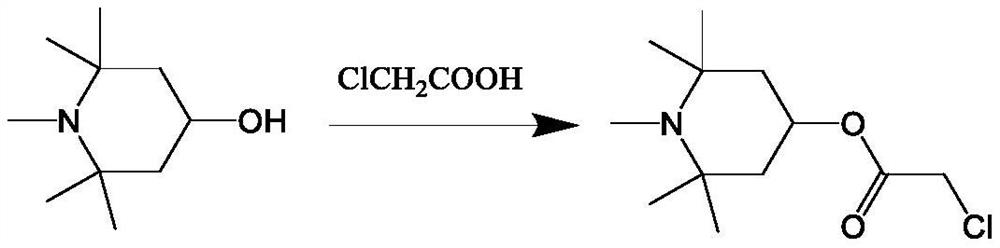

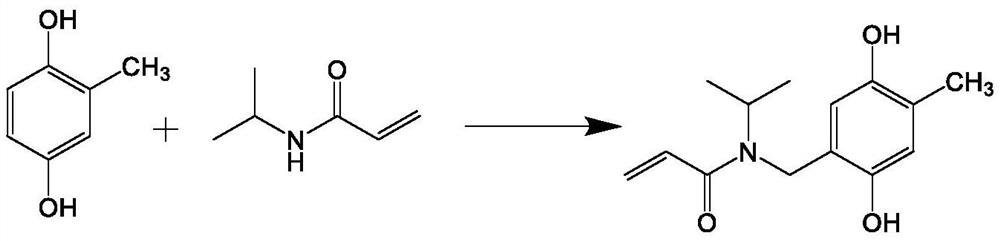

The present invention relates to a removable pressure-sensitive adhesive composition containing an acrylic polymer, a photopolymerization initiator and a crosslinking agent, in which the acrylic polymer and the photopolymerization initiator each are chemically bonded to the crosslinking agent. The present invention also relates to a removable pressure-sensitive adhesive composition containing an acrylic polymer and a photopolymerization initiator, the composition further containing a crosslinking agent having a reactive functional group which is capable of reacting with a reactive functional group of the acrylic polymer and a reactive functional group of the photopolymerization initiator.

Owner:NITTO DENKO CORP

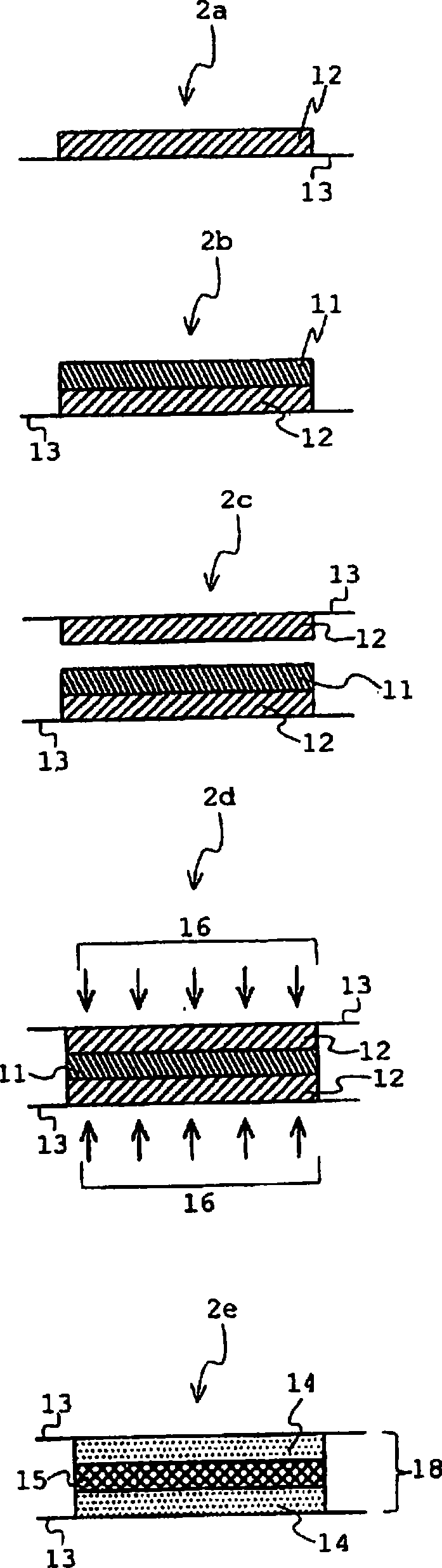

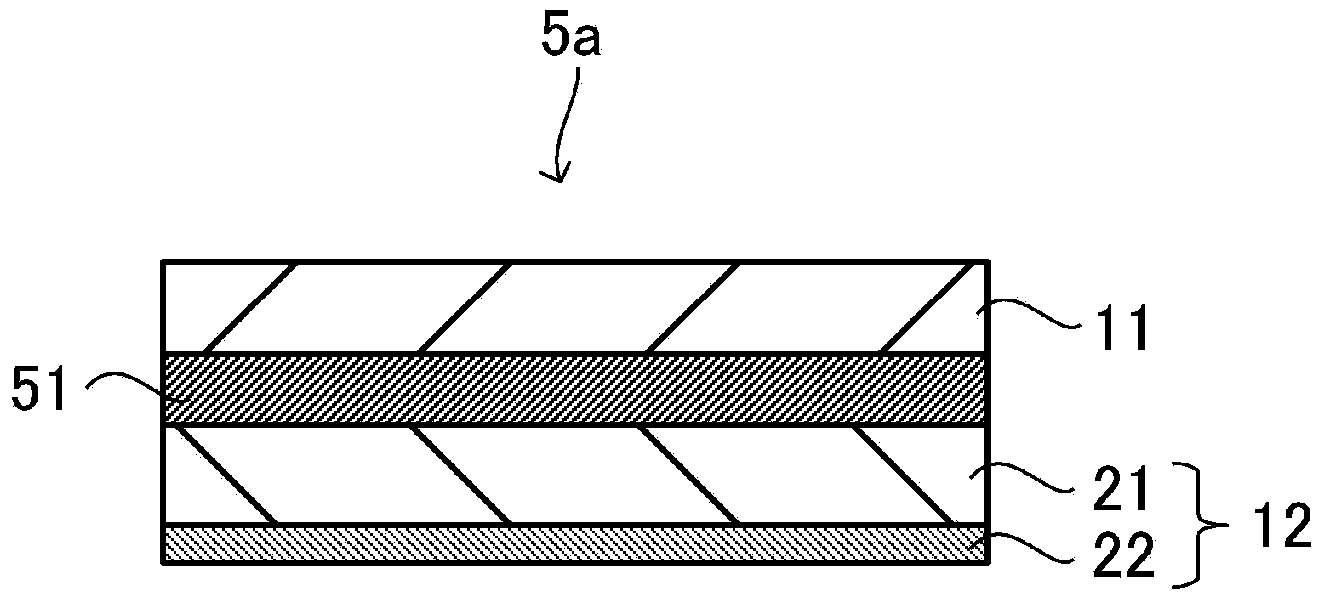

Thermally foamable repeelable acrylic pressure-sensitive adhesive tape or sheet

InactiveCN101535436AReduced bond strengthHigh normal bond strengthNon-macromolecular adhesive additivesSynthetic resin layered productsFoaming agentMicroparticle

The present invention relates to a thermally-foamable re-releasable acrylic pressure-sensitive adhesive tape or sheet including a microparticle-containing viscoelastic substrate and a thermal foaming agent-containing pressure-sensitive adhesive layer provided on at least one surface of the microparticle-containing viscoelastic substrate. The thermally-foamable re-releasable acrylic pressure-sensitive adhesive tape or sheet of the present invention can be easily separated or disassembled at the separation or disassembling of the bonded part while maintaining a high normal-state adhesive strength at the bonding.

Owner:NITTO DENKO CORP

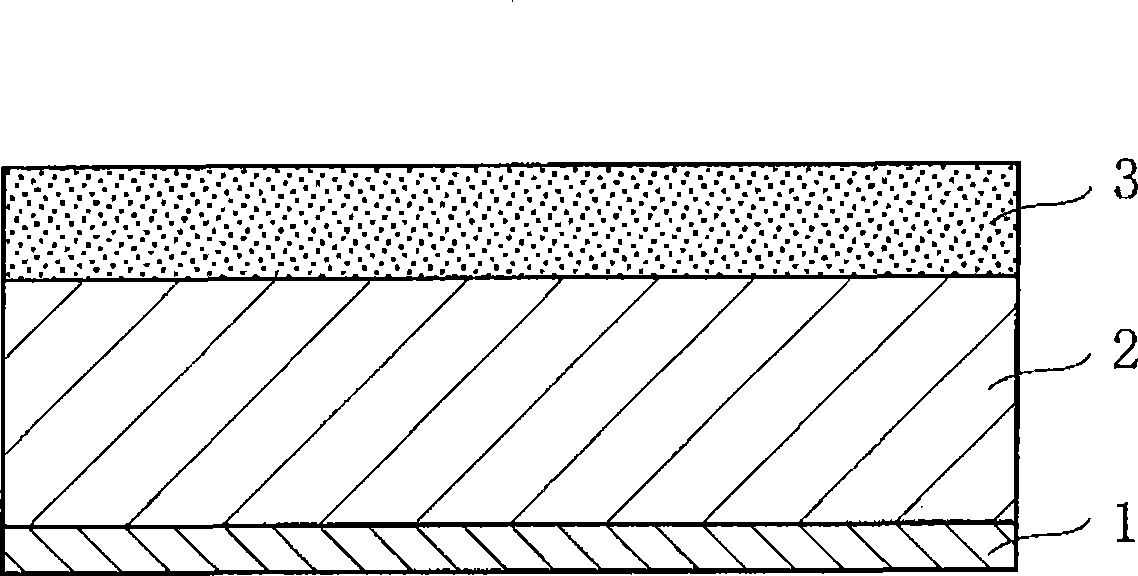

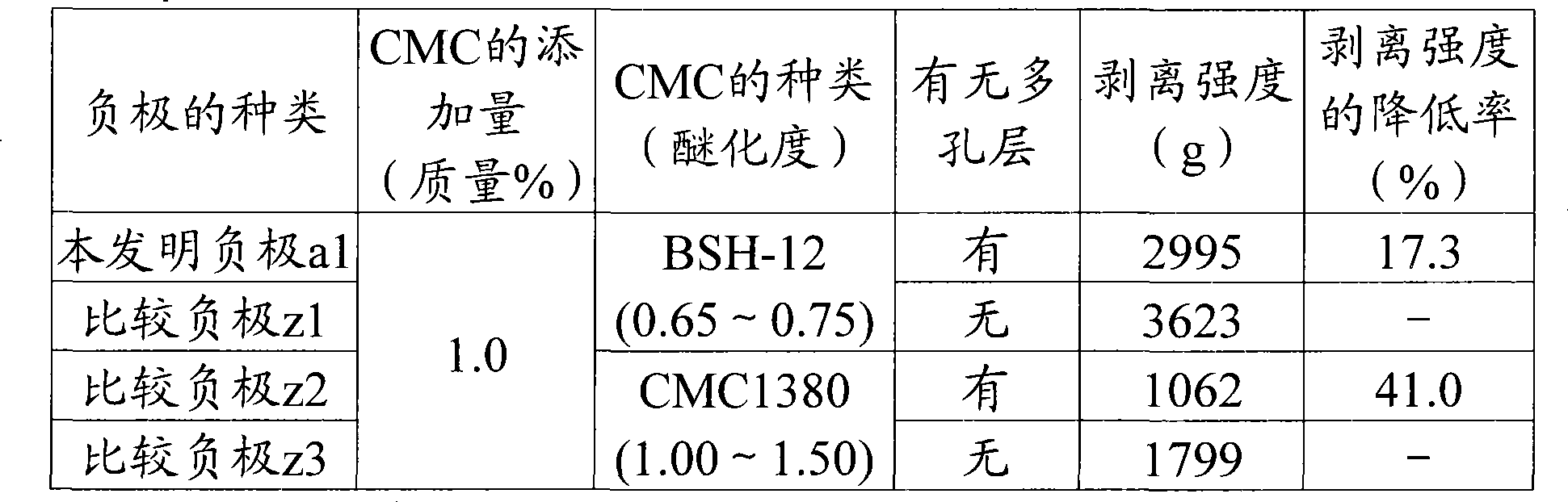

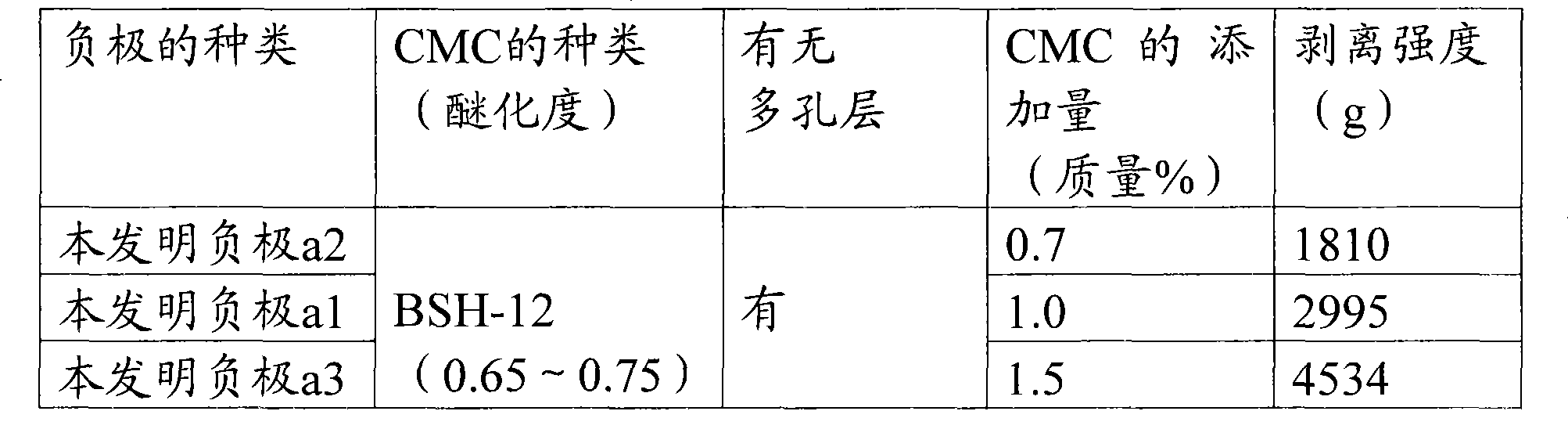

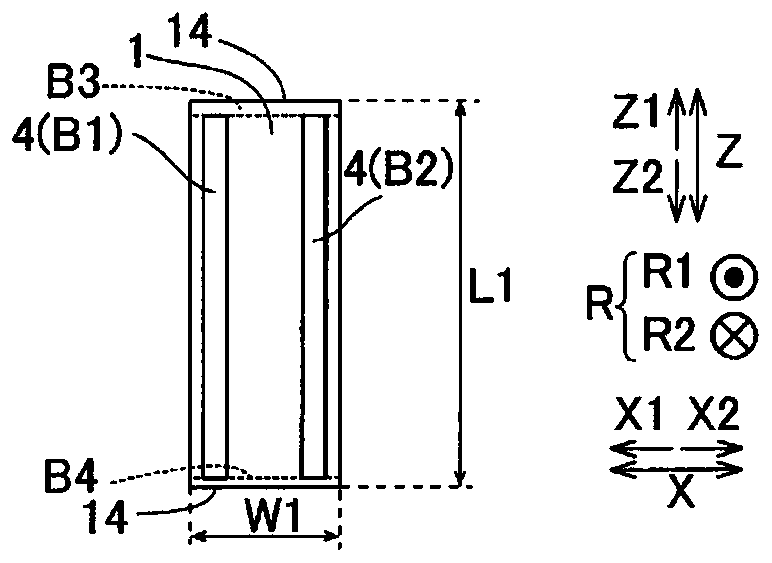

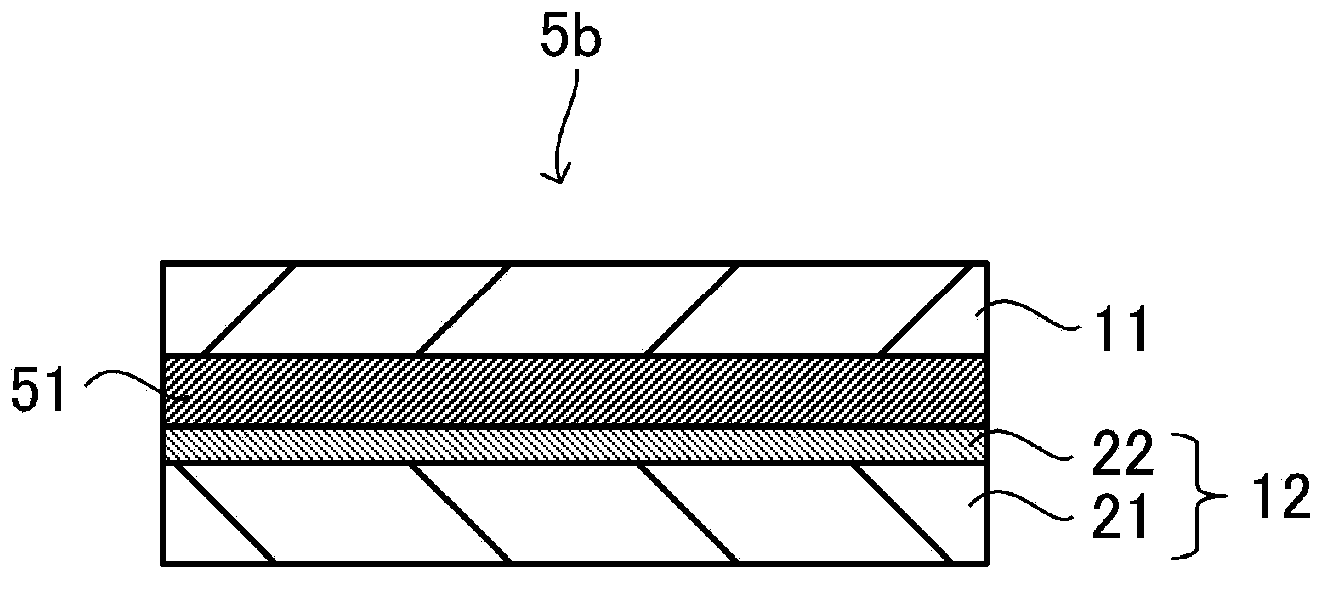

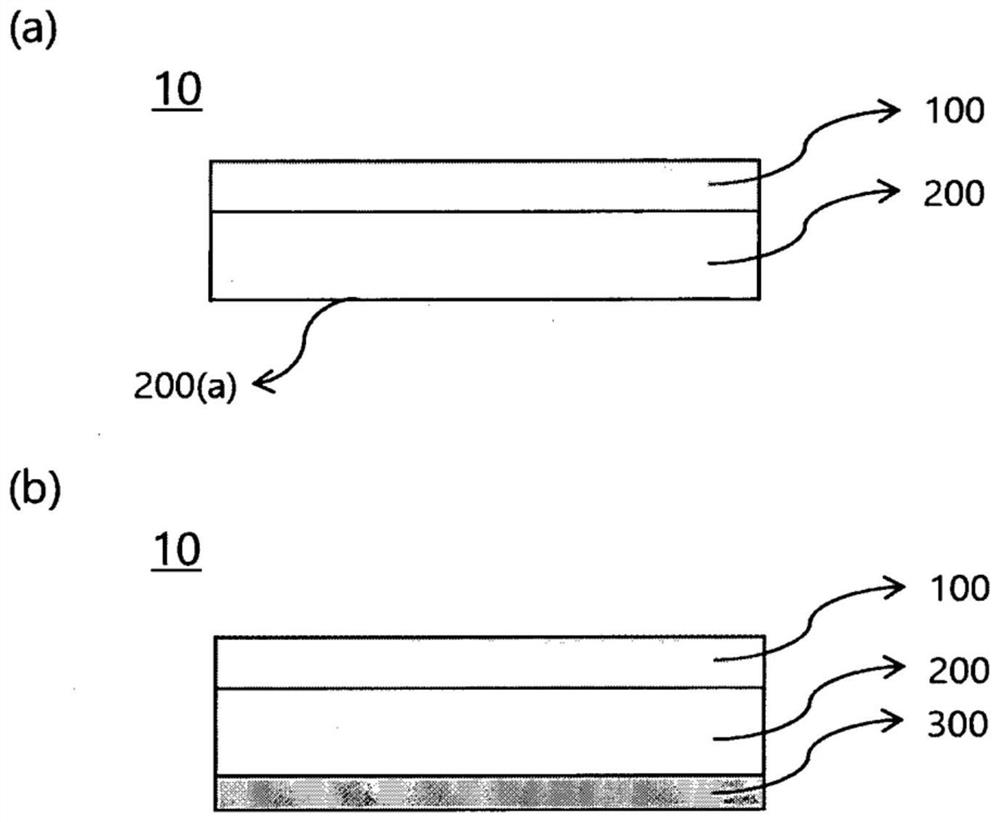

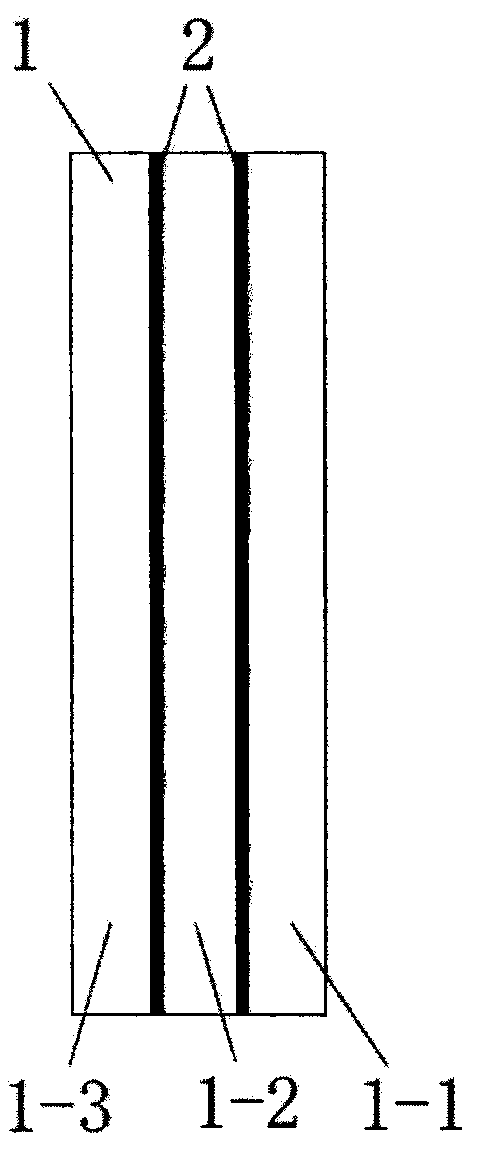

Non-aqueous electrolyte battery and negative electrode used therein

InactiveCN101364641AReduced bond strengthEnsuring electronic conductivityNegative electrodesLi-accumulatorsWater basedAdhesion strength

The invention provides a non-aqueous electrolyte battery and a negative electrode used in this battery in which the electron conductivity between the negative electrode active material and the negative electrode current collector is ensured by preventing the adhesion strength of the negative electrode current collector and the negative electrode active material from decreasing even if a porous layer is formed on the surface of the negative electrode. In a negative electrode for a non-aqueous electrolyte battery, in which a negative electrode active material layer (2) containing a negative electrode active material and a water-based binder for the negative electrode active material layer is formed on the surface of a negative electrode current collector (1), a porous layer (3) containing inorganic particles and a non-water based binder for the porous layer is formed on the surface of the negative electrode active material layer (2). The binder for the negative electrode active material layer contains carboxymethyl cellulose (CMC) whose degree of etherification is 0.5 or greater and 0.75 or less.

Owner:SANYO ELECTRIC CO LTD

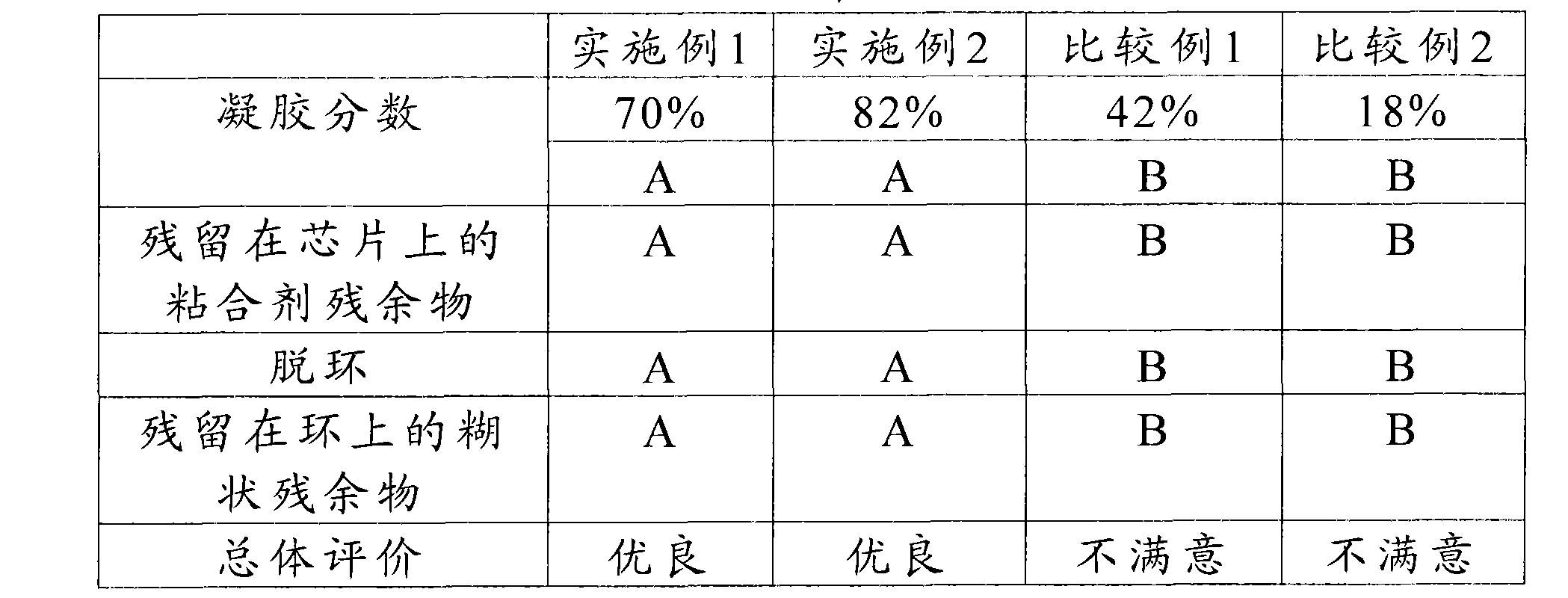

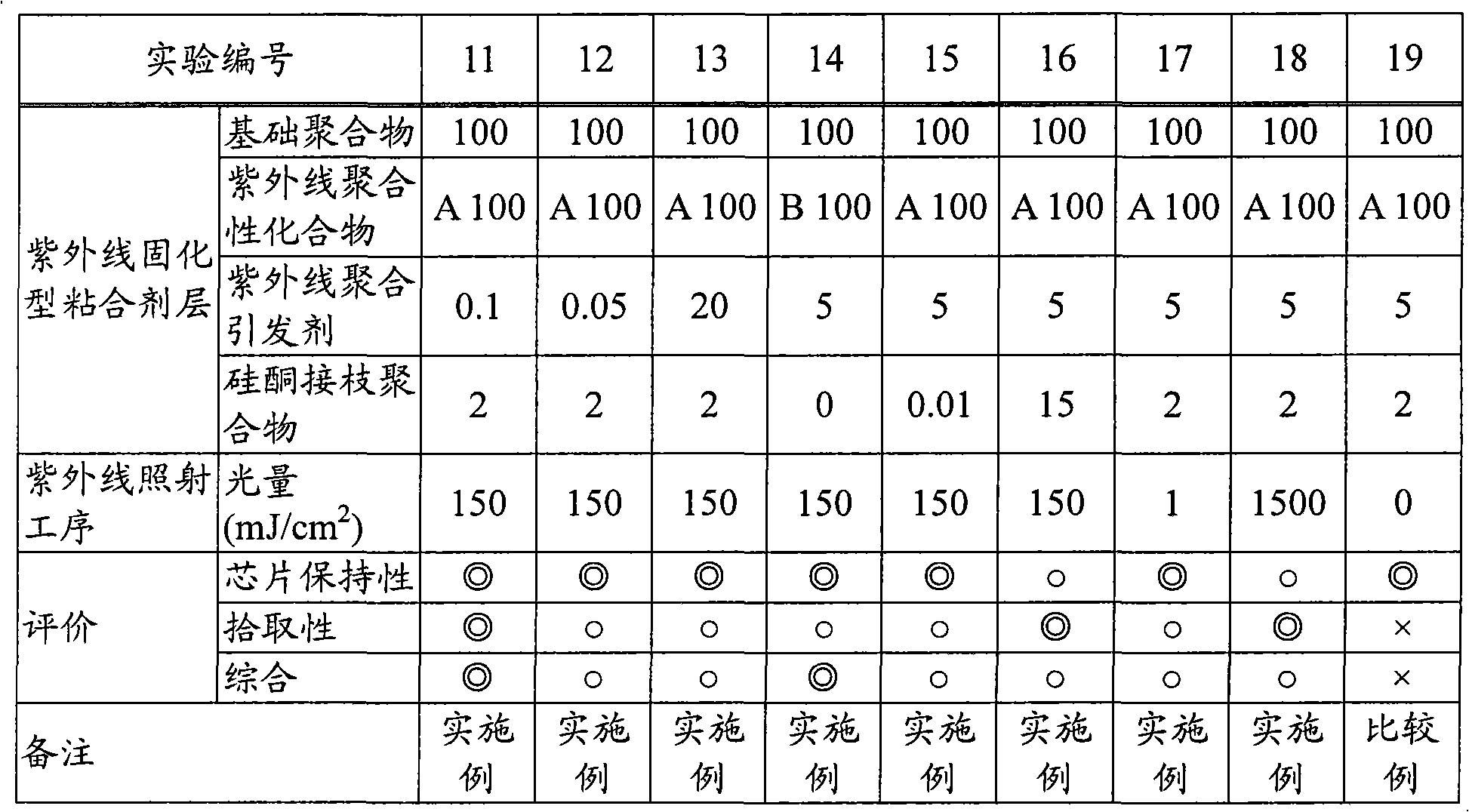

Pressure-sensitive adhesive sheet for dicing and dicing method

ActiveCN101381587AStrong cohesionEasy to peelSolid-state devicesSemiconductor/solid-state device manufacturingIrradiationPressure sensitive

The present invention relates to a pressure-sensitive adhesive sheet for dicing comprising a substrate layer and an active energy ray-curable pressure-sensitive adhesive layer provided on the substrate layer, in which the active energy ray-curable pressure-sensitive adhesive layer has a gel fraction before irradiation with an active energy ray of 50% or more. Furthermore, the invention also provides a method for dicing an adherend, which comprises attaching the pressure-sensitive adhesive sheet for dicing to an adherend, followed by cutting the adherend using a round blade. The pressure-sensitive adhesive sheet for dicing of the invention is free from leaving any adhesive residue on chips, from peeling of the pressure-sensitive adhesive sheet from the ring for fixing it, as well as from leaving any paste residue on the ring.

Owner:NITTO DENKO CORP

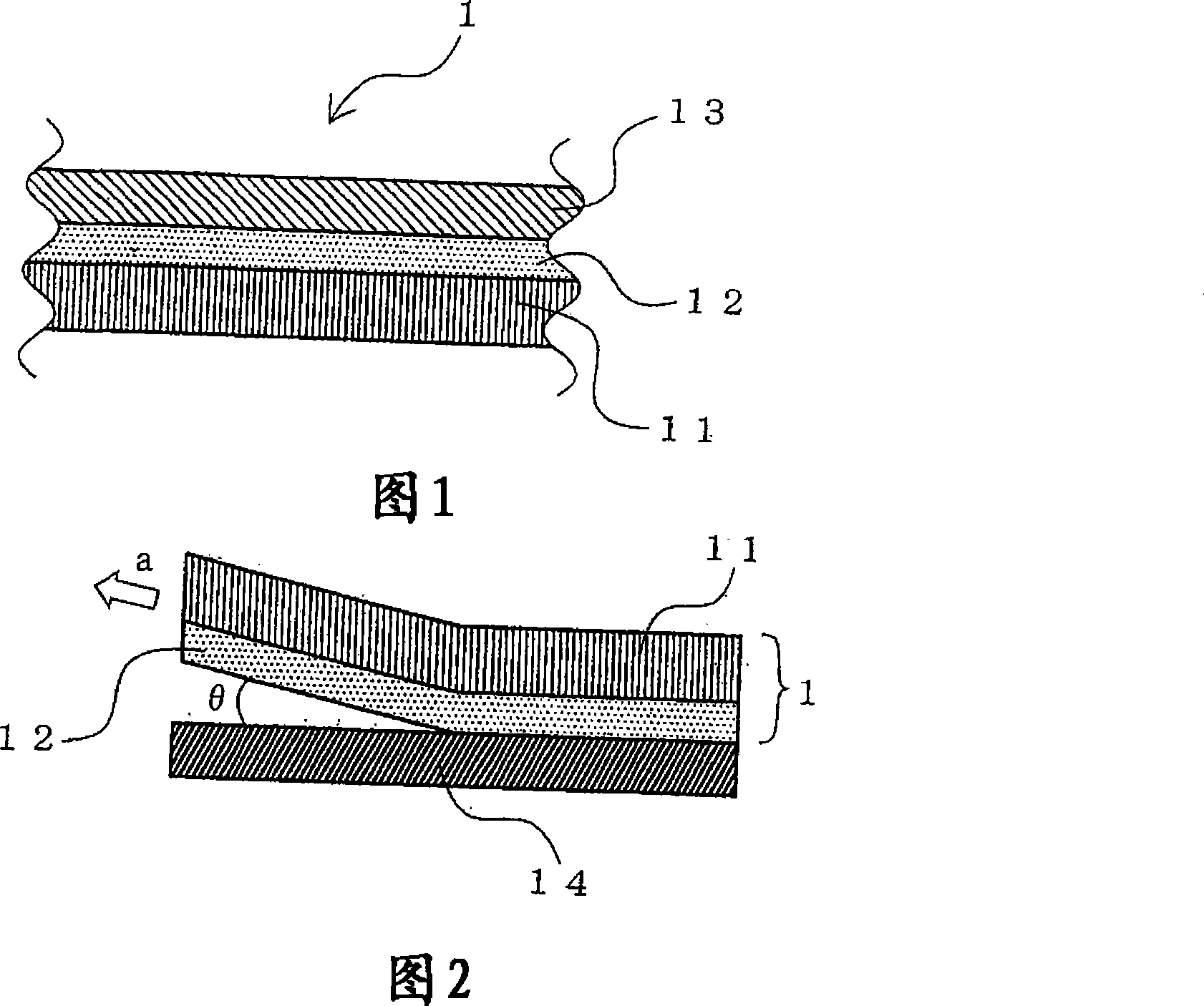

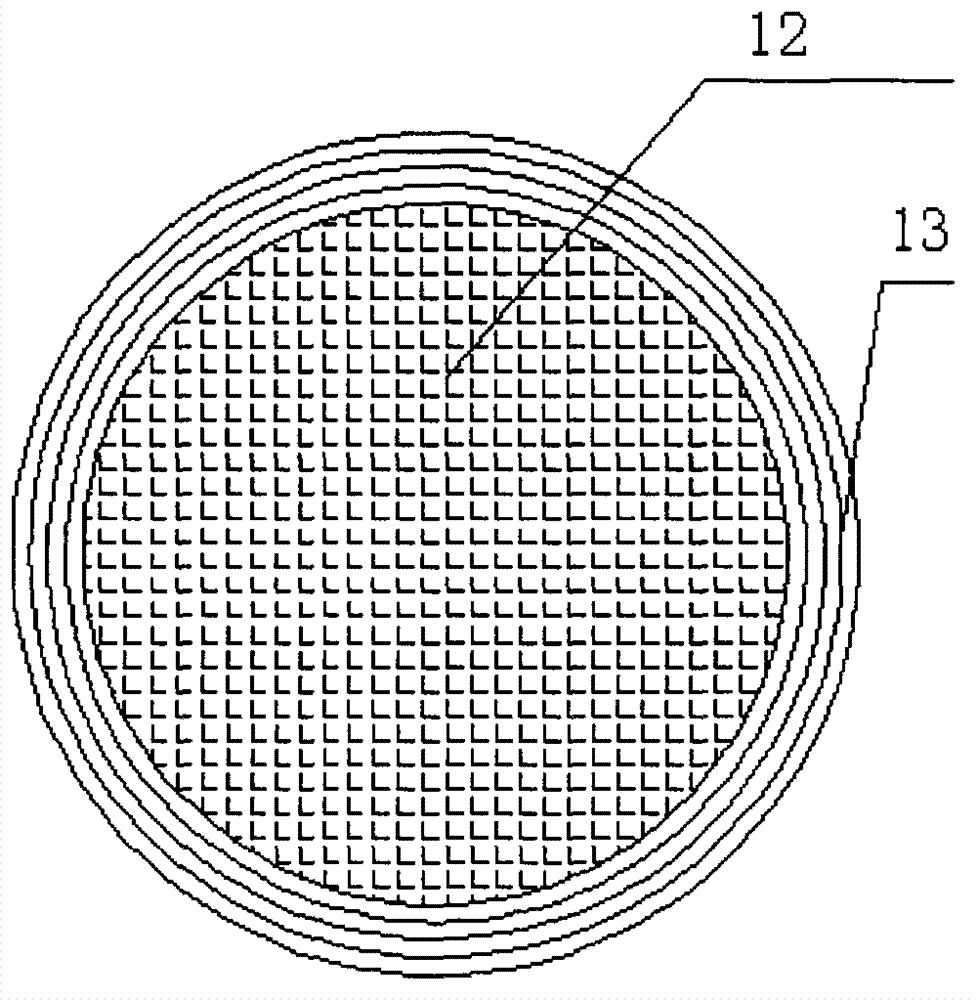

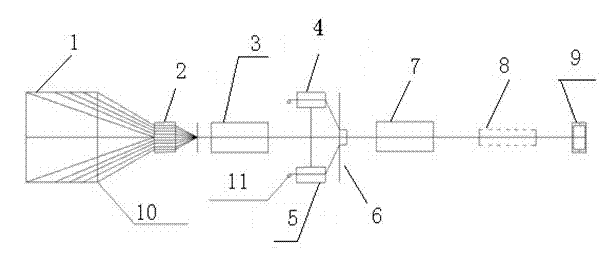

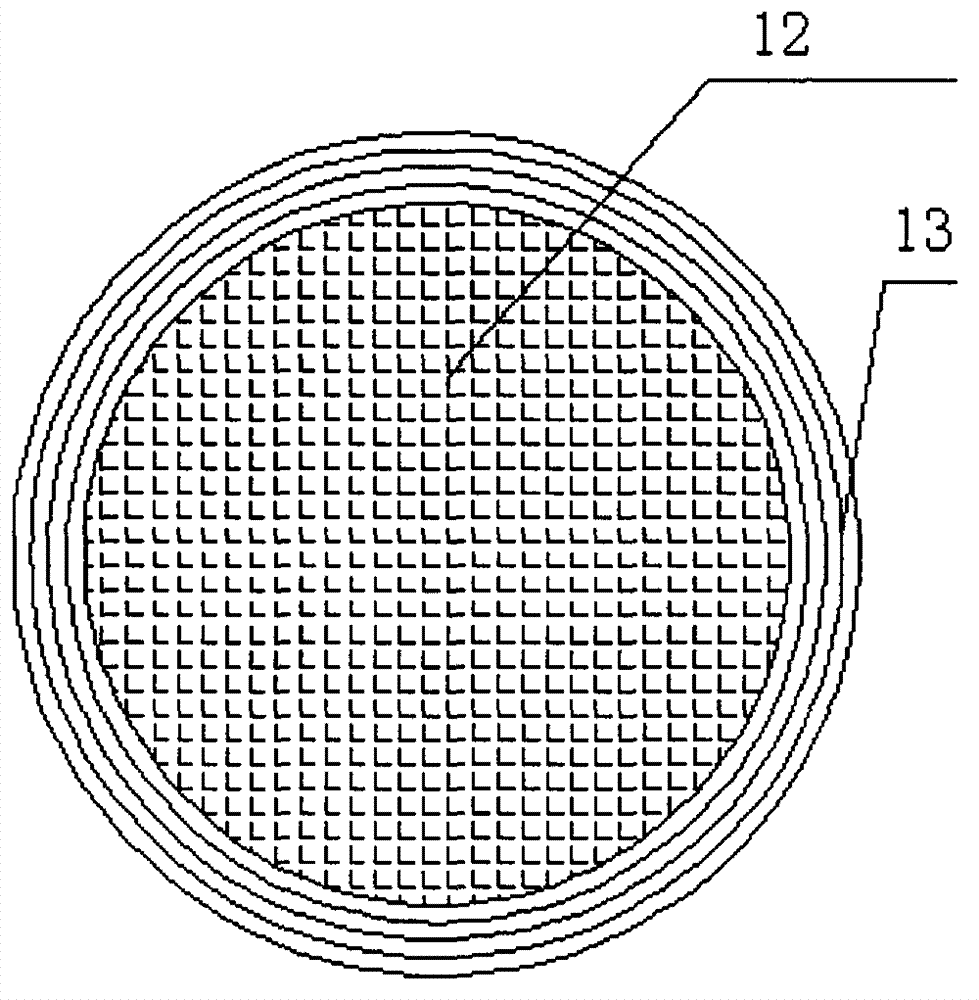

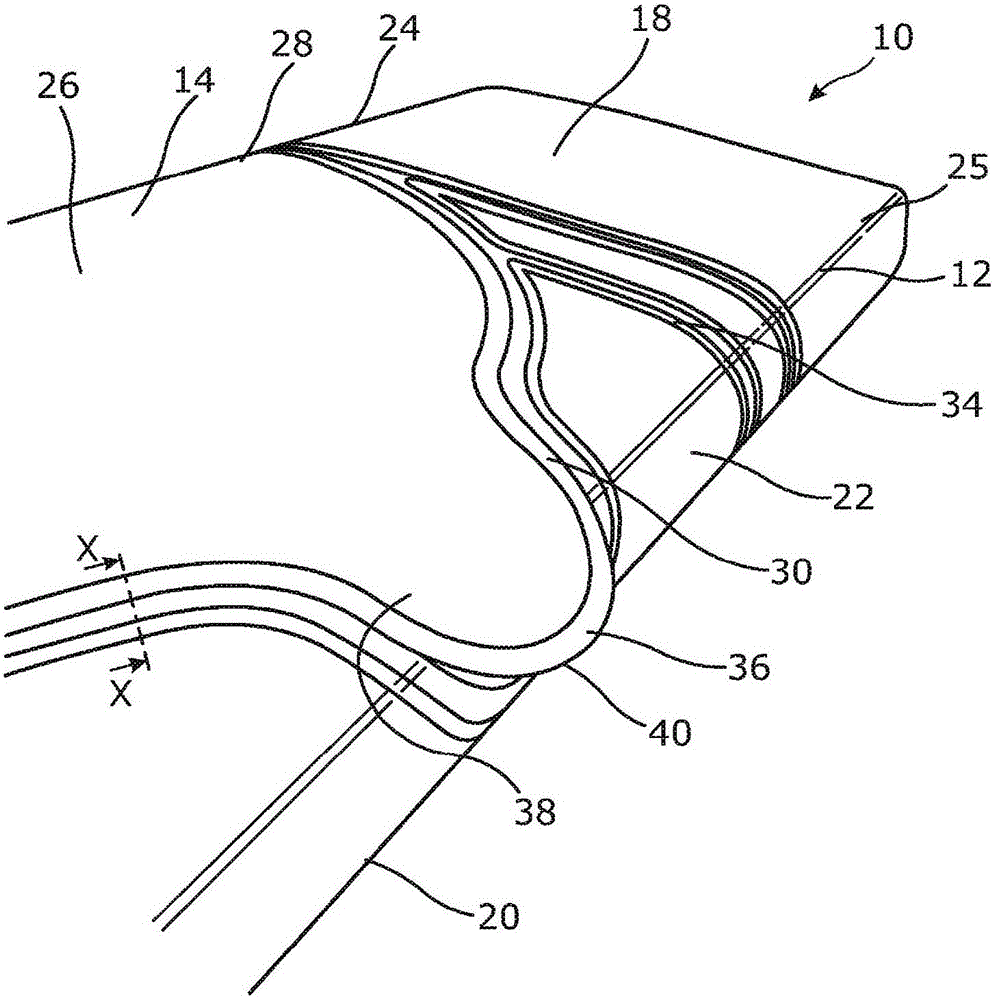

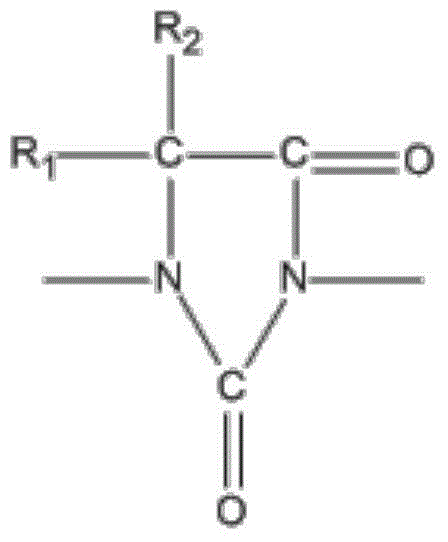

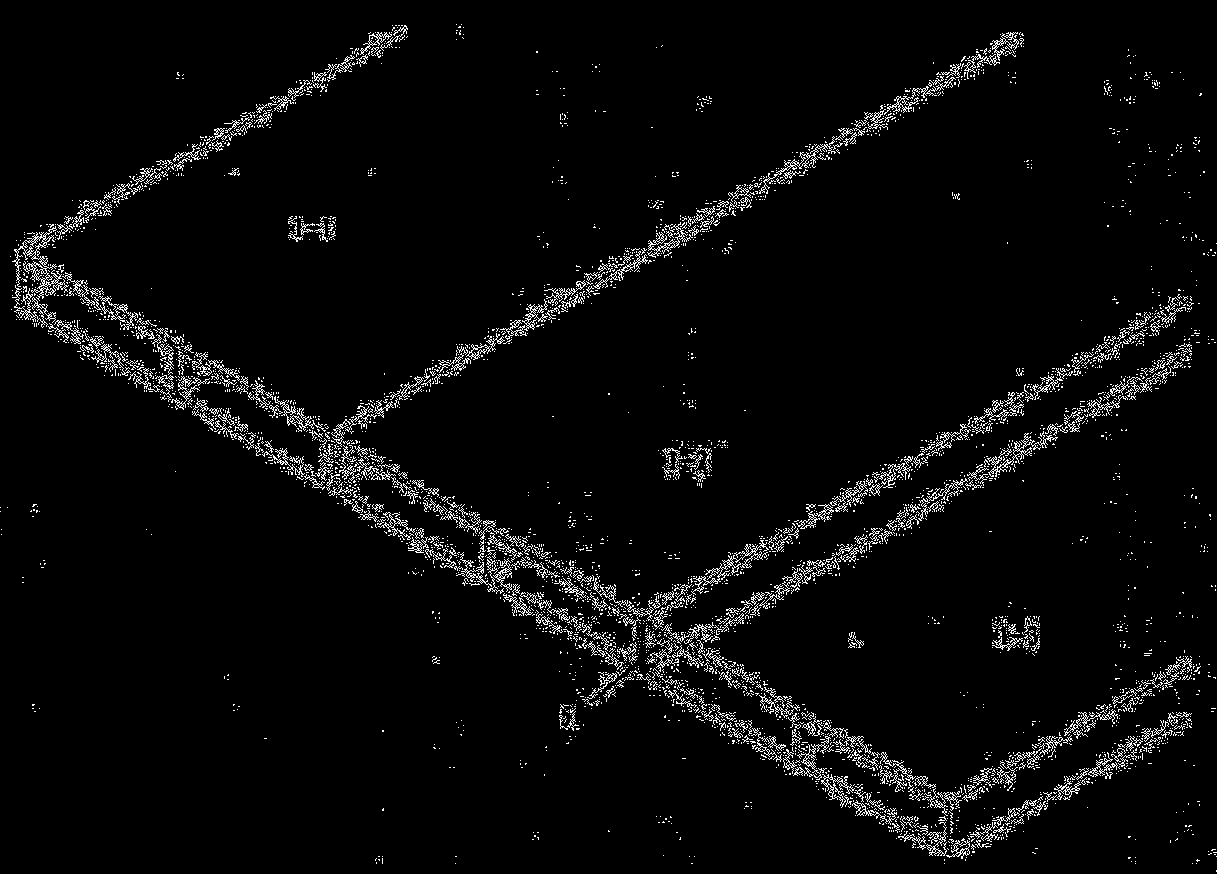

Carbon fiber composite material cable core

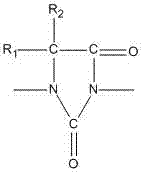

InactiveCN103310878ALow viscosity requirementImprove high temperature resistancePlastic/resin/waxes insulatorsInsulated cablesFiberEpoxy

The invention relates to a carbon fiber composite material cable core, which comprises a load bearing core (12) and a protection layer (13), wherein the protection layer (13) is covered outside the load bearing core (12) through a winding process, the load bearing core (12) is a high-temperature-resistance mechanical property epoxy resin and carbon fiber compound, and the protection layer (13) is a compound of high-temperature-resistance and weather-resistance epoxy resin compositions and glass fibers. The carbon fiber composite material cable core adopts the blending epoxy resin of the hydantoin epoxy resin and low-viscosity epoxy resin as resin substrates, the requirement of glass fibers on the low viscosity of the resin can be met, and the cable core can also have excellent high-temperature-resistance performance.

Owner:喻聪

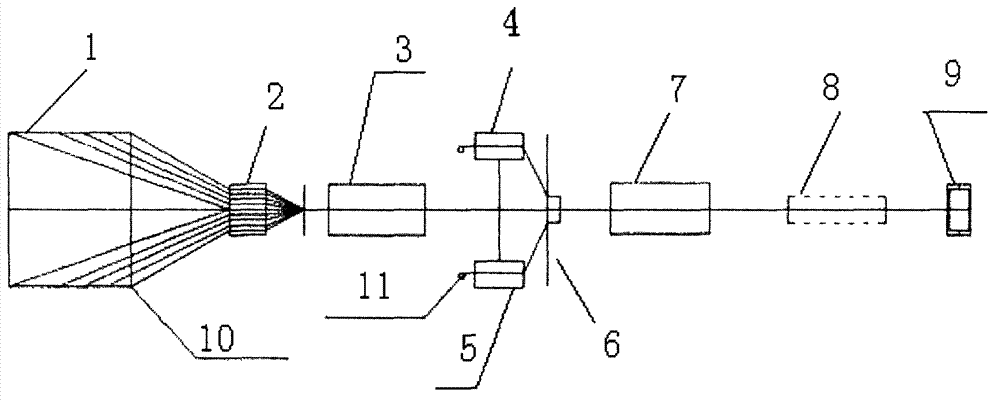

Manufacture method of cable core

InactiveCN103093897AImprove mechanical propertiesExtend working lifeCable/conductor manufactureGlass fiberEpoxy

The invention relates to a manufacture method of a cable core. The manufacture cost of the cable core comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is epoxy resin with heat-resisting high mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite core are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree reaches more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resistant and weather resistant; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through the second curing oven after being compounded, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:STATE GRID CORP OF CHINA +1

Waterproof paint for building material and preparation method thereof

InactiveCN107011772AStrong corrosion resistanceIncreased durabilityAntifouling/underwater paintsPaints with biocidesEpoxyEmulsion

The invention discloses a waterproof paint for a building material, belonging to the technical field of building materials. The waterproof paint comprises the following raw materials by weight: 50 to 60 parts of epoxy resin emulsion, 3 to 10 parts of polyacrylate, 1 to 5 parts of a dispersing agent, 40 to 45 parts of cement, 8 to 12 parts of talcum powder, 0.2 to 5 parts of a dehydrating agent, 0.5 to 2 parts of a silane coupling agent, 0.2 to 0.4 part of an antiseptic, 1 to 3 parts of a polycarboxylate water reducer, 5 to 10 parts of pigment, 0 to 2 parts of a pH value regulating agent, 3 to 6 parts of a plasticizer, 0 to 2 parts of an antifoaming agent and 0.8 to 1 part of a liquid aromatic. The invention also discloses a preparation method for the waterproof paint for the building material. The waterproof paint provided by the invention has good corrosion resistance, durability, impermeability, compactness and high adhesion stress; and the preparation method is simple and reliable.

Owner:合肥慧林建材有限公司

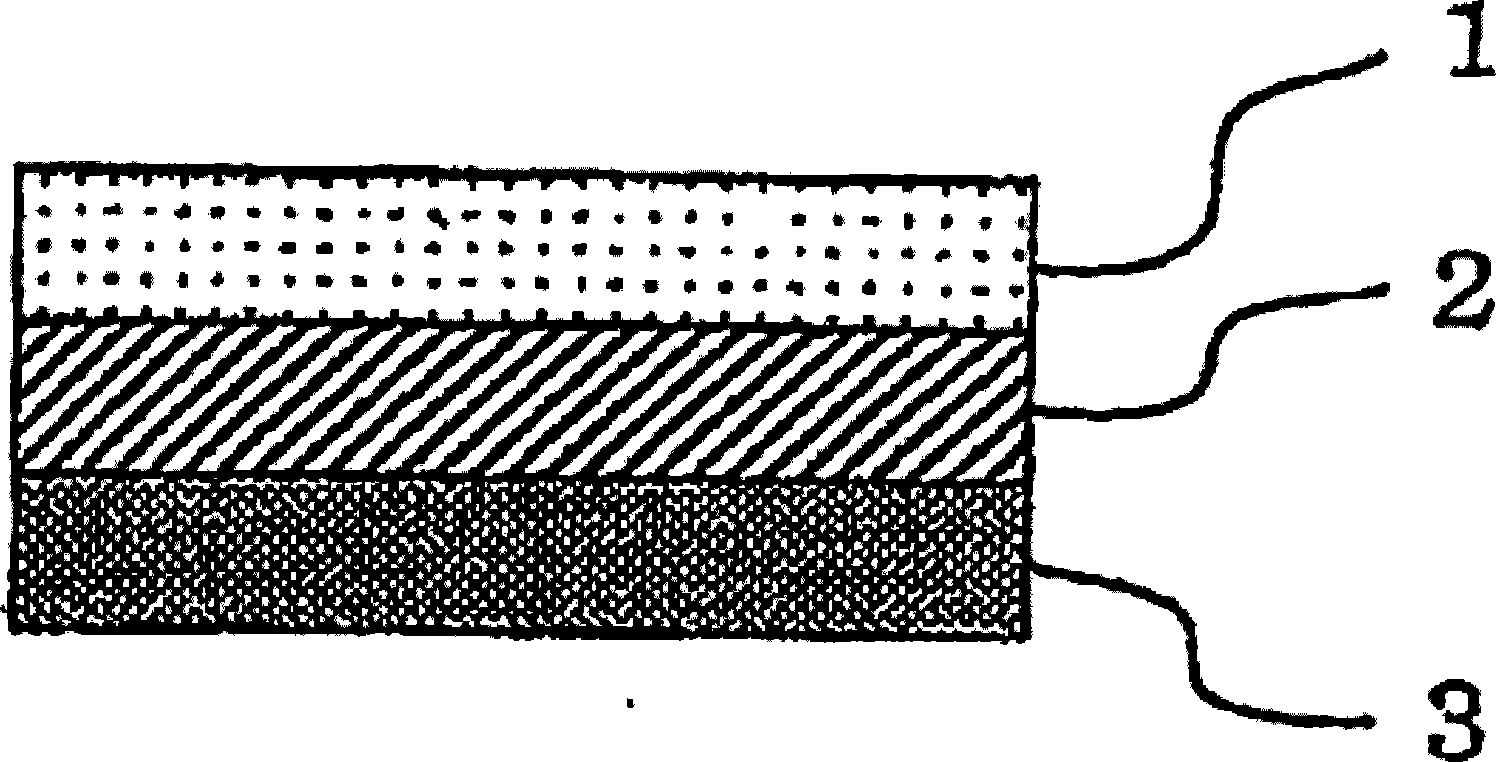

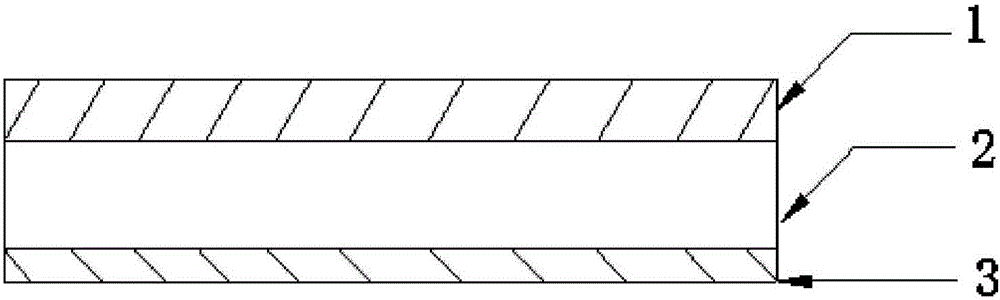

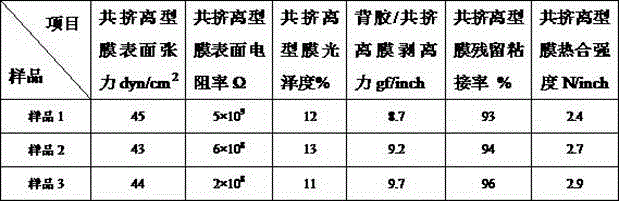

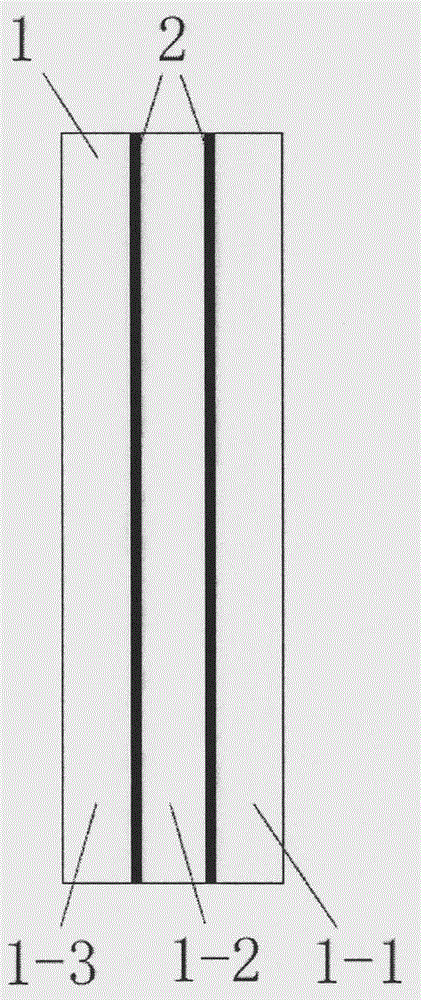

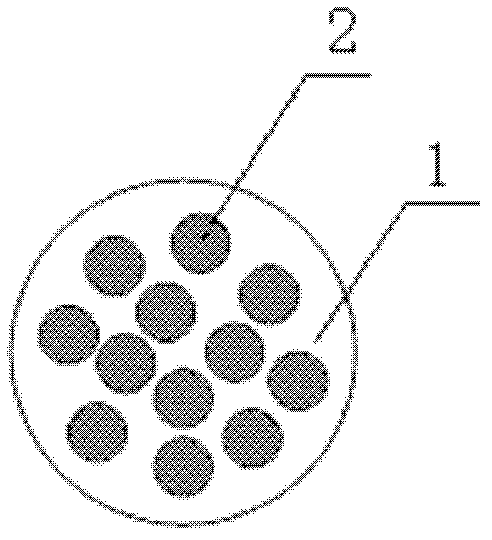

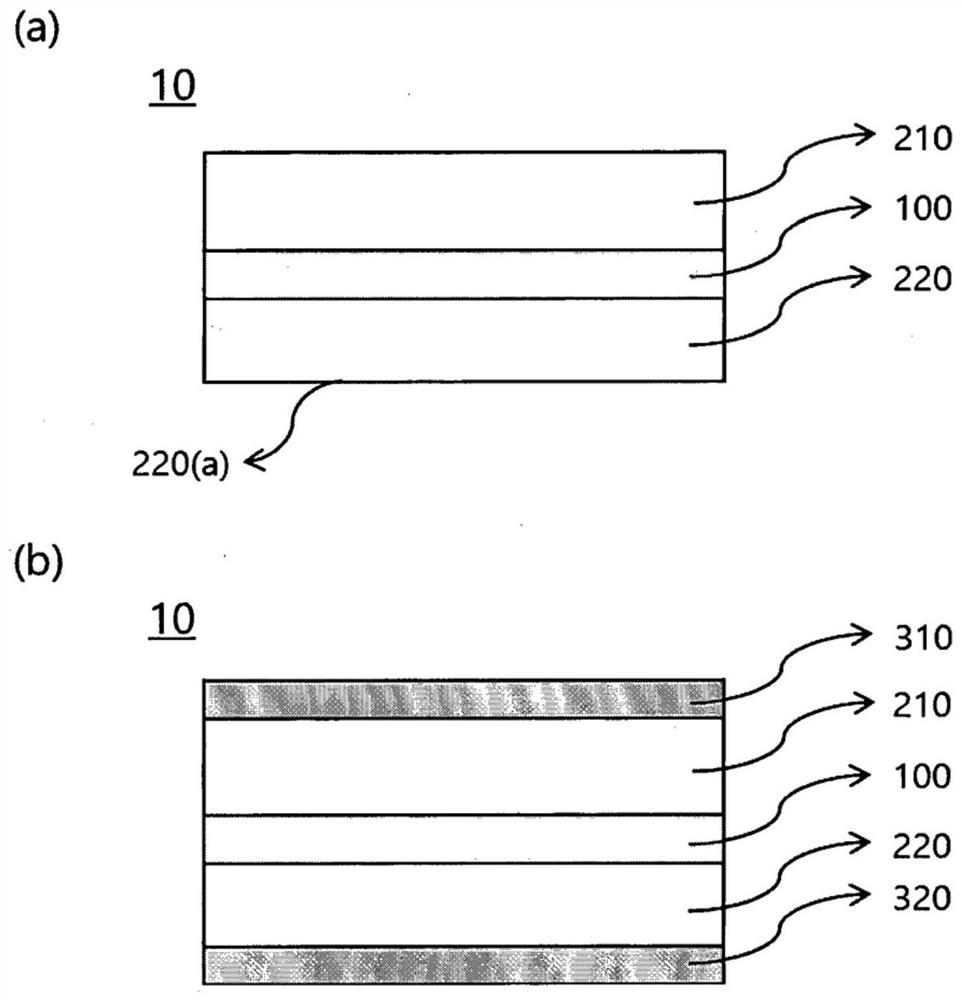

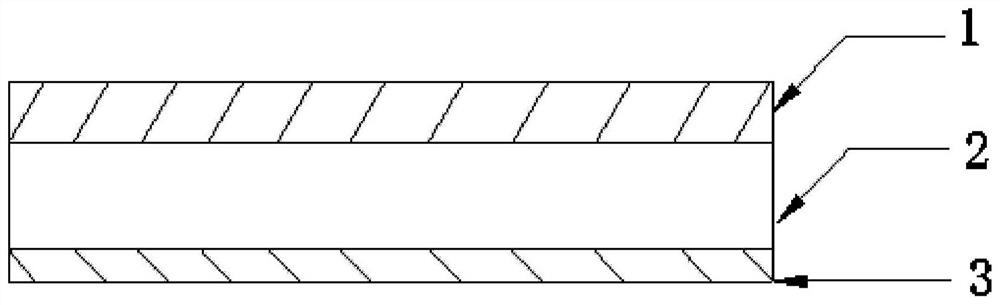

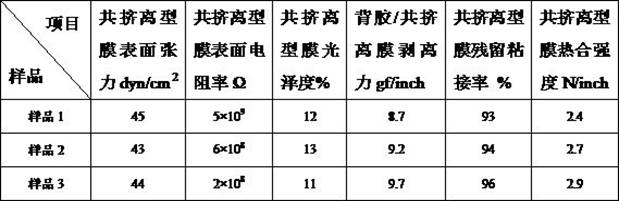

Disposable hygroscopic article

ActiveCN106832538AWith mattingAntistaticPersonal careSynthetic resin layered productsPolyolefinAdhesive

The invention discloses a disposable hygroscopic article, which comprises a liquid-permeable top layer, an absorption core body, a liquid-impermeable bottom layer and a multi-layer coextruded composite release film from top to bottom, wherein the multi-layer coextruded composite release film comprises a surface layer (1), a core layer (2) and a release layer (3). The disposable hygroscopic article is characterized in that the surface layer (1) is prepared from matting resin and polyolefin resin A; the core layer (2) is prepared from a filling material, polyolefin resin B and a thermoplastic elastomer; the release layer (3) is prepared from alpha-olefin polymer resin produced by metallocene, C4 to C14 polyolefin resin produced by a Z-N catalyst and fluorosilicon resin. The surface layer (1) of the multi-layer coextruded composite release film has the surface wetting tension not less than 38dyn / cm<2>, the surface electrical resistivity not less than 10<10>omega and the glossiness less than 15 percent; the release layer has the stripping force of 8.0gf / inch to 18gf / inch, the release residual adhesion rate not less than 90 percent and the heat bonding strength not less than 1.5N / inch. Compared with the prior art, the multi-layer coextruded composite release film has matting, antistatic and release anti-adhesion effects; further, the viscosity loss or the adhesive transfer of a back adhesive of a hygienic article can be effectively prevented.

Owner:FUJIAN HENGAN HLDG CO LTD +2

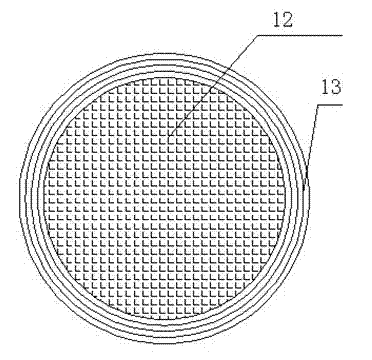

Manufacturing method of carbon fiber composite material cable wire

ActiveCN103310908ALow viscosity requirementImprove high temperature resistanceCable/conductor manufactureEpoxyFiber

The invention relates to a manufacturing method of a carbon fiber composite material cable wire. The carbon fiber composite material cable wire comprises a load bearing core (12) and a protection layer (13), wherein the protection layer (13) is covered outside the load bearing core (12) through a winding process, the load bearing core (12) is a high-temperature-resistance mechanical property epoxy resin and carbon fiber compound, and the protection layer (13) is a compound of high-temperature-resistance and weather-resistance epoxy resin compositions and glass fibers. The carbon fiber composite material cable wire adopts the blending epoxy resin of the hydantoin epoxy resin and low-viscosity epoxy resin as resin substrates, the requirement of glass fiber on the low viscosity of the resin can be met, and the cable core can also have excellent high-temperature-resistance performance.

Owner:HOHHOT HALLYUEN CARBON FIBER

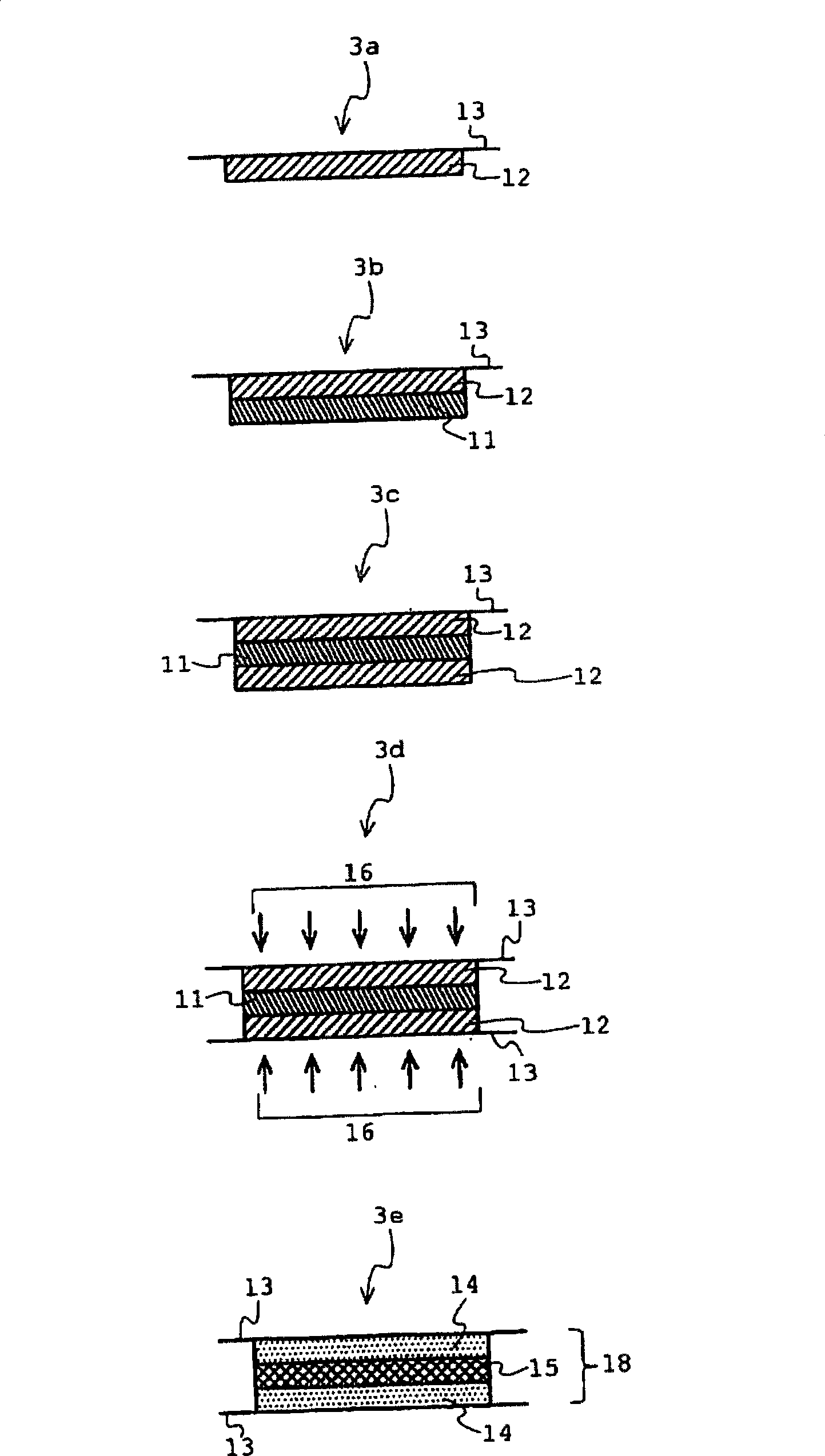

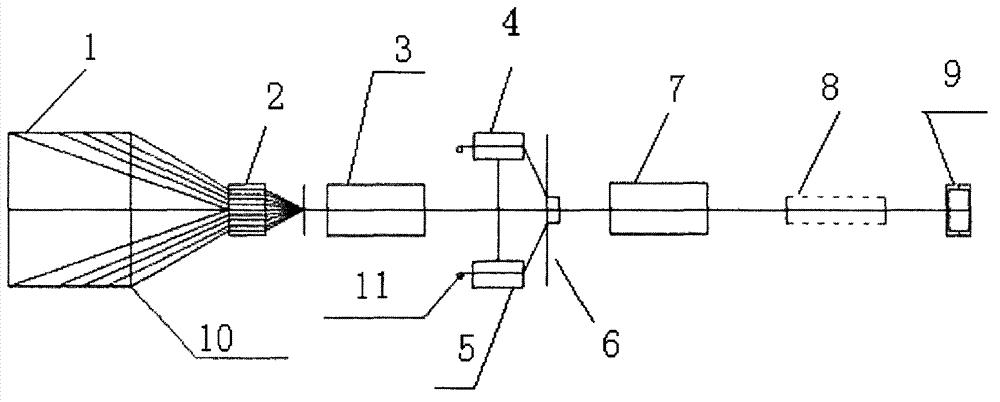

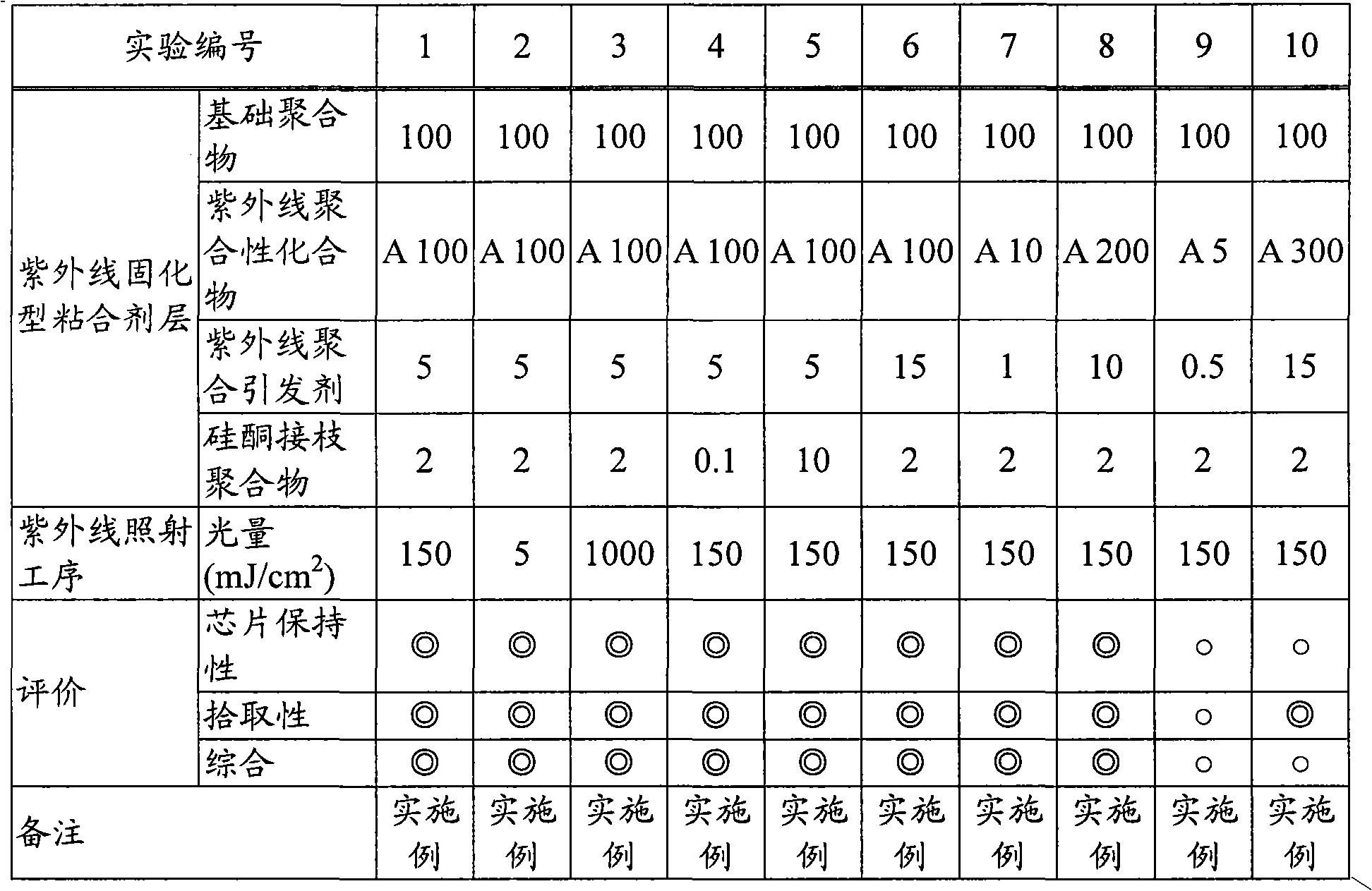

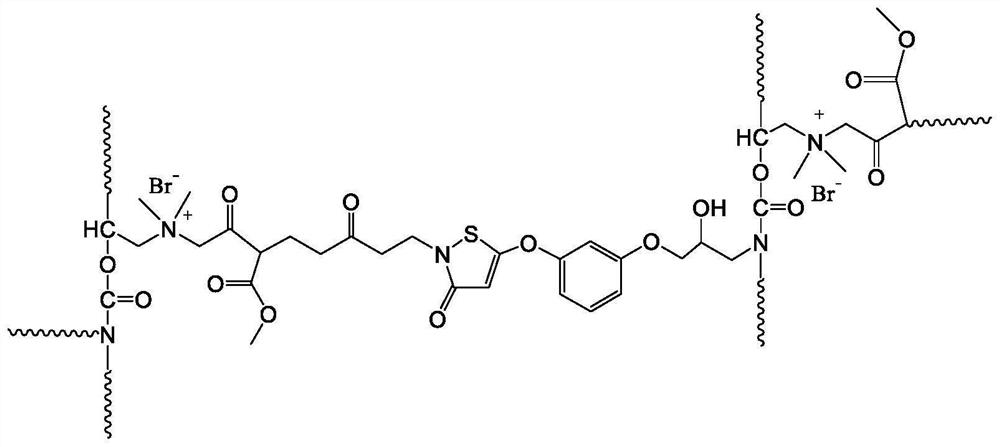

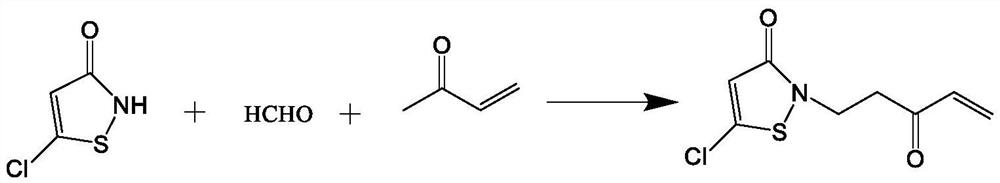

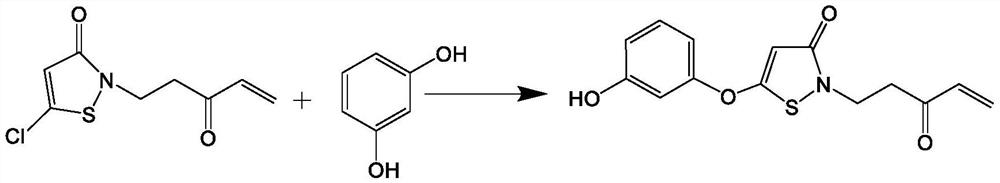

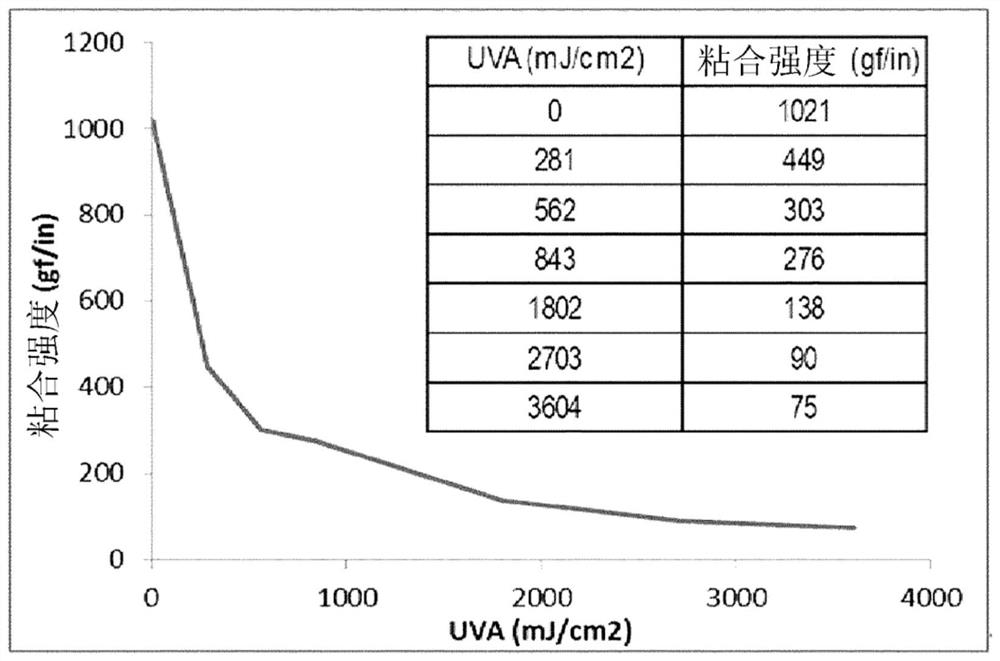

Dicing method

ActiveCN102047393AReduced bond strengthImprove cohesionNon-macromolecular adhesive additivesFilm/foil adhesivesUV curingUltraviolet lights

With the invented dicing method, by increasing the cohesive strength while decreasing the adhesive strength of an ultraviolet-curing adhesive in advance, mixing of the ultraviolet-curing adhesive layer of an adhesive sheet with a die attach film on a dicing line can be decreased and pickup failures can be reduced, when picking up chips having a die attach film after dicing. The dicing method for a semiconductor wafer with a die-attach film comprises a first gluing step in which a die attach film is affixed to an adhesive sheet having an ultraviolet-curing adhesive laminated on a base materialfilm, a second gluing step in which a semiconductor wafer is affixed to the opposite side of the die attach film affixed to the adhesive sheet, an ultraviolet irradiation step in which the ultraviolet-curing adhesive is irradiated with ultraviolet light, and a dicing step in which the semiconductor wafer and the die attach film affixed to the adhesive sheet are diced.

Owner:DENKA CO LTD

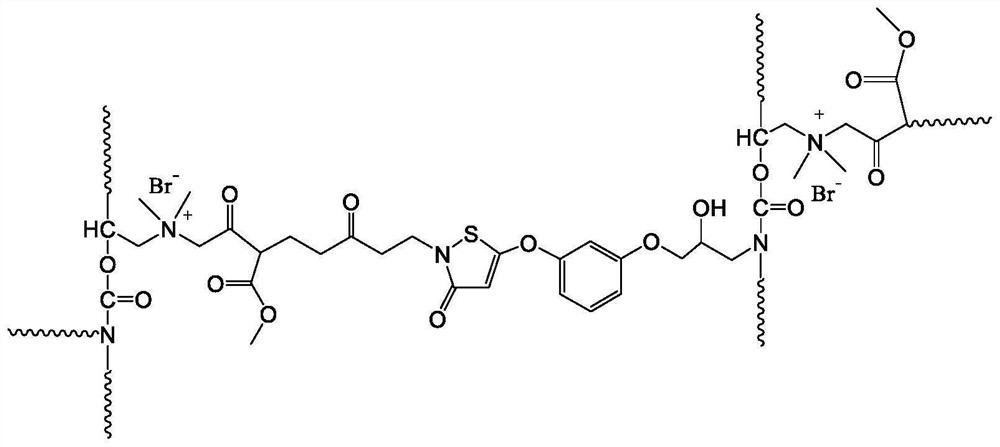

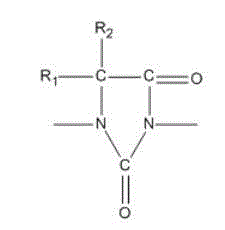

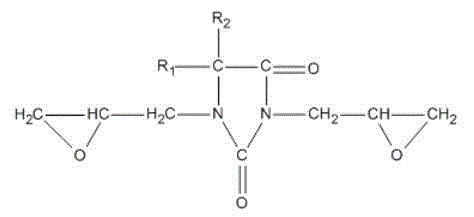

Preparation method of high-temperature-resistant and high-humidity-resistant polyurethane adhesive

ActiveCN112143436AHigh activityAttached tightlyBiocidePolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a preparation method of a high-temperature-resistant and high-humidity-resistant polyurethane adhesive, which comprises the following steps: weighing a certain amount of antimicrobial crosslinking agent, assistant antimicrobial polymer and ethanol solution, simultaneously adding the substances into a reaction kettle, stirring to dissolve, heating to react for 2 hours, then,adding triethylamine, and carrying out reacting, cooling, and discharging; removing the solvent, adding the solid substance into ethanol, and stirring to prepare polyurethane adhesive mucilage; one end of the prepared antibacterial cross-linking agent is connected with one side of carbonyl of ester groups in -NH-COO- in the auxiliary antioxidant polymer, and the other end of the antibacterial cross-linking agent is connected with one end of hydroxyl of the ester groups, so that when the adhesive is hydrolyzed in high-temperature water, polymer chains are still connected through the antibacterial cross-linking agent and can still be tightly compounded on the surface of a test piece; and the bonding strength is not reduced due to hydrolysis.

Owner:佛山市龙源镭射科技有限公司

Aluminum alloy cavity board for furniture and manufacturing method thereof

ActiveCN105332981ASplicing and forming speed is fastIncrease flexibilityMaterial gluingAlloyLarge size

Disclosed is a manufacturing method of an aluminum alloy cavity board for furniture. Two or more aluminum alloy cavity veneers are bonded and spliced in a side surface parallel mode, and the side surfaces of the aluminum alloy cavity veneers are bonded and spliced in parallel. The aluminum alloy cavity board for the furniture is manufactured through the manufacturing method of the aluminum alloy cavity board for the furniture. Compared with an existing large-size profile extrusion technology and an existing welded profile, the bonded aluminum alloy cavity board is high in splicing and forming speed, high in flexibility, small in flatness tolerance and small in weight, the demands of different application fields can be met, the operation is convenient and fast, and therefore the purposes of saving raw materials and reducing product manufacturing cost are achieved.

Owner:宋丽萍

Protective film having variable adhesive force for foldable display and foldable display device including same

PendingCN113966373AEfficient removalWrong damageSynthetic resin layered productsEster polymer adhesivesDisplay deviceEngineering

The present disclosure provides a foldable display protective film having variable adhesive strength and a foldable display device including the same.

Owner:LG CHEM LTD

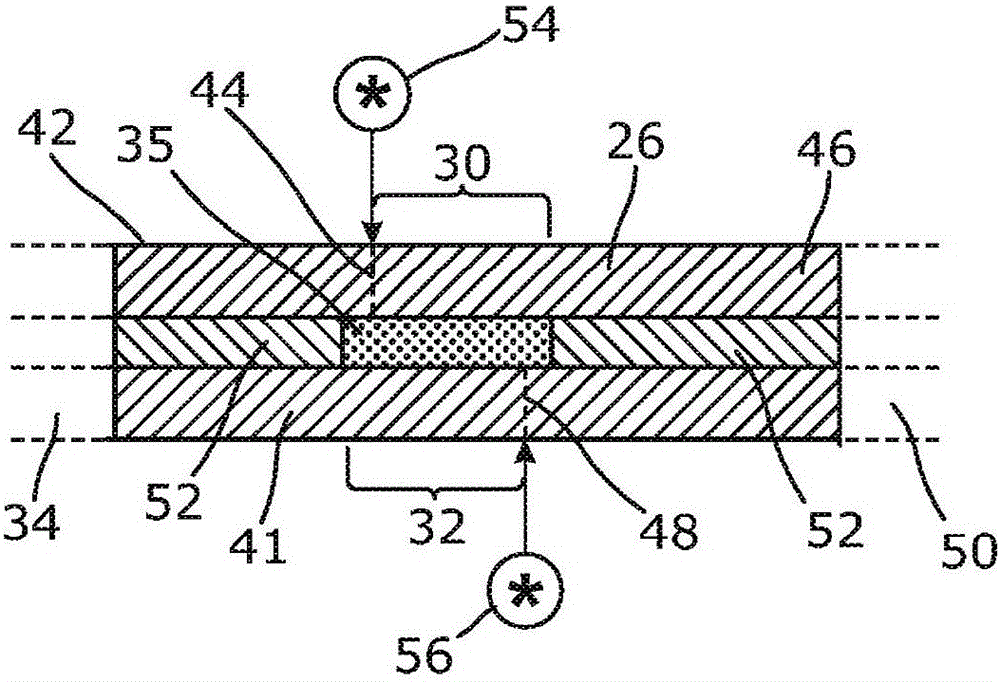

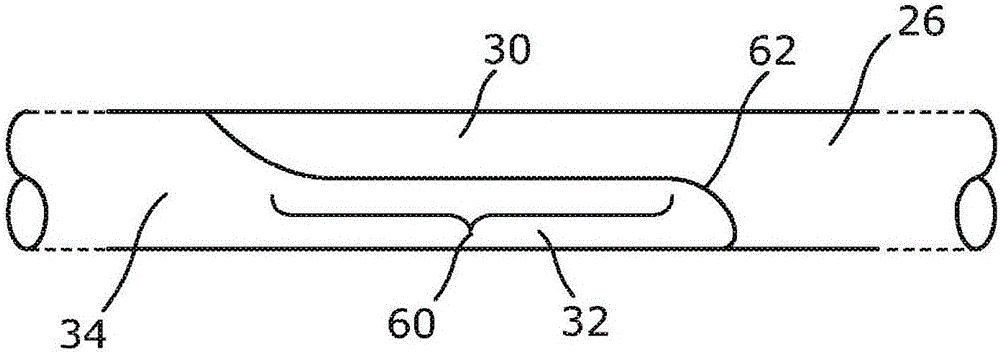

Packaging with easy opening feature

The invention discloses a packaging assembly (10). The packaging assembly (10) comprises a flow-wrapped package (12) containing a product. The wrapper (14) has an opening feature such as a flap (26) or tear strip comprising a portion of the wrapper material that can be preferentially folded outwardly to produce an opening. A tab (36) is attached to the opening feature that can be manually grasped to initiate opening. The tab protrudes from the surface of the wrapper material. The package may have at least two faces, the tab being located at an intersection between two faces (18, 22). The tab (36) may be partially bonded to an underlying portion of the wrapper, the bond strength reducing in a direction from a base of the tab proximal to the opening feature towards a tip portion distal from the opening feature.

Owner:MONDELEZ UK R&D

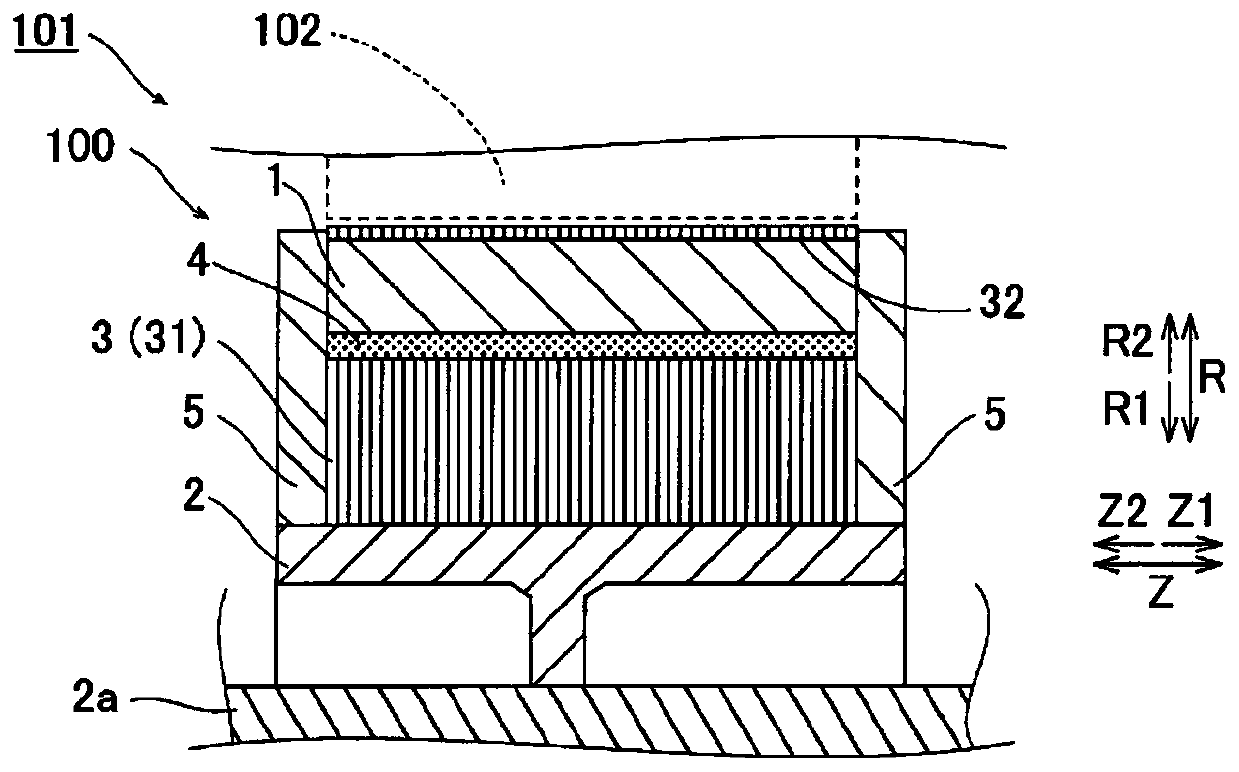

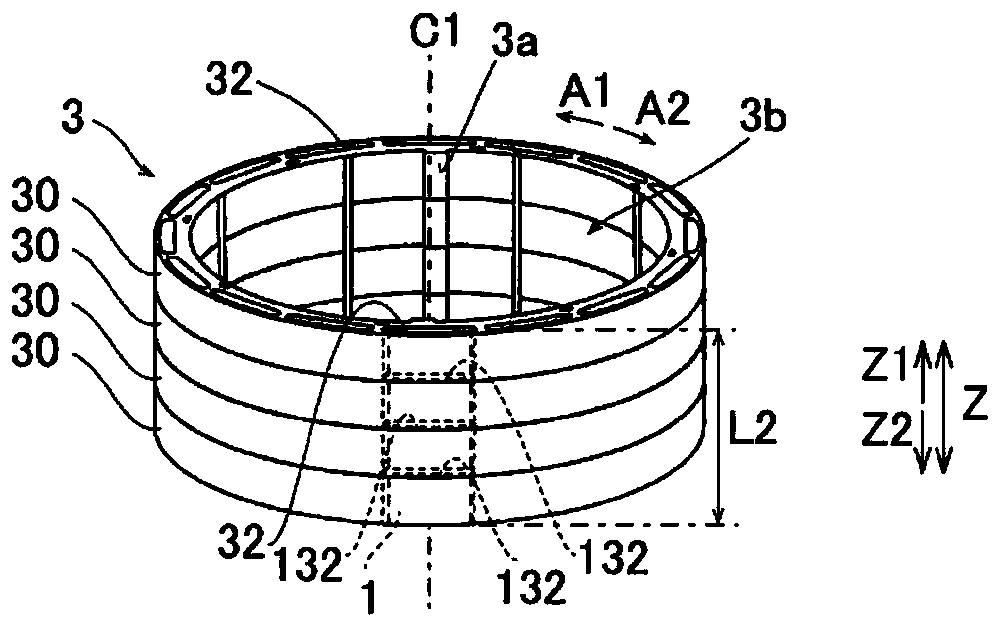

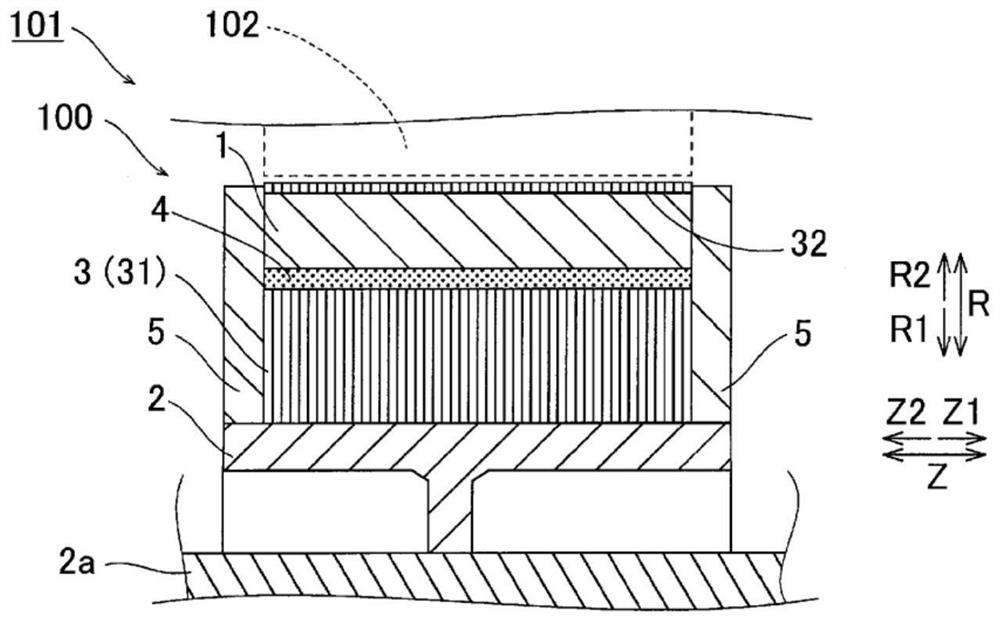

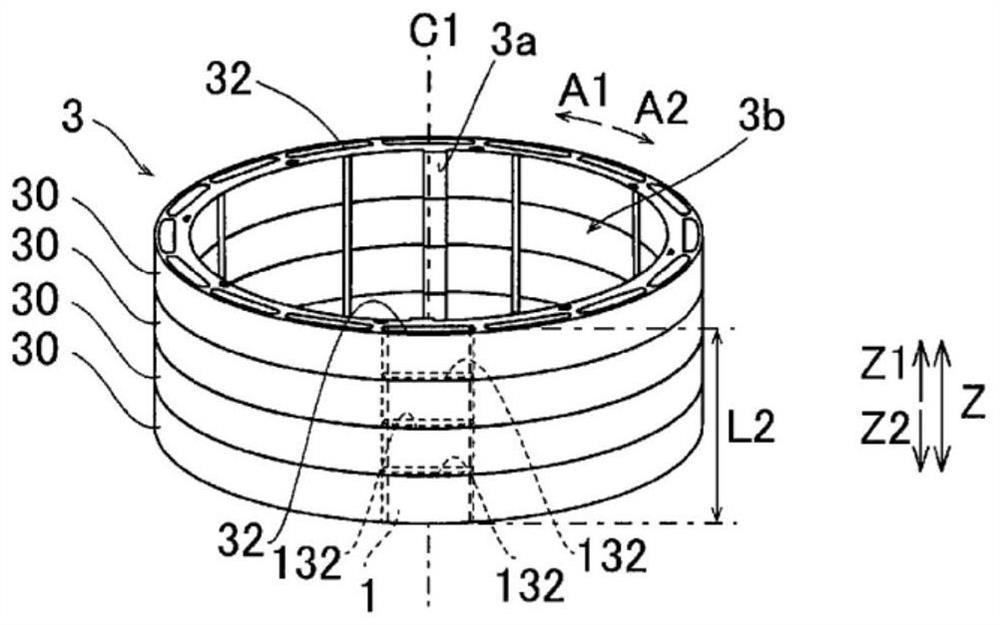

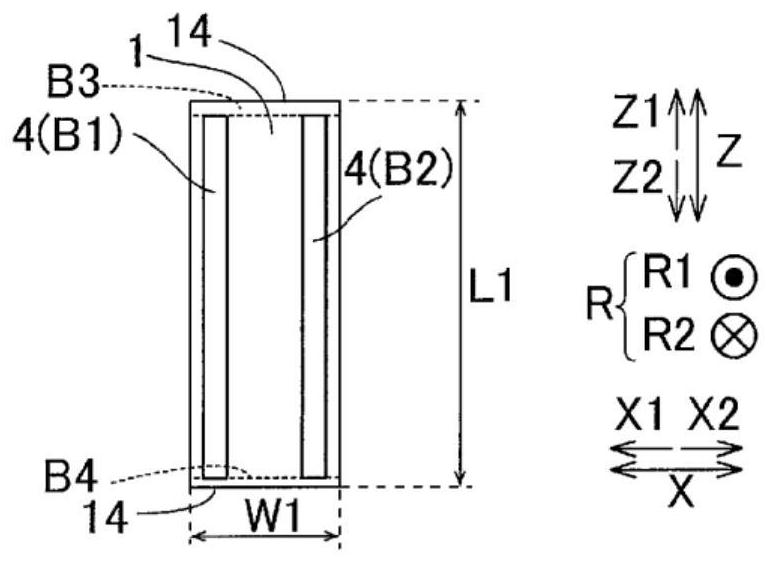

Rotor manufacturing method and rotor manufacturing device

ActiveCN110771010AInhibition of excessive inflationShorten heating timeMagnetic circuit rotating partsManufacturing stator/rotor bodiesAdhesiveEngineering

A rotor manufacturing method is provided with a step of evaporating a diluting solvent by: heating an adhesive to a temperature in a temperature band of not lower than a vaporization start temperatureat which the diluting solvent evaporates and lower than an expansion onset temperature; and increasing the temperature of the adhesive at a temperature increase rate lower than a temperature increaserate at which the heating is performed from a heating start temperature to the temperature in the temperature band not lower than the vaporization start temperature and lower than the expansion onsettemperature.

Owner:AISIN AW CO LTD

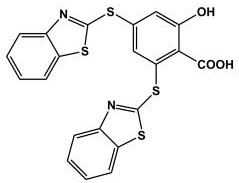

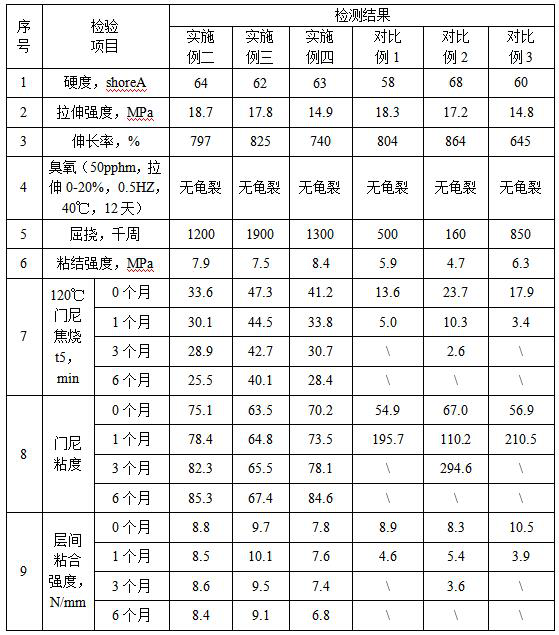

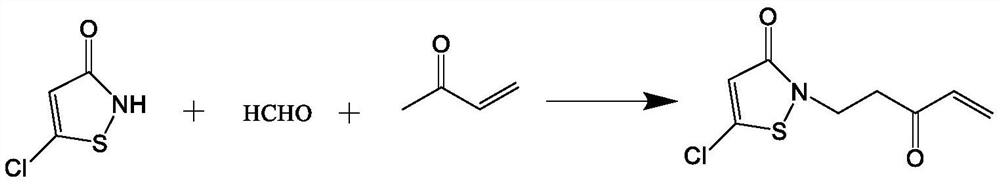

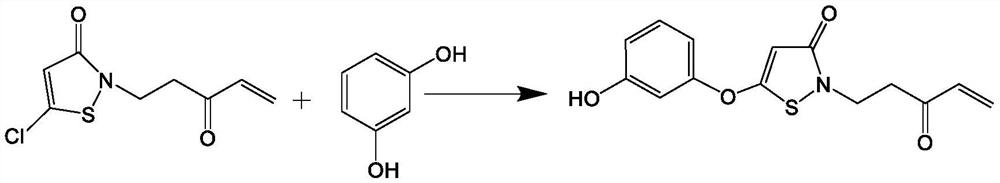

Anti-scorching CR unvulcanized rubber capable of being stored for long time at room temperature, preparation method thereof and preparation method of anti-scorching agent

ActiveCN113929991AExcellent scorch safetyGood storage stabilityOrganic chemistryRolling resistance optimizationRubber materialPolymer science

The invention relates to anti-scorching CR unvulcanized rubber capable of being stored for a long time at room temperature, a preparation method thereof and a preparation method of an anti-scorching agent. The materials comprise raw rubber, a reinforcing filler, a plasticizer, a vulcanization accelerator, a coupling agent, an anti-aging agent, the anti-scorching agent, an active agent and a processing aid. The preparation method of the unvulcanized rubber comprises the steps of firstly, preparing the materials into a prefabricated rubber sheet; then adding the prefabricated rubber sheet into an internal mixer or an open mill, adding the active agent, the reinforcing filler, the plasticizer, the coupling agent, the anti-scorching agent, other processing aids and the like, mixing at low temperature, and discharging rubber to prepare a first section of rubber compound; and finally, standing and cooling the first section of rubber compound, adding the vulcanization accelerator and the anti-aging agent into an open mill for mixing, fully opening cooling water during open mixing, performing low-temperature thin passing, uniformly mixing, and batching off to obtain the final rubber compound. Through multi-aspect improvement, the generated rubber material not only has excellent scorching safety, but also can be stored for a long time.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

A kind of preparation method of high temperature resistant high humidity polyurethane adhesive

ActiveCN112143436BAttached tightlyHigh activityBiocidePolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a method for preparing a high-temperature-resistant and high-humidity polyurethane adhesive. The specific preparation process is as follows: Weigh a certain amount of antibacterial crosslinking agent, antibacterial-promoting polymer and ethanol solution and add them into a reaction kettle at the same time, stir and dissolve, then heat up and react 2h, then add triethylamine thereinto, after the reaction, then cool and discharge, remove the solvent, add the solid matter into ethanol, stir to configure polyurethane adhesive liquid. One end of the antibacterial cross-linking agent prepared by the present invention is connected to the carbonyl side of the ester group in the antioxidant-promoting polymer -NH-COO-, and the other end is connected to the hydroxyl end of the ester group in it, so that the adhesive is hydrolyzed in high-temperature water At the same time, the polymer chains are still connected by the antibacterial cross-linking agent, and can still be tightly compounded on the surface of the test piece, and the adhesive strength will not be reduced due to hydrolysis.

Owner:佛山市龙源镭射科技有限公司

Rotor manufacturing method and rotor manufacturing device

ActiveCN110771010BShorten heating timeReduced bond strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesThermodynamicsEngineering

The present invention relates to a rotor manufacturing method and a rotor manufacturing device. The method for manufacturing the rotor includes: heating the binder to a temperature in a temperature range between the vaporization start temperature and lower than the expansion start temperature at which the diluent solvent volatilizes; The process of volatilizing the diluent solvent by raising the temperature of the adhesive at a slow temperature rise rate in the temperature range.

Owner:AISIN AW CO LTD

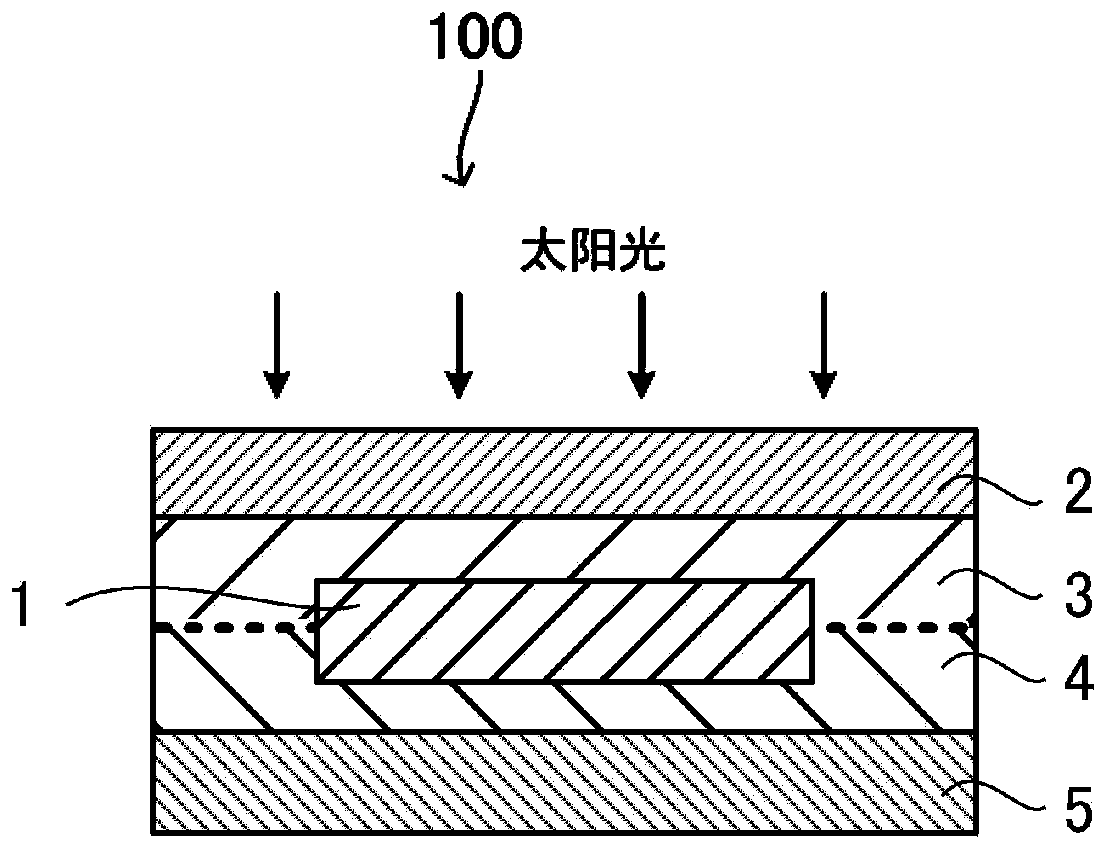

Polyurethane adhesive, adhesive for solar cell protective sheet, and backside protective sheet for solar cell

ActiveCN103339214BLong-term stable maintenance of adhesive strengthImprove adhesion strengthPolyureas/polyurethane adhesivesPhotovoltaic energy generationPolyesterPolyurethane adhesive

Provided is an adhesive that has favorable adhesive strength for use in the untreated surface material of an untreated polyester film or the like; suppresses a decrease in adhesion strength over time, even in outdoor exposure conditions; and is capable of maintaining adhesion strength over a long period of time. This polyurethane adhesive is a polyurethane adhesive using a main agent and a curing agent, wherein the main agent contains a specific polyester polyol (A), a specific polycarbonate polyurethane polyol (B), and a specific bisphenol type epoxy resin (C) at a specific ratio, and the curing agent contains a specific amount of a polyisocyanate component with an isocyanurate skeleton.

Owner:TOYO INK SC HOLD CO LTD

Rubber type pressure-sensitive adhesive as well as preparation method and application thereof

ActiveCN102277104BLess types of materialsSimple recipeNon-macromolecular adhesive additivesFilm/foil adhesivesSolvent freeButyl rubber

The invention provides a rubber type pressure-sensitive adhesive as well as a preparation method and an application thereof. The rubber type pressure-sensitive adhesive comprises the following substances in parts by weight: 100 parts of butyl rubber, 30-70 parts of polyisobutene, 30-90 parts of solid terpene resin, 30-70 parts of liquid terpene resin and 150-250 parts of superfine kaolin. The rubber type pressure-sensitive adhesive disclosed by the invention has high strength and shallow color, is the solvent-free unvulcanized rubber type pressure-sensitive adhesive and can be used as a pressure-sensitive adhesive in self-adhesion rubber waterstops used in the railway.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +1

Production method of biodegradable thermally bonded two-component composite filament fiber

ActiveCN102560709BGuaranteed spinnabilityAdhesion barrierMelt spinning methodsConjugated synthetic polymer artificial filamentsRoom temperatureViscose

Owner:TEXTILE INST JIANGSU PROVINCE

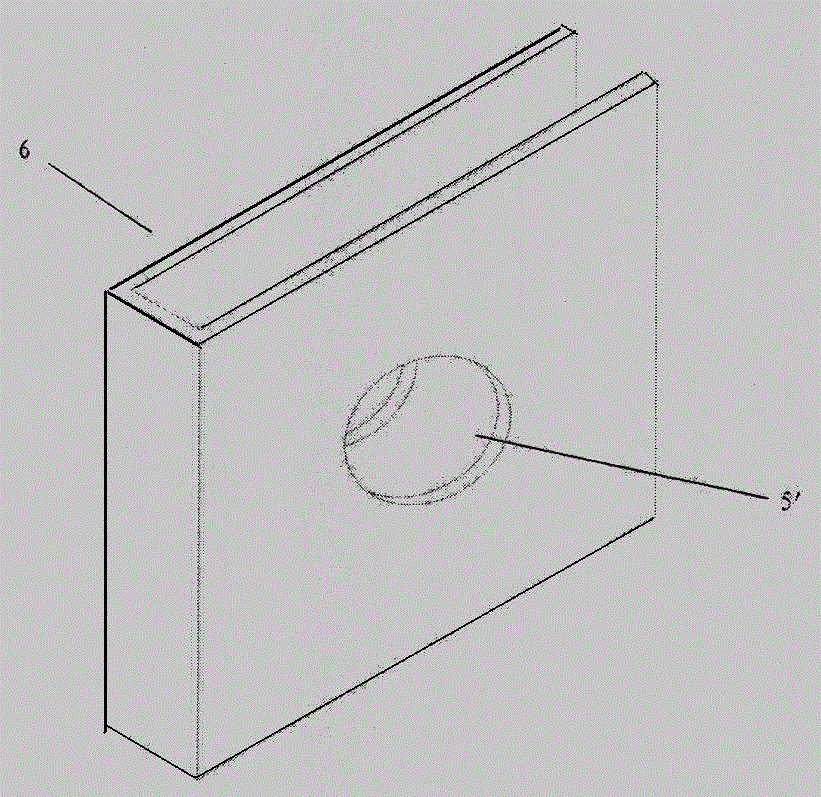

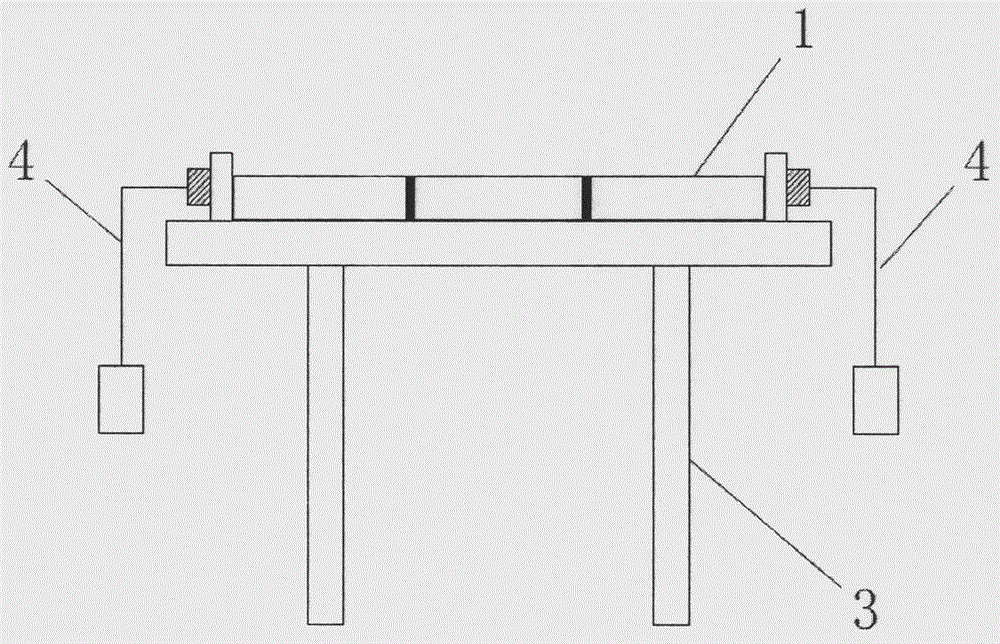

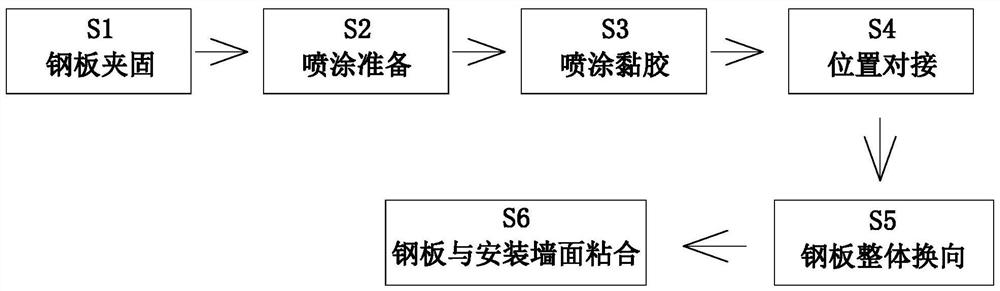

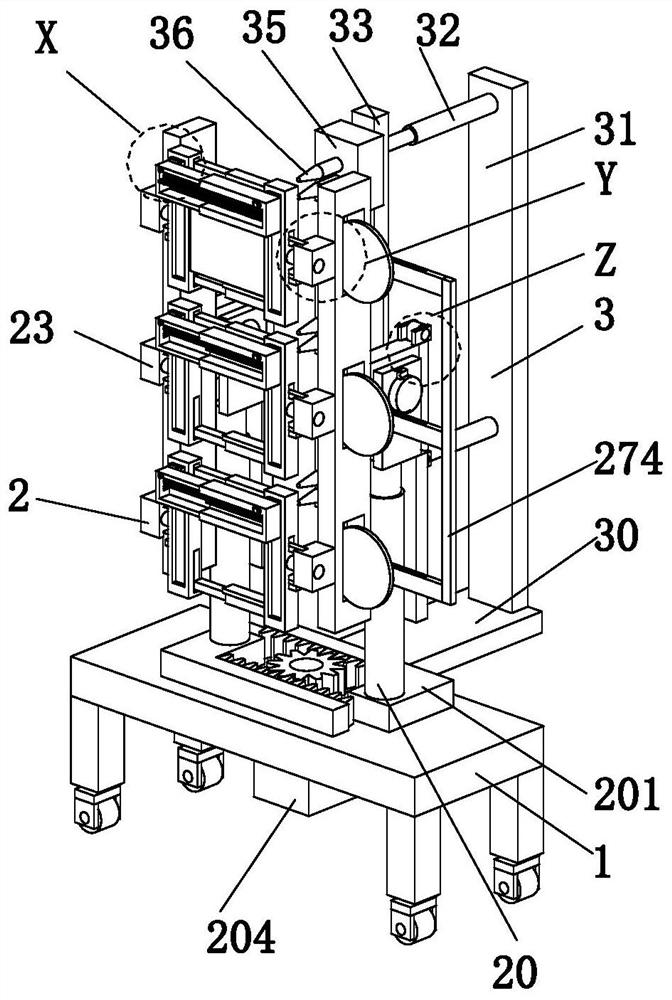

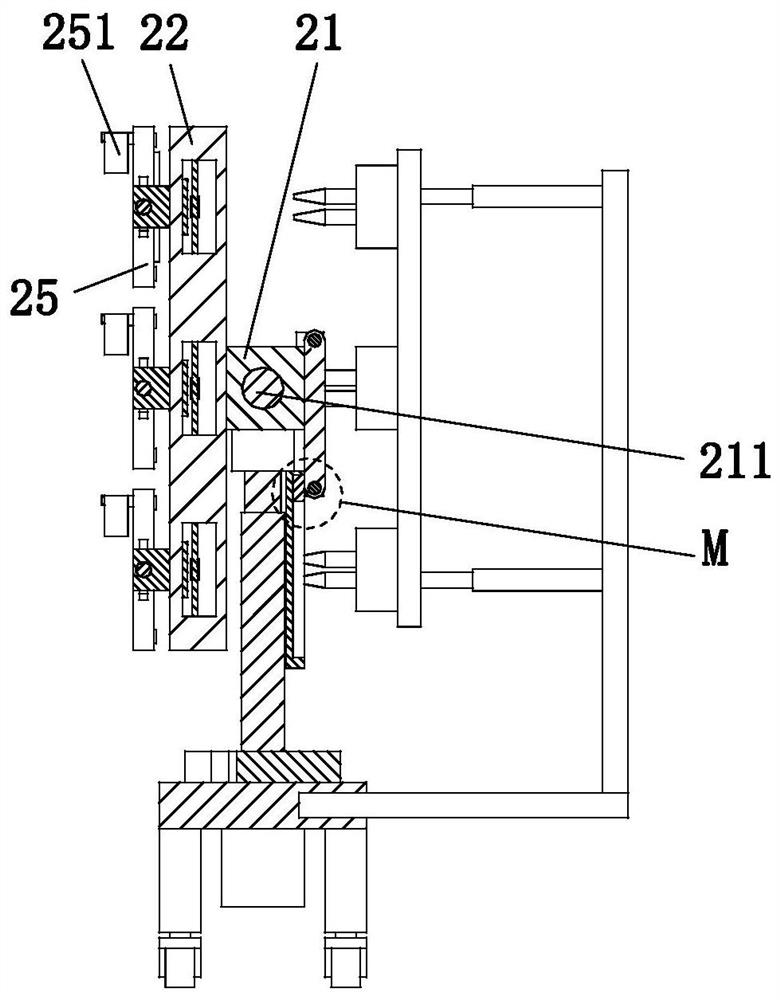

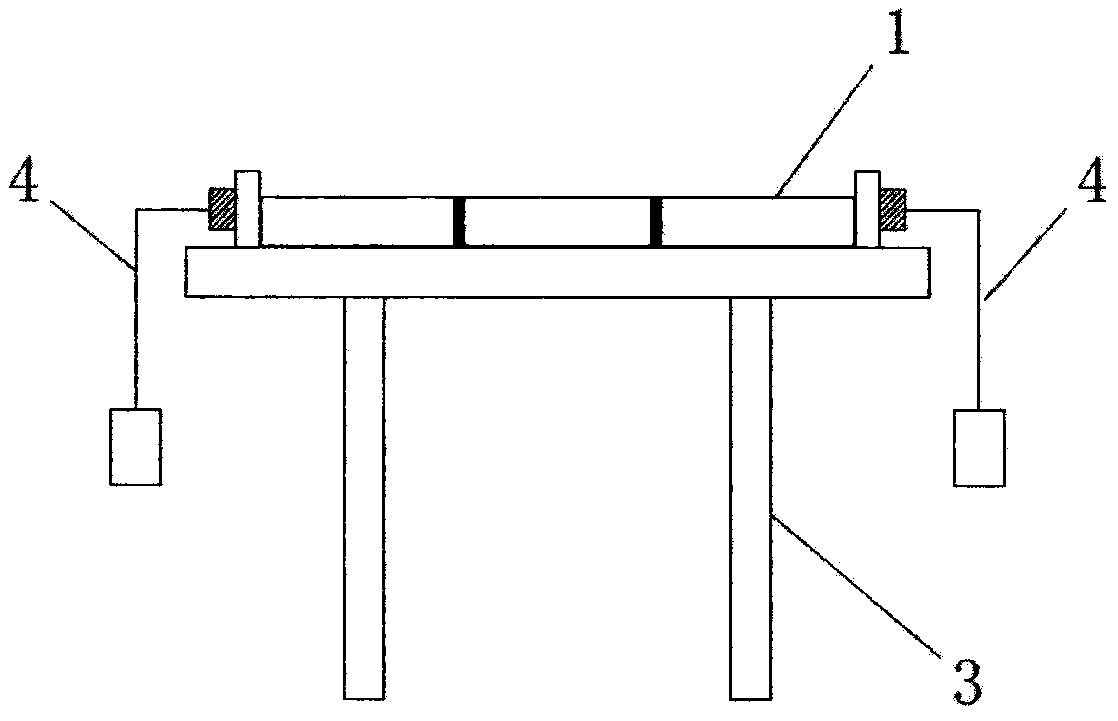

A method for repairing and strengthening reinforced concrete buildings by sticking steel

ActiveCN112878723BTo achieve the purpose of clampingImprove fitnessBuilding repairsReinforced concreteArchitectural engineering

The present invention relates to a method for repairing and strengthening the bonded steel of a reinforced concrete building, which uses a device for repairing and reinforcing the bonded steel of a reinforced concrete building. The lower end of the platform is connected to the existing ground through a sliding fit, the upper end of the mobile platform is provided with a fixing mechanism, and the right side of the fixing mechanism is provided with a spraying mechanism. The present invention adopts the design concept of combining multiple control structures to repair reinforced concrete buildings with steel Reinforcement, the overall size of the structure that acts as a clamping steel plate can be adaptively adjusted according to the size of the steel plate to be clamped, and then achieve the purpose of corresponding clamping, and expand the range of processing objects that the device is applicable to.

Owner:中海建筑有限公司

Goodyear type foaming rubber material

The invention relates to a Goodyear type foaming rubber material, which is prepared from a first part and a second part, wherein the first part is prepared from the following raw materials: styrene-butadiene rubber, natural rubber, zinc oxide, octadecanoic acid, N-isopropyl-N'-phenyl p-phenylenediamine, 2,2,4-trimethyl-1,2-dihexahydro quinoline, a reinforcing agent, coumarone resin, short fibers and a foaming agent; the second part comprises sulfur, accelerant dibenzothiazyl disulfide, accelerant CZ and accelerant TMTD added on the basis of the first part. The foamed sole prepared from the rubber material has the advantages of being soft, good in elasticity, good in wear resistance, small in specific gravity and the like, and the foaming rubber material has high sticking degree with the upper.

Owner:JIHUA 3515 LEATHER & SHOES

Adhesive sheet for temporary attachment and semiconductor device producing method using same

ActiveCN111655811AProper bond strengthReduced bond strengthSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialPhysical chemistry

Owner:LG CHEM LTD

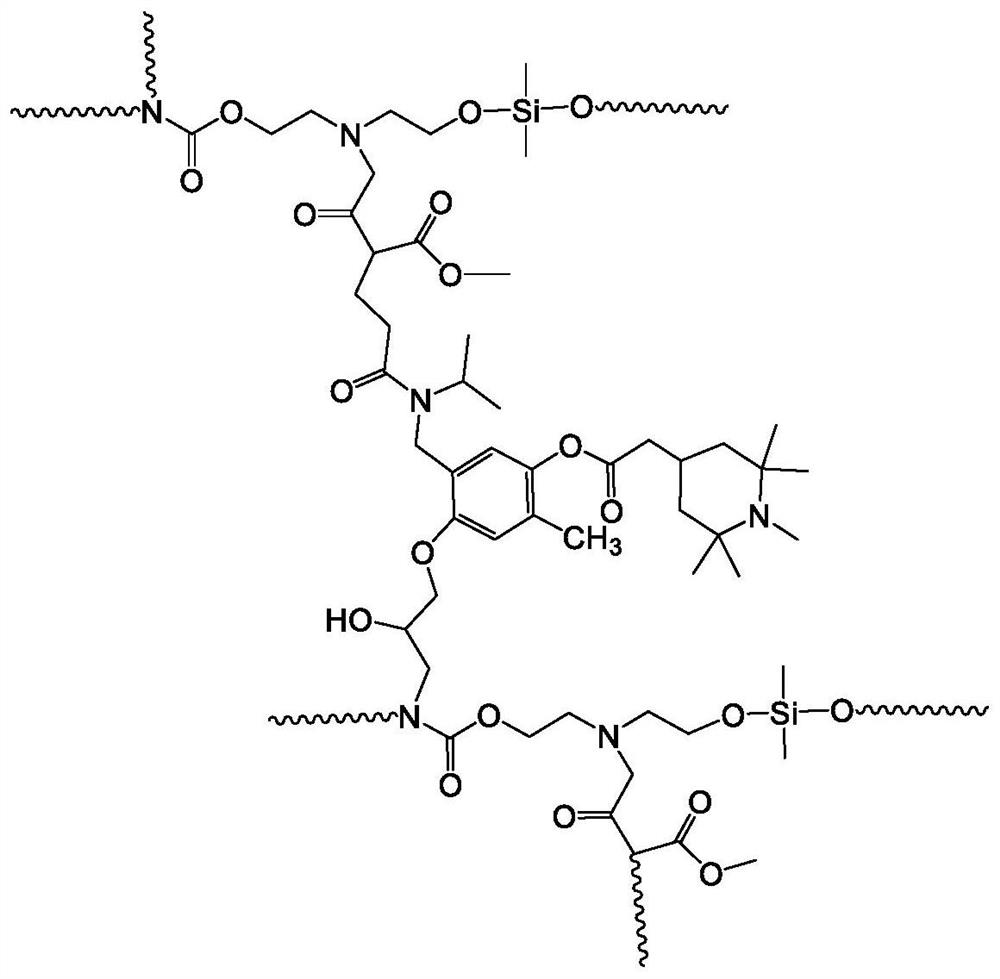

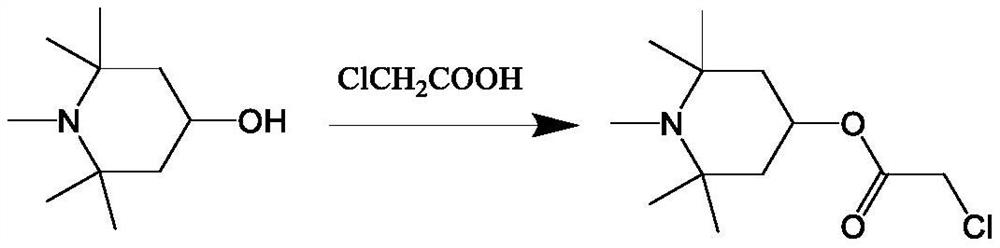

Preparation method of weather-resistant hydrolysis-resistant polyurethane adhesive

ActiveCN112143438AImprove adhesive performanceImprove adhesionPolyureas/polyurethane adhesivesPolyurethane adhesiveCarbonyl group

The invention discloses a preparation method of a weather-resistant hydrolysis-resistant polyurethane adhesive. The method comprises: weighing a certain amount of a free radical capture cross-linkingagent and an ethanol solution, adding the weighed products into a reaction kettle, carrying out stirring for dissolving, then, adding a polymer glue solution, heating to a temperature of 110-115 DEG Cwhile stirring, carrying out reaction for 2h, adding triethylamine, cooling to 75-80 DEG C, reacting for 6-7 hours, then, carrying out cooling and discharging, carrying out rotary evaporation to obtain a solid substance, adding the solid substance into ethanol, and stirring to prepare the polyurethane adhesive. One end of the prepared free radical capture cross-linking agent is connected with oneside of a carbonyl group of an ester group in -NH-COO-, and the other end of the free radical capture cross-linking agent is connected with one end of a hydroxyl group of the ester group, so that polymer chains are still connected through the free radical capture cross-linking agent when the adhesive is hydrolyzed in high-temperature water, and the adhesive strength of the adhesive is not reduceddue to high-temperature hydrolysis.

Owner:浙江圣腾胶业股份有限公司

A kind of room temperature curing epoxy resin composition and preparation method thereof

ActiveCN102977557BLow viscosity requirementImprove high temperature resistanceAntioxidantResin matrix

The invention relates to a room temperature curing epoxy resin composition and a preparation method thereof. The room temperature curing epoxy resin composition is characterized by comprising a component A and a component B, wherein the component A comprises the following ingredients: 100 parts of epoxy resin, 5-10 parts of diluent, and 0.5-3 parts of silane coupling agent; the component B comprises the following ingredients: 15-35 parts of amine curing agent, 0.1-3.0 parts of accelerant and 0.01-0.1 part of antioxidant. Blend epoxy resin of a hydantoin epoxy resin and a low-viscosity epoxy resin (at least one of bisphenol-A and bisphenol-F diglycidyl ether epoxy resins) is used as a resin matrix. Therefore, not only can the demand of vacuum leading-in and forming of a fiber reinforced composite material on low viscosity of the resin be met, but also the composite product can have excellent high-temperature resistance.

Owner:北京蓝星清洗有限公司

A disposable hygroscopic article

ActiveCN106832538BImprove adhesionLow unsaturationPersonal careSynthetic resin layered productsElastomerPolymer science

The invention discloses a disposable hygroscopic article, which comprises a liquid-permeable top layer, an absorption core body, a liquid-impermeable bottom layer and a multi-layer coextruded composite release film from top to bottom, wherein the multi-layer coextruded composite release film comprises a surface layer (1), a core layer (2) and a release layer (3). The disposable hygroscopic article is characterized in that the surface layer (1) is prepared from matting resin and polyolefin resin A; the core layer (2) is prepared from a filling material, polyolefin resin B and a thermoplastic elastomer; the release layer (3) is prepared from alpha-olefin polymer resin produced by metallocene, C4 to C14 polyolefin resin produced by a Z-N catalyst and fluorosilicon resin. The surface layer (1) of the multi-layer coextruded composite release film has the surface wetting tension not less than 38dyn / cm<2>, the surface electrical resistivity not less than 10<10>omega and the glossiness less than 15 percent; the release layer has the stripping force of 8.0gf / inch to 18gf / inch, the release residual adhesion rate not less than 90 percent and the heat bonding strength not less than 1.5N / inch. Compared with the prior art, the multi-layer coextruded composite release film has matting, antistatic and release anti-adhesion effects; further, the viscosity loss or the adhesive transfer of a back adhesive of a hygienic article can be effectively prevented.

Owner:FUJIAN HENGAN HLDG CO LTD +2

A preparation method of a weather-resistant hydrolysis-resistant polyurethane adhesive

ActiveCN112143438BImprove adhesionReduced bond strengthPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a method for preparing a weather-resistant hydrolysis-resistant polyurethane adhesive. The specific preparation process is as follows: a certain amount of free radical capture crosslinking agent and ethanol solution are weighed and added to a reaction kettle, stirred and dissolved, and then polymer glue is added. , raise the temperature to 110-115°C for 2 hours while stirring, then add triethylamine to it, cool down to 75-80°C and react for 6-7h, then cool and discharge the material, spin evaporate to obtain a solid substance, and then add the solid substance to ethanol , stir to form a polyurethane glue. One end of the free radical capture crosslinking agent prepared in the present invention is connected to the carbonyl side of the ester group in -NH-COO-, and the other end is connected to the hydroxyl end of the ester group in it, so that when the adhesive is hydrolyzed in high temperature water, the polymer The chains are still connected by the free radical capture crosslinking agent, so that the adhesive will not reduce its adhesive strength due to high temperature hydrolysis.

Owner:浙江圣腾胶业股份有限公司

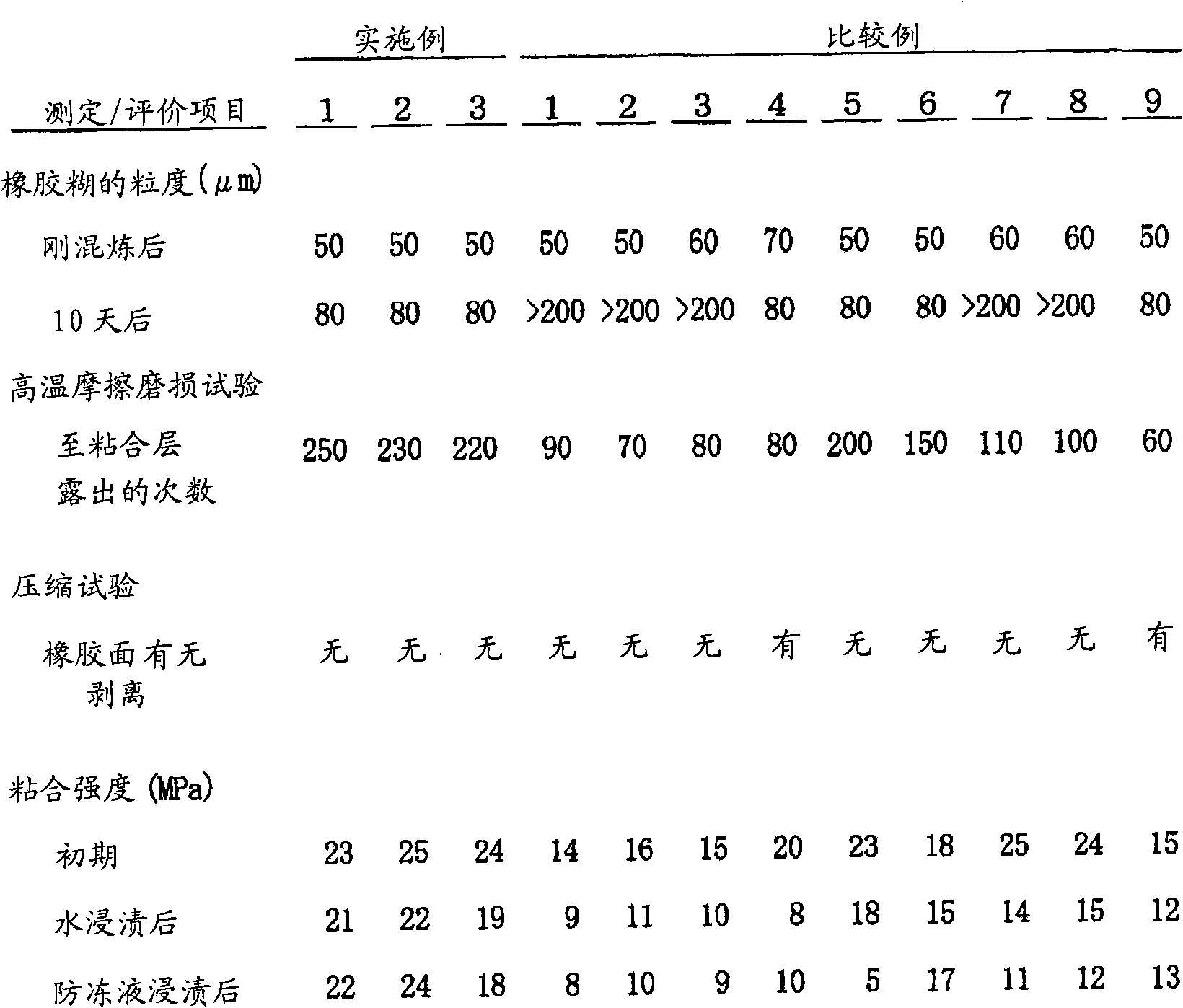

Layered rubber/metal product

InactiveCN102666091BImprove friction resistanceGood wear characteristicsNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer scienceOrganic solvent

Disclosed is a rubber metal laminate comprising NBR and metal that are bonded to each other through an adhesive comprising novolak-type and resol-type phenol resins, NBR, white carbon, and a vinyltrialkoxysilane coupling agent having an alkoxyl group containing two or more carbon atoms. As the adhesive, a mixed solution of a phenol resin-based adhesive solution and a rubber paste that is an organic solvent solution of an NBR compound comprising NBR, white carbon, and a silane coupling agent is specifically used. The rubber metal laminate has excellent friction and wear resistance characteristics at high temperatures and less decrease in adhesive strength after immersion in water or an antifreeze solution, and is capable of effectively preventing peeling, etc., caused thereby.

Owner:NOK CORP

Aluminum alloy cavity plate for furniture and manufacturing method thereof

ActiveCN105332981BSplicing and forming speed is fastIncrease flexibilityMaterial gluingLarge sizeApplication areas

Disclosed is a manufacturing method of an aluminum alloy cavity board for furniture. Two or more aluminum alloy cavity veneers are bonded and spliced in a side surface parallel mode, and the side surfaces of the aluminum alloy cavity veneers are bonded and spliced in parallel. The aluminum alloy cavity board for the furniture is manufactured through the manufacturing method of the aluminum alloy cavity board for the furniture. Compared with an existing large-size profile extrusion technology and an existing welded profile, the bonded aluminum alloy cavity board is high in splicing and forming speed, high in flexibility, small in flatness tolerance and small in weight, the demands of different application fields can be met, the operation is convenient and fast, and therefore the purposes of saving raw materials and reducing product manufacturing cost are achieved.

Owner:宋丽萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com