Production method of biodegradable thermally bonded two-component composite filament fiber

A composite filament and thermal bonding technology, which is applied in the fiber field, can solve problems such as complex process, unsatisfactory bonding effect, and affecting the spinnability of materials, so as to achieve good flexibility, good biodegradability, and ensure spinnability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

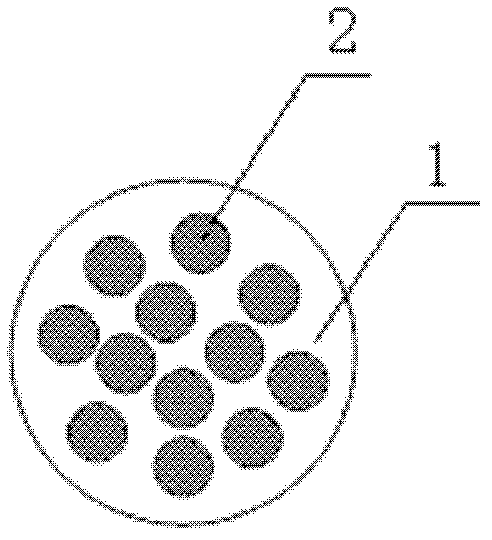

Image

Examples

Embodiment 1

[0022] Embodiment one: a kind of production method of biodegradable thermal bonding two-component composite filament fiber, comprises the following process steps:

[0023] (1) Vacuum-dry polybutylene succinate at 40°C for 8 hours, and vacuum-dry polylactic acid at 90°C for 24 hours, with a vacuum degree of -0.1MPa;

[0024] (2) The vacuum-dried polybutylene succinate and polylactic acid are respectively melt-extruded in the two screws of the twin-screw compound spinning machine, and the screw extrusion of polybutylene succinate The temperature is 200°C, and the screw extrusion temperature of polylactic acid is 225°C; after being metered by a metering pump, it enters the composite spinning assembly together, and the volume ratio of polybutylene succinate and polylactic acid melt is 80:20, Sprayed through the composite spinneret, cooled to room temperature, coated with spinning oil, coiled at a speed of 800m / min to form coiled filaments;

[0025] (3) Stretch the winding yarn af...

Embodiment 2

[0026] Embodiment two: a kind of production method of biodegradable thermal bonding two-component composite filament fiber, comprises the following process steps:

[0027] (1) Vacuum-dry polybutylene succinate at 50°C for 4 hours, and vacuum-dry polylactic acid at 100°C for 12 hours, with a vacuum degree of -0.1MPa;

[0028] (2) The vacuum-dried polybutylene succinate and polylactic acid are respectively melt-extruded in the two screws of the twin-screw compound spinning machine, and the screw extrusion of polybutylene succinate The temperature is 200°C, and the screw extrusion temperature of polylactic acid is 225°C; after being metered by a metering pump, it enters the composite spinning assembly together, and the volume ratio of polybutylene succinate and polylactic acid melt is 40:60, Sprayed through the composite spinneret, cooled to room temperature, coated with spinning oil, coiled at a speed of 1000m / min to form coiled filaments;

[0029] (3) Stretch the winding yarn ...

Embodiment 3

[0030] Embodiment three: a kind of production method of biodegradable heat-adhesive two-component composite filament fiber, comprises the following process steps:

[0031] (1) Vacuum-dry polybutylene succinate at 50°C for 5 hours, and vacuum-dry polylactic acid at 95°C for 16 hours, with a vacuum degree of -0.1MPa;

[0032] (2) The vacuum-dried polybutylene succinate and polylactic acid are respectively melt-extruded in the two screws of the twin-screw compound spinning machine, and the screw extrusion of polybutylene succinate The temperature is 210°C, and the screw extrusion temperature of polylactic acid is 230°C; after being metered by a metering pump, it enters the composite spinning assembly together, and the volume ratio of polybutylene succinate and polylactic acid melt is 50:50, Sprayed through the composite spinneret, cooled to room temperature, coated with spinning oil, coiled at a speed of 1200m / min to form coiled filaments;

[0033] (3) Stretch the winding yarn a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com