Manufacturing method of carbon fiber composite material cable wire

A composite material and production method technology, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as inability to apply to occasions with high temperature requirements, damage to epoxy resin composites, and poor high temperature resistance of cured products. , to solve the effect of long curing time at room temperature, shortening curing time and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

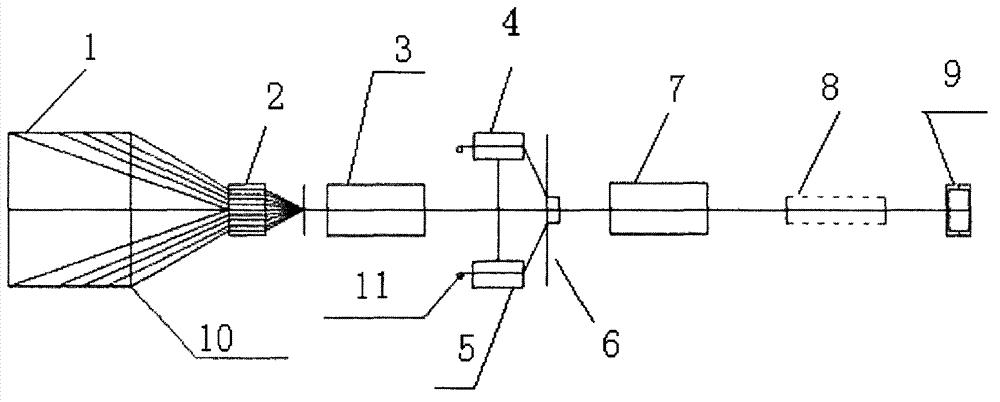

[0040] Combine below figure 1 and figure 2 , the present invention is further described:

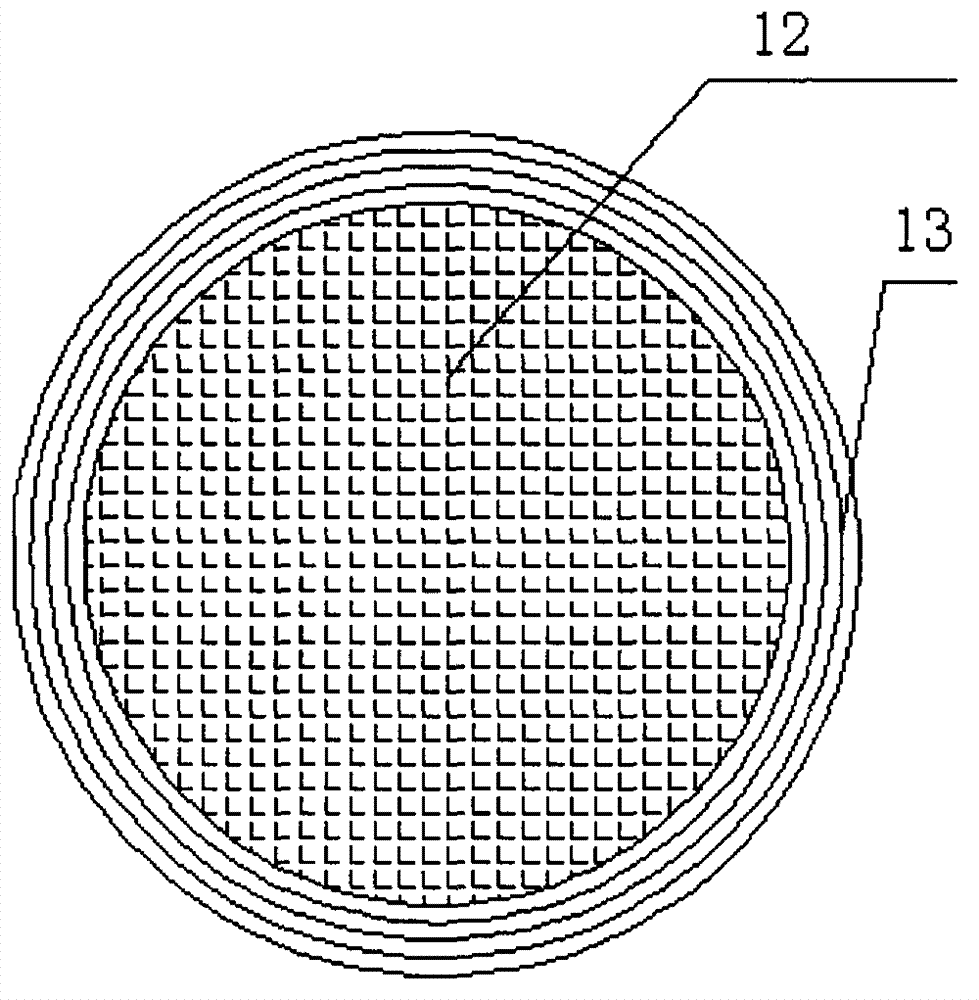

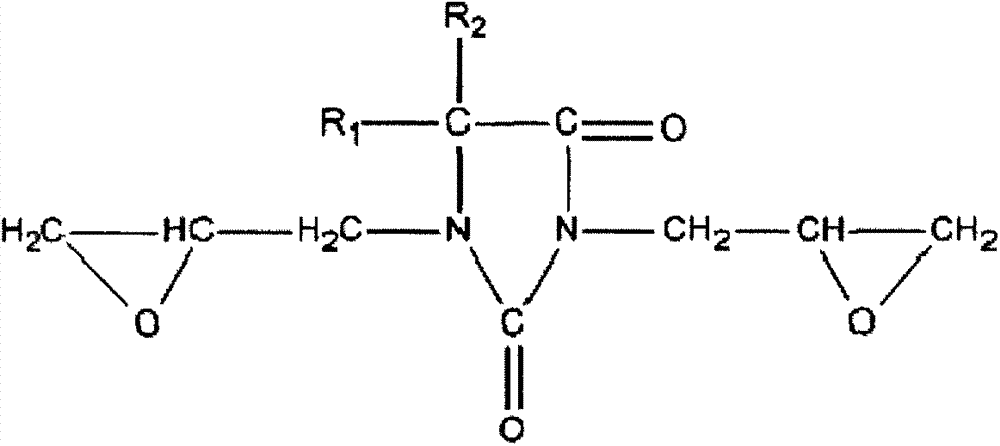

[0041] Such as figure 1 As shown, a method for making a carbon fiber composite cable includes a load-bearing core 12 and a protective layer 13. The protective layer 13 is wrapped on the outside of the load-bearing core 12 through a winding process. The load-bearing core 12 is a ring with high temperature resistance and high mechanical properties. The composite of oxygen resin and carbon fiber, the protective layer 13 is a composite of high temperature and weather resistance epoxy resin composition and glass fiber, and the high temperature and weather resistance epoxy resin composition is made of the following components: including component A and group Part B, wherein component A includes the following ingredients: 100 parts by mass of epoxy resin, 5-10 parts by mass of diluent and 0.5-3.0 parts by mass of silane coupling agent; component B includes the following ingredients: 15-35 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com