Production process of a motor punching sheet

A production process, a technology of motor punching, applied in the field of motor punching technology, can solve the problems of increased production energy consumption, achieve the effects of reducing equipment energy consumption, improving speed, and avoiding pollution of the working environment and punching machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A production process for punching electric motors, characterized in that the sheet punching includes the following steps:

[0050] S1: unfold the sheet and coil to obtain the sheet;

[0051] S2: Transport the sheet to the punching machine, and before the sheet enters the punching press, attach a layer of liquid film on the upper and lower surfaces of the sheet, the liquid film is formed by punching liquid, and the punching liquid includes the following raw materials and their quality Number of copies:

[0052] 100 parts of solvent,

[0053] 20-30 parts of film-forming agent,

[0054] The solvent is water; the film-forming agent is dihydrogen phosphate and the phosphate of dihydrogen phosphate is insoluble in the solvent;

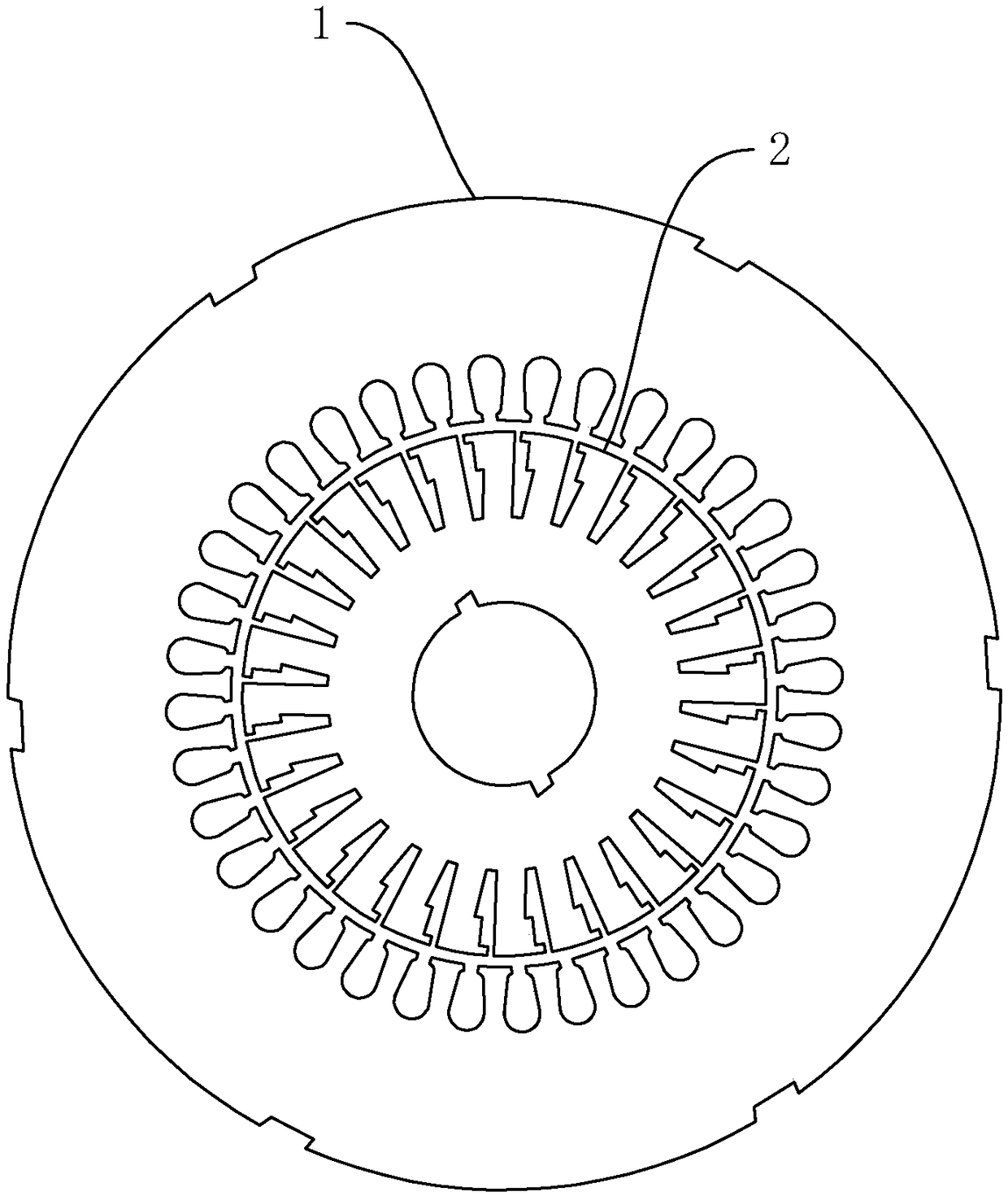

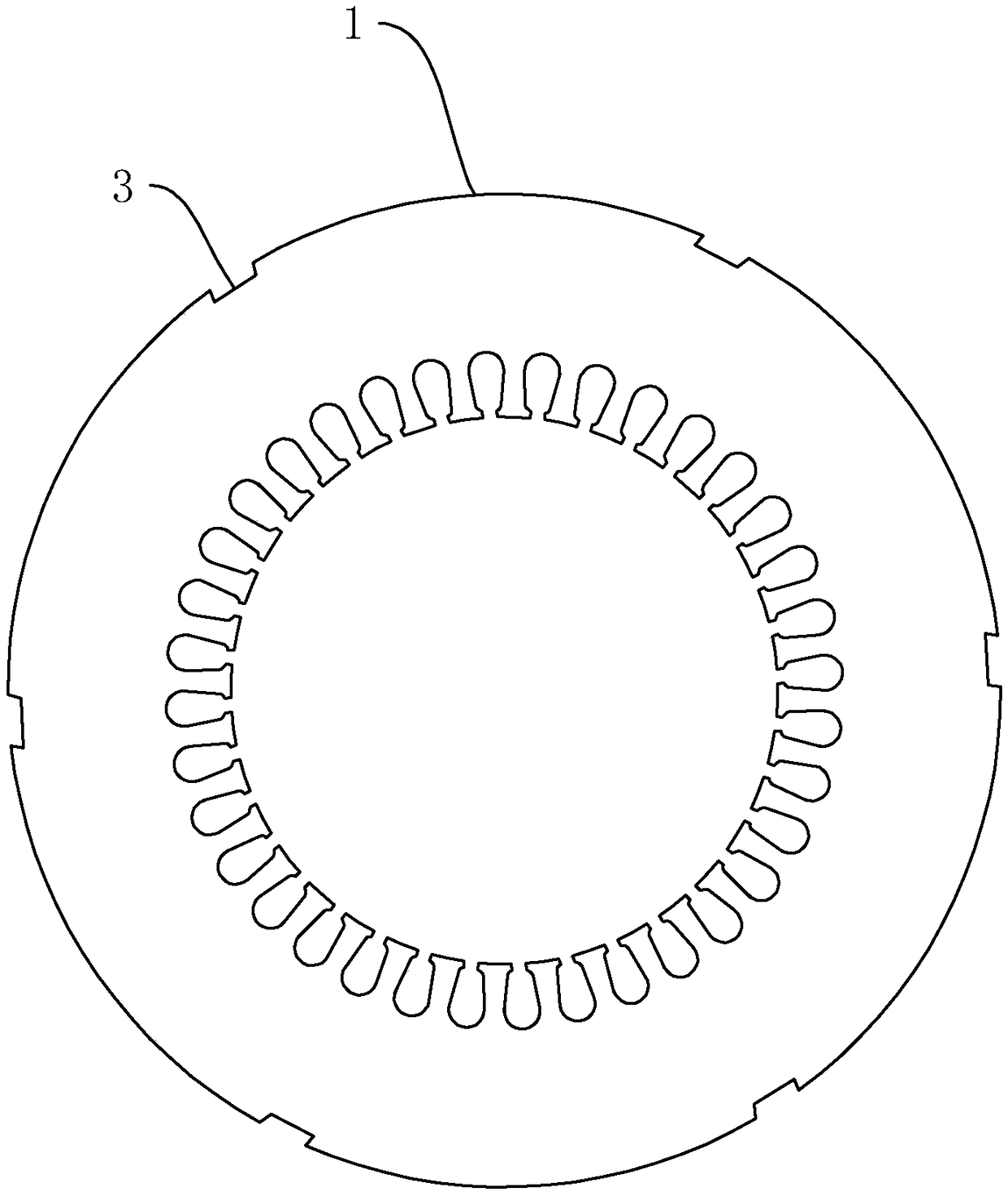

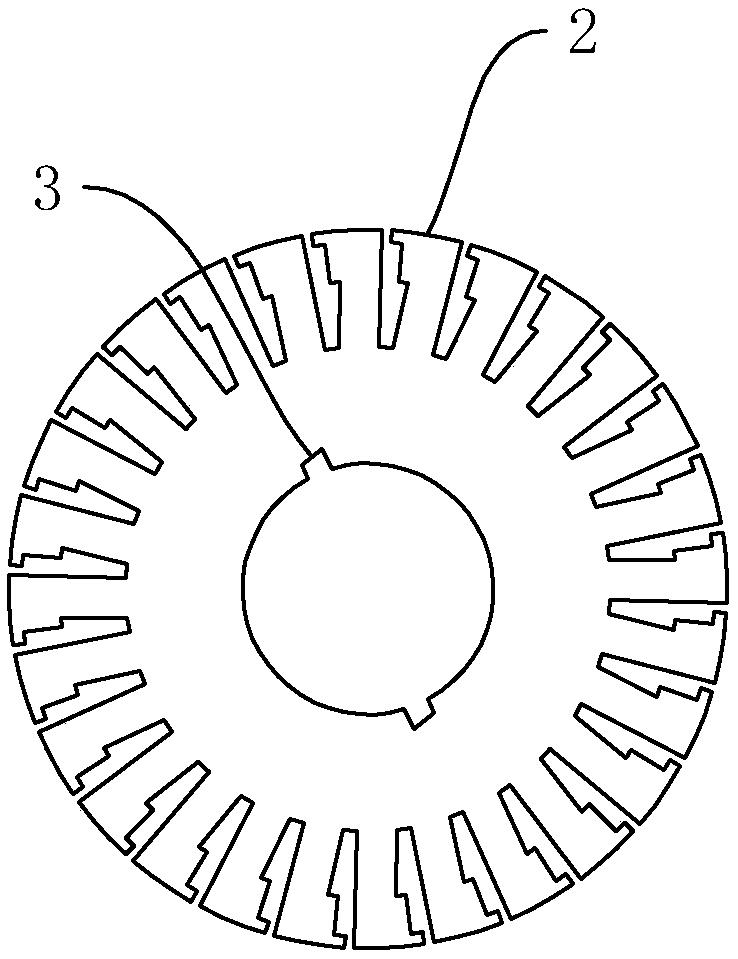

[0055] S3: Punching the plate, punching to obtain the initial sheet material of the stator and rotor, and punching the outer contour of the stator punching prefabricated part 1 on the initial sheet material of the stator and rotor;

[0056] S4: Pu...

Embodiment 2

[0068] A production process for punching a motor. On the basis of Example 1B, a flow aid is added to the raw material of the punching liquid, and the flow aid is graphene or a graphene derivative. The raw materials of blanking fluid are assisted in mixing under ultrasonic vibration, so that the flow aid can be dispersed evenly. The ingredients and dosage of the glidant are as follows.

[0069] According to the above-mentioned process, embodiment 2A-2I is set, flow aid and consumption are as follows.

[0070]

[0071] The self-flowing pavement test and the incision surface insulation resistivity detection of the punched prefabricated parts were carried out on the obtained blanking fluid.

[0072] Self-flowing pavement test: Select a flat plate with the same material as the punched sheet as the substrate, place the substrate horizontally in a windless and airtight environment, mark the origin and a reference line of fixed length on the substrate with a laser pointer, and the...

Embodiment 3

[0077] A production process for electric motor punching. On the basis of Example 1E, a flow aid is added to the raw material of the punching liquid, and the flow aid is graphene or a derivative of graphene. The raw materials of blanking fluid are assisted in mixing under ultrasonic vibration, so that the flow aid can be dispersed evenly. The composition and dosage of the flow aid and the test results of the self-flowing paving of the blanking fluid and the test results of the insulation resistivity of the cut surface are as follows.

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com