Method for machining blanking blanks of compressor shell

A technology of a compressor casing and a processing method, which is applied to the processing field of compressor parts, can solve the problems of increasing costs, many stamping times, wasting raw materials, etc., and achieves the effects of reducing production costs, reducing stamping times, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the blank 1 of the compressor casing is blanked.

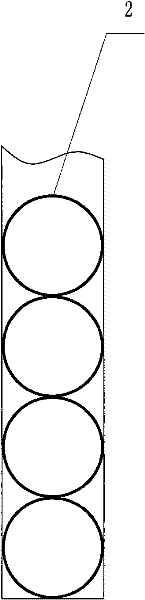

[0025] Such as figure 2 As shown, the layout method 2 of the blanking blanks of the compressor casing before the present invention is improved is that a single blanking blank 1 is arranged in sequence.

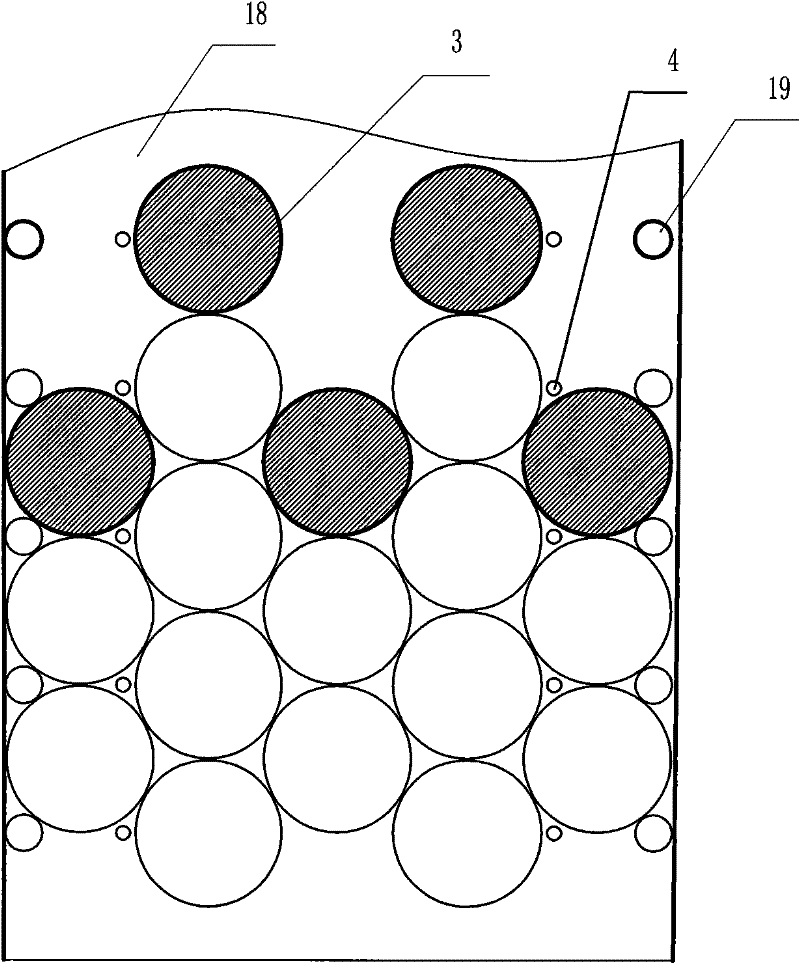

[0026] Such as image 3 As shown, the layout mode 3 of the blanking blanks of the compressor casing used in the present invention determined on the raw material strip 18, wherein 5 or more blanking blanks 1 of the casing filled with the section line are processed and formed at one time, The guiding hole 19 is used for guiding and positioning the raw material strip 18 in the mould, and the positioning hole 4 is used for positioning during punching.

[0027] Such as Figure 4 , 5 As shown, the mold used in the processing method of the compressor shell blank blank of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com