A kind of room temperature curing epoxy resin composition and preparation method thereof

A technology of epoxy resin and room temperature curing, which is applied in the field of room temperature curing epoxy resin composition and its preparation, can solve the problems of insufficient toughness and poor high temperature resistance of room temperature curing epoxy resin, and solve the problem of excessive room temperature curing time, Good thermal stability and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

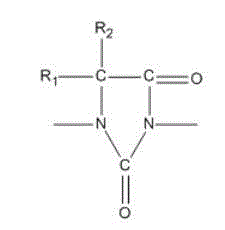

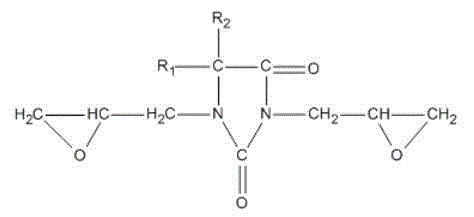

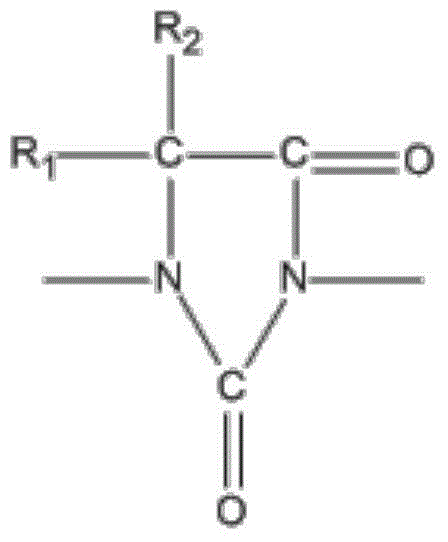

Method used

Image

Examples

Embodiment 1

[0026]Example 1: 10.0g hydantoin epoxy resin MHR-070 (purchased from Wuxi Meihua Chemical Co., Ltd., epoxy value 0.70-0.74), 90.0g bisphenol A glycidyl ether epoxy resin E-51 (Purchased from Wuxi Resin Factory of Blue Star Chemical New Materials Co., Ltd., epoxy value is 0.48-0.54) Mechanically stir and disperse at 800 rpm at 25°C for 5 minutes, add 5g of 1,4-butyl in turn while stirring Diol diglycidyl ether, 0.5g γ-glycidyl etheroxypropyl trimethoxysilane, mechanically stirred at a speed of 800 rpm to disperse for 10 minutes, then stand at room temperature for use, mix 15.0g polyetheramine D230 and 20.0 g triethylenetetramine was mechanically stirred and dispersed at room temperature at a speed of 600 rpm for 5 minutes, and 0.5 g of 2,4,6-tris(dimethylaminomethyl)phenol, 0.08 g of tetrakis[β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.02 g of didodecyl thiodipropionate were mechanically stirred and dispersed at a speed of 600 rpm at room temp...

Embodiment 2

[0027] Example 2: 30.0g hydantoin epoxy resin MHR-070 (purchased from Wuxi Meihua Chemical Co., Ltd., epoxy value 0.70-0.74), 70.0g bisphenol A glycidyl ether epoxy resin E-51 (purchased from Wuxi Resin Factory of Bluestar Chemical New Materials Co., Ltd., epoxy value is 0.48-0.54) Mechanically stir and disperse at 900 rpm at 30°C for 8 minutes, and add 5.0g of 1,4- Butanediol diglycidyl ether, 2.5g γ-glycidyl ether oxypropyltrimethoxysilane, mechanically stirred at a speed of 900 rpm to disperse for 10 minutes, then left to stand at room temperature for use, 5.0g polyetheramine D230 and 10.0g of triethylenetetramine was mechanically stirred and dispersed at room temperature at a speed of 600 rpm for 5 minutes, and 3.0g of 2,4,6-tris(dimethylaminomethyl)phenol, 0.0095g of tetrakis[β- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and 0.0005g of didodecyl thiodipropionate were dispersed by mechanical stirring at a speed of 600 rpm at room temperature fo...

Embodiment 3

[0028] Example 3: 20.0g hydantoin epoxy resin MHR-070 (purchased from Wuxi Meihua Chemical Co., Ltd., epoxy value 0.70-0.74), 80.0g bisphenol A glycidyl ether epoxy resin E-51 (Purchased from Wuxi Resin Factory of Blue Star Chemical New Materials Co., Ltd., epoxy value is 0.48-0.54) Mechanically stir and disperse at 1000 rpm at 27°C for 8 minutes, while stirring, add 5.0g of cyclohexane Alcohol diglycidyl ether, 3.0g γ-(methacryloyloxy)propyltrimethoxysilane, mechanically stirred at a speed of 1000 rpm to disperse for 10 minutes, then stand at room temperature for use, and 2.0g polyetheramine D230, 8.0g of polyetheramine D2000 and 15.0g of tetraethylenepentamine were mechanically stirred and dispersed at room temperature at a speed of 700 rpm for 10 minutes, and 2.5g of boron trifluoride ethylamine and 0.04g of tetra[β -(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and 0.005g of didodecyl thiodipropionate were mechanically stirred at a speed of 700 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com