Layered rubber/metal product

A technology of rubber metal and laminated body, which is applied in the direction of metal layered products, adhesives, layered products, etc. It can solve the problems of adhesive layer peeling, rubber instantaneous wear, poor water resistance, LLC resistance, etc., and achieve adhesion Less decrease in strength, excellent wear characteristics, anti-peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

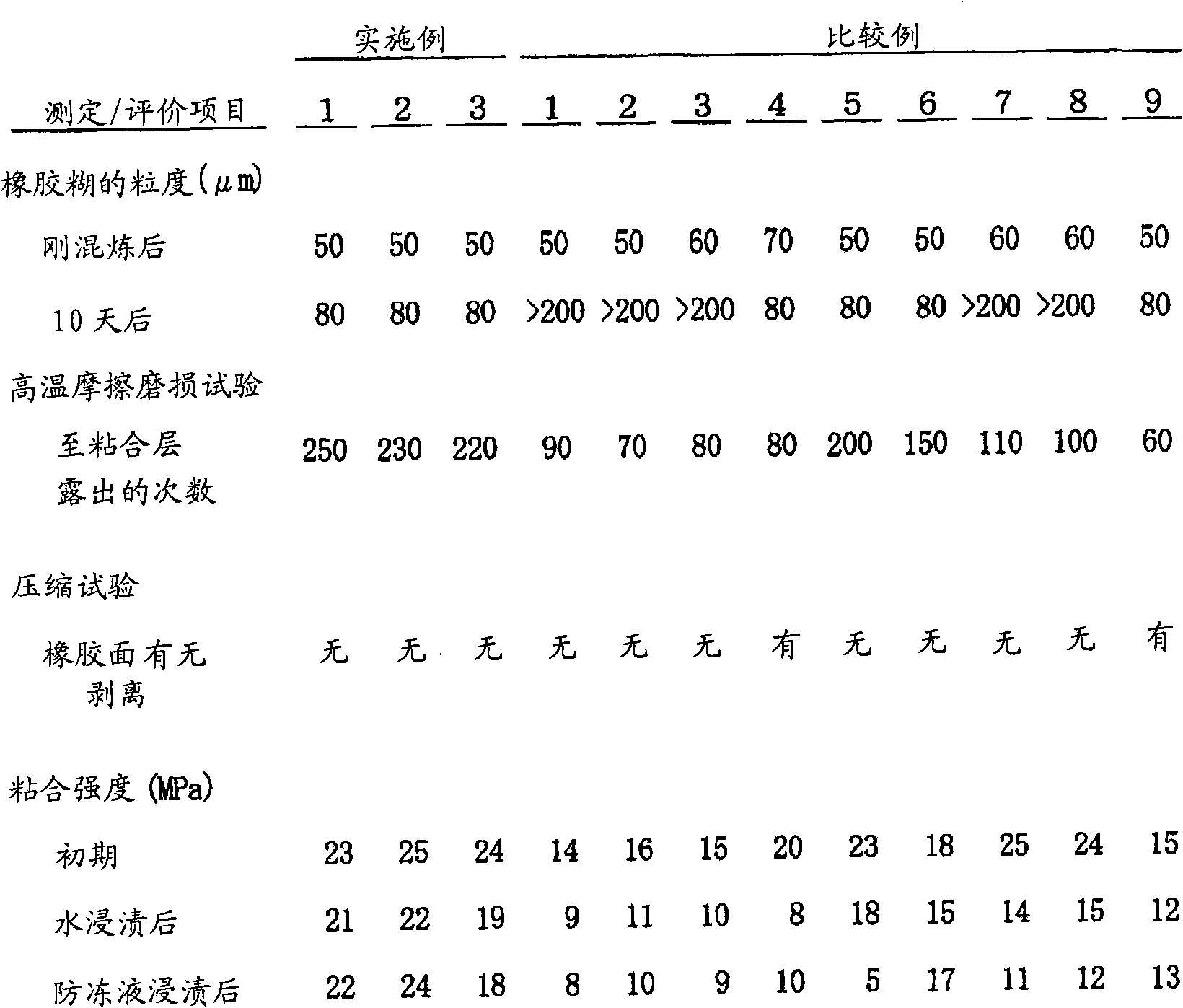

Examples

preparation example Construction

[0044] The preparation of the adhesive is carried out as follows: the NBR composite compounded with various ingredients in NBR is left for about 0 to 15 days after preparation, and after cutting, it is dissolved in, for example, methyl ethyl ketone-toluene (weight ratio 1:9) In the mixed solvent, a rubber paste having a solid content (NBR composite) concentration of about 10 to 30% by weight is prepared, and then an organic solvent such as a phenolic resin-based binder solution and methyl ethyl ketone is added thereto. Relative to the NBR in the rubber paste, the ratio of the phenolic resin in the phenolic resin-based adhesive solution is used in the above ratio, and the solid content concentration in the adhesive (the concentration of the solid content composed of the NBR composite and the phenolic resin) is About 2 to 15% by weight, preferably about 3 to 10% by weight.

[0045] The diluted concentration of the binder solution is appropriately selected according to the coatin...

Embodiment 1

[0055] (1) NBR (JSR product N235S; CN content 36%): 100 parts by weight

[0056] SRF carbon black (I 2 Adsorption capacity 29g / kg, DBP oil absorption capacity 72ml / 100g): 60 parts by weight

[0057] White carbon (Nipsil LP from Japan Silica products; specific surface area 200m 2 / g, particle size 0.02μm): 40 parts by weight

[0058] Zinc oxide: 5 parts by weight

[0059] Stearic acid: 2 parts by weight

[0060] Antiaging agent (Ouchi Shinko Chemicals, Nocrac 224): 2 parts by weight

[0061] Triallyl isocyanurate (Nippon Kasei, TAIC): 1.2 parts by weight

[0062] 1,3-bis(tert-butylperoxyisopropyl)benzene (Sanjian Chemical Products, Sunperox TY-13): 6 parts by weight

[0063] Vinyl tris(2-methoxyethoxy)silane (product of Momentive Performance Materials, A-172): 3 parts by weight

[0064] (total) 219.2 parts by weight

[0065] For the above ingredients, after kneading the polymer with a kneader, first add carbon black, zinc oxide, stearic acid and anti-aging agent for mix...

Embodiment 2

[0093] In Example 1(1), an equal amount of vinyltris(isopropoxy)silane (manufactured by Toray Dow Corning, Z-6550) was used as a silane-based coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com