Disposable hygroscopic article

A disposable and product technology, applied in applications, home appliances, layered products, etc., can solve the problems of easy generation of static electricity, high surface resistance, and affecting the appearance of products, and achieve the effect of preventing loss of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

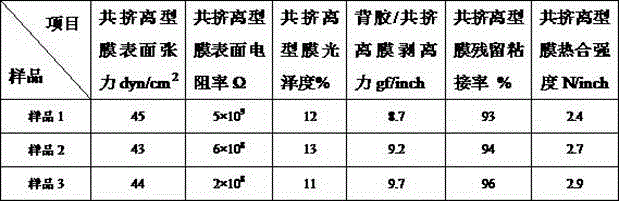

Embodiment 1

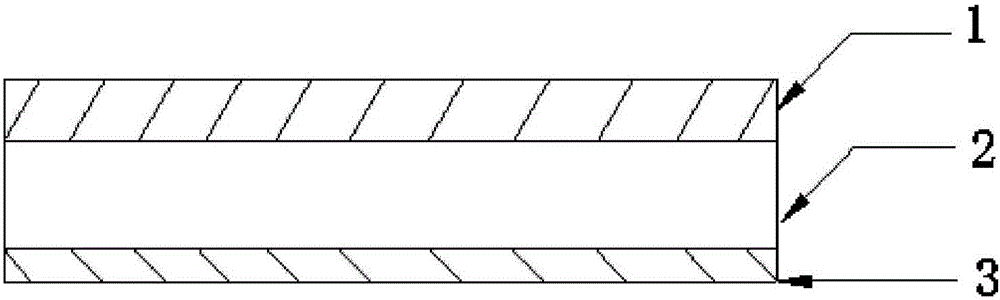

[0028] A disposable hygroscopic article, from top to bottom, includes a liquid-permeable top layer, an absorbent core, a liquid-impermeable bottom layer and a multi-layer co-extruded composite release film.

[0029] The material of the liquid-permeable top layer is air-through non-woven fabric with a specification of 168mm*20gsm, purchased from Yanjiang Company.

[0030] The absorbent core is dust-free paper with a specification of 168mm*60gsm, purchased from Tianjin BBA Company.

[0031] The liquid-impermeable bottom layer is a gas-permeable film with a specification of 168mm*35gsm, which is purchased from Korea Hans Corporation.

[0032] The multi-layer co-extruded composite release film is a self-made material, including a surface layer, a core layer and a release layer. Its preparation method is as follows: Step 1. Weigh 0.5wt% of antistatic agent Irgastat P18 (Basf), 39.5wt% of matting resin FB2230 (Borealis), 60wt% of LLDPE-FS150A (Sumitomo, Japan) and mix them evenly i...

Embodiment 2

[0035] A disposable hygroscopic article, from top to bottom, includes a liquid-permeable top layer, an absorbent core, a liquid-impermeable bottom layer and a multi-layer co-extruded composite release film.

[0036] The material of the liquid-permeable top layer is air-through non-woven fabric with a specification of 168mm*20gsm, purchased from Yanjiang Company.

[0037] The absorbent core is dust-free paper with a specification of 168mm*60gsm, purchased from Tianjin BBA Company.

[0038] The liquid-impermeable bottom layer is a gas-permeable film with a specification of 168mm*35gsm, which is purchased from Korea Hans Corporation.

[0039] The multi-layer co-extruded composite release film is a self-made material, including a surface layer, a core layer and a release layer. Its preparation method is as follows: step 1, weighing 1.0wt% antistatic agent Irgastat P18 (Basf), 50wt% matting resin FB2230 (Borealis), 39wt% LLDPE-5220G (Dow), 10wt% LDPE-FD0474 ( Lotrene) was mixed e...

Embodiment 3

[0042] A disposable hygroscopic article, from top to bottom, includes a liquid-permeable top layer, an absorbent core, a liquid-impermeable bottom layer and a multi-layer co-extruded composite release film.

[0043] The material of the liquid-permeable top layer is air-through non-woven fabric with a specification of 168mm*20gsm, purchased from Yanjiang Company.

[0044] The absorbent core is dust-free paper with a specification of 168mm*60gsm, purchased from Tianjin BBA Company.

[0045] The liquid-impermeable bottom layer is a gas-permeable film with a specification of 168mm*35gsm, which is purchased from Korea Hans Corporation.

[0046] The multi-layer co-extruded composite release film is a self-made material, including a surface layer, a core layer and a release layer. Its preparation method is as follows: step 1, weighing 1.5wt% antistatic agent Irgastat P18 (Basf), 80wt% matting resin FB2230 (Borealis), 8.5wt% LLDPE-7042 (Lanzhou Petrochemical), 10wt% LDPE- XUS60901.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com