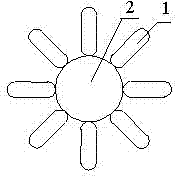

Matt eight-leaf polyester fibers and production method thereof

A technology of polyester fiber and production method, applied in the field of matte eight-leaf polyester fiber and its production, can solve the problems of difficult cleaning of the filter element of the melt filter, rare composite function, unfavorable spinning, etc., and achieves moisture absorption. Quick-drying bionic effect, excellent bionic effect, and the effect of improving moisture absorption and moisture conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Beating: First melt and mix PTA20Kg (120.48mol) and EG7.9Kg (127.45mol), and add antimony ethylene glycol as a catalyst. The amount of antimony ethylene glycol is 0.03% of the weight of purified terephthalic acid, and then Send to esterification I kettle;

[0033] (2) In esterification The esterification rate in the kettle reaches more than 70%, and enters the esterification Kettle for continuous esterification reaction, esterification temperature 240 ℃, after the esterification rate reaches 89%, add polyethylene glycol and stabilizer trimethyl phosphate, the molar weight of polyethylene glycol is 0.25% of the molar weight of purified terephthalic acid mol%, the weight of trimethyl phosphate is 0.02% of the weight of purified terephthalic acid, mixed and stirred, and transported to the polycondensation tank;

[0034] (3) Vacuumize, heat up the polycondensation tank, heat up the polycondensation reaction to 270°C, and at the same time polycondensate to the target...

Embodiment 2

[0039] (1) Beating: First melt and mix PTA20Kg (120.48mol) and EG8.0Kg (129.03mol), and add catalyst antimony trioxide, the amount of antimony trioxide is 0.05% of the weight of purified terephthalic acid, and then send to Esterification 1 kettle;

[0040] (2) In esterification The esterification rate in the kettle reaches more than 75%, and enters the esterification Continuous esterification reaction in the kettle, the esterification temperature is 230°C, and after the esterification rate reaches 92%, polyethylene glycol and stabilizer trimethyl phosphate are added, and the molar weight of polyethylene glycol is 0.5% of that of purified terephthalic acid. mol%, the weight of trimethyl phosphate is 0.04% of the weight of purified terephthalic acid, mixed and stirred, and delivered to the polycondensation tank;

[0041] (3) Vacuumize, heat up the polycondensation tank, heat up the polycondensation reaction to 265°C, and at the same time polycondensate to the target viscosity ...

Embodiment 3

[0046] (1) Beating: First melt and mix PTA20Kg (120.48mol) and EG8.2Kg (132.25mol), and add antimony ethylene glycol as a catalyst. The amount of antimony ethylene glycol is 0.07% of the weight of purified terephthalic acid, and then Send to esterification I kettle;

[0047] (2) In esterification The esterification rate in the kettle reaches more than 80%, and enters the esterification The kettle carries out continuous esterification reaction, the esterification temperature is 252°C, and after the esterification rate reaches 94%, polyethylene glycol and stabilizer triphenyl phosphate are added, and the molar weight of polyethylene glycol is 1 mol of the molar weight of purified terephthalic acid %, the weight of trimethyl phosphate is 0.06% of the weight of purified terephthalic acid, mixed and stirred, and delivered to the polycondensation tank;

[0048] (3) Vacuumize, heat up the polycondensation tank, the temperature of the polycondensation reaction is raised to 270°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com