A kind of preparation method of high temperature resistant high humidity polyurethane adhesive

A polyurethane adhesive, high temperature resistant technology, applied in polyurea/polyurethane adhesives, botanical equipment and methods, adhesives, etc., can solve the problems of reduced bonding performance of polyurethane adhesives and achieve high adhesion , the effect of high antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

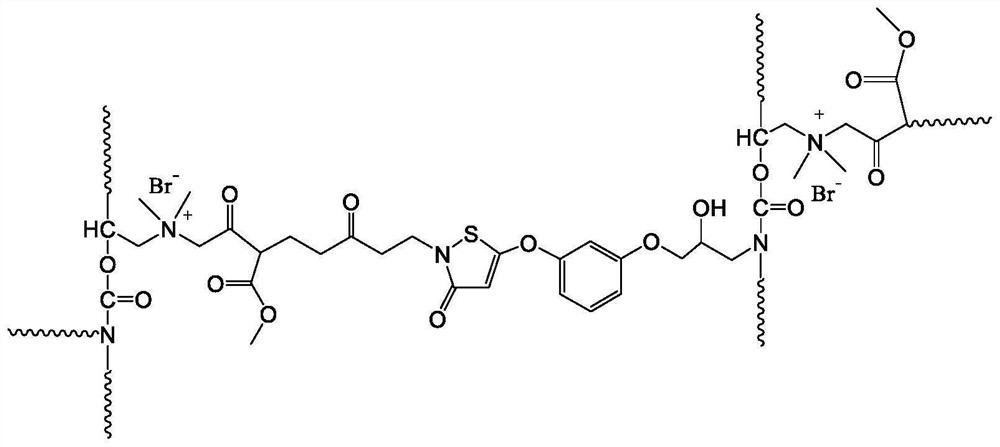

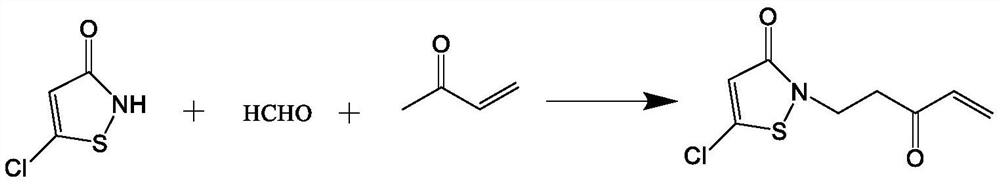

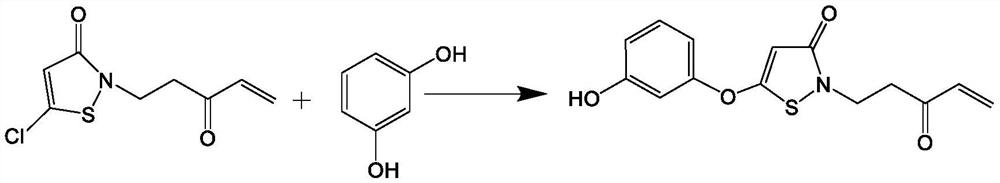

[0034] The concrete preparation process of antibacterial cross-linking agent is as follows:

[0035] (1) Add 2 mol of methyl 3-mercaptopropionate and 300 mL of ammonia water with a mass concentration of 25% into a reaction kettle at a temperature of 5°C, stir and react for 2 hours, then slowly heat up to 60°C for 4 hours, and then evaporate The ammoniacal liquor of reaction obtains 3-mercaptopropionamide; Carry out infrared analysis to product and know, at 3189cm -1 and 3366cm -1 Amino doublets appeared at the place;

[0036] (2) Add 2mol 3-mercaptopropionamide and 100mL dichloromethane into the reaction kettle at the same time, raise the temperature to 45°C, then add 3mol sulfonyl chloride dropwise, control the dropwise addition within 1h, then keep the temperature for 7h, and carry out rotary evaporation , reclaim the solvent, then recrystallize the product obtained with petroleum ether to obtain 5-chloroisothiazolinone; carry out infrared analysis on the product, it can b...

Embodiment 2

[0044] The concrete preparation process of linking agent is as follows:

[0045] (1) Add a mixed solvent of 200mL ethanol and 100mL water, 80g paraformaldehyde and 226 (2mol) g N-isopropylacrylamide into the reaction tank, stir and dissolve, heat up to 65°C, and then add 396g (2.1mol) Nitrophenol, stirred and reacted for 7 hours, crystals were precipitated after the solvent was evaporated, and the obtained crystals were recrystallized with ethanol to obtain acrylamide nitrophenol. The reaction structure was as follows, and the product was carried out by infrared analysis. -1 The infrared absorption peak of conjugated olefin appeared at 3350cm -1 The infrared absorption peak of the phenolic hydroxyl group appears, and the carbon atoms in the ortho-position of the phenolic hydroxyl group and the meta-position of the nitro group contain active hydrogen, which can carry out aminomethylation reactions. By controlling the amount of N-isopropylacrylamide added, the One of the ortho-...

Embodiment 3

[0049] The concrete preparation process of linking agent is as follows:

[0050] Add 200mL of ethanol and 100mL of mixed solvent of water, 80g of paraformaldehyde and 113g (1mol) g of N-isopropylacrylamide into the reaction tank, stir and dissolve, heat up to 65°C, and then add 396g (2.1mol) of p-nitrophenol , stirred and reacted for 7h, crystals were precipitated after the solvent was evaporated, and the obtained crystals were recrystallized with ethanol to obtain acrylamidonitrophenol; the reaction structure was as follows, and the product was carried out by infrared analysis. -1 The infrared absorption peak of conjugated olefin appeared at 3350cm -1 There is no infrared absorption peak of the phenolic hydroxyl group, and the carbon atoms in the ortho-position of the phenolic hydroxyl group and the meta-position of the nitro group contain active hydrogen, which can carry out aminomethylation reaction. By controlling the amount of N-isopropylacrylamide added, the One of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com