Dicing method

A cutting method and chip technology, applied in adhesive types, film/sheet adhesives, polyurea/polyurethane adhesives, etc., can solve the difficulty of chip peeling, increase the difficulty of chip picking, and pick up Defects and other problems can be achieved to reduce the phenomenon of mixing and suppress the effect of chip pick-up defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] As a method for producing the (meth)acrylate polymer, emulsion polymerization, solution polymerization, or the like can be used. The (meth)acrylate polymer is preferably an acrylic rubber prepared by emulsion polymerization in consideration of pick-up property.

[0046] Examples of the rubber-based adhesive include natural rubber, synthetic isoprene rubber, styrene-butadiene rubber, styrene-butadiene block copolymer, styrene-isoprene block copolymer, Butyl rubber, polyisobutylene, polybutadiene, polyvinyl ether, silicone rubber, polyvinyl isobutyl ether, neoprene, nitrile rubber, craft rubber, recycled rubber, styrene vinyl ・Butene block copolymer, styrene-propylene-butylene block copolymer, styrene-isoprene block copolymer, polyisobutylene-ethylene-propylene copolymer, ethylene-vinyl acetate copolymer, polyisobutylene ・Silicone rubber, polyvinyl isobutyl ether, chloroprene, etc. The aforementioned rubber-based adhesive may be one of them or a mixture thereof.

[0047]...

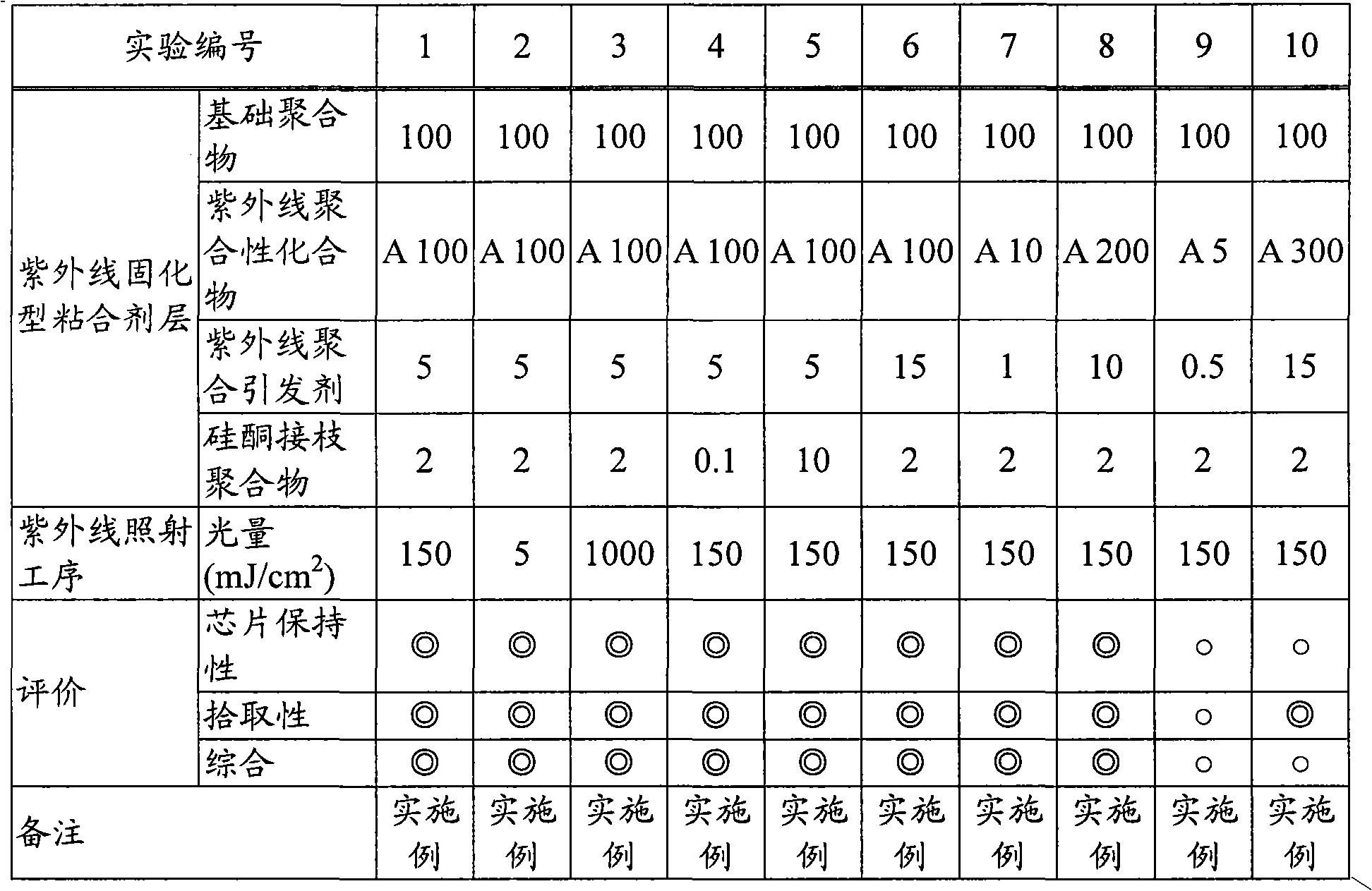

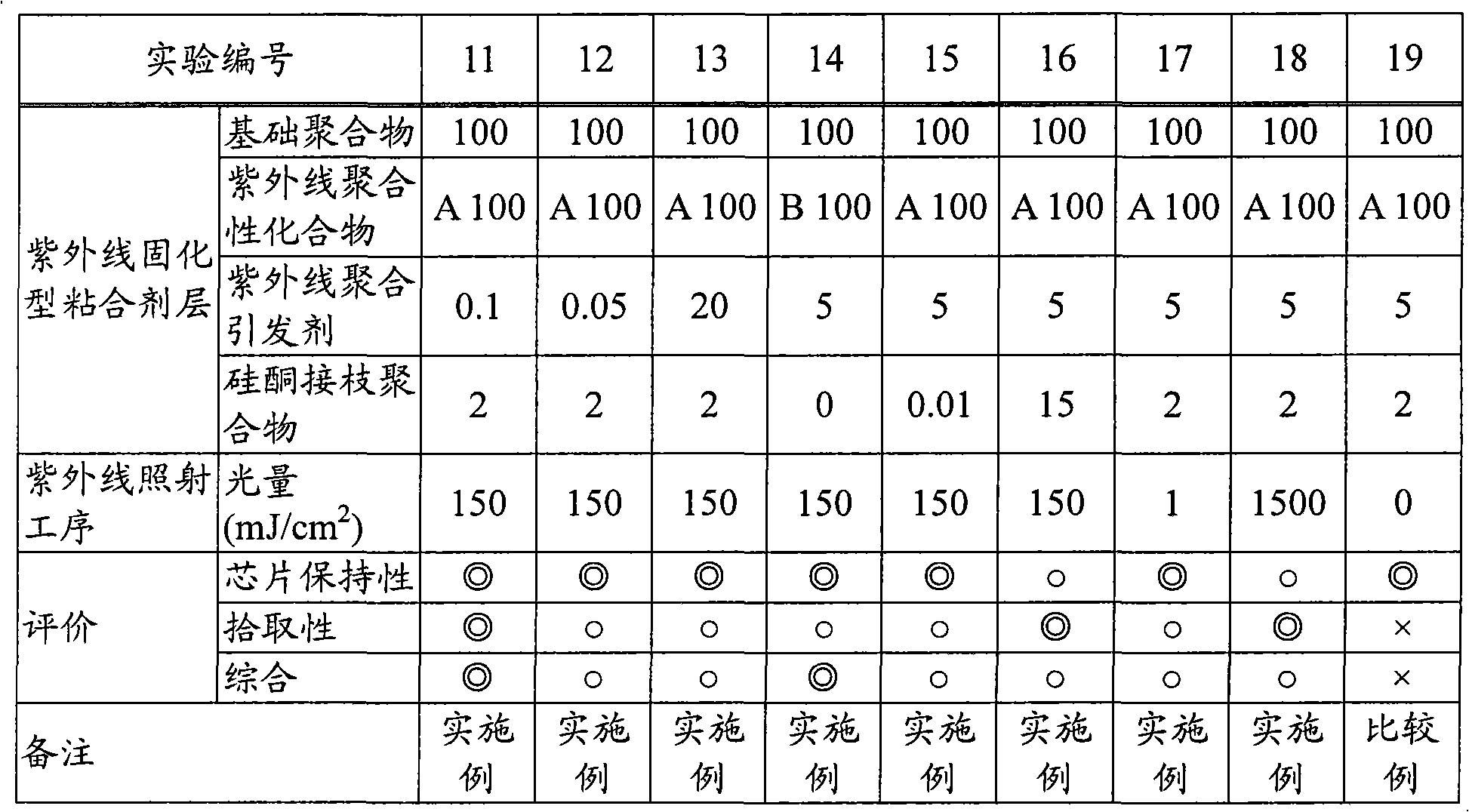

Embodiment

[0094] Hereinafter, the present invention will be further described through examples, but the present invention is not limited to the following examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com