Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about How to "To achieve the purpose of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

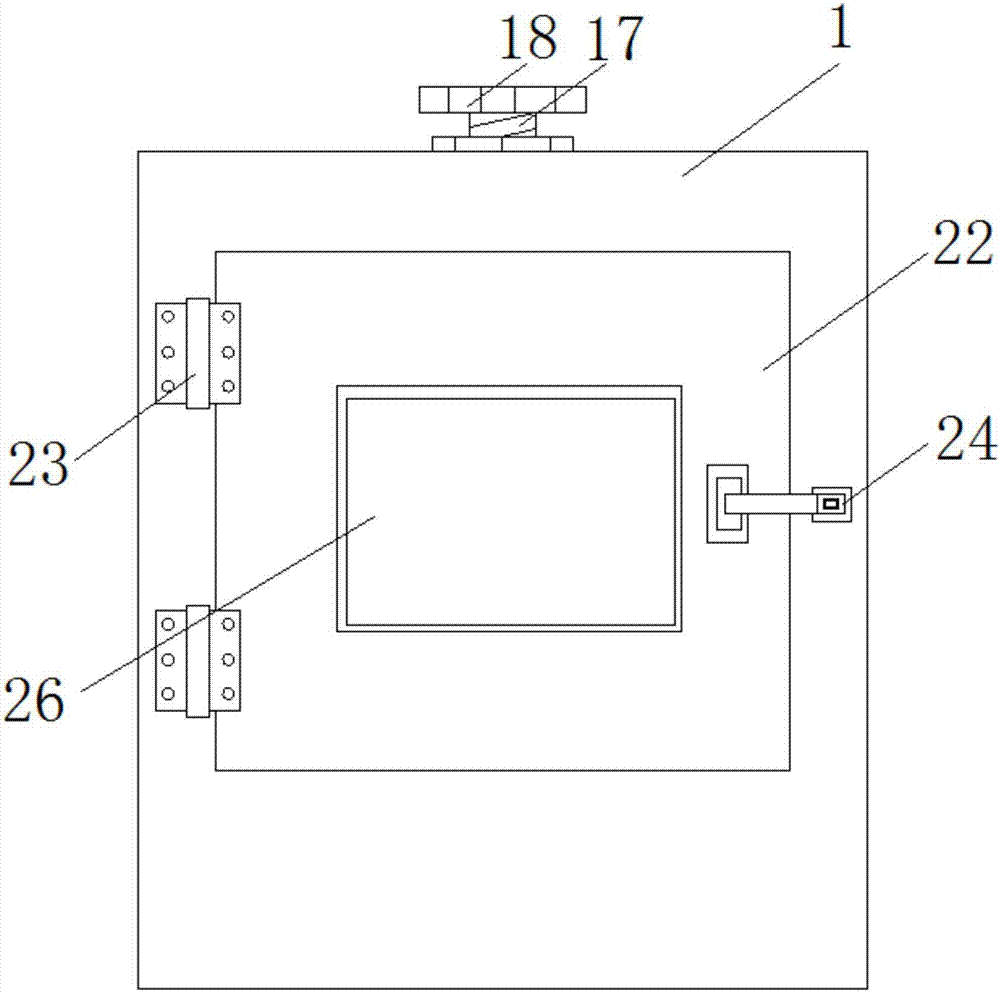

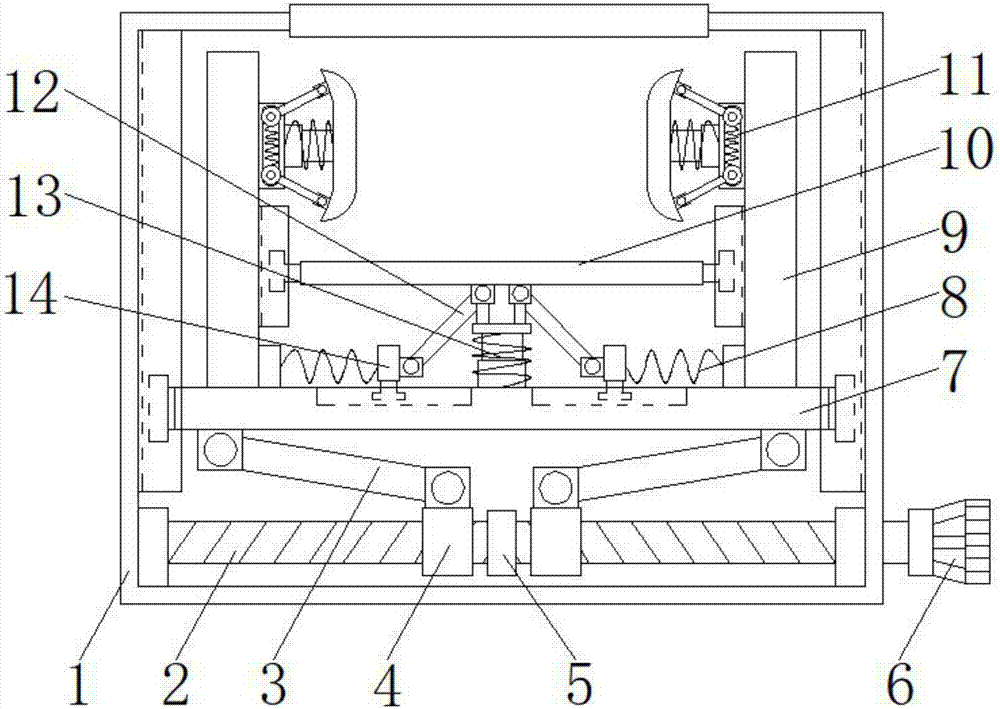

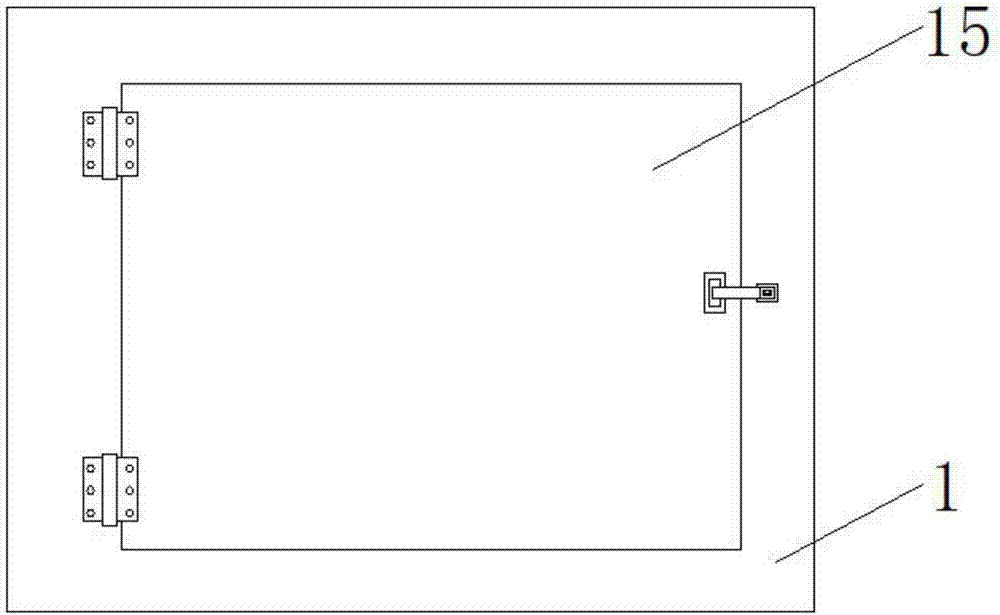

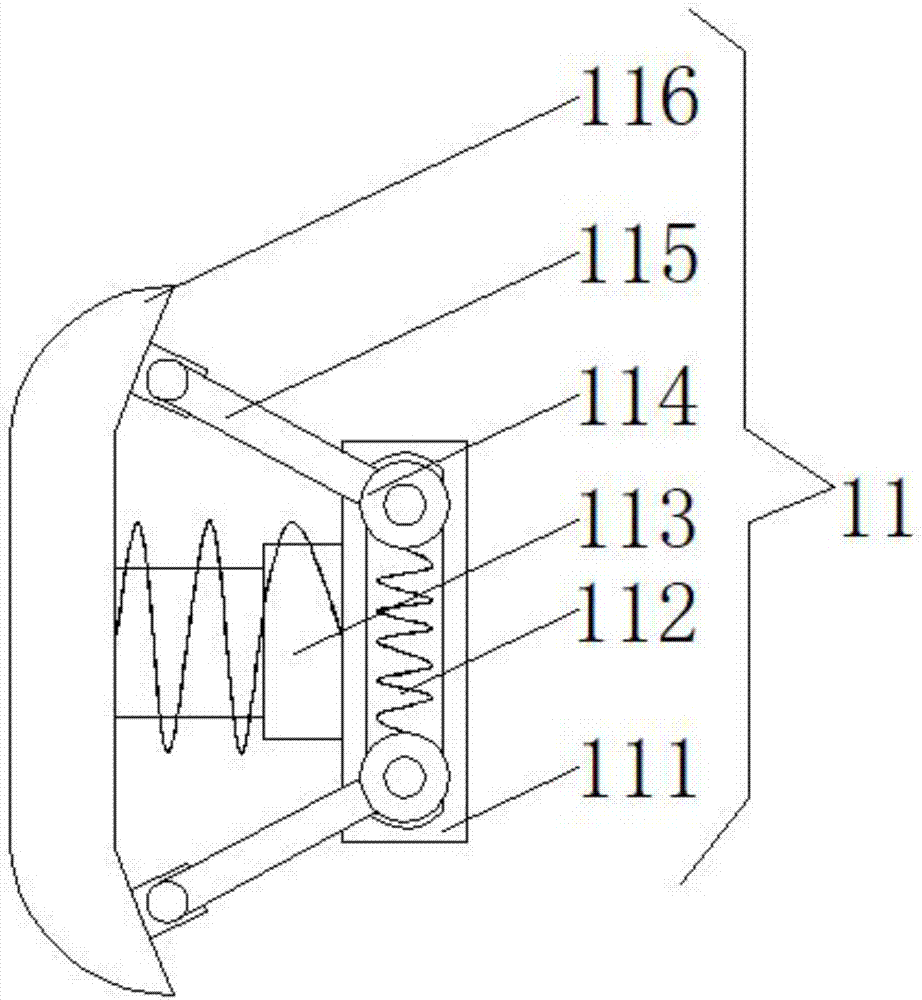

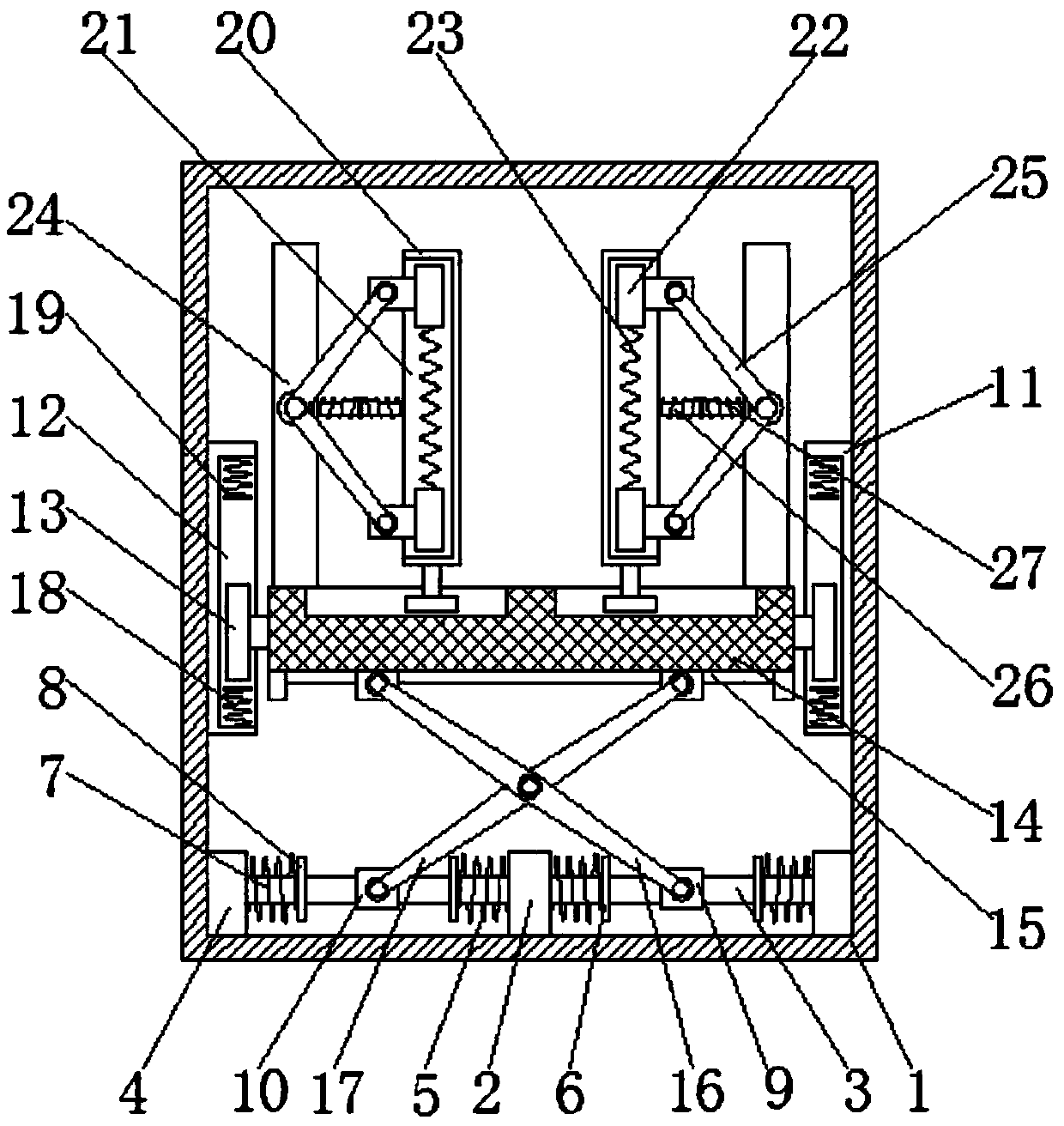

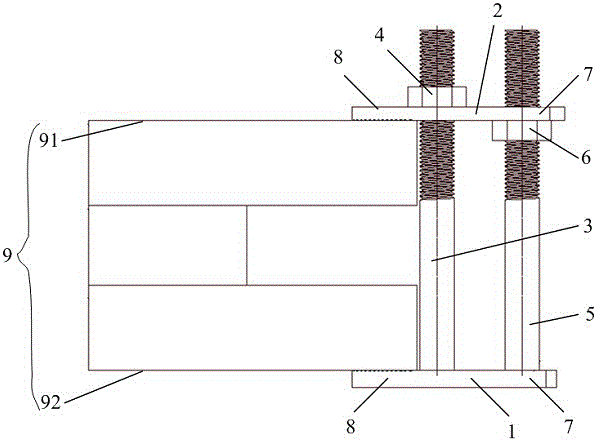

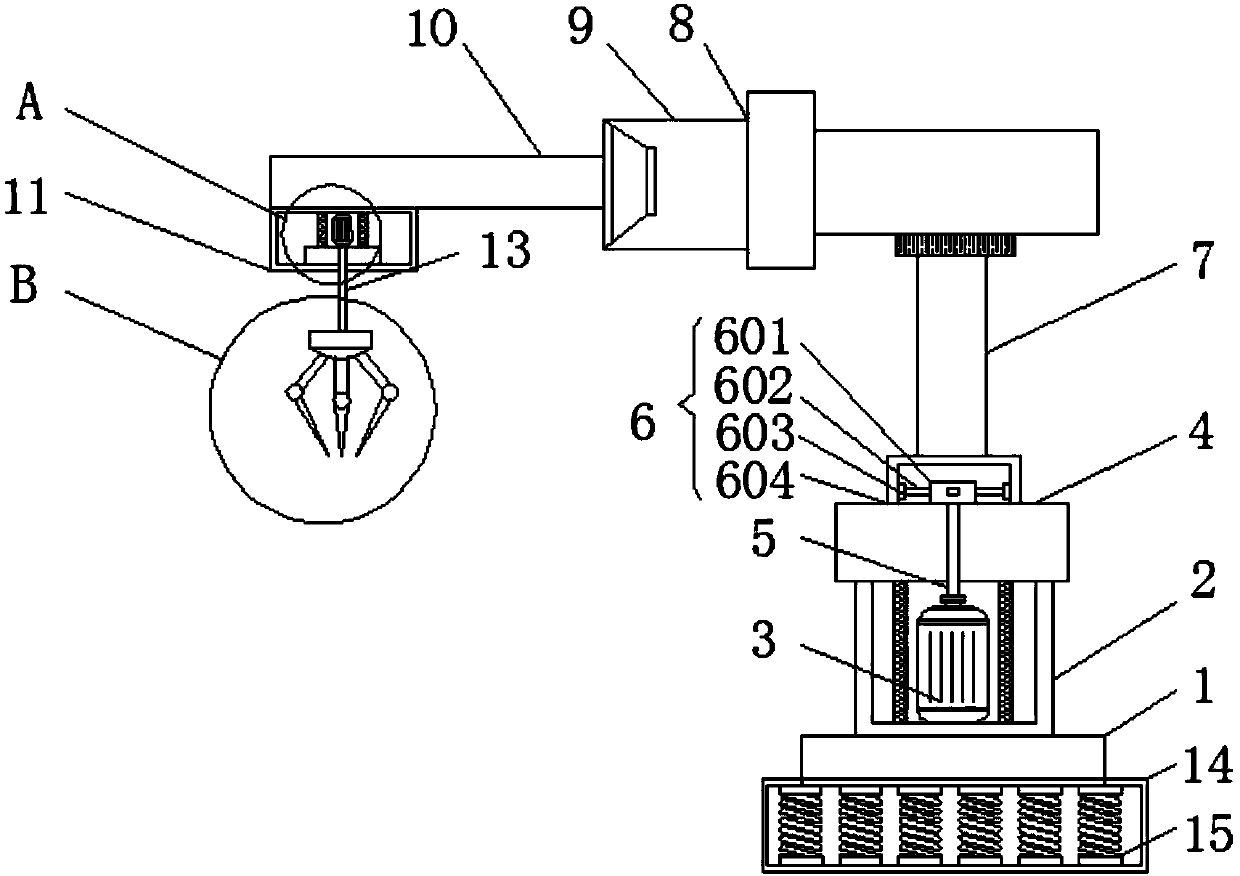

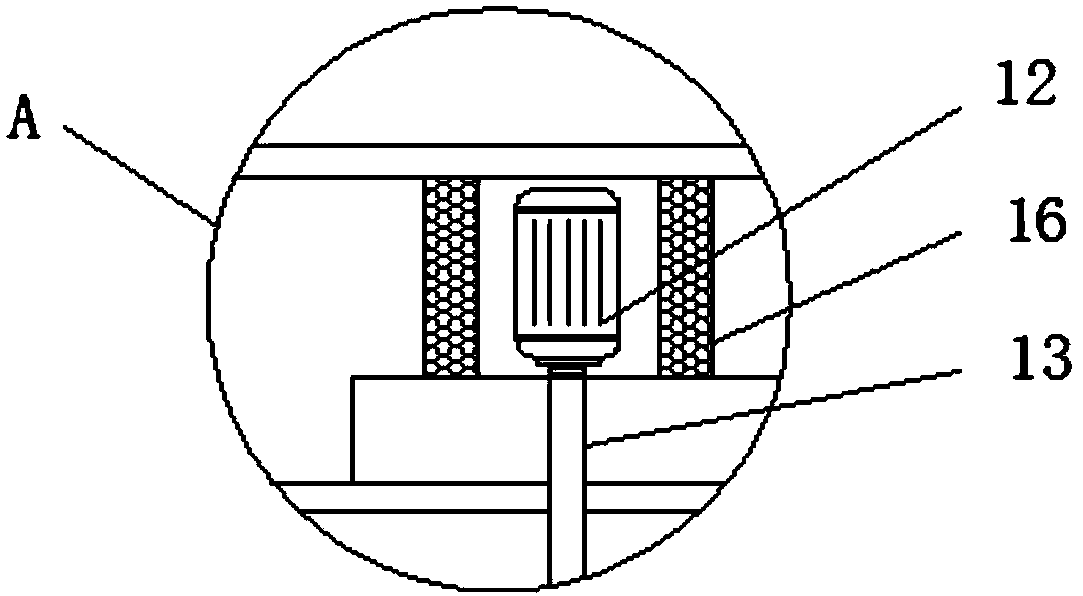

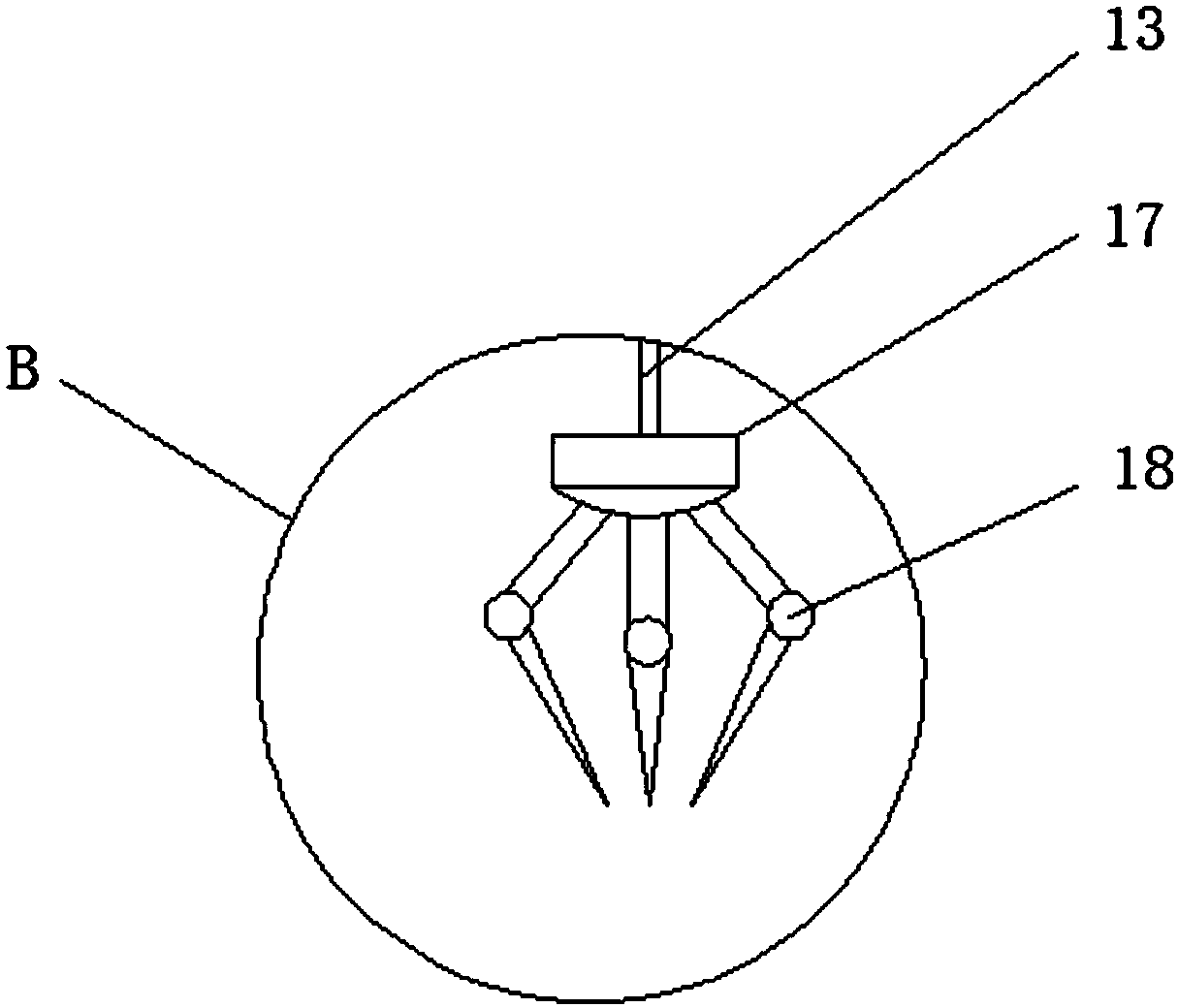

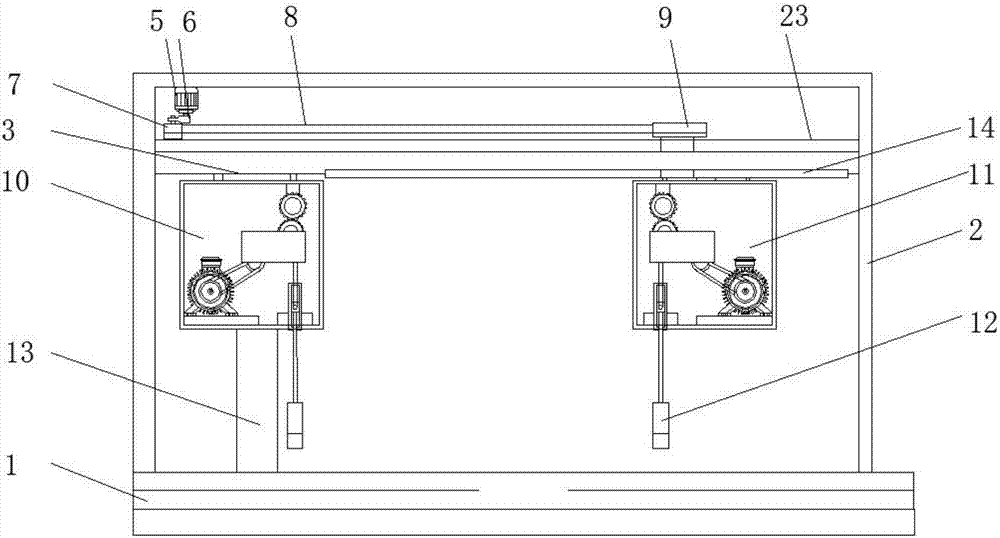

Damping clamping device of power equipment

InactiveCN107257093ATo achieve the purpose of shock absorptionAvoid damageAnti-seismic devicesSubstation/switching arrangement boards/panels/desksPower equipmentEngineering

The invention discloses a shock-absorbing clamping device for electric equipment, which comprises an outer frame, a bottom frame is fixedly connected to both sides of the bottom of the inner wall of the outer frame, and a sliding head is slidably connected to the surface of the bottom frame through a chute. A first spring is fixedly connected between one side of the slider and one side of the inner wall of the bottom frame, and the surface of the slider is rotatably connected to a connecting rod, and the end of the connecting rod away from the slider is rotatably connected to a top seat, and the top of the top seat is fixed A supporting frame is connected, and the invention relates to the technical field of electric equipment. The shock-absorbing clamping device of the power equipment achieves the purpose of shock-absorbing the power equipment, prevents the damage of the power equipment in the use project, prolongs the service life of the power equipment, prevents the power equipment from sliding during use, and avoids the damage of the power equipment The drop can avoid unnecessary waste, can adapt to the size of different electrical equipment, increase the practicability of the device, and protect electrical equipment more comprehensively.

Owner:方敏

Safe lithium battery transportation device facilitating taking and putting of lithium batteries

ActiveCN107380659AEasy accessReduce laborRigid containersInternal fittingsEngineeringLithium battery

The invention discloses a safe lithium battery transportation device facilitating taking and putting of lithium batteries and relates to the technical field of lithium batteries. The safe lithium battery transportation device comprises an outer frame. The two sides of the bottom of the inner wall of the outer frame are rotationally connected with lead screws correspondingly through a base; the two sides of the surface of each lead screw are connected with moving blocks in a threaded mode correspondingly; the tops of the moving blocks are rotationally connected with a supporting plate through connecting rods correspondingly; the two sides of the top of the supporting plate are both fixedly connected with vertical plates; the opposite sides of the two vertical plates are directly and slidably connected with a pushing plate; the two sides of the top of the pushing plate are both rotationally connected with rotating rods; one ends of the rotating rods are rotationally connected with sliding blocks; and first springs are fixedly connected between one sides of the sliding blocks and one sides of the vertical plates. According to the safe lithium battery transportation device facilitating taking and putting of the lithium batteries, the device can rise and fall, taking and putting of the lithium batteries are facilitated so that people can conveniently use the lithium batteries, the labor amount of workers is decreased, the lithium batteries are prevented from being damaged in the transportation process, the property loss is avoided, and the practicability of the device is improved.

Owner:合肥青鸾新能源科技有限公司

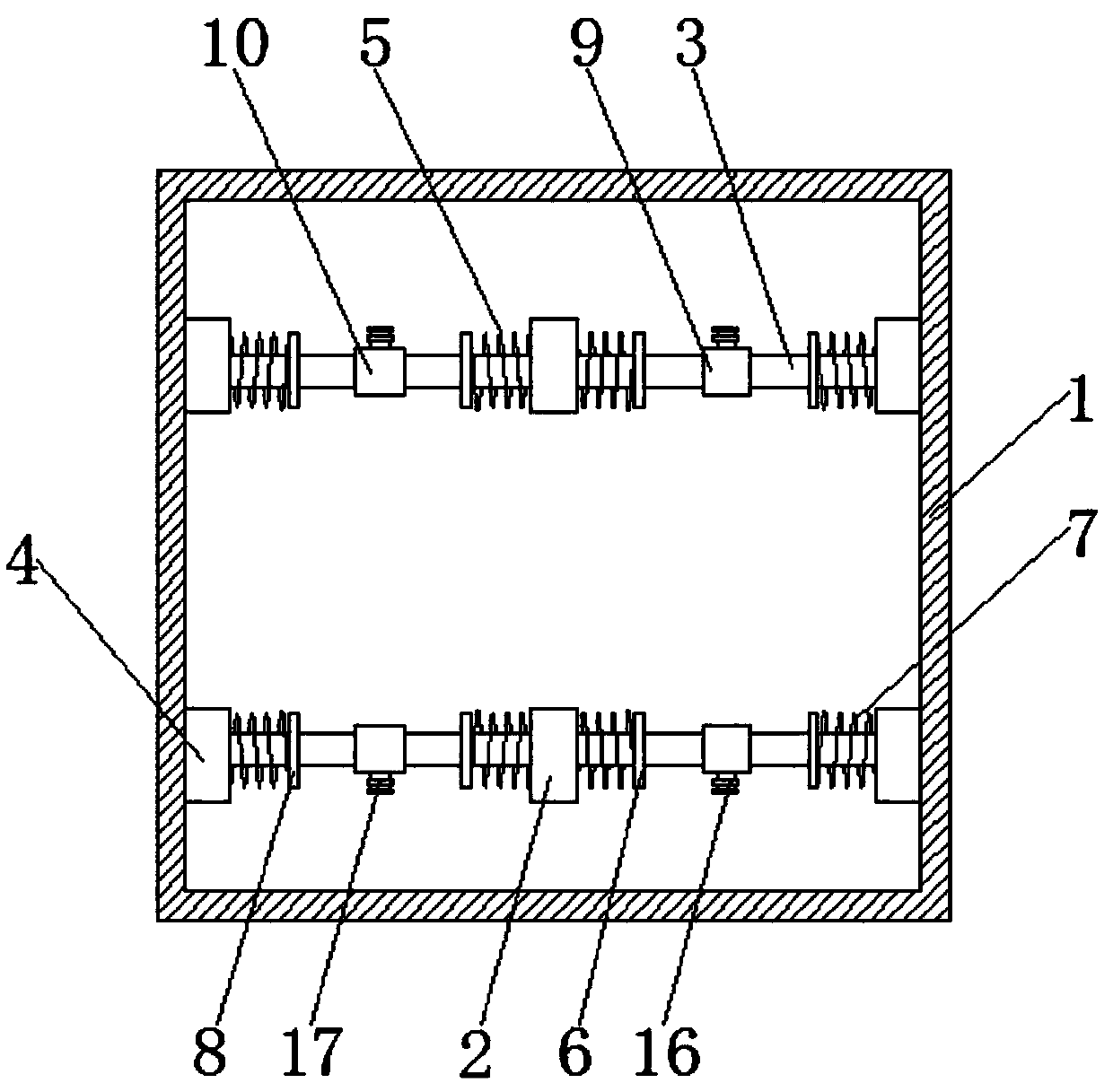

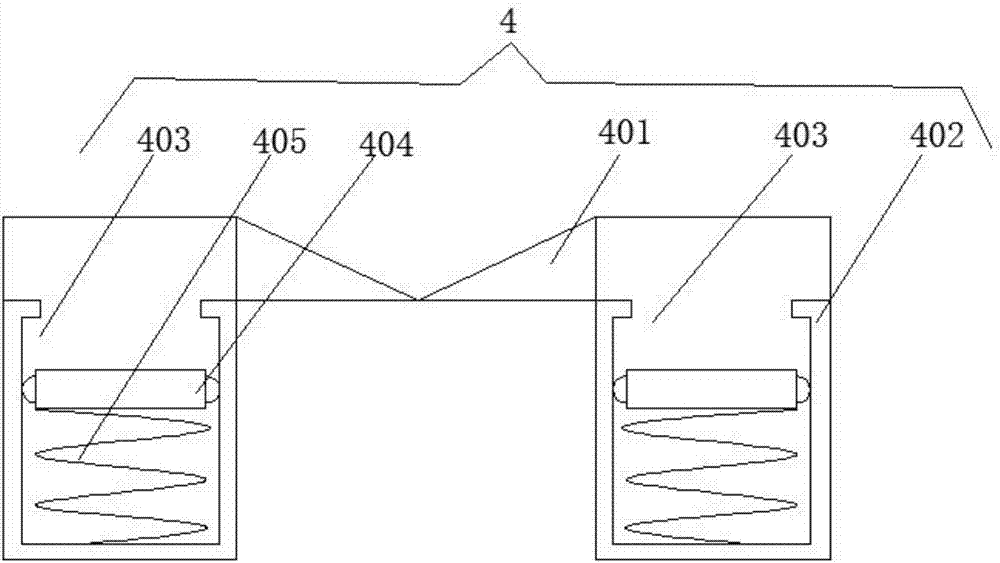

Damping and clamping device for electrical equipment

ActiveCN107613685ATo achieve the purpose of shock absorptionLower sales profitCasings/cabinets/drawers detailsElectrical devicesEngineering

The invention discloses a damping and clamping device for electrical equipment. The damping and clamping device comprises a box, wherein the bottom of an inner wall of the box is rotationally connected with a slide bar through a first fixed block; two ends of the slide bar are fixedly connected with both sides of the inner wall of the box through second fixed blocks respectively; both sides of thefirst fixed block are fixedly connected with first springs; one end which is far away from the first fixed block of each first spring is fixedly connected with a first baffle plate; the surface of afirst baffle plate center hole is in sliding connection with the surface of the slide bar; one side which is close to the first fixed block of each second fixed block is fixedly connected with a second spring; and one end which is far away from the second fixed blocks of each second spring is fixedly connected with a second baffle plate. The invention relates to the technical field of electrical equipment. Through adoption of the damping and clamping device for the electrical equipment, the aim of damping in the vertical direction of the electrical equipment is fulfilled, and damage to the electrical equipment and influence on final use and sale due to bumping of the electrical equipment caused by bad transportation road surfaces are avoided.

Owner:广西华煜联创电气科技有限公司

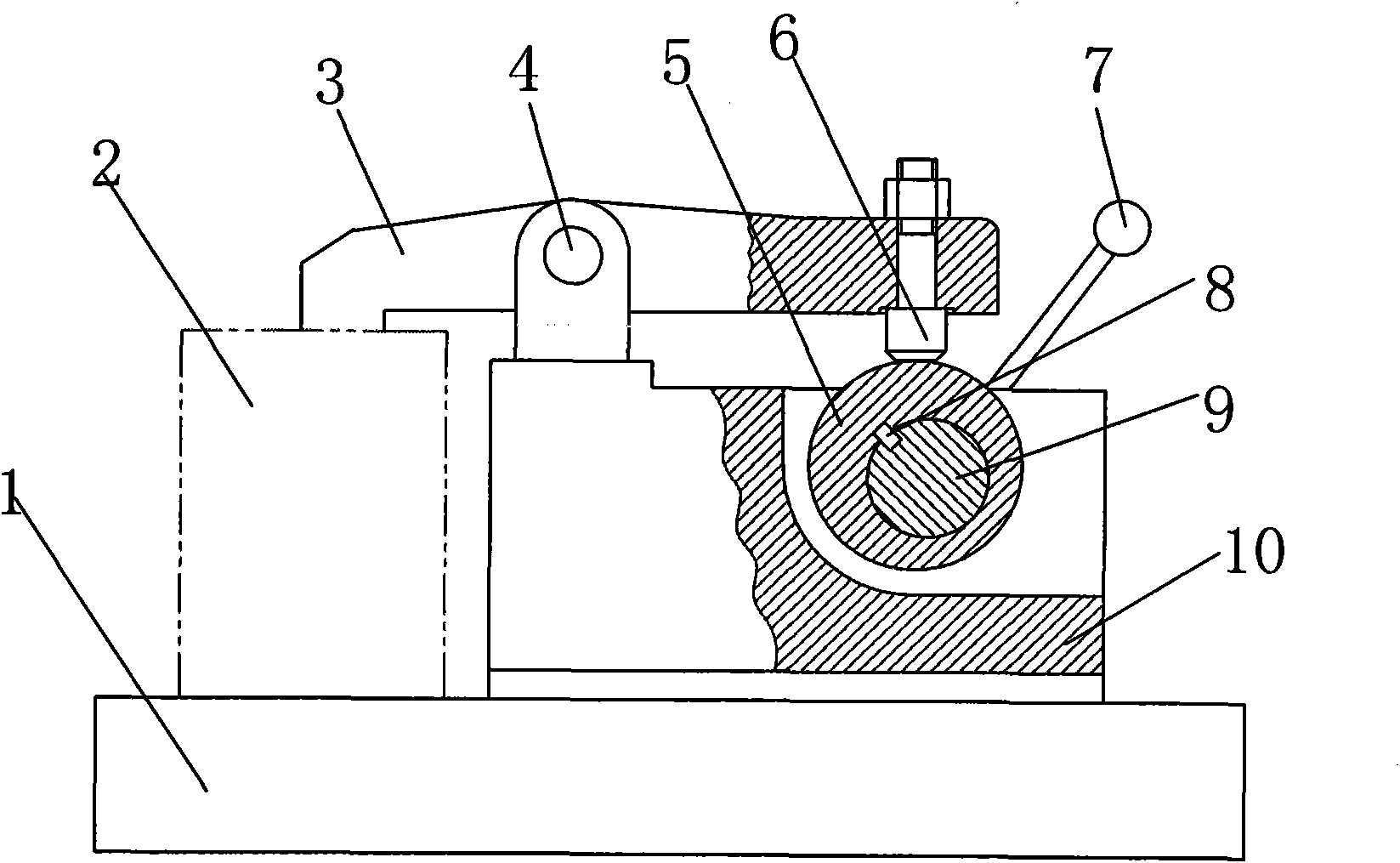

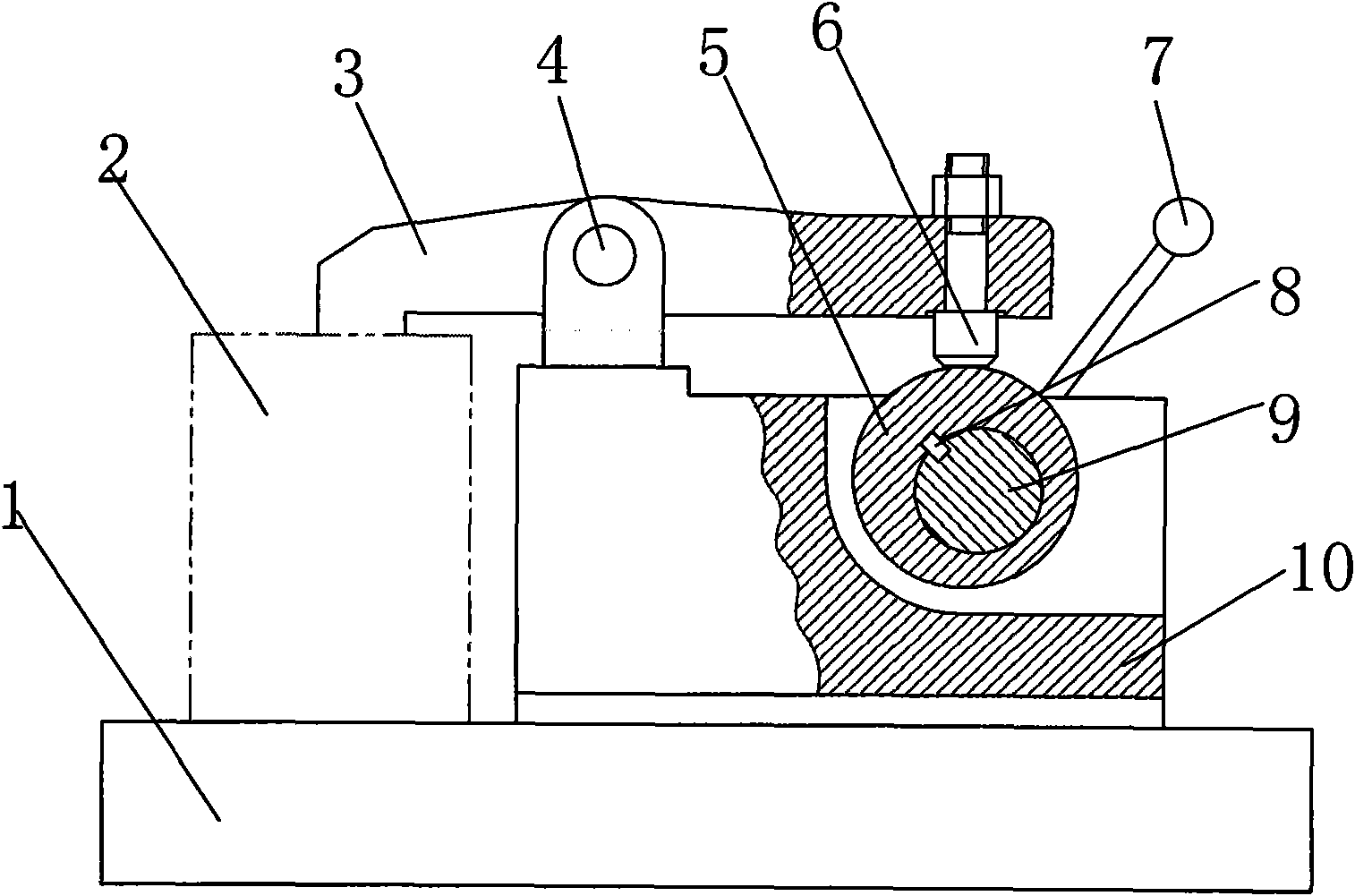

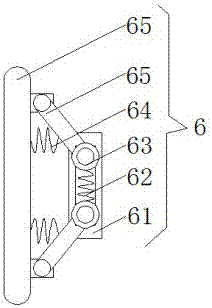

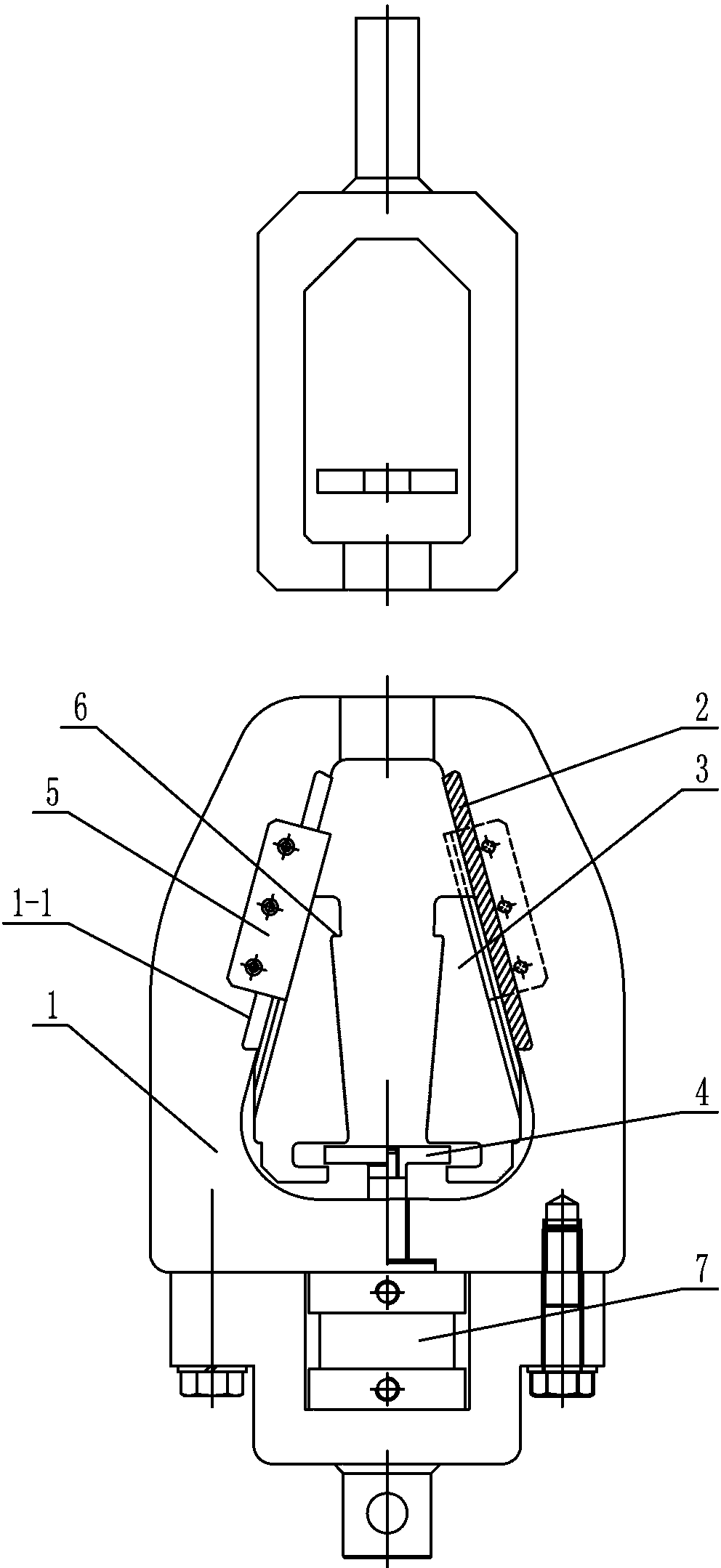

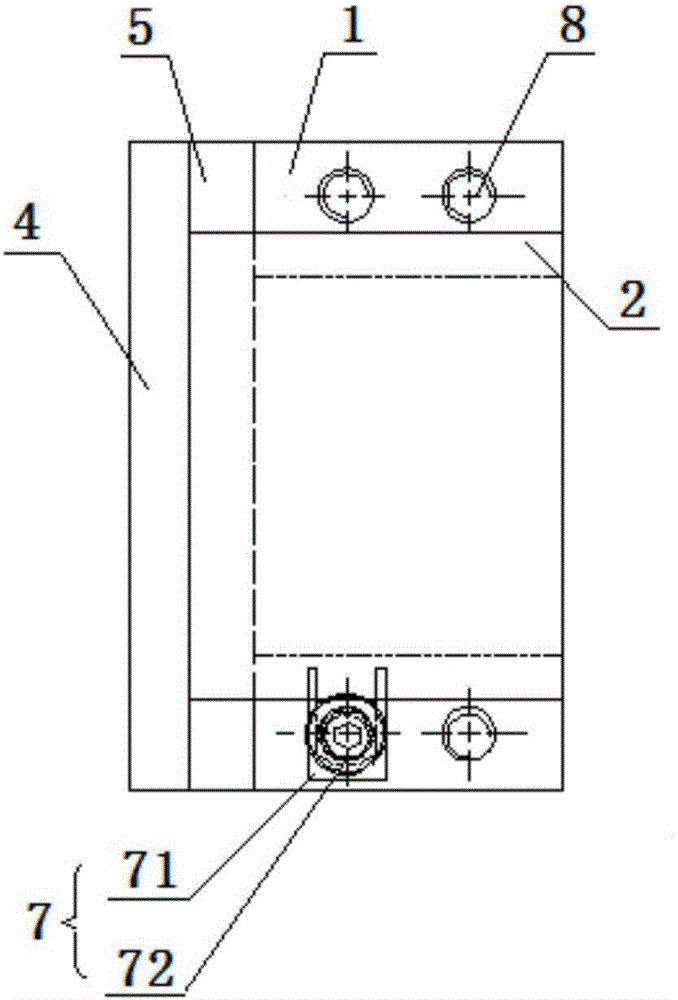

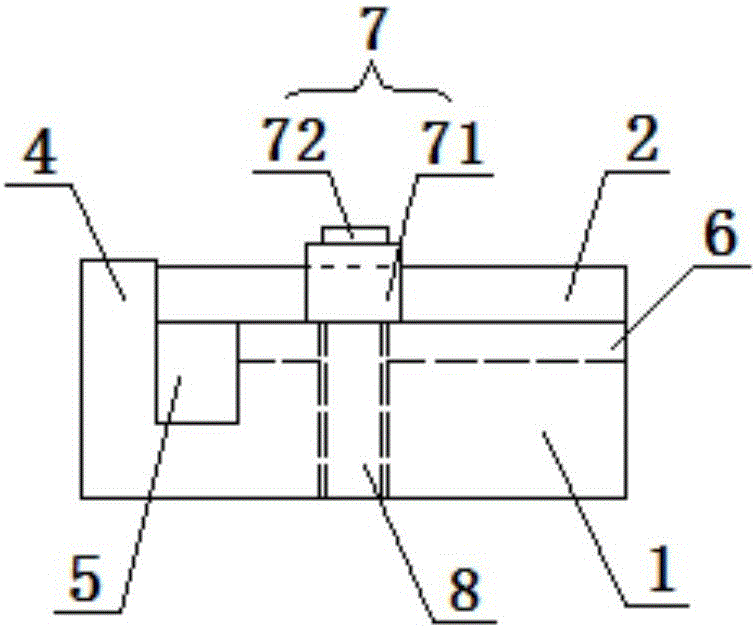

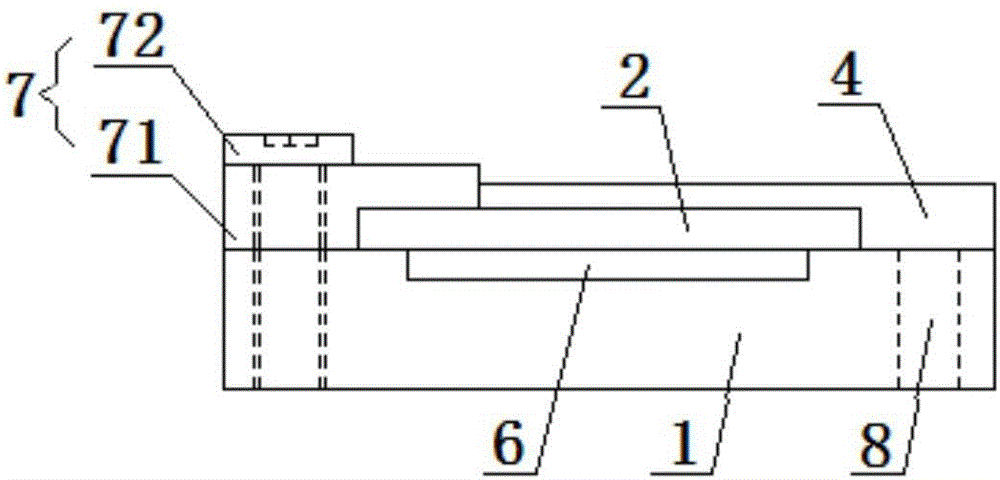

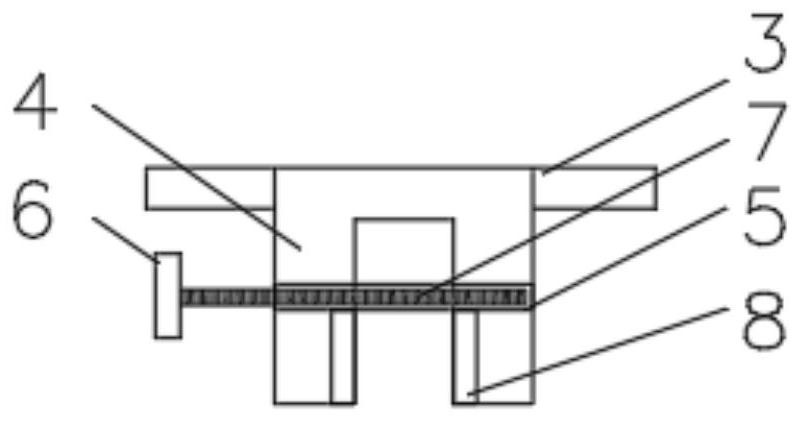

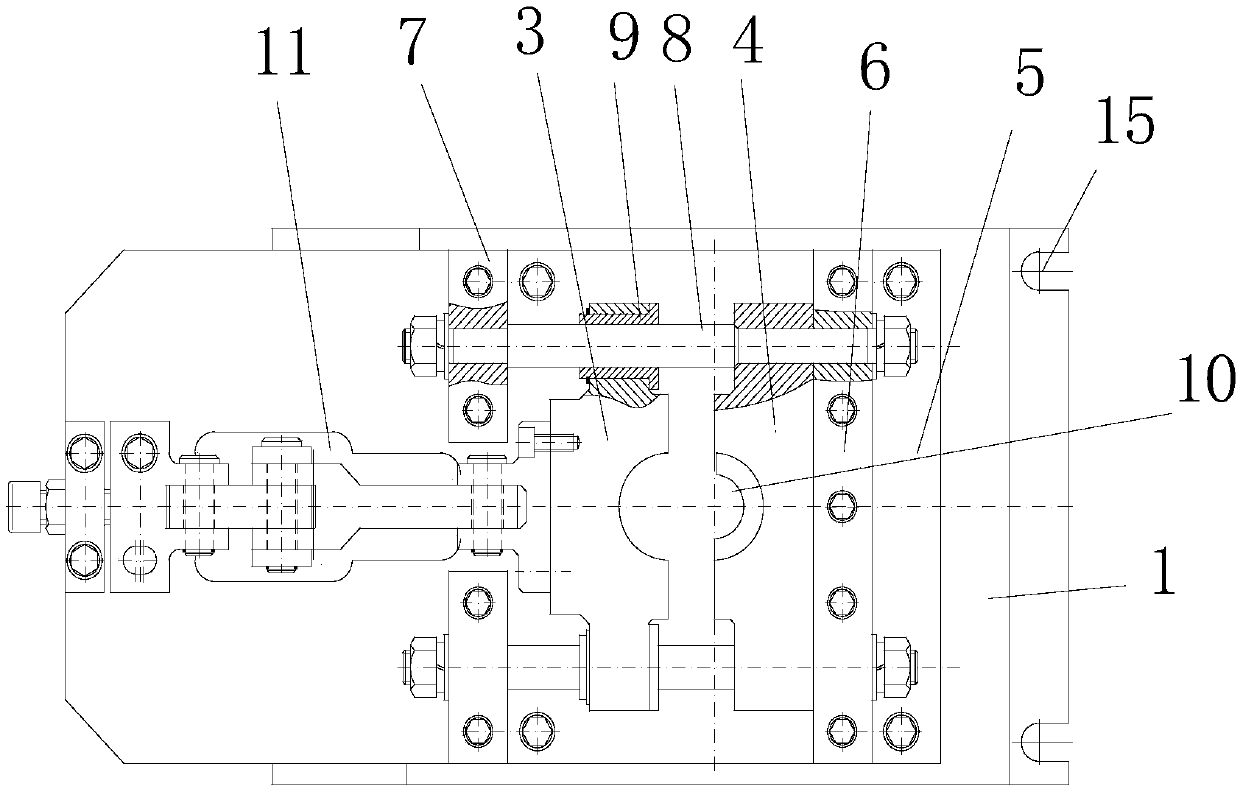

Quick clamping device of cam

InactiveCN102029580AQuick clampingEasy clampingWork holdersPositioning apparatusSoftware engineeringCam

The invention discloses a quick clamping device of a cam, comprising a base [1], a fixed block [10], a pressure lever [3] and a cam device, wherein the fixed block [10] is fixed on the base [1]; the pressure lever [3] is hinged at one end of the fixed block [10] to from a left end and a right end; the cam device is connected with the other end of the fixed block [10] and comprises a pressure shaft [5], a rotating shaft [9] and a handle [7]; the pressure shaft [5] is provided with an eccentric hole the diameter of which is matched with that of the rotating shaft [9]; the rotating shaft [9] is sleeved and fixed in the eccentric hole; two ends of the rotating shaft [9] are movably connected with the fixed block [10]; and the handle [7] is fixedly connected with the pressure shaft [5]. The invention can realize the quick clamping of the workpieces at high clamping efficiency.

Owner:蒋泽军

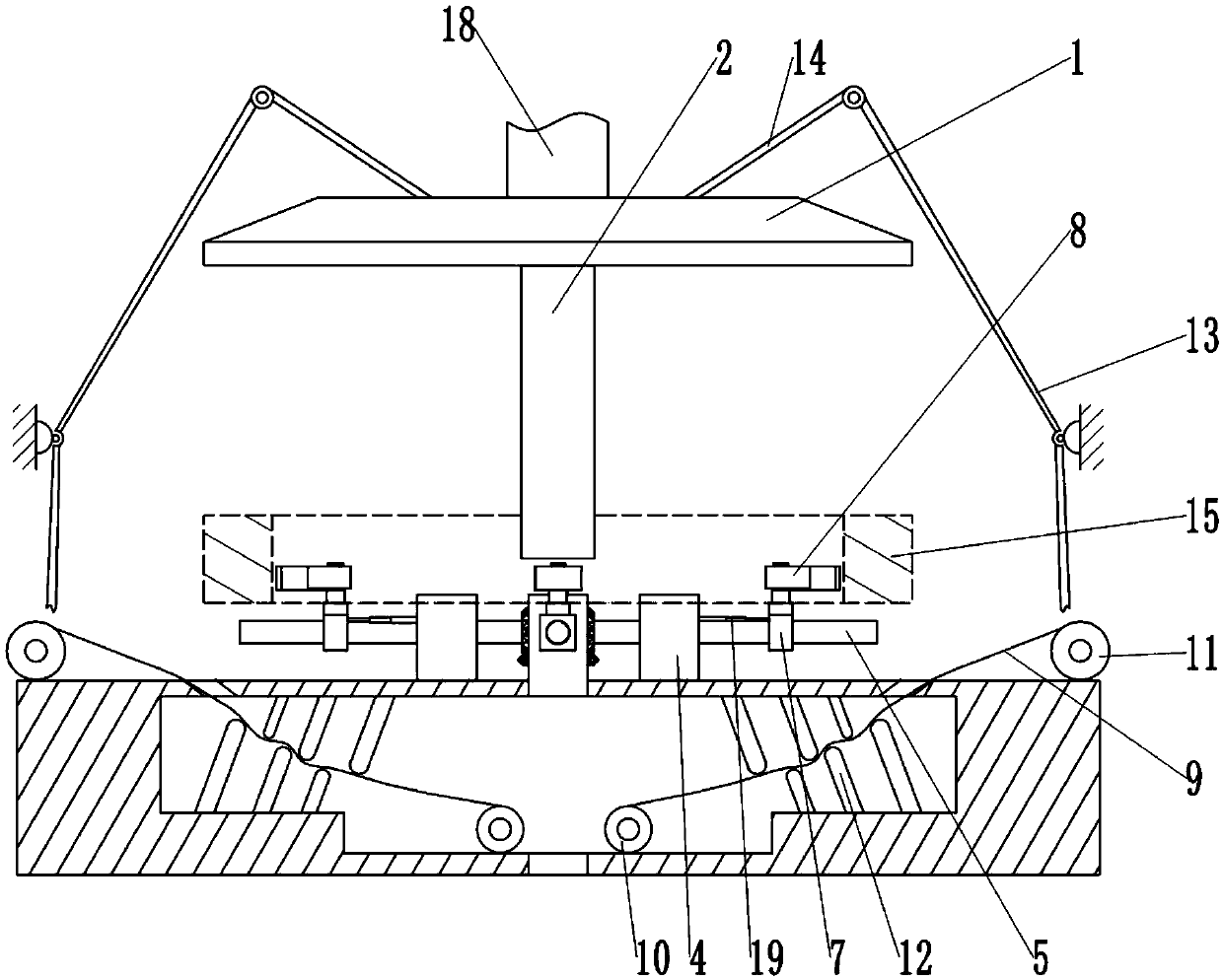

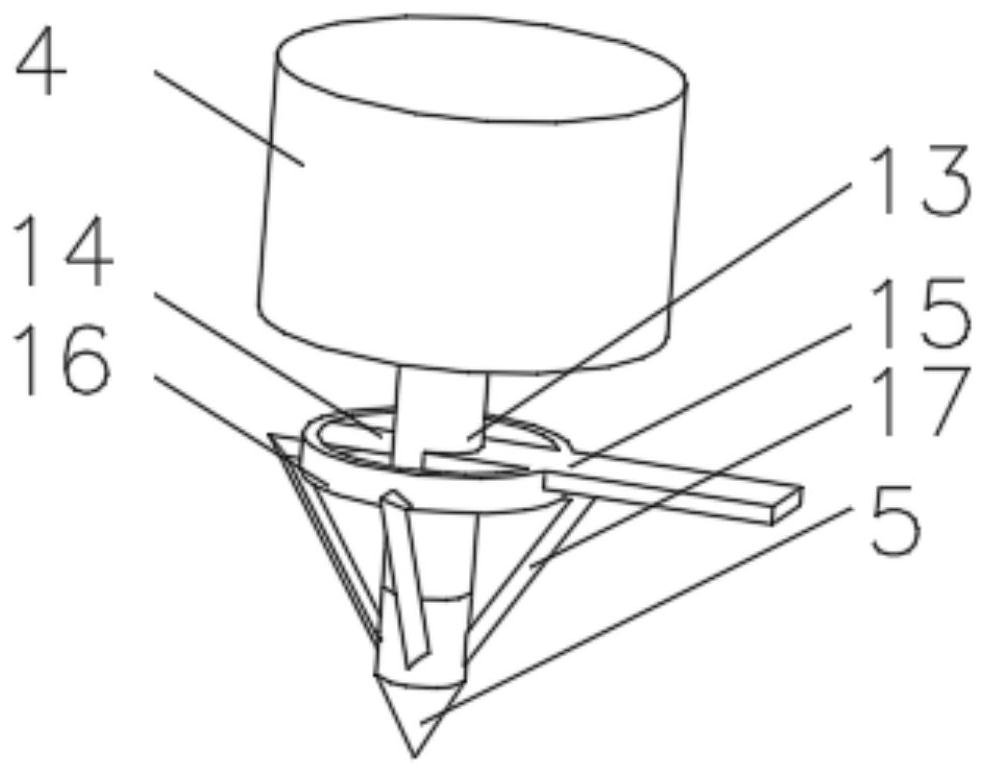

Handheld photographing rod convenient to mount

The invention discloses a handheld photographing rod convenient to mount and relates to the field of photographing rods. The handheld photographing rod comprises a bottom frame. The top of the bottom frame is slidably connected with a supporting rod. The top end of the supporting rod is fixedly connected with a top frame. A lead screw is rotationally connected between the two sides of the inner wall of the top frame through a fixed seat, and the two sides of the surface of the lead screw are both connected with moving blocks in a threaded mode. The tops of the moving blocks are fixedly connected with vertical rods. The top ends of the vertical rods penetrate through the top frame and extend out of the top frame. The ends, located outside the top frame, of the vertical rods are fixedly connected with clamping devices. According to the handheld photographing rod convenient to mount, a webcam is clamped, operation during fixing is simplified, the position of an outer frame can be adjusted, so that cameras of different sizes are fixed, the practicability of the handheld photographing rod is improved, the cameras are prevented from falling off and protected more comprehensively, damage to the cameras is avoided, and the cameras can be taken and placed conveniently and rapidly.

Owner:阜阳创启工艺品有限公司

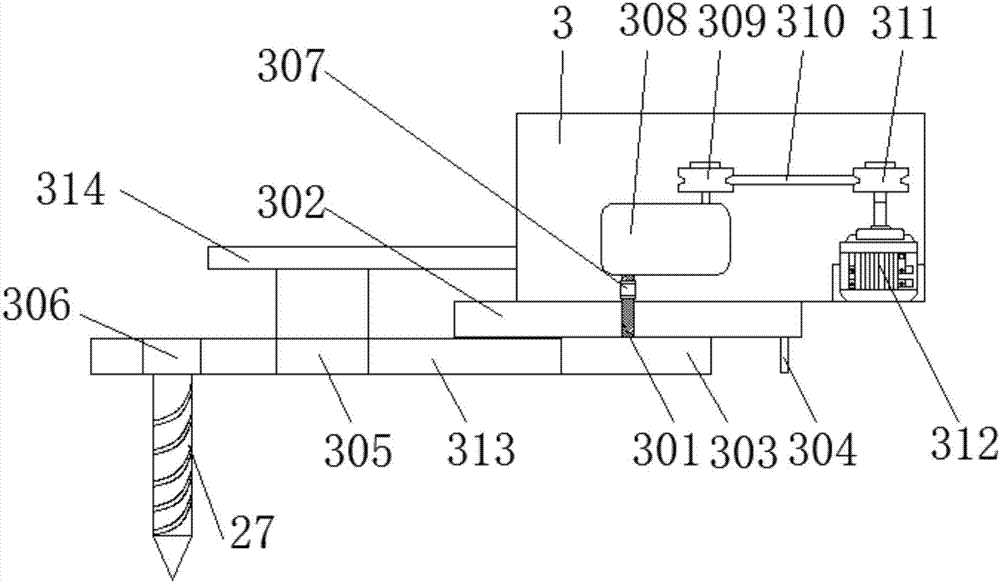

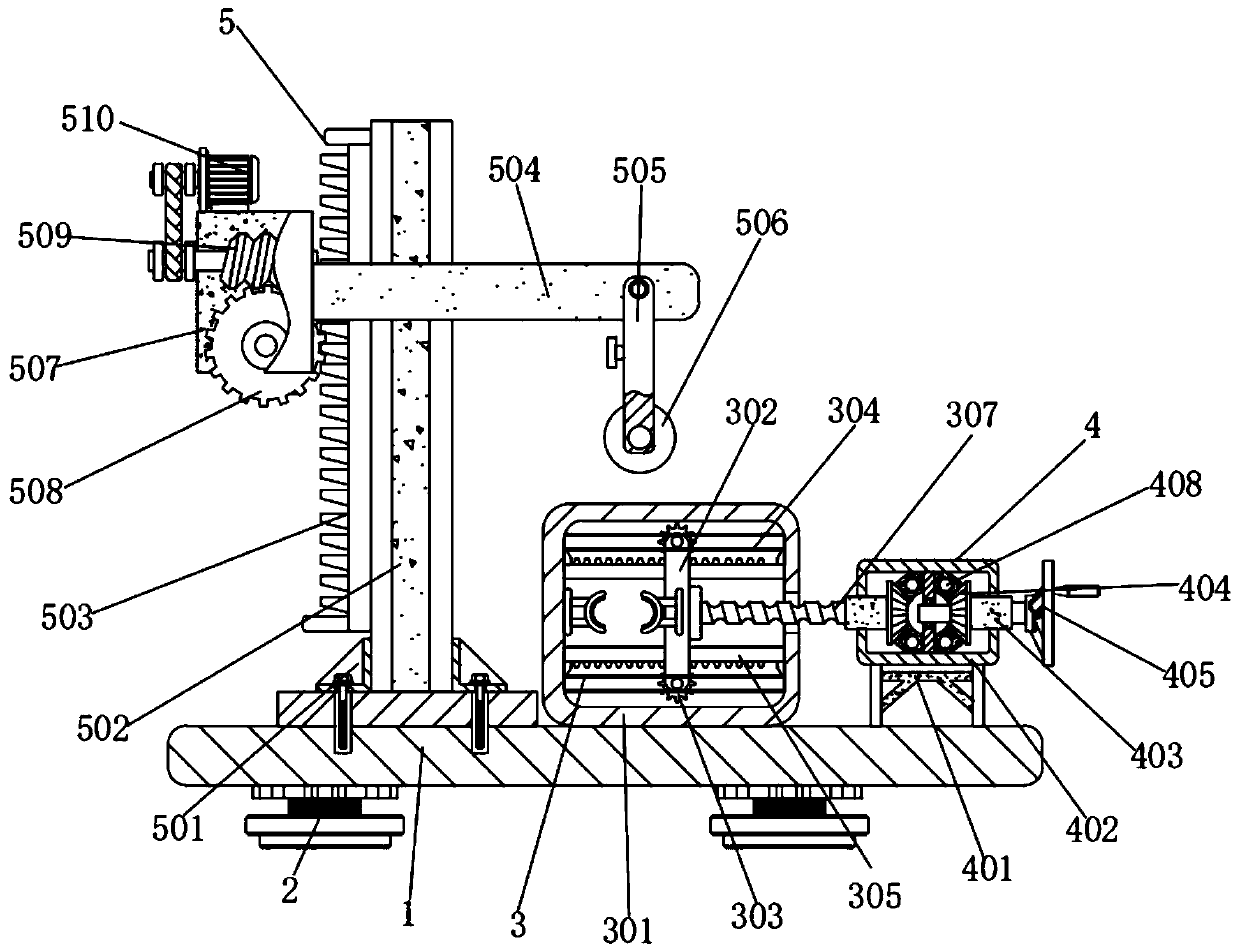

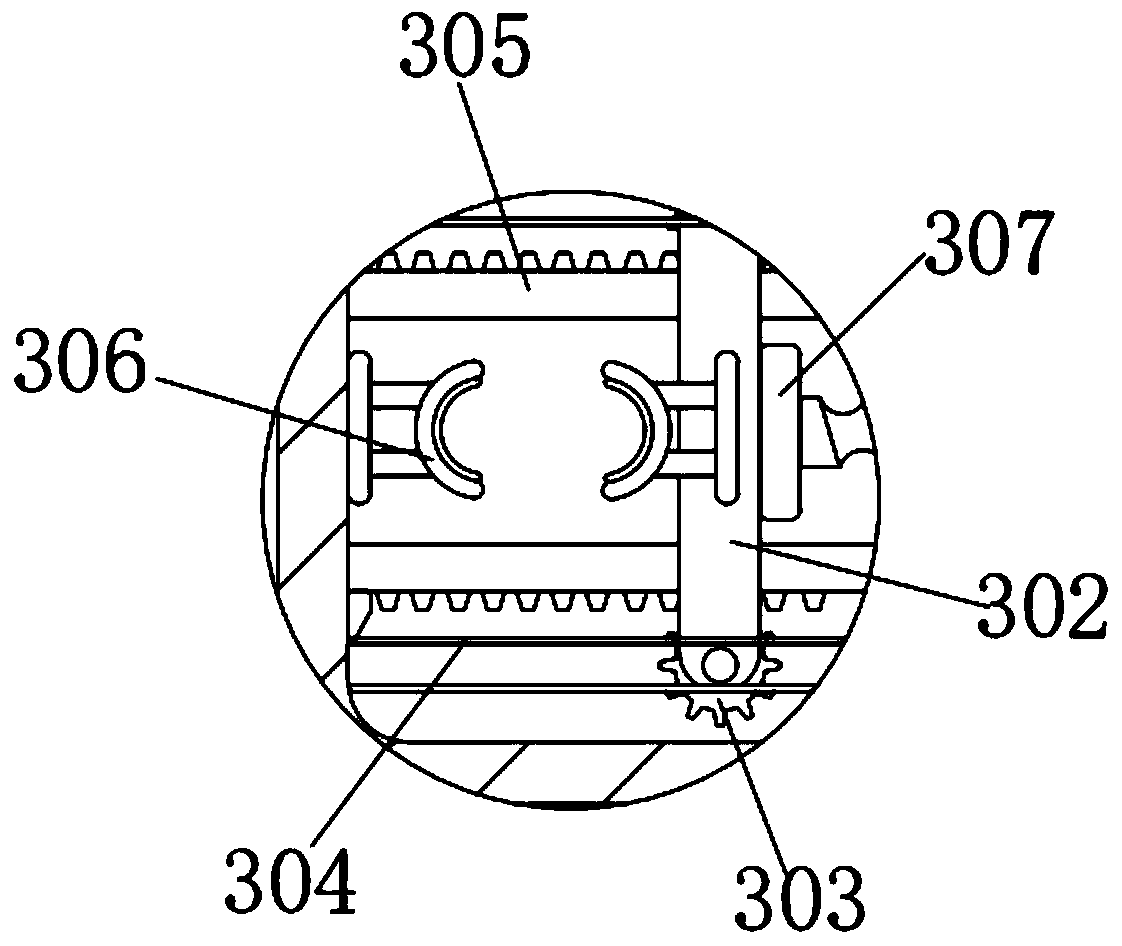

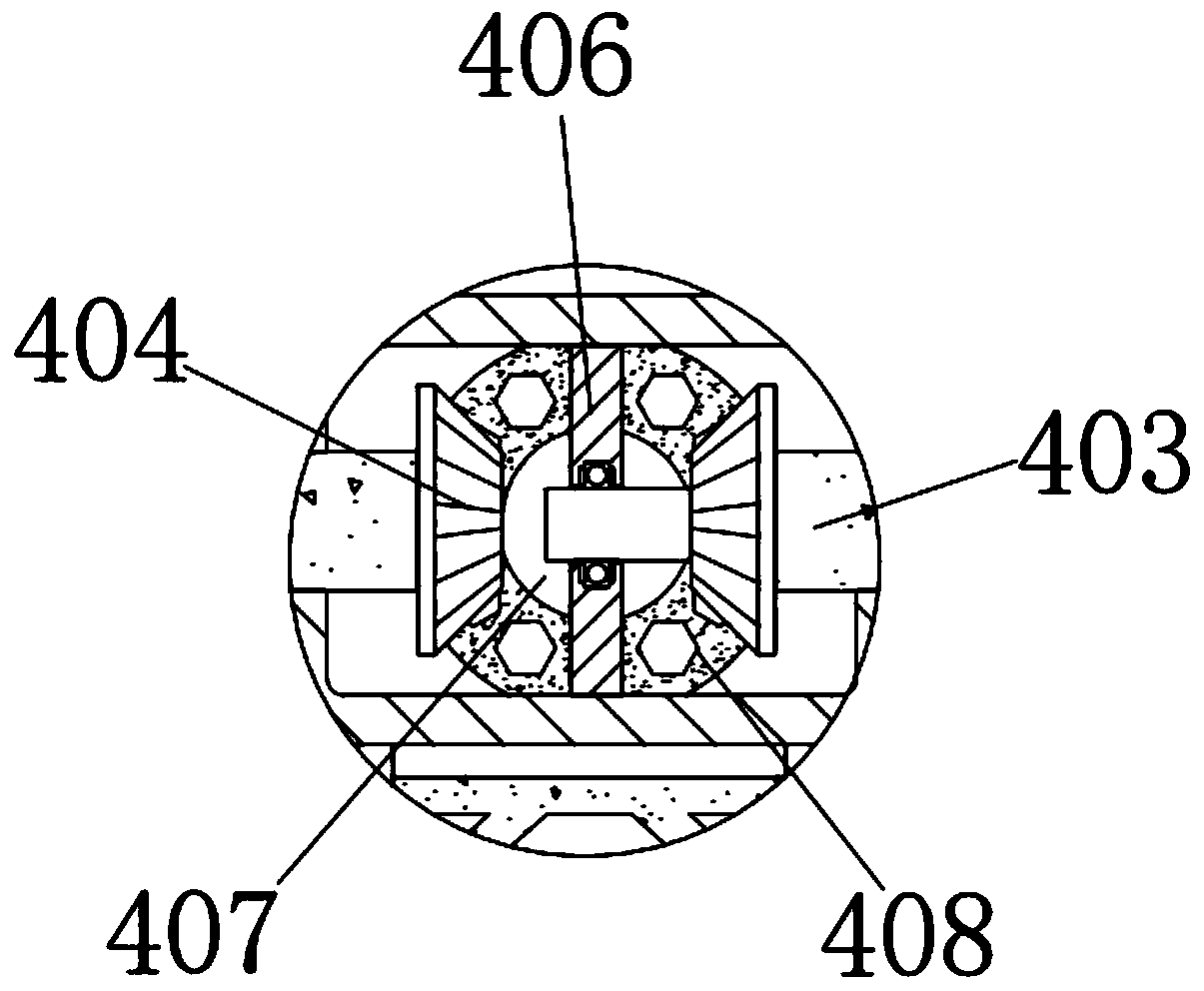

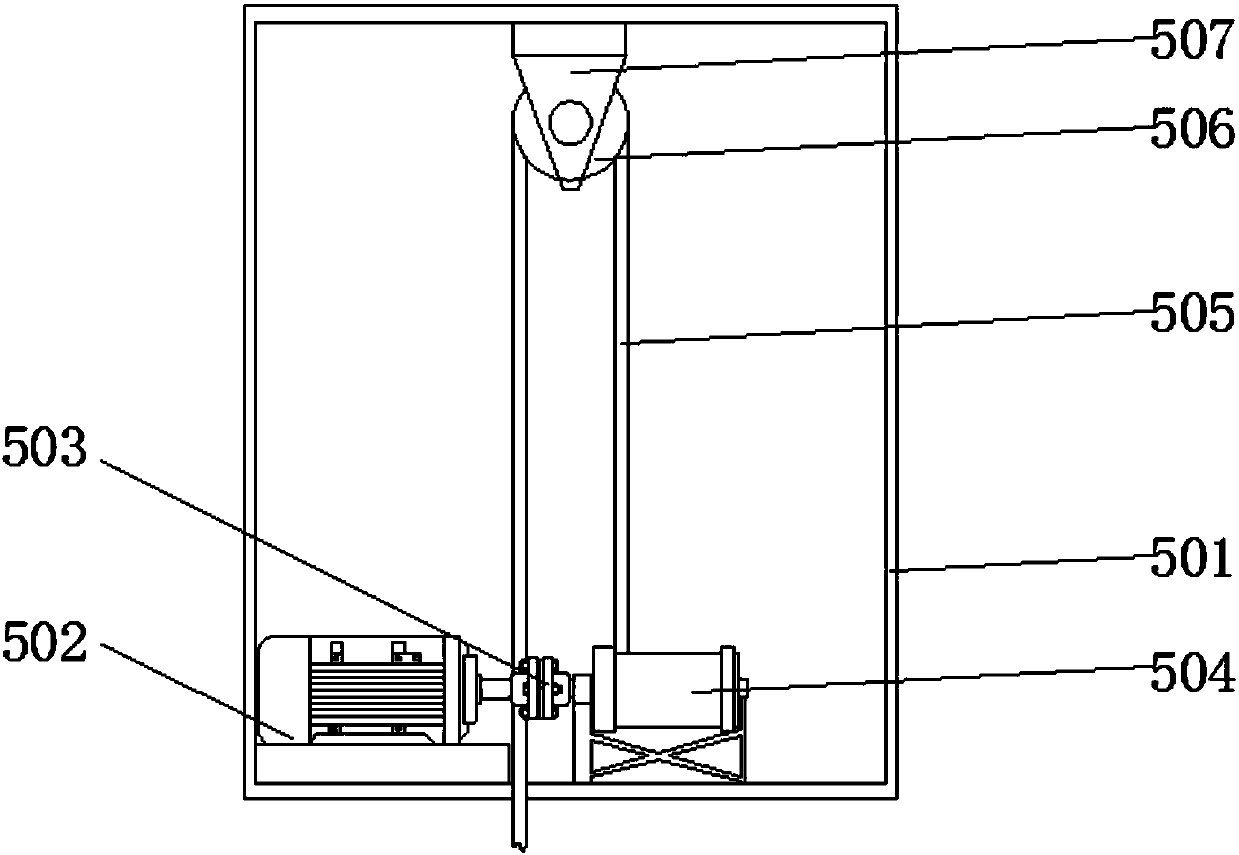

Portable efficient drilling machine

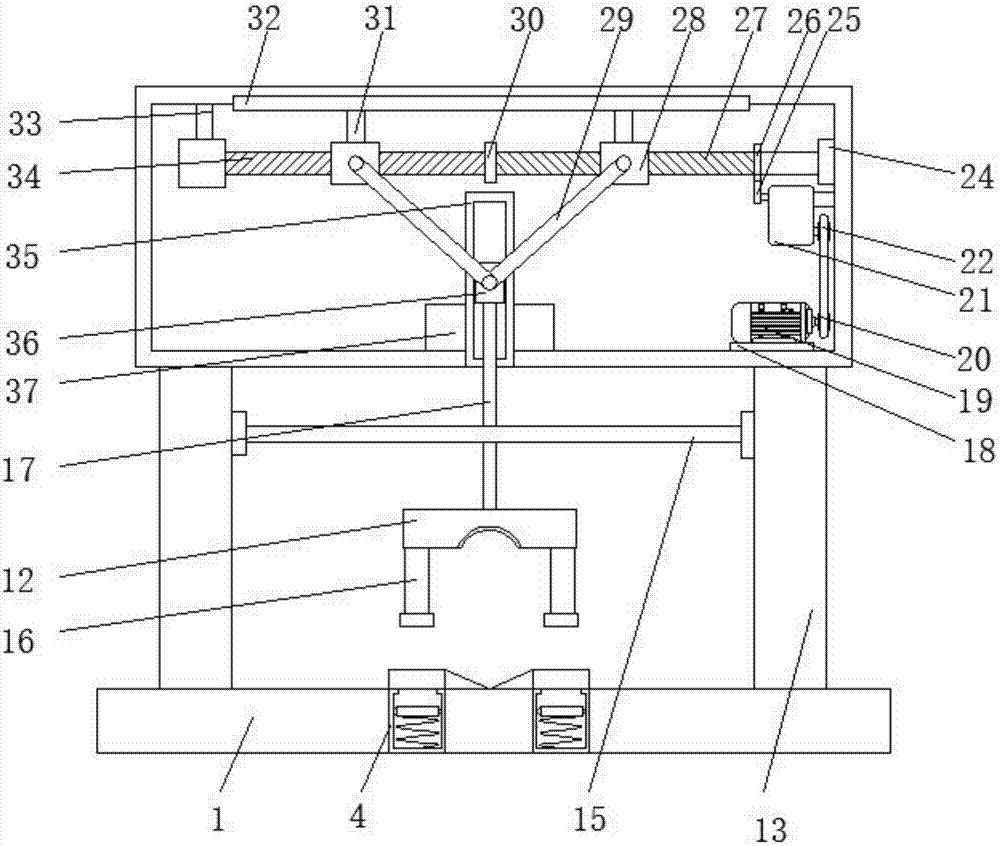

InactiveCN107322055ARealize moving up and downAchieve positioningBoring/drilling componentsBoring/drilling machinesEngineeringDrilling machines

The invention discloses a portable efficient drilling machine. The drilling machine comprises a bottom plate; a motor box is fixedly connected in the middle of the top of the bottom plate; a motor mounting platform is fixedly connected at the bottom of the inner wall of the motor box; a first motor is fixedly connected at the top of the motor mounting platform; an output shaft of the first motor is fixedly connected with a first conical wheel; the first conical wheel is connected with a second conical wheel in a meshing manner; the second conical wheel is fixedly connected with a threaded shaft through a flat key; the outer wall of the threaded shaft is sleeved with a sliding block; and a fastening screw is arranged in the middle of one side of the sliding block. The invention relates to the technical field of engineering machinery. With the portable efficient drilling machine, the purpose that the drilling machine is adjustable vertically and horizontally, drill bits are replaceable, workpieces at different heights on a workbench can be perforated, and workpieces with relatively large horizontal sizes can be machined are achieved, the purpose of changing the bits quickly is achieved, the high working efficiency is guaranteed, light rays required during working can be supplemented, and the working quality can be guaranteed.

Owner:HUZHOU WUXING HUALONG MACHINERY CO LTD

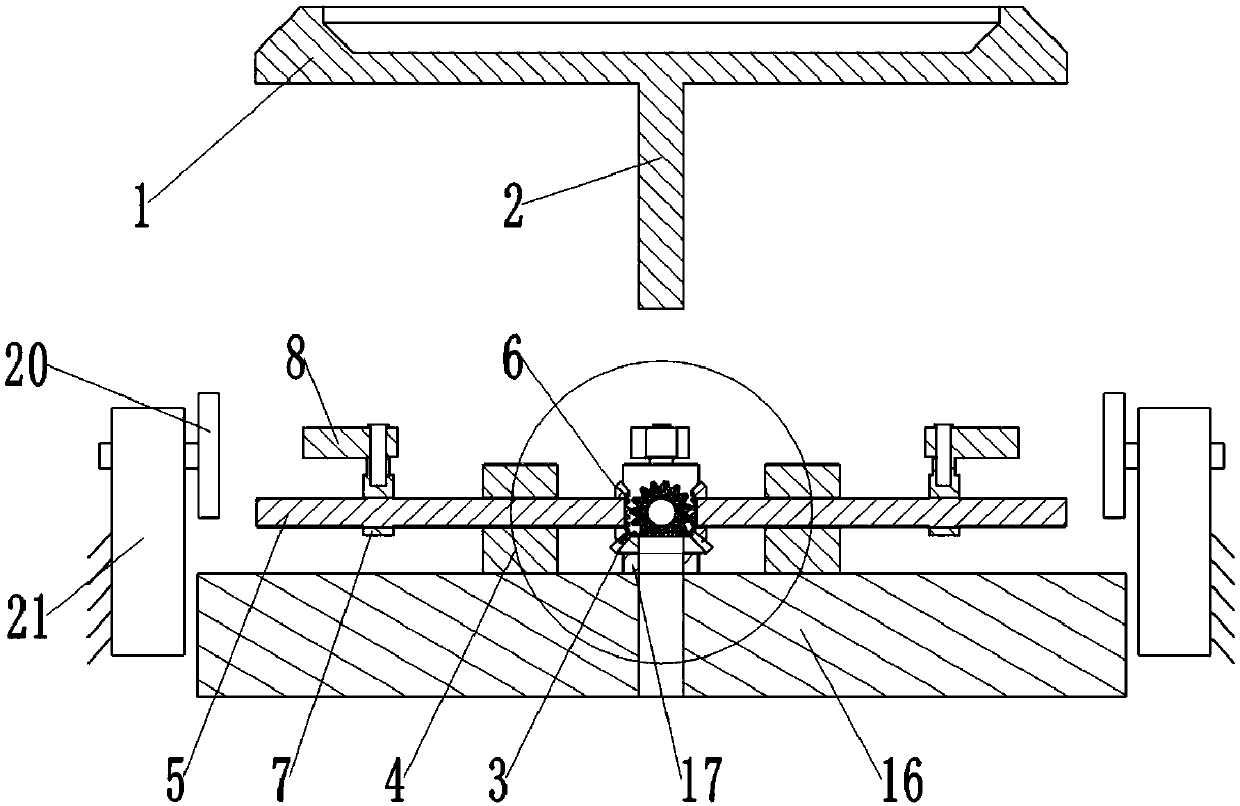

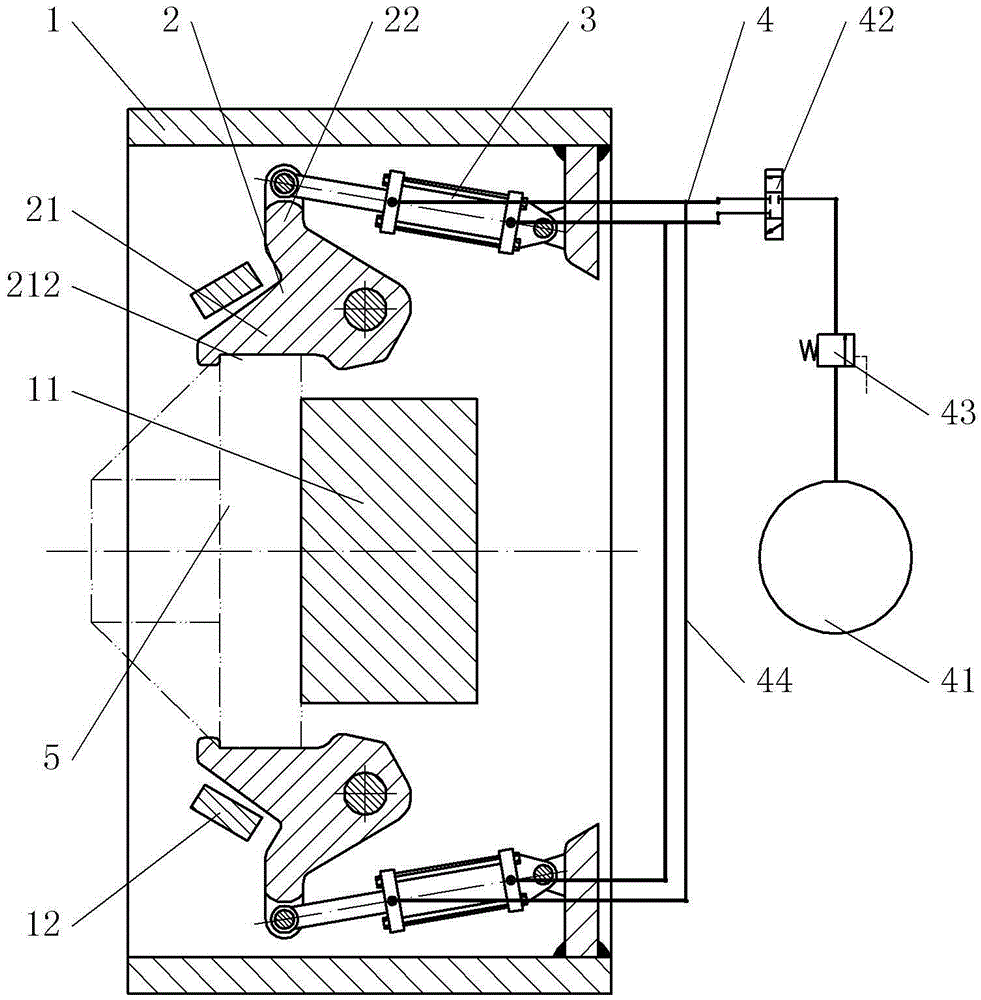

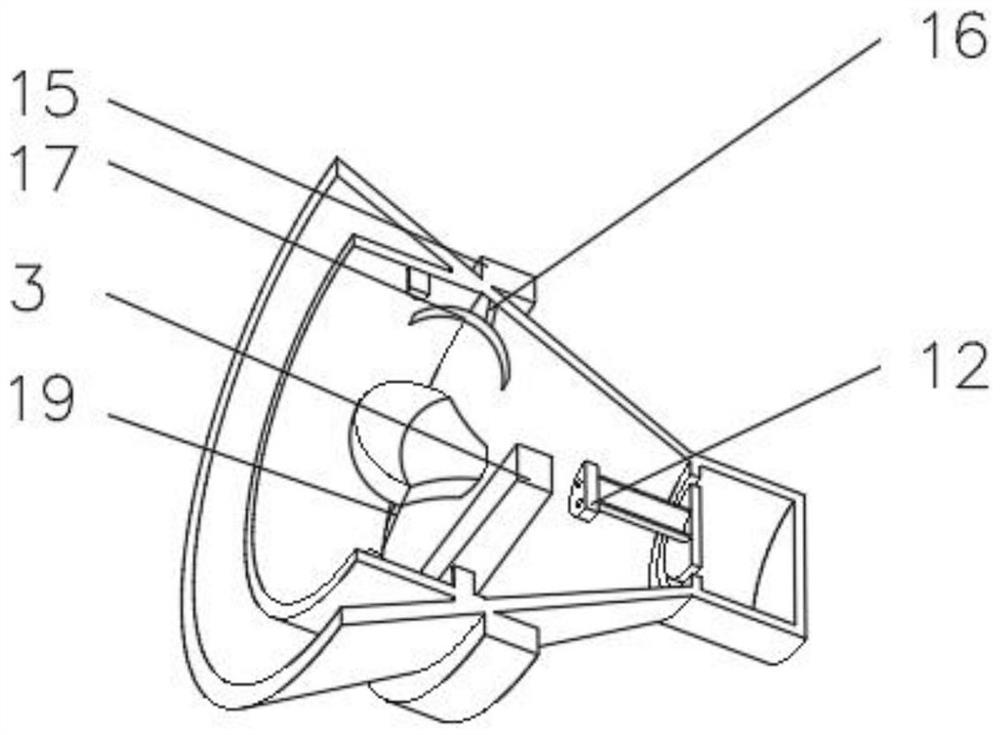

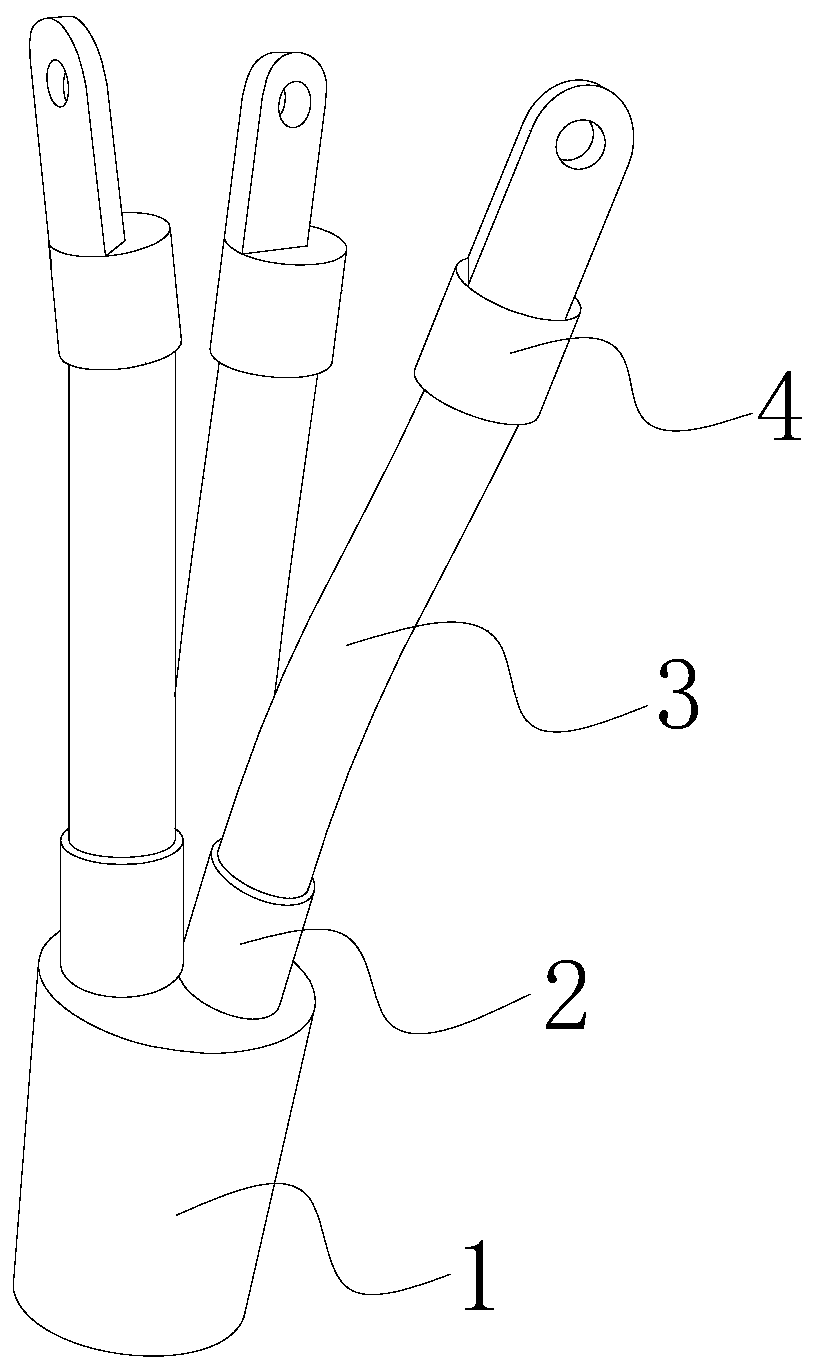

Automobile hub grinding device

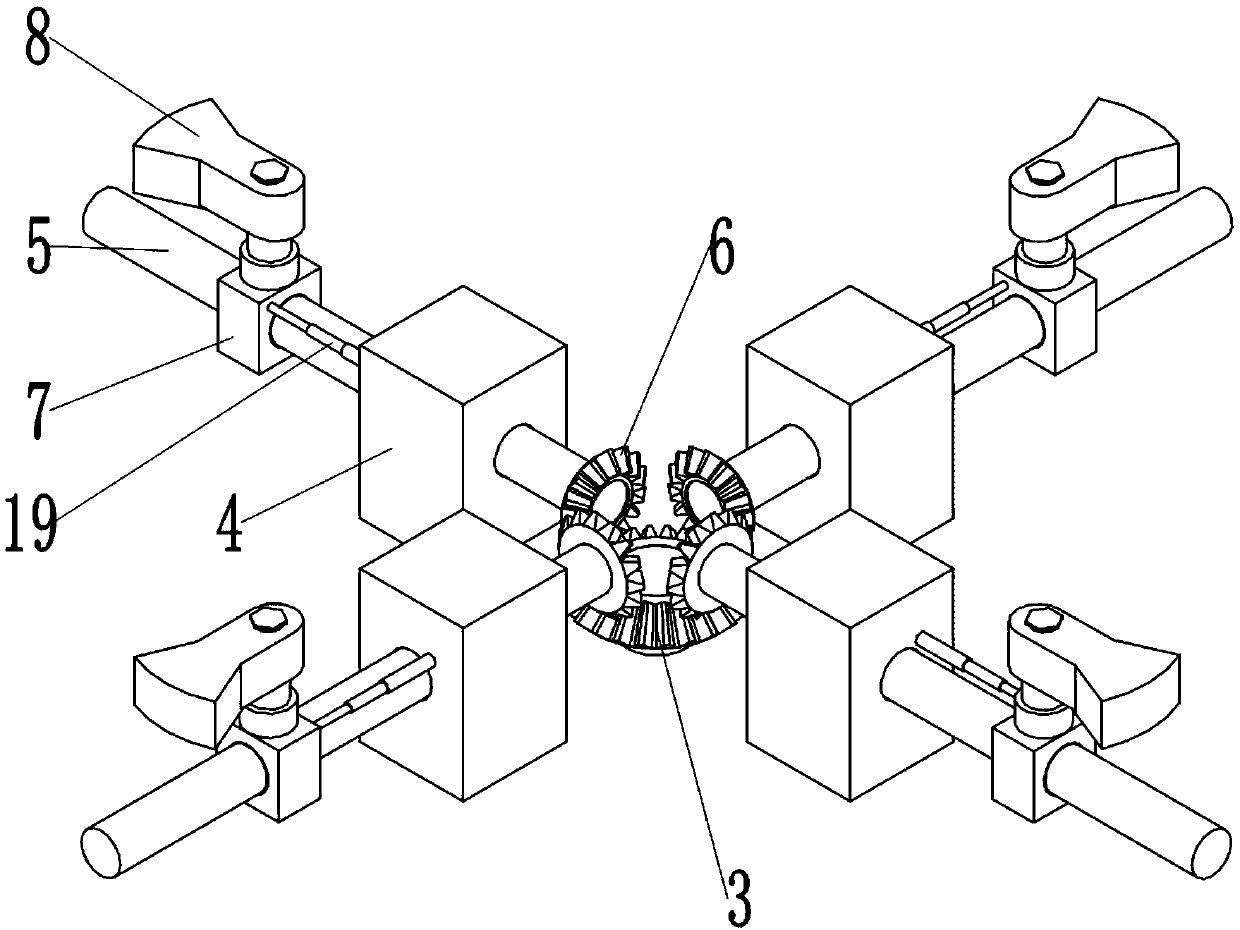

InactiveCN109623571ATo achieve the purpose of limitingTo achieve the purpose of clampingGrinding drivesGrinding machinesGear wheelDrive shaft

The invention relates to the technical field of devices used for grinding or polishing, and specifically discloses an automobile hub grinding device. The automobile hub grinding device comprises a rack and a positioning mechanism, and is further equipped with a cleaning mechanism for clearing refuse and dust, wherein the positioning mechanism comprises a horizontal positioning assembly and a vertical limiting part; the vertical limiting part comprises a pressing cover and a drive shaft; a driven bevel gear which is in threaded transmission to the drive shaft is rotatably arranged on the rack;the horizontal positioning assembly comprises at least three positioning parts, and each positioning part comprises a positioning pedestal, a threaded rod and a limiting block, the positioning pedestal is fixedly arranged on the rack, and the middle part of the threaded rod is rotatably connected to the positioning pedestal; and ends, close to each other, of the threaded rods are coaxially and fixedly equipped with transmission bevel gears which are engaged with drive bevel gears; the free ends of the threaded rods are in threaded connection to the limiting blocks. With the adoption of the scheme, multiple freedoms of the hub can be positioned and clamped simultaneously, so that integral processing efficiency is quickened, accuracy of hub positioning further can be guaranteed, and grindingquality is improved.

Owner:CHONGQING UNIV OF TECH

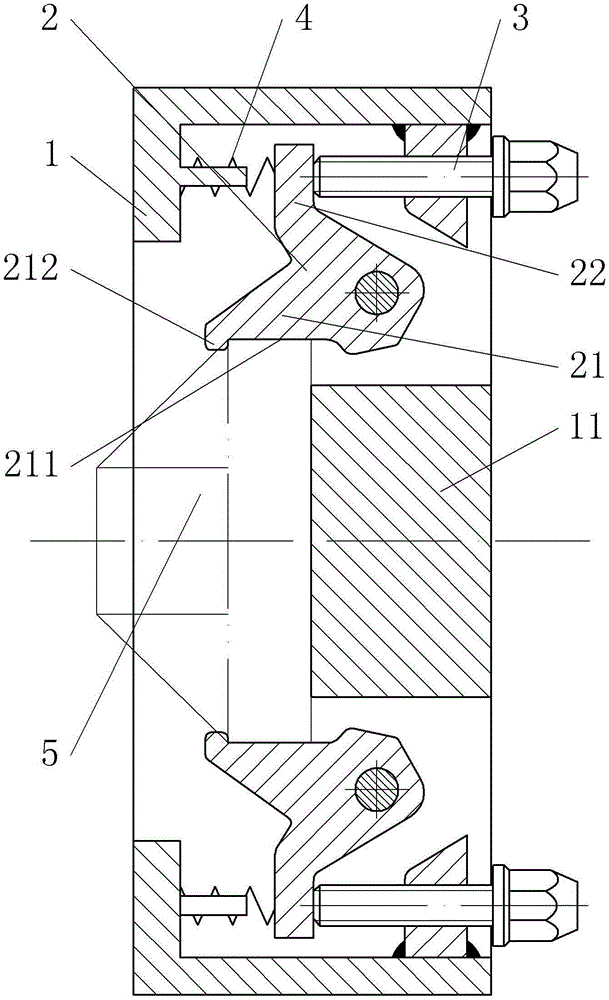

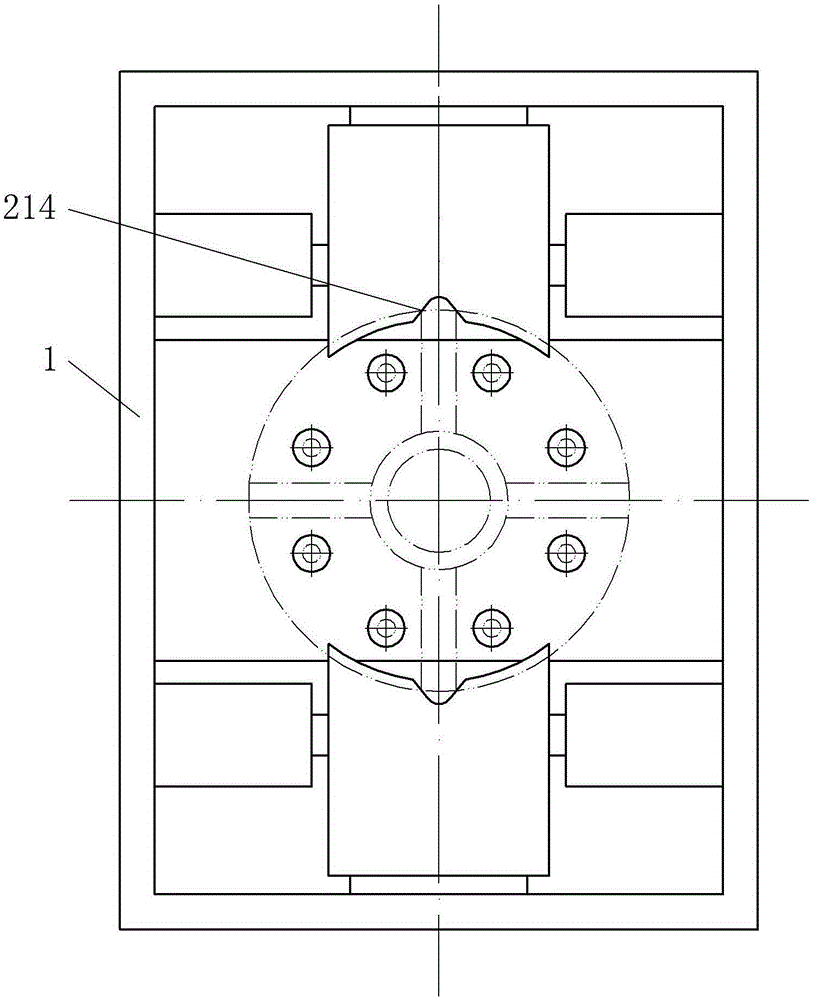

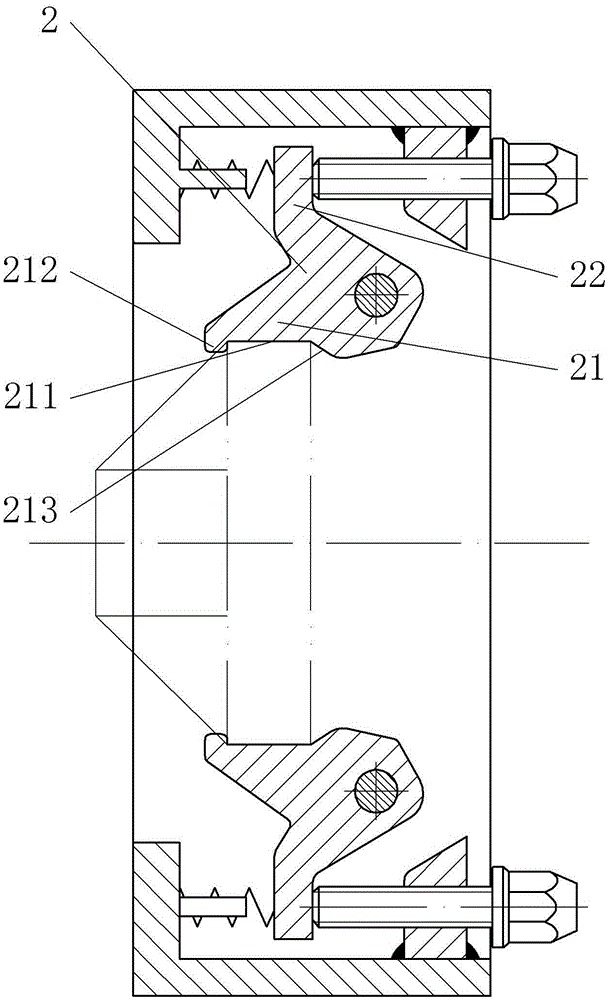

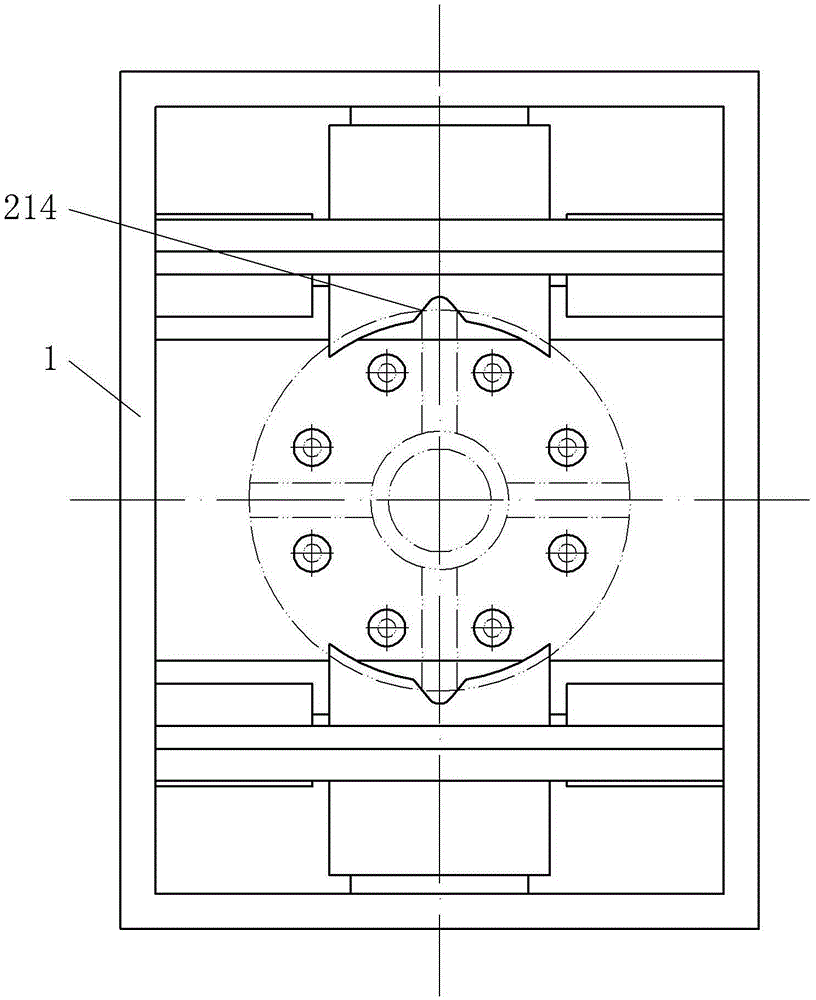

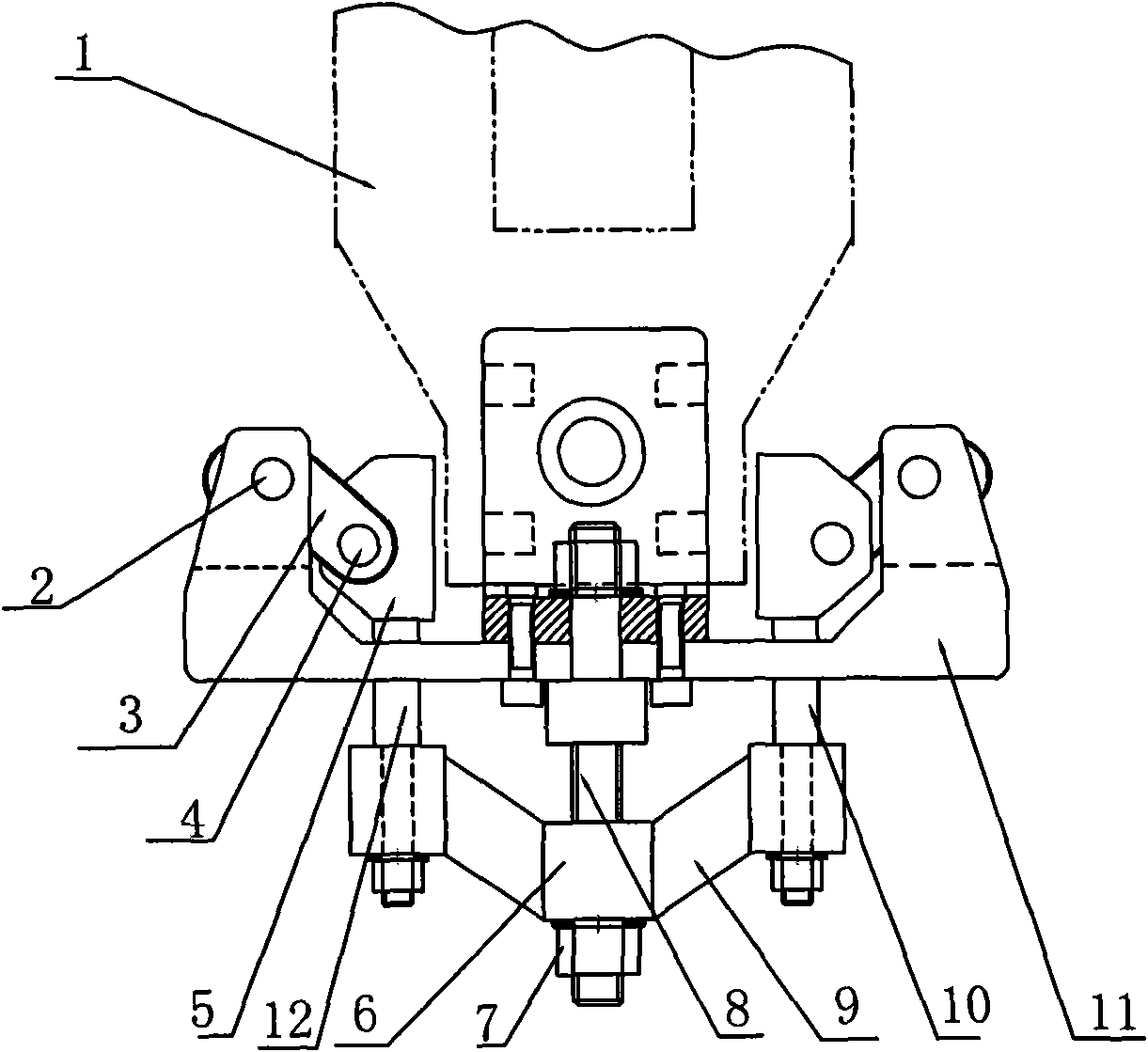

Clamping and positioning device for flange

PendingCN105382562ATo achieve the purpose of clampingGuaranteed angular positioningWork clamping meansPositioning apparatusEngineeringMachining process

The invention discloses a clamping and positioning device for a flange and relates to a flange clamp. The clamping and positioning device for the flange comprises a clamping seat, clamping jaws and pressing bolts. The clamping seat is provided with a clamping seat inner cavity, and the two clamping jaws are symmetrically hinged to the clamping seat inner cavity. One ends of the clamping jaws are clamping ends, and the other ends of the clamping jaws are stress ends. The clamping ends are provided with circular-arc-shaped clamping faces. The clamping faces are perpendicular to the stress ends. A circular-arc-shaped protrusion is arranged on the clamping face of the front end of each clamping jaw, and a limiting notch is formed in each circular-arc-shaped protrusion. The pressing bolts are screwed on the clamping seat and located on the rear sides of the clamping jaws, stretch into the clamping seat inner cavity and abut against the stress ends of the clamping jaws. A rear limiting part is further arranged on the rear side of each clamping jaw. According to the clamping and positioning device for the flange, machining processes in the flange machining process can be reduced, and positioning and clamping of the flange can be achieved rapidly.

Owner:CHONGQING SHUAICHANG MACHINE MFG

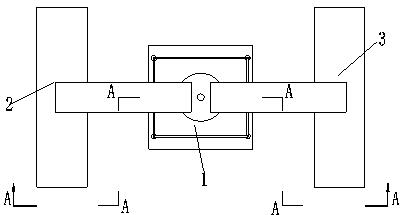

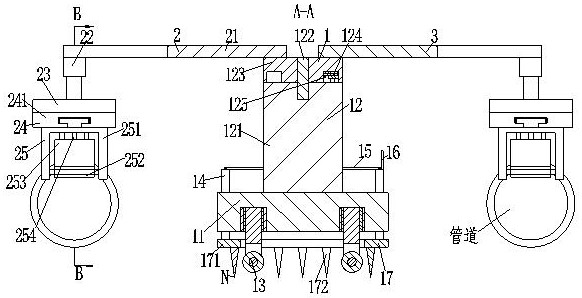

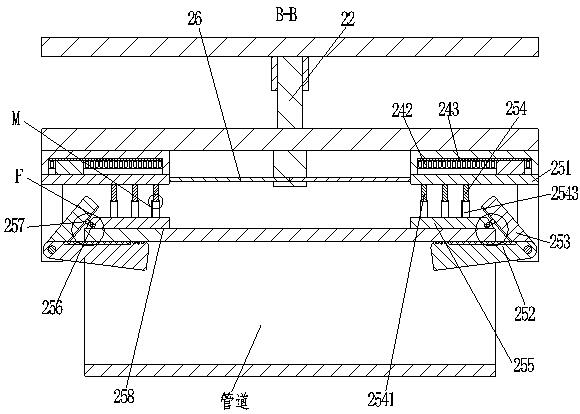

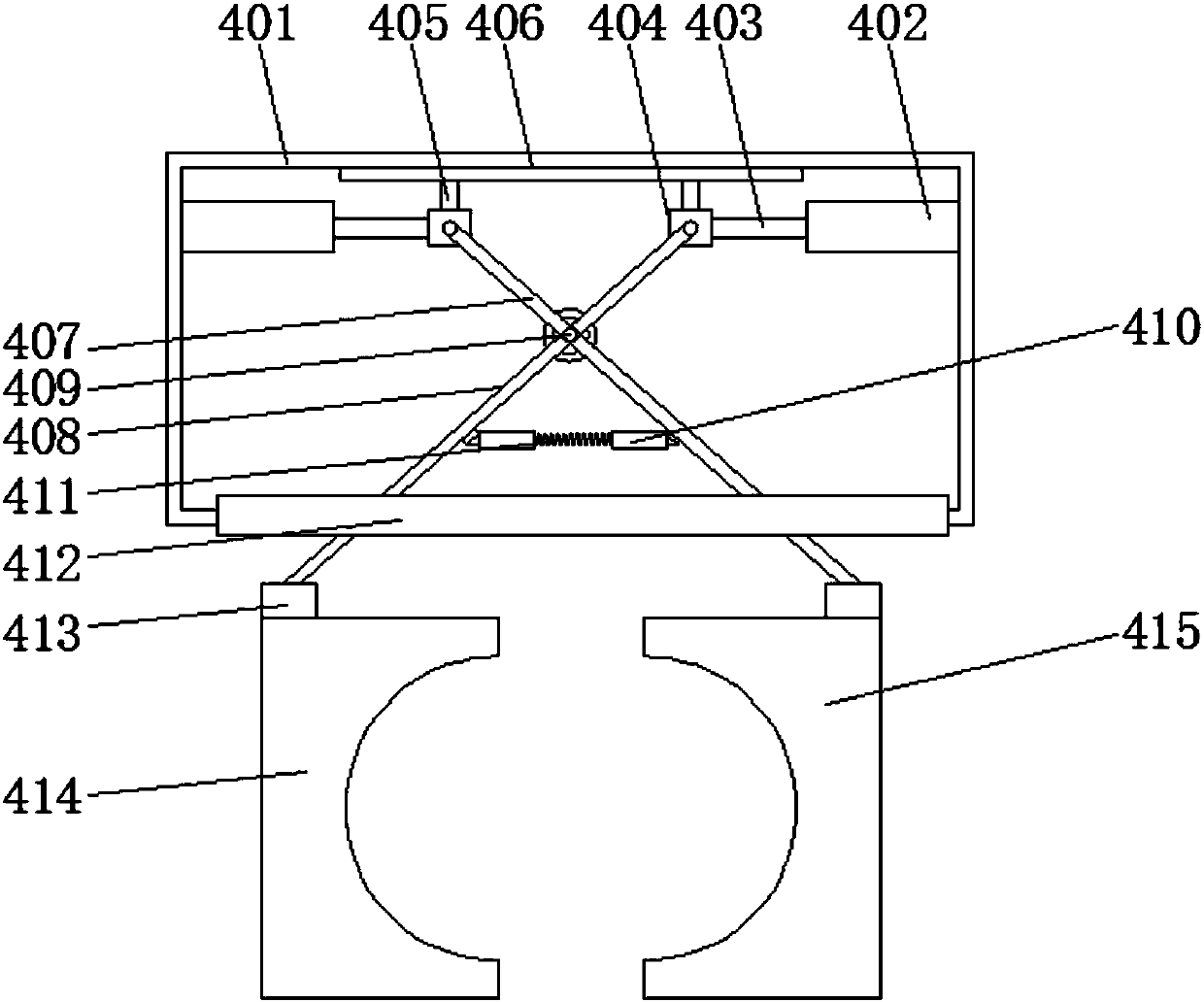

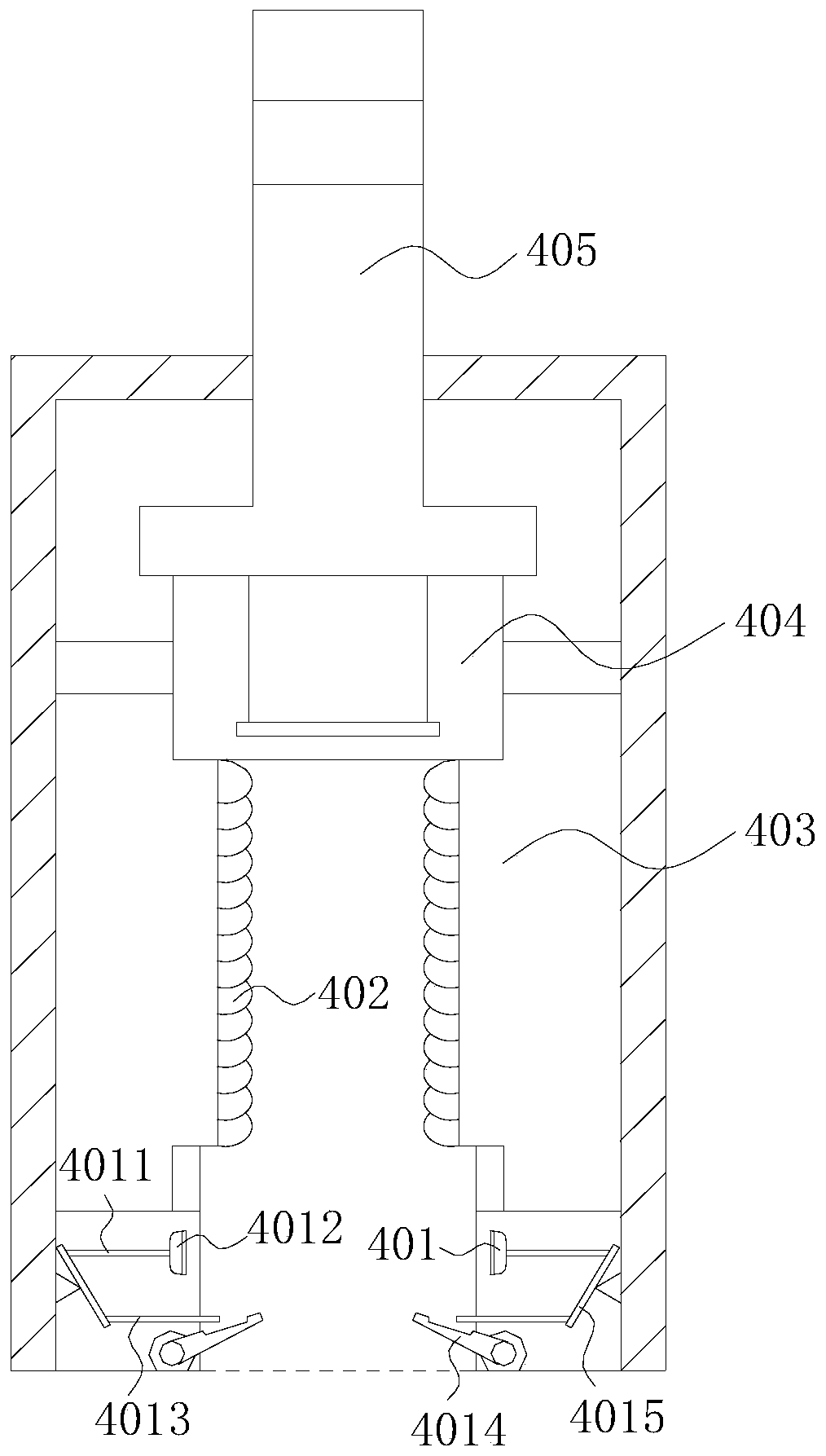

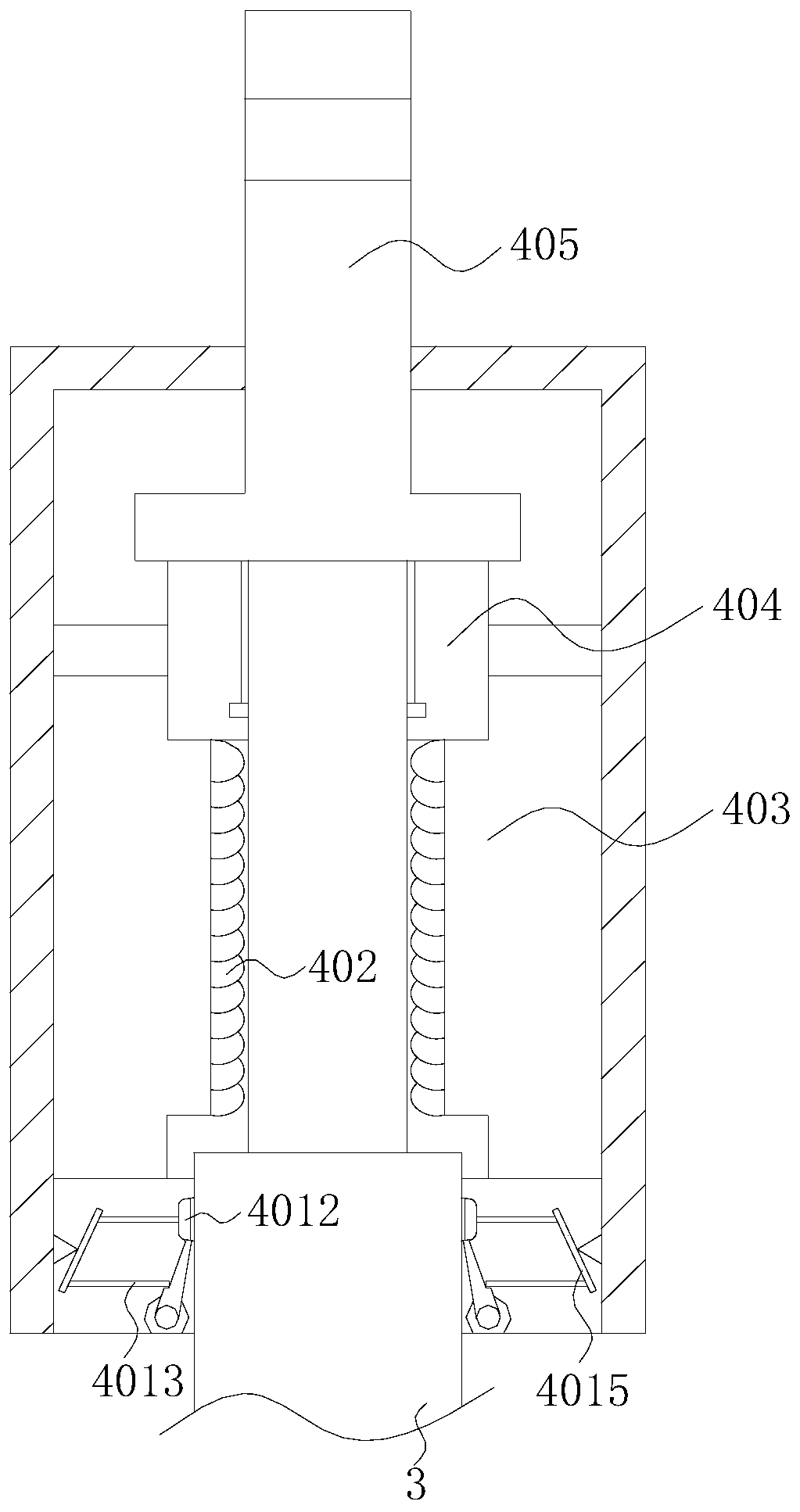

Underground water conveying pipeline construction placement equipment

ActiveCN111692425AImprove processing efficiencyImprove work efficiencyPipe laying and repairLoad-engaging elementsArchitectural engineeringMechanical engineering

The invention relates to underground water conveying pipeline construction placement equipment. The equipment comprises a moving device, a fixing device I and a fixing device II, wherein the fixing device I and the fixing device II are symmetrically and fixedly arranged on the left side and the right side of the upper end of the moving device correspondingly; and the fixing device I comprises a long supporting plate, a telescopic support, a supporting plate, sliding rails, clamping frames and an electric push rod, and the clamping frames comprise inverted-L-shaped plates, pressing plates, limiting plates, telescopic rods, clamping plates, large springs, large balls and rubber plates. According to the underground water conveying pipeline construction placement equipment, the equipment is fixed through the moving device, through the cooperation between the fixing device I and the fixing device II, a pipeline is fixed on one side of the equipment, and the pipeline is mounted and positioned on the other side of the equipment, so that the purpose of improving the machining efficiency of the equipment is achieved; and meanwhile, the pipeline is clamped and fixed through the gravity of the water conveying pipeline, so that the energy loss of the equipment is reduced, and therefore the working efficiency of the equipment is improved.

Owner:扬州市通达建设发展有限公司

Movable fixture for casting sand box

InactiveCN105834380ATo achieve the purpose of clampingLarge adjustment spaceMoulding flasksEngineeringMechanical engineering

The invention discloses a movable fixture for casting a sand box. The movable fixture comprises a base plate, a clamping plate, a first screw rod, a first nut, a second screw rod and a second nut, wherein the first screw rod and the second screw rod are fixedly arranged at a fixed end of the base plate; the first screw rod is near a clamping end of the base plate; the second screw rod is far from the clamping end of the base plate; the first screw rod and the second screw rod penetrate through screw holes in the clamping plate for coating the clamping plate on the first screw rod and the second screw rod; and the first nut is screwed on the first screw rod above the clamping plate, and the second nut is screwed on the second screw rod below the clamping plate for limiting the clamping plate between the first nut and the second nut. Through a mode of matching two screw rods with the nuts, the fixture has larger adjusting space of a clamping range, and is wider in the application range compared with a U-shaped fixture; and meanwhile, the movable fixture uses the base plate and the clamping plate for clamping the sand box to solve the problem of incapability of inserting in the screw rods for fastening due to disalignment of upper and lower boxes.

Owner:KOCEL EQUIP

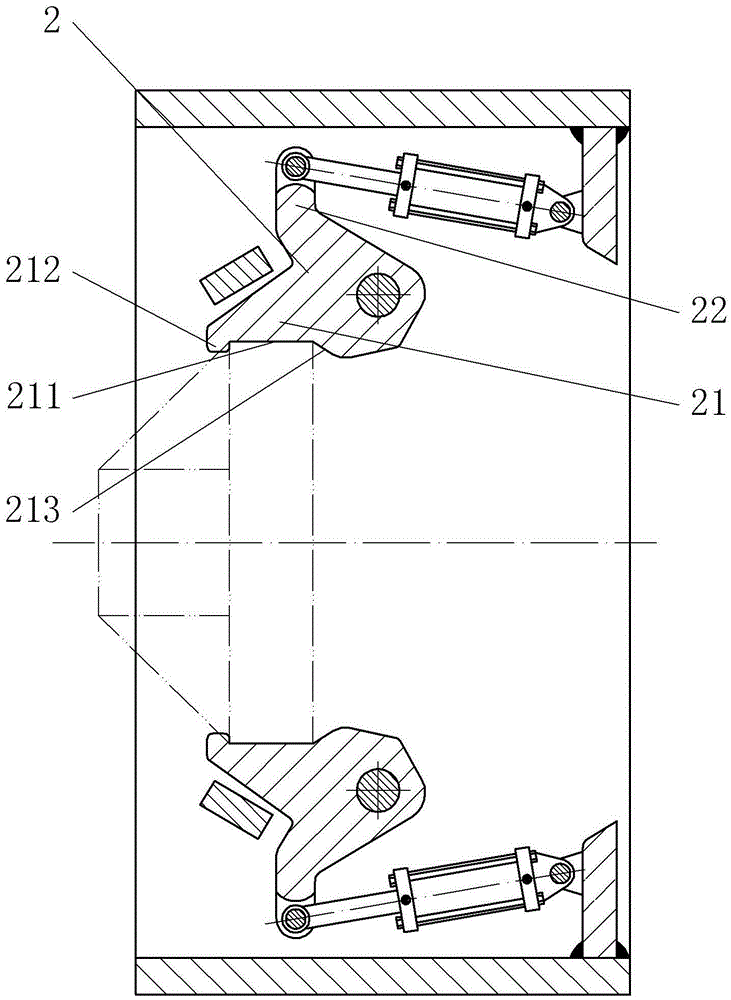

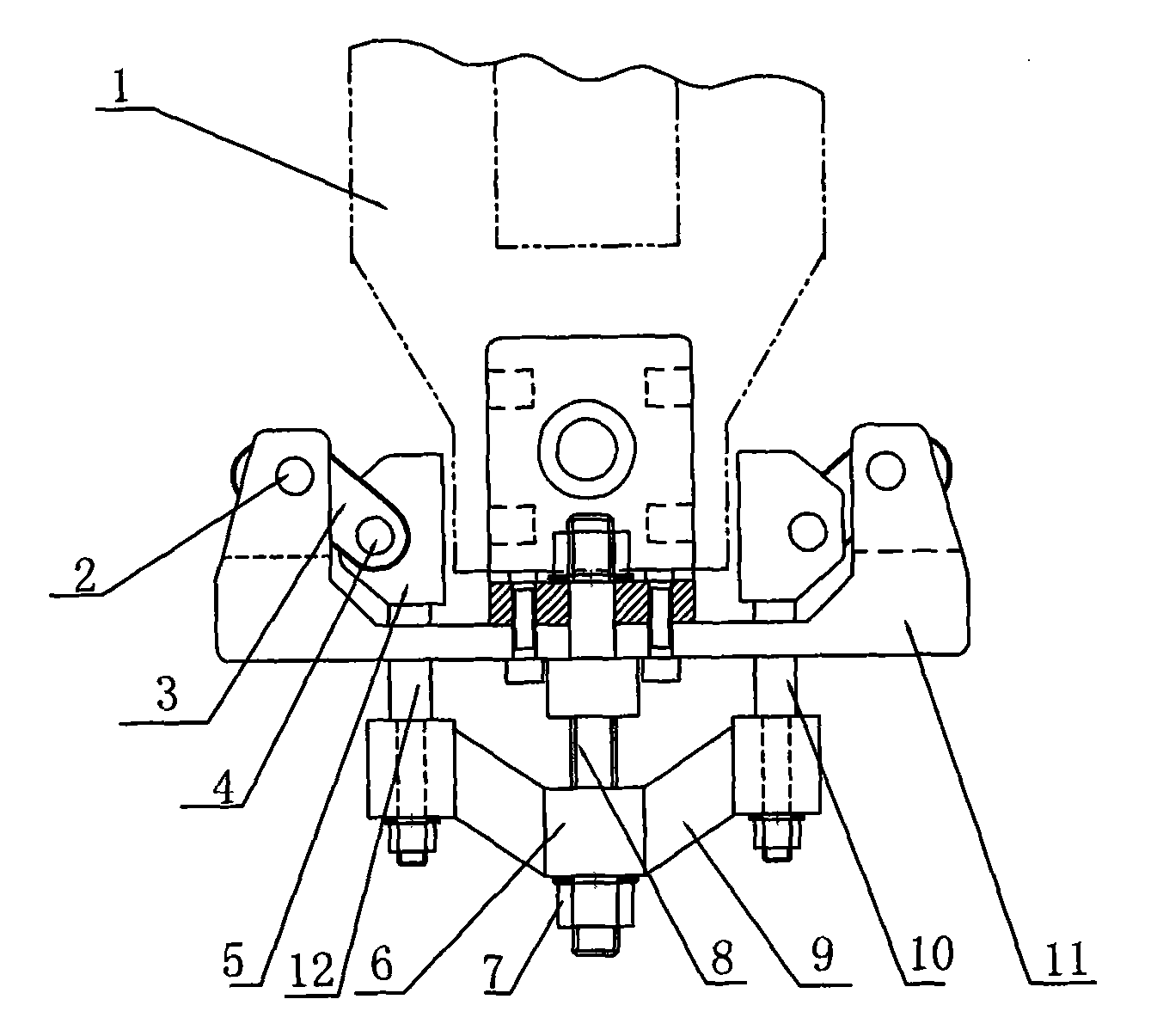

Clamping and positioning device for pneumatic flange

InactiveCN105382563ATo achieve the purpose of clampingGuaranteed angular positioningWork clamping meansPositioning apparatusControl systemEngineering

The invention discloses a clamping and positioning device for a pneumatic flange and relates to a flange clamp. The clamping and positioning device for the pneumatic flange comprises a clamping seat, clamping jaws, driving air cylinders and a control system. A clamping seat inner cavity is formed in the clamping seat. The two clamping jaws are symmetrically hinged to the clamping seat inner cavity. One ends of the clamping jaws are clamping ends, and the other ends of the clamping jaws are stress ends. The clamping ends are provided with circular-arc-shaped clamping faces. A circular-arc-shaped protrusion is arranged on the clamping face of the front end of each clamping jaw, and a limiting notch is formed in each circular-arc-shaped protrusion. Cylinder bodies of the driving air cylinders are hinged to the clamping seat, and piston rods are hinged to the stress ends of the clamping jaws. A control system is used for controlling the driving air cylinders, and a rear limiting part is arranged on the rear side of each clamping jaw. According to the clamping and positioning device, machining processes in the flange machining process can be reduced, and positioning and clamping of the flange can be achieved rapidly.

Owner:CHONGQING SHUAICHANG MACHINE MFG

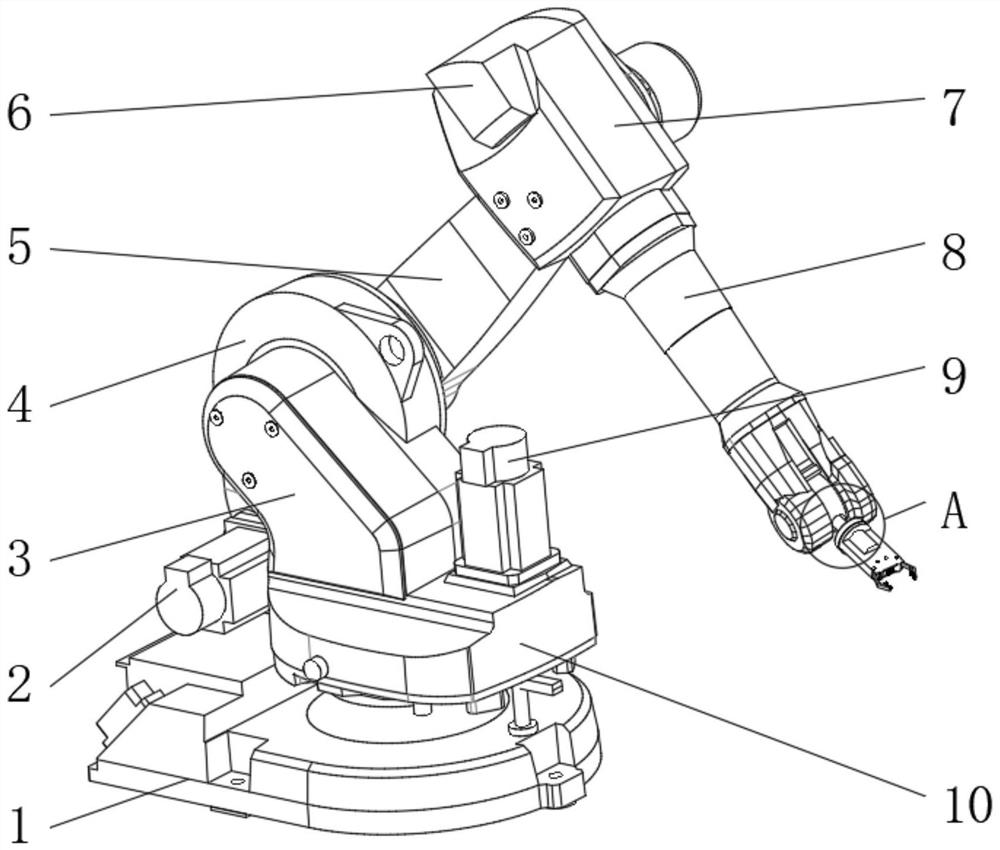

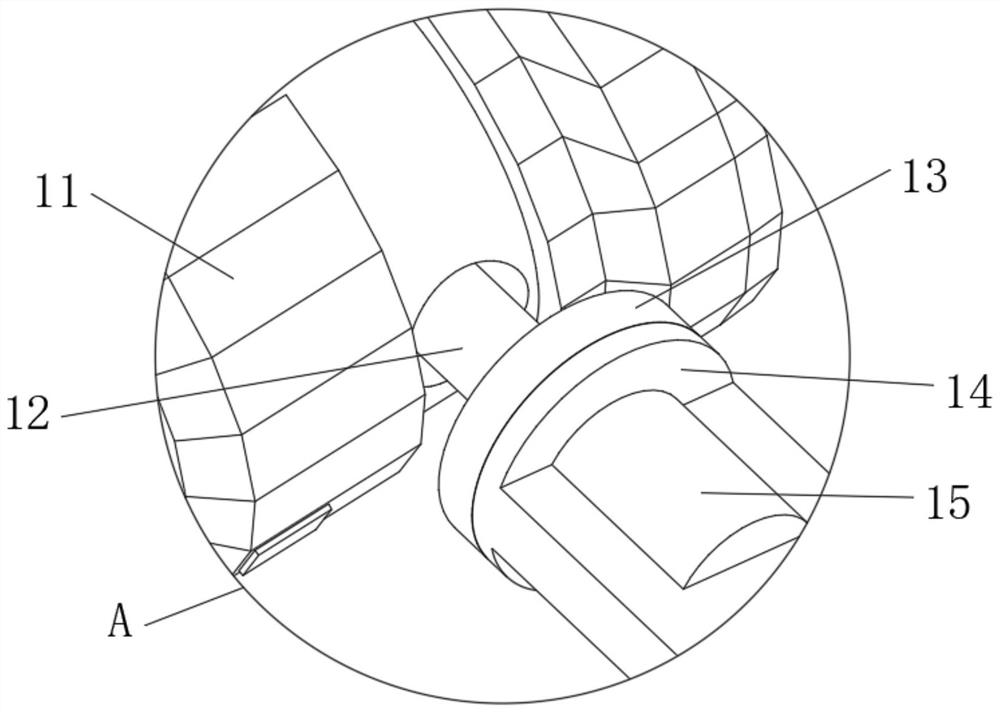

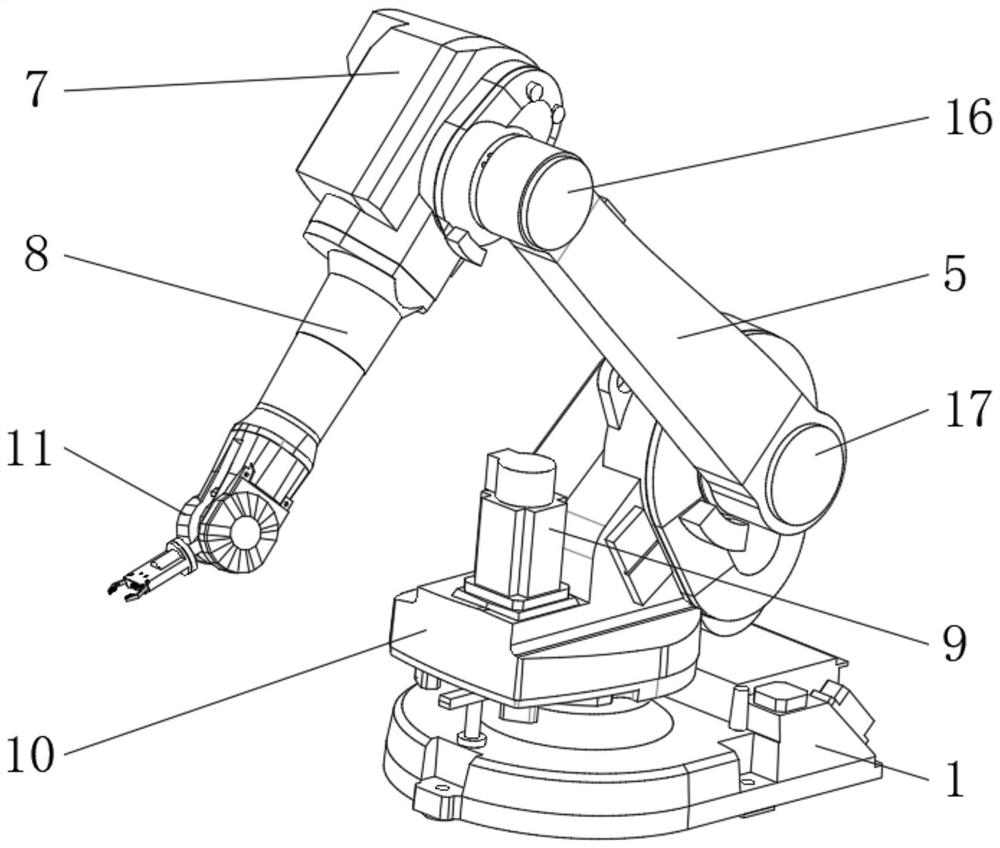

Industrial robot clamping arm

InactiveCN107717962AReduce vibrationReduce noiseProgramme-controlled manipulatorArmsLow noiseHydraulic cylinder

The invention discloses an industrial robot clamping arm. The industrial robot clamping arm comprises an arm base. The upper surface of the arm base is fixedly connected with a motor outer frame. Theinterior of the motor outer frame is fixedly connected with a first motor. The end, away from the arm base, of the motor outer frame is fixedly connected with a supporting frame. The output end of thefirst motor is fixedly connected with a rotation rod. The rotation rod penetrates the supporting frame and is movably connected with a rotation mechanism. The rotation mechanism comprises a rotationshaft, a connecting rotation rod, a rotation block and a rotation shell. The rotation rod is fixedly connected to the outer side of the rotation shaft. The end, away from the rotation shaft, of the rotation rod is fixedly connected with the rotation block, the end, away from the rotation rod, of the rotation block is fixedly connected with the rotation shell, a force arm is fixedly connected to the upper surface of the rotation mechanism, the end, away from the rotation mechanism, of the force arm is fixedly connected with a hydraulic cylinder, and the side, away from the force arm, of the hydraulic cylinder is fixedly connected with a telescopic rod. The industrial robot clamping arm has the beneficial effects that the production cost is reduced, noise is low, and adjustment can be achieved.

Owner:WUXI IDO SCI & TECH CO LTD

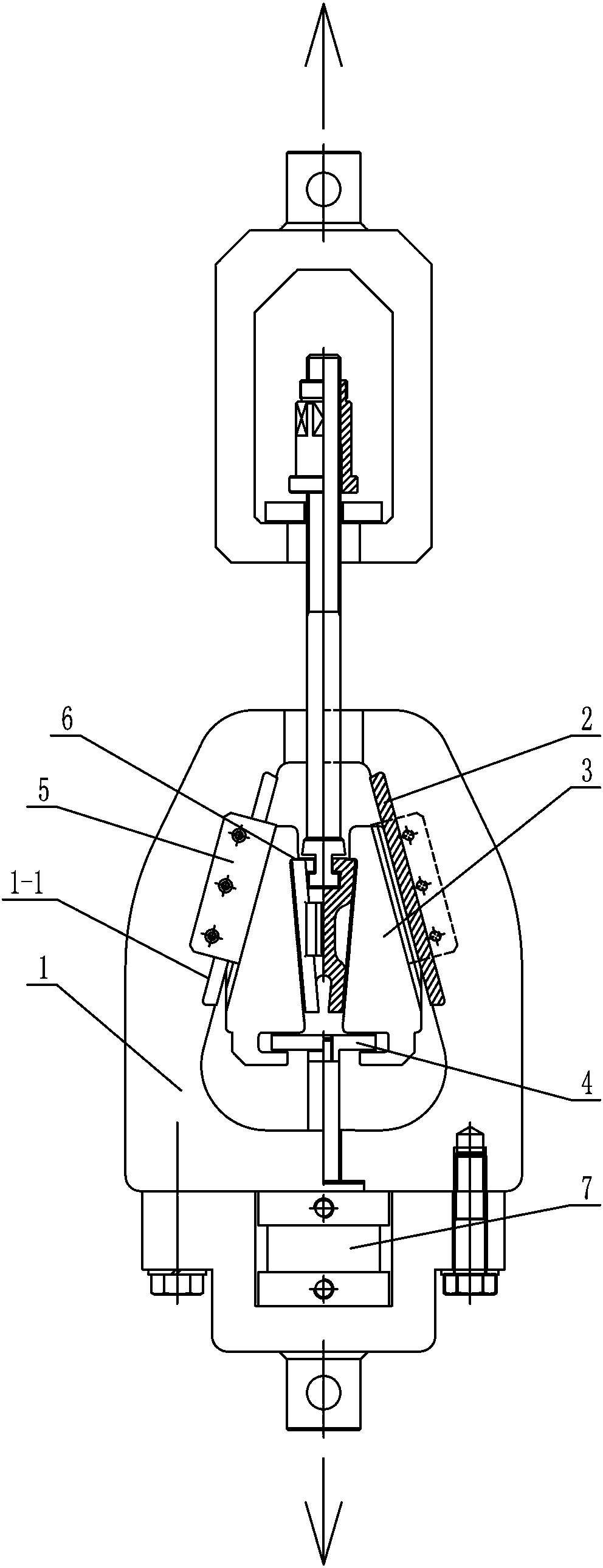

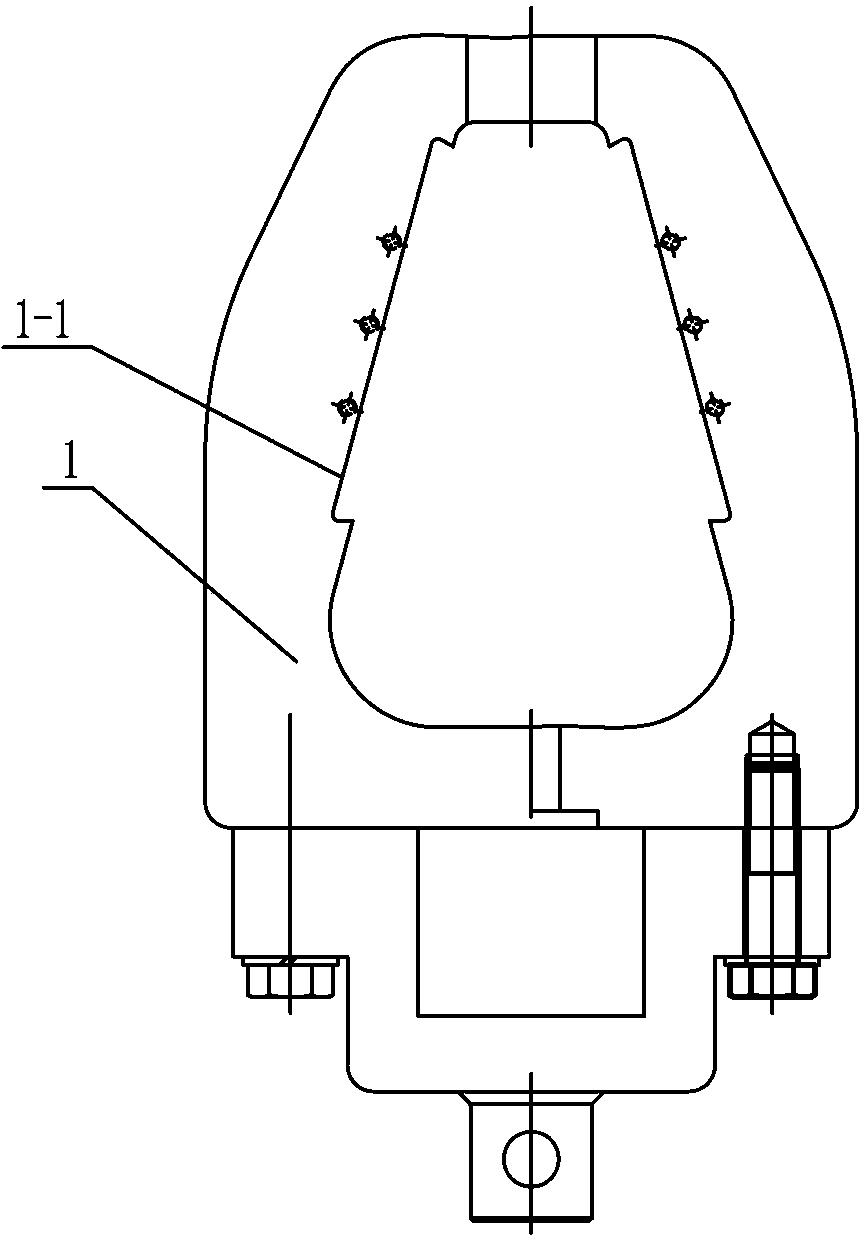

Clamp special for combined tension test of gate valve closing member

The invention discloses a clamp special for a combined tension test of a gate valve closing member. The clamp comprises a clamp base, wherein a concave bayonet is formed in each of the left side and the right side of the upper part of the clamp base, a cutting board is arranged at the inner side of each concave bayonet, the inner side of each cutting board is clung to a pressing piece, a top plate capable of moving up and down is arranged below the clamp base, the top plate is capable of pushing the pressing piece to move upwards, a surface at the inner side of each cutting board and matched with the pressing piece is an inclined surface, the pressing piece supports against the inclined surface and is capable of aslant sliding along the inclined surface, the inclined surfaces at the inner sides of the two cutting boards form a splayed sliding surface, the two pressing pieces are capable of aslant sliding up and down along the splayed sliding surface, fixing boards are arranged at the front side and the rear side of each concave bayonet, the two fixing boards located on the same concave bayonet are used for clamping the front side and the rear side of the pressing piece, the mutually opposite inner side surfaces of the two pressing pieces are reversed inclined surfaces, the two reversed inclined surfaces are of an inverted splayed structure, and convex anti-skidding bosses are arranged on the upper parts of the reversed inclined surfaces of the pressing pieces.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

Work fixture for mechanical arm

PendingCN113070892AFastenedFit tightlyProgramme-controlled manipulatorGripping headsRobotic armEngineering

The invention discloses a work fixture for a mechanical arm, and relates to the technical field of industrial instruments. The work fixture comprises a mounting base and a connecting base; the front side face of the connecting base is fixedly connected with a fixture box; and the inner wall of the rear end of the fixture box is fixedly connected with an air cylinder. According to the work fixture, by arranging a spring barrel and side face clamping rods, a workpiece can be limited through three side faces; the workpiece is clamped more firmly by the stability capacity of a triangle; due to the fact that a large number of anti-skid discs can be tightly attached to the surface of the workpiece, the purpose of firm clamping can be better achieved; and by arranging a tensioning spring, a telescopic rod can stretch out and draw back in the spring barrel when being stressed, and accordingly, diameters among three arc-shaped clamping pieces are adjusted; meanwhile, due to the fact that jacking columns can stretch out and draw back in limiting barrels, the work fixture can well adapt to workpieces with different diameters when being used for clamping the workpieces with the different diameters, thereby achieving the purpose that the workpieces with different diameters can be clamped.

Owner:武汉熙锐自动化设备有限公司

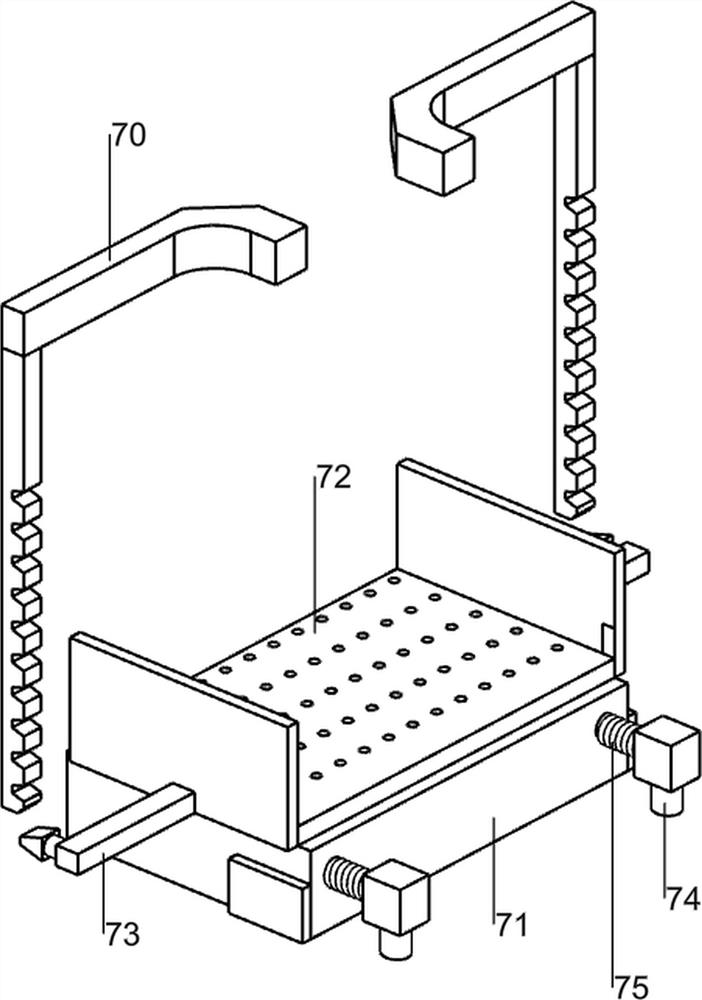

Thin aluminum plate middle grooving machining tool

ActiveCN106078277AFast 3D positioningTo achieve the purpose of clampingPositioning apparatusMaintainance and safety accessoriesMachine partsEngineering

The invention discloses a thin aluminum plate middle grooving machining tool. The thin aluminum plate middle grooving machining tool comprises a base connected with a machine tool; rectangular positioning surfaces matched with the bottom surfaces of workpieces to be machined are symmetrically projected at two ends of the base; a strip-shaped positioning boss perpendicular to and higher than the positioning surfaces is arranged at one side edge of the base; a cutter feeding groove for feeding a cutter is formed in the base between the positioning boss and the positioning surfaces; a concave part formed between the two positioning surfaces serves as a chip removing groove for cleaning chips; and the two positioning surfaces are both detachably provided with pressing modules for pressing the workpieces to be machined. The thin aluminum plate middle grooving machining tool is simple in structure, realizes quick three-dimensional positioning of the workpieces through the positioning surfaces on the base, the positioning boss and the pressing modules, enables the machined parts to easily reach the process size and geometric tolerance requirements, and effectively improves the product pass percent.

Owner:GUANGXI YUCHAI MASCH CO LTD

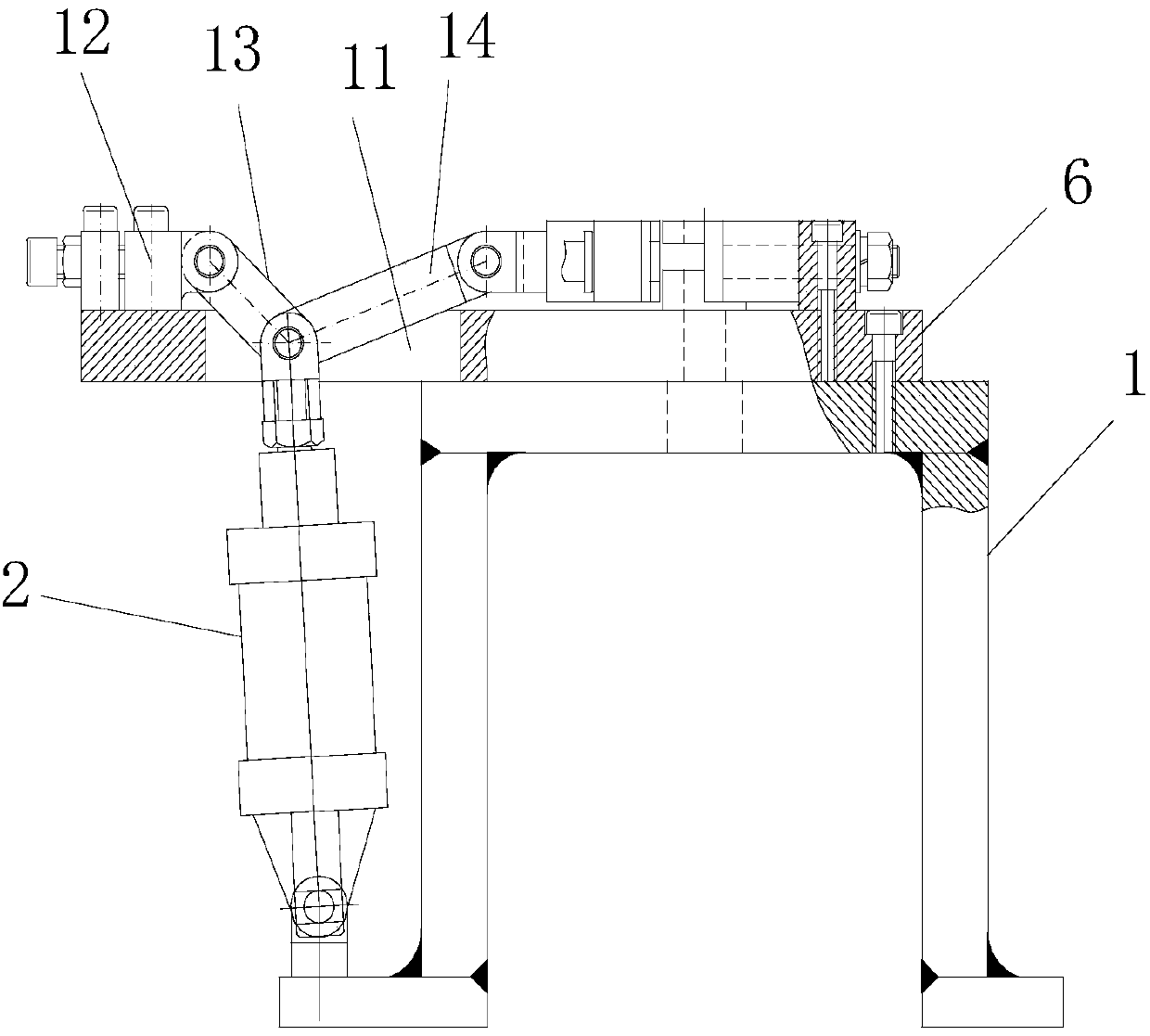

Self-positioning fixture

InactiveCN102049690AHigh precisionAchieve positioningPositioning apparatusMetal-working holdersEngineeringSelf positioning

The invention relates to a self-positioning fixture. The self-positioning fixture comprises a U-shaped seat frame body [11], a lifting device and a clamping device, wherein the lifting device comprises a screw [8], a nut [7], two carrier rods and a carrier rod seat; one end of the screw [8] is fixedly connected to the middle of the seat frame body [11]; on the carrier rod seat, two transverse rods [9] are fixedly connected to the two side faces of a shaft sleeve [6] symmetrically; the shaft sleeve [6] is sleeved on the screw [8]; a through hole is formed on the two sides of the seat frame body [11] respectively; the two carrier rods are positioned in the through holes; the two transverse rods [9] are connected with the lower ends of the two carrier rods respectively; the clamping device comprises two clamping blocks [5] and two rotating levers [3]; the two clamping blocks [5] are fixedly connected to the upper ends of the two carrier rods respectively; and each clamping block is hinged with one end of each rotating lever [3], and the other end of each rotating lever [3] is hinged with the upper parts of the two sides of the seat frame body [11]. The self-positioning fixture can clamp and position workpieces, so machining accuracy and machining efficiency are greatly improved.

Owner:汪焱

Mechanical part welding clamping device

ActiveCN107186416ATo achieve the purpose of clampingImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesMachine partsMechanical components

The invention discloses a mechanical part welding clamping device, and relates to the technical field of mechanical equipment. The mechanical part welding clamping device comprises a bottom plate; the top of the bottom plate is fixedly connected with a rack; the inner wall of the rack is fixedly connected with a fixed bracket; the bottom of the fixed bracket is fixedly connected with a sliding rail and a fixed working box; one side of the outer wall, far from the fixed working box, of the fixed bracket, is fixedly connected with the sliding rail; the sliding rail is slidingly connected with a sliding working box through a sliding rod; the top of the inner wall of the rack is fixedly connected with a first motor; and the first motor is rotationally connected with an I-shaped rotary drum through a speed reducing connector. The mechanical part welding clamping device achieves the effects that the purpose of circularly demonstrating a computer is realized, the clamping of mechanical parts is realized, the mechanical parts in different models and sizes can be clamped, the working efficiency and the production stability re improved, the fixing of a machine body is realized, the machine body is more stable, and a fixture body is buffered through a V-shaped fixture.

Owner:江苏博创升降机械有限公司

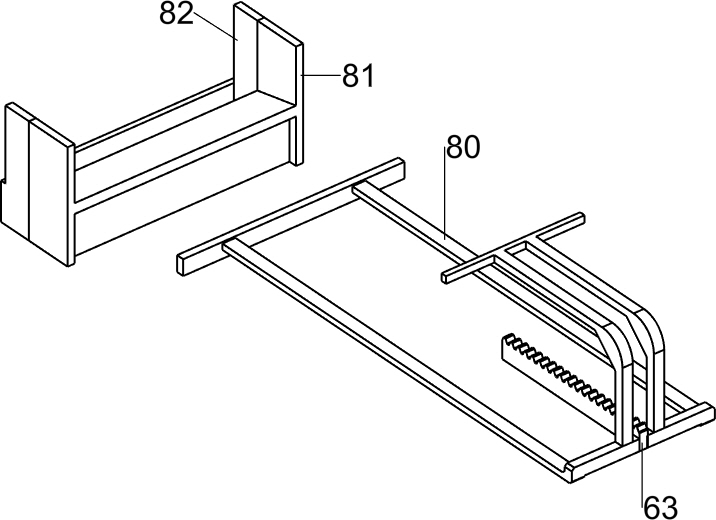

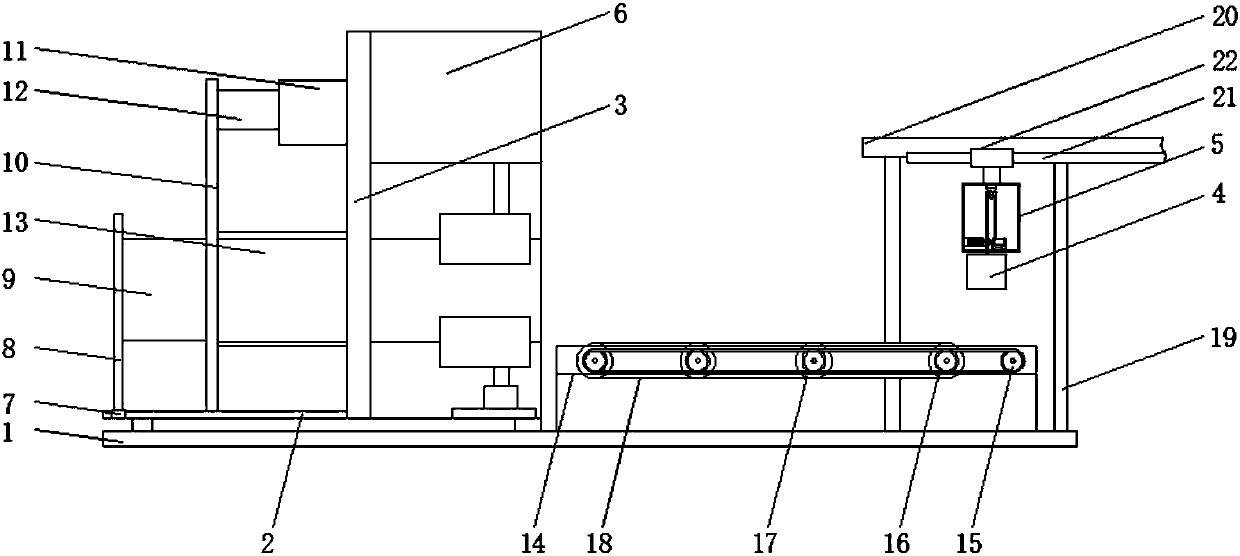

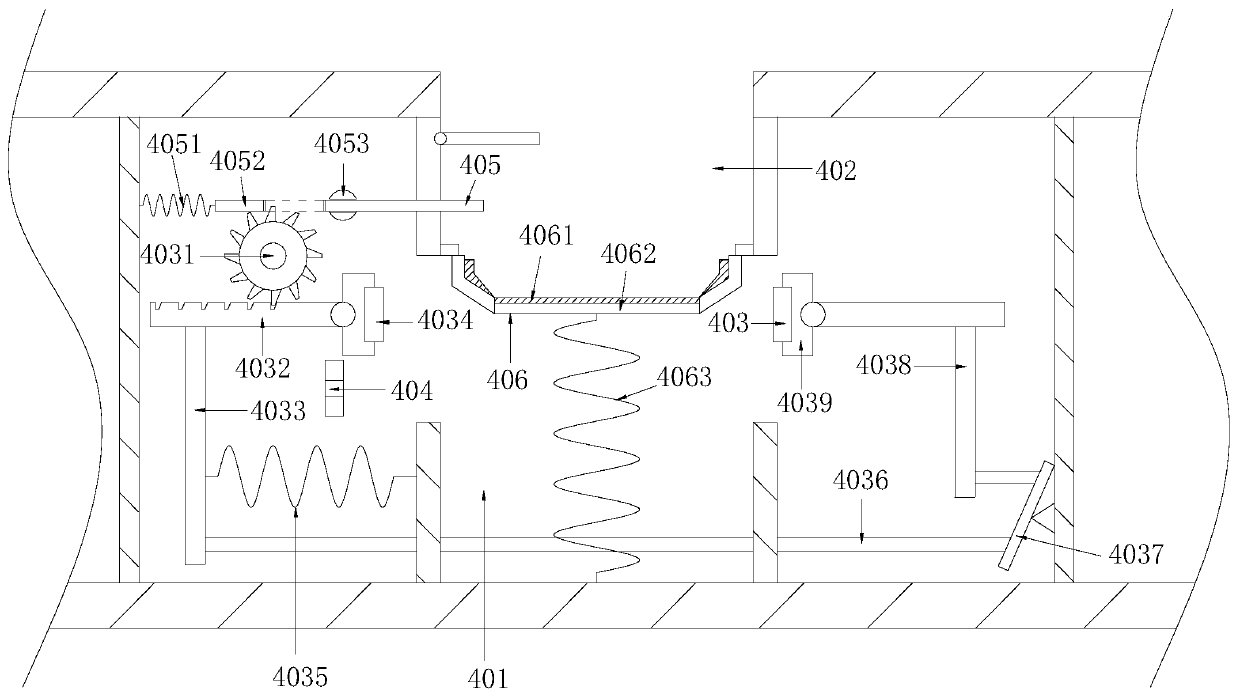

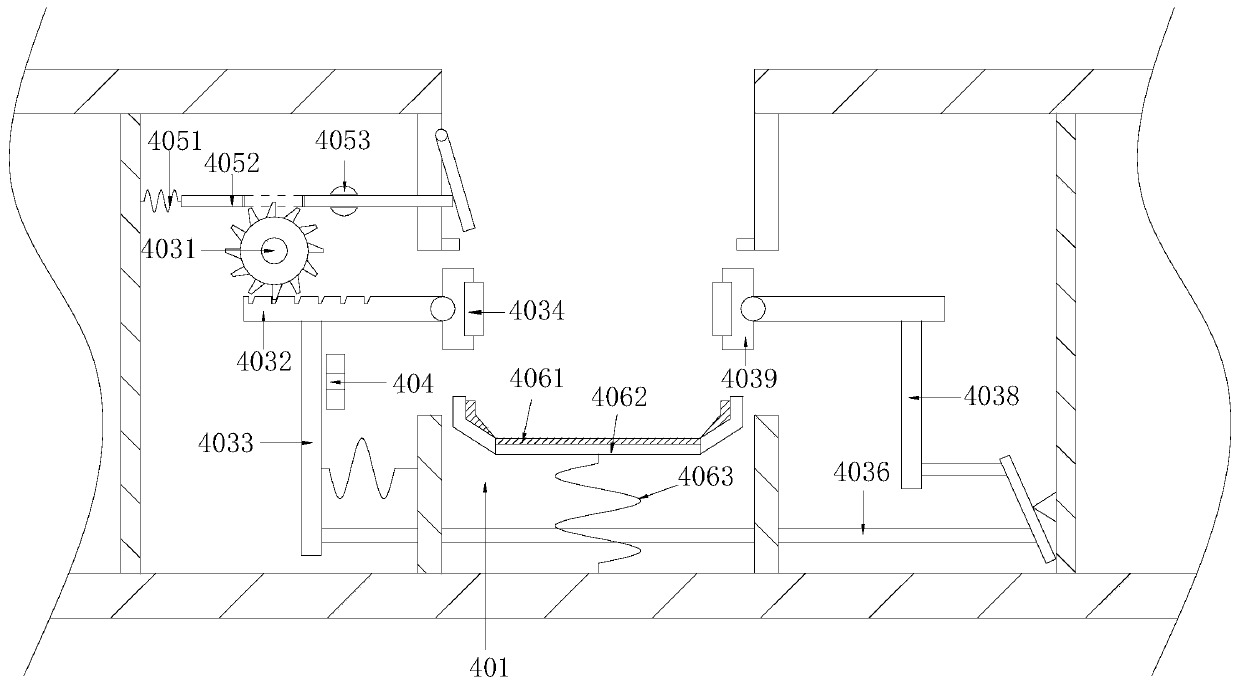

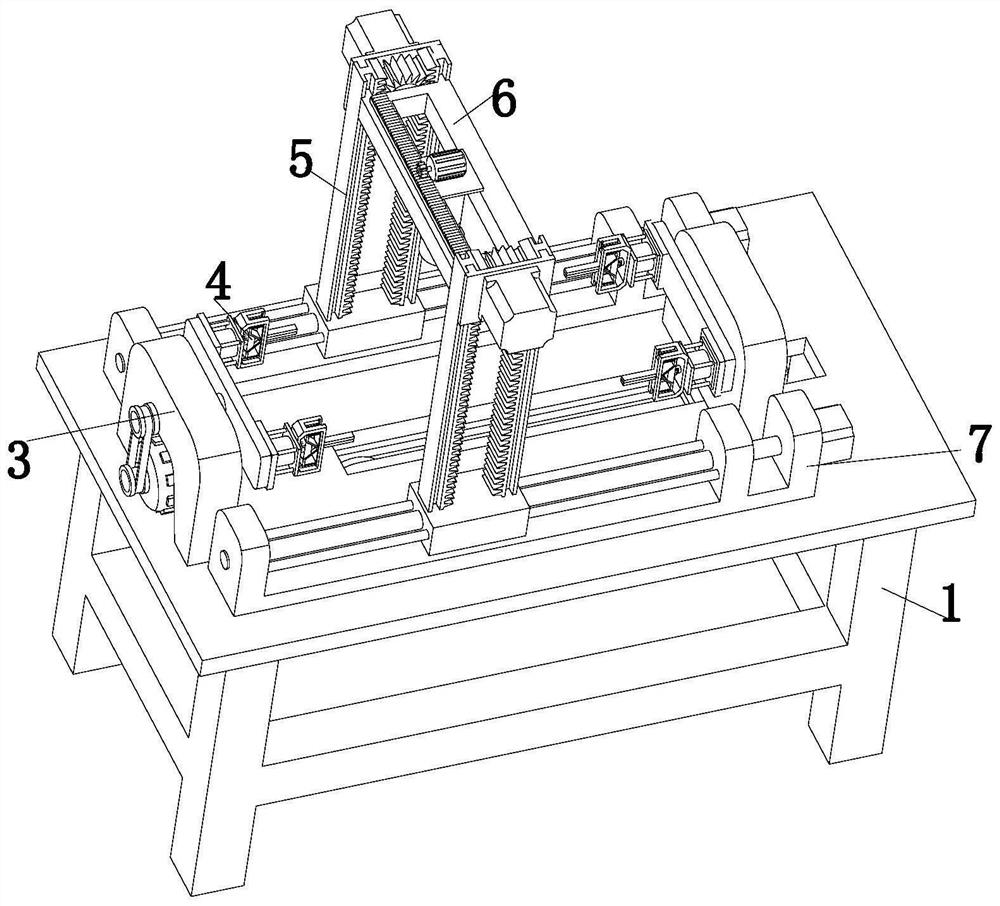

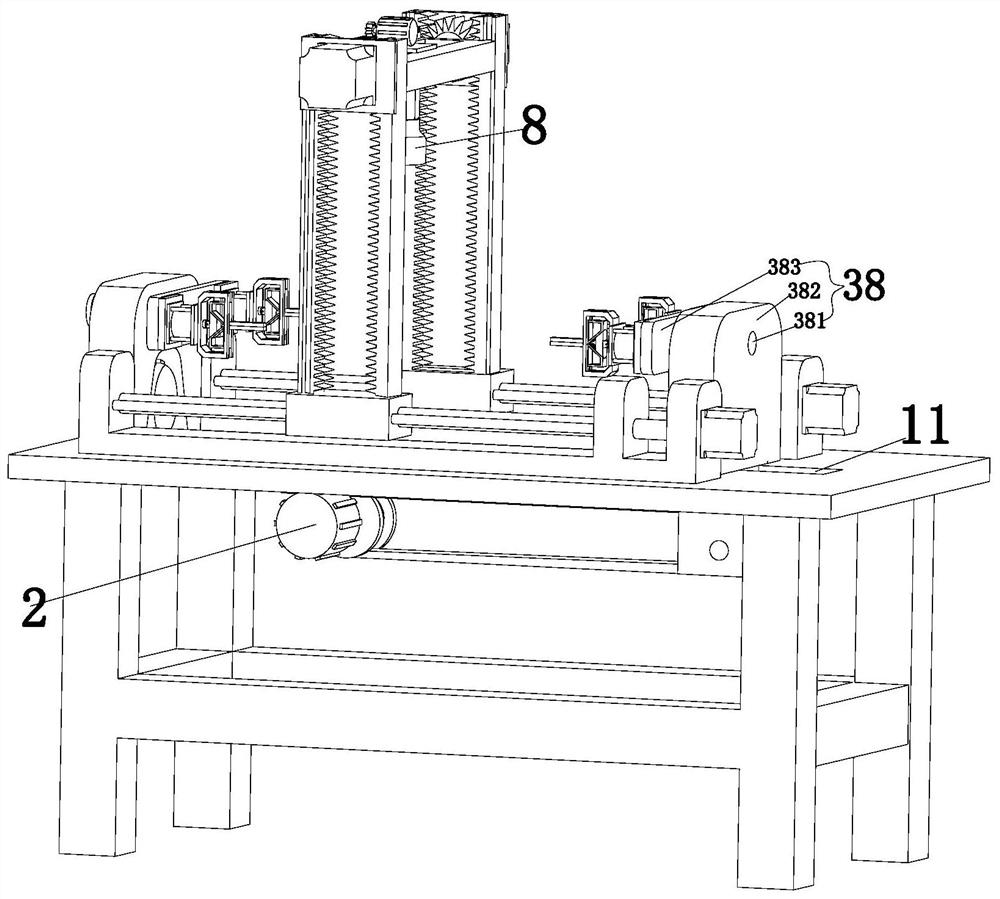

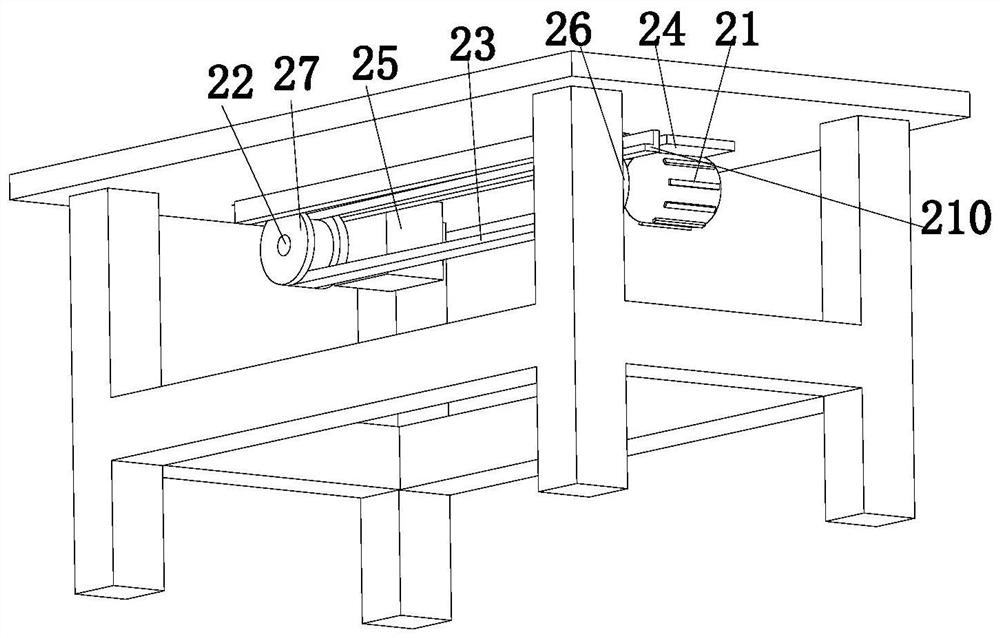

Automatic pipeline feeding device

ActiveCN107570576AEasy deliveryEasy to operateConveyorsMetal-working feeding devicesEngineeringMachining

The invention discloses an automatic pipeline feeding device and relates to the technical field of pipeline machining equipment. The automatic pipeline feeding device comprises an outer frame. A top plate and a bottom plate are fixedly connected between the two sides of the inner wall of the outer frame in sequence from top to bottom. The bottom of the inner wall of the outer frame is fixedly connected with a first motor. One end of an output shaft of the first motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The back face of the second belt wheel is fixedly connected with a first gear. One side of the first gear is engaged with a second gear. According to the automatic pipeline feeding device, a pipeline can be clamped and fixed to be prevented from deviating in the cutting process, and the fixing effect is improved; manual clamping and manual feeding are not needed, operationis easy, the labor quantity of workers is relieved, and using of people is facilitated; and feeding is facilitated, the using performance of the device is improved, feeding precision is guaranteed, and errors caused by manual feeding are avoided.

Owner:GUANGDONG JUNCHI TECH HLDG

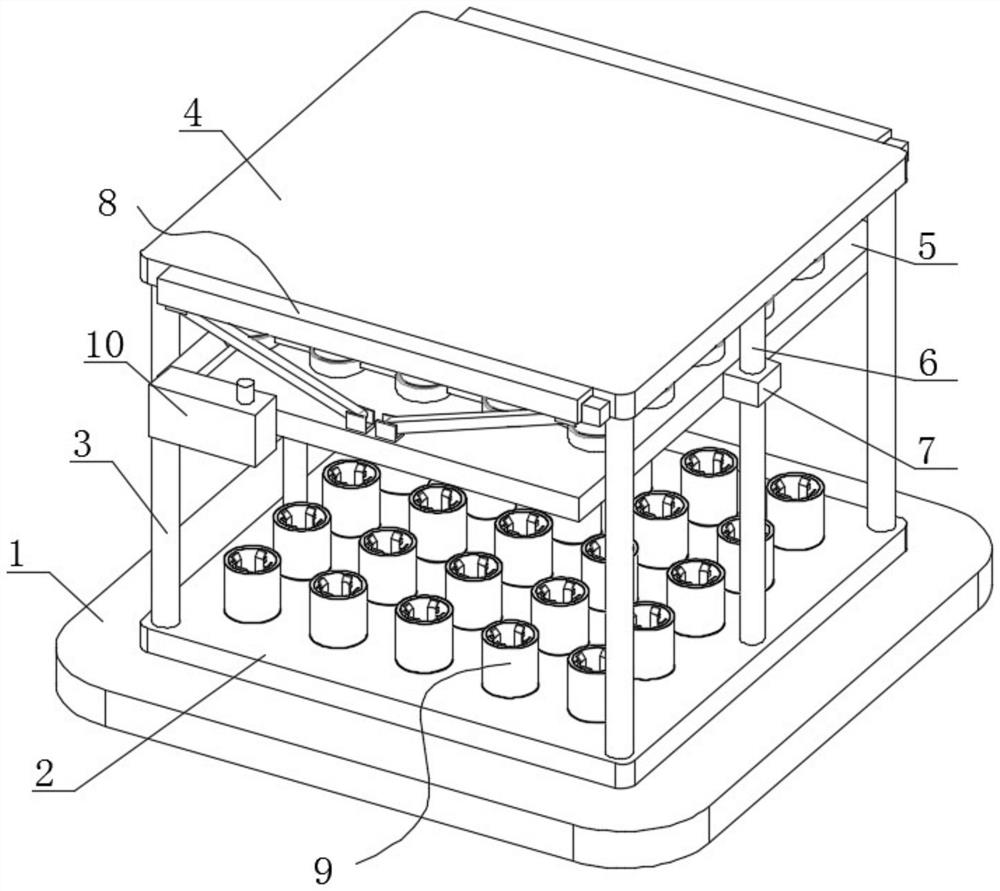

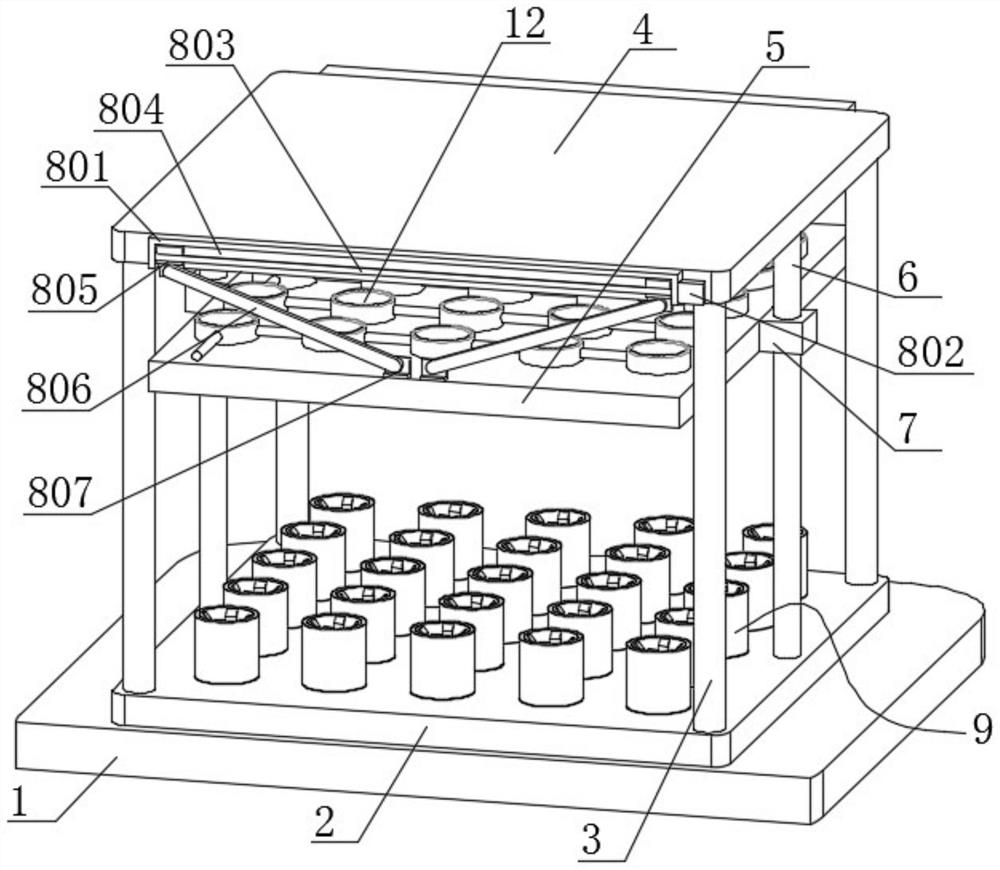

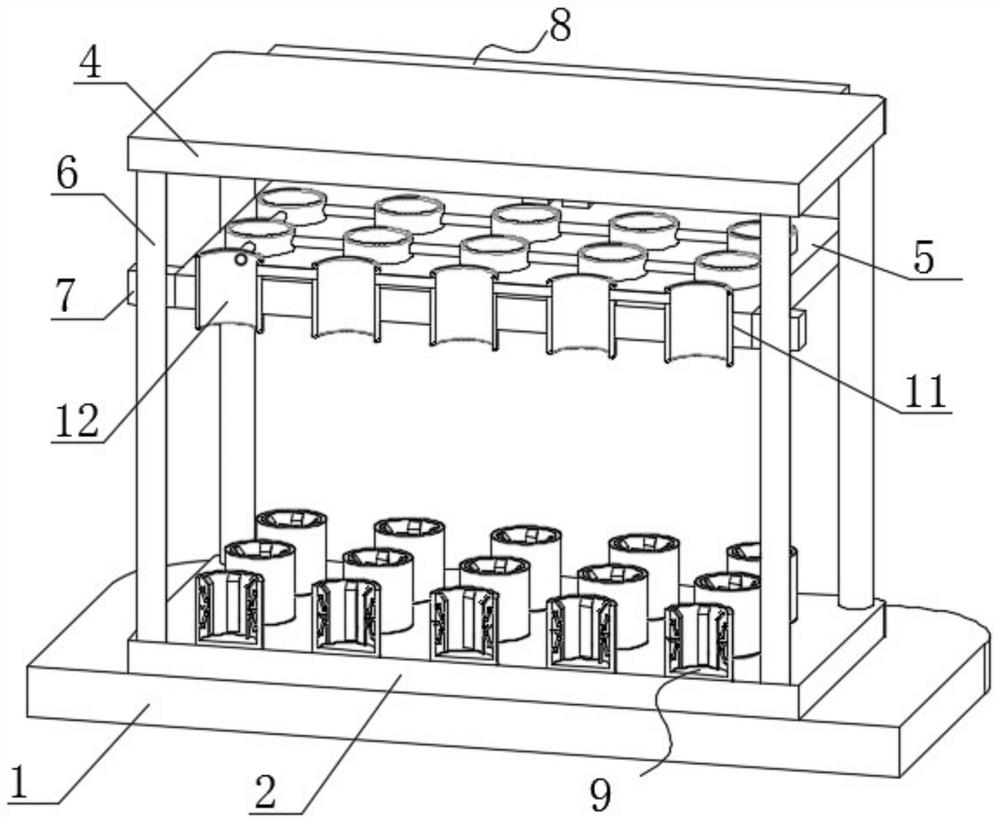

Gas cylinder container with anti-collision function and using method

InactiveCN112696611AReach the limit effectEasy accessContainer filling methodsContainer discharging methodsPost collisionGas cylinder

The invention discloses a gas cylinder container cell with an anti-collision function and a using method, and belongs to the technical field of container cells. The gas cylinder container cell comprises a bearing plate; the upper surface of the bearing plate is fixedly connected with a bottom plate; four corners of the upper surface of the bottom plate are fixedly connected with stand columns; a top plate is arranged above the bottom plate; the upper surface of each stand column is fixedly connected to the bottom surface of the top plate; lifting mechanisms are arranged on the two side faces of the top plate; a moving plate is arranged below the top plate; through holes arranged at equal intervals are formed in the moving plate; and an air bag is fixedly connected into each through hole. According to the gas cylinder container cell, the lifting mechanism is arranged, so that a gas cylinder can be automatically limited; the gas cylinder is convenient to take; the effect of clamping the gas cylinder in advance is achieved by arranging the limiting mechanism; the stability of gas is guaranteed; through an inflation and suction dual-purpose pump, the through holes and the air bags, the situation that a single gas cylinder is impacted and then transferred to other gas can be avoided; and the safety during gas storage is improved.

Owner:杭州峰峦贸易有限公司

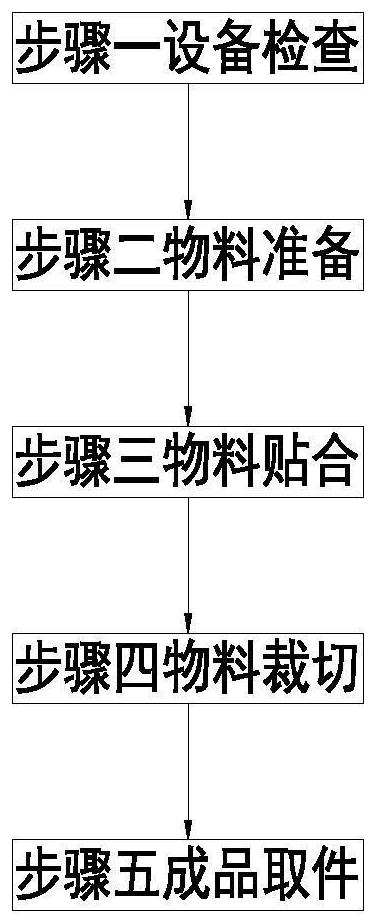

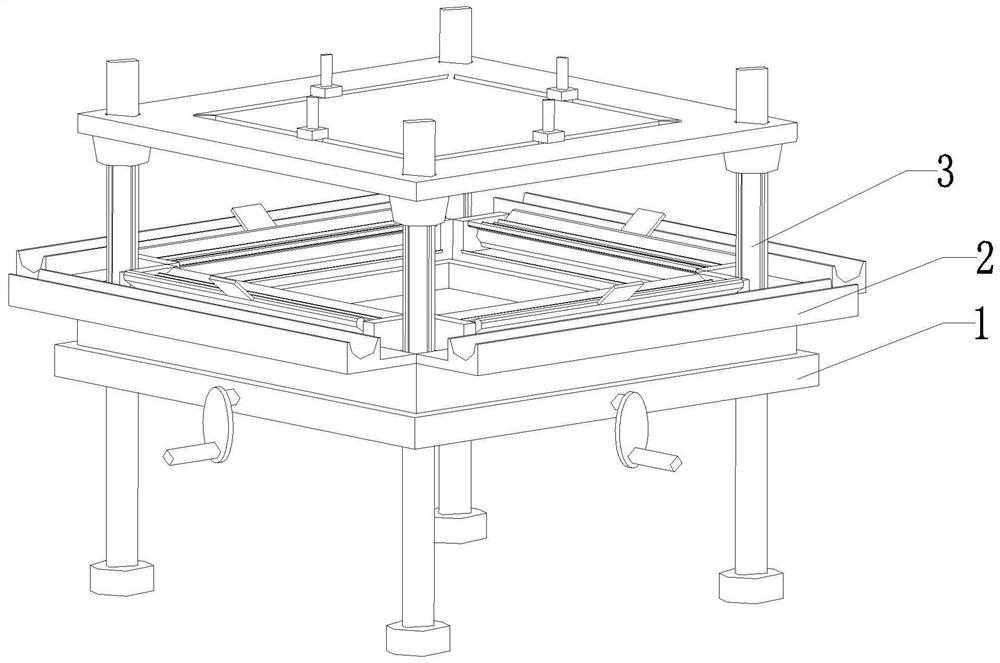

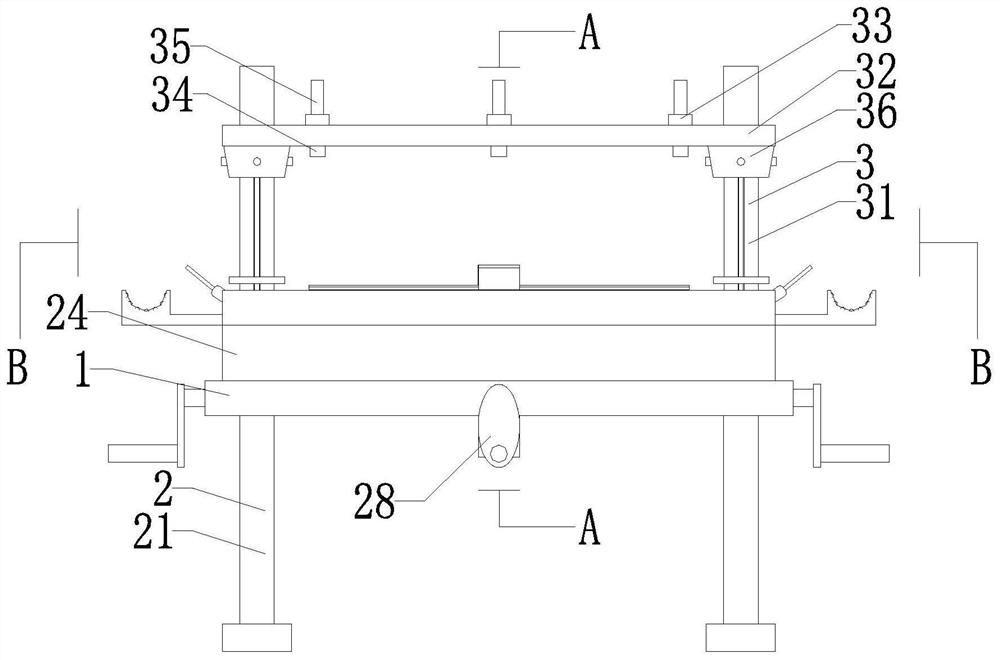

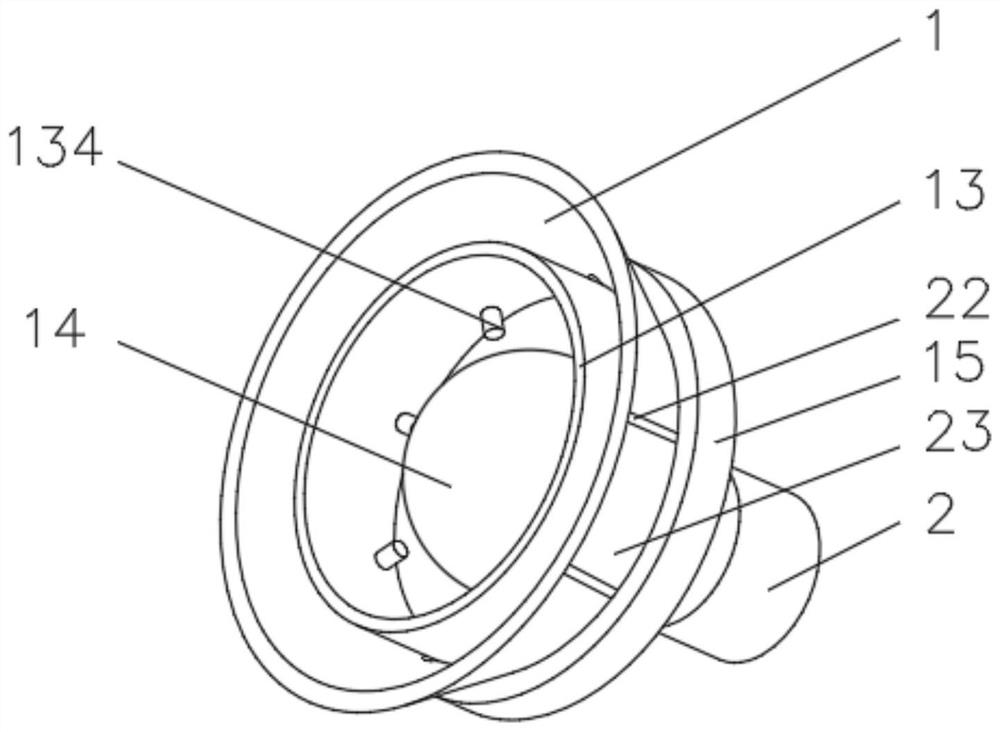

Silk-screen printing plate manufacturing method

InactiveCN112776461AIncrease workloadTo achieve the purpose of clampingLamination ancillary operationsLaminationScreen printingMechanical engineering

The invention relates to a silk-screen printing plate manufacturing method. The silk-screen printing plate manufacturing method mainly comprises the following steps of device inspection, material preparation, material attachment, material cutting and finished product taking. A printing silk-screen plate manufacturing device comprises an installation base plate, a bonding kit and a cutting kit, the bonding kit is arranged at the upper end of the installation base plate, and the cutting kit is arranged at the upper end of the bonding kit. The silk-screen printing plate manufacturing method can solve the following problems in production and preparation of an existing screen printing plate that a, when the existing screen printing plate is manufactured, a screen and a photosensitive film generally need to be attached together, the photosensitive film can be wrinkled in the attaching process, then attaching treatment needs to be carried out again, and the production progress is greatly slowed down accordingly; and b, when the existing screen printing plate is manufactured, the photosensitive film is directly attached to the surface of a screen, then the screen and the photosensitive film are generally attached insufficiently, manual secondary pressing is needed, the workload of workers is greatly increased, and manpower is wasted.

Owner:南京云中雨科技有限公司

Automobile part paint spraying device

ActiveCN112619959AReach the purpose of recyclingIncrease the value of repeated useSpraying apparatusMotor vehicle partEngineering

The invention discloses an automobile part paint spraying device, which comprises an outer frame; one side of the outer frame is communicated with a storage barrel; a fixing rod is installed on the inner wall of the outer frame; a clamping plate is installed on one side of the fixing rod; an installation hole is formed in one side of the clamping plate; a thread is arranged on the inner wall of the installation hole; a nut is connected to one side of the clamping plate; a threaded rod is installed on one side of the nut; and one end of the threaded rod penetrates through the clamping plate to be connected with the installation hole. The purpose of clamping a part is achieved through the arrangement of the clamping plate and the threaded rod, the problem that the part falls off from the interior of the device in the machining process is solved, and troubles brought to later work are avoided; and the side, away from the nut, of the clamping plate is fixedly connected with a rubber plate. The invention relates to the technical field of paint spraying. According to the automobile part paint spraying device provided by the invention, the purpose of recycling splashed paint is achieved, and the repeated use value of the paint is increased.

Owner:长春市富锋冲压件有限公司

Rubber product processing device

InactiveCN112549150AImprove applicabilityPerfect for adjusting aperture sizeMetal working apparatusElectric machineryStructural engineering

The invention discloses a rubber product processing device which comprises a base. A telescopic rod is fixedly connected to the top of the base, so that the purpose of vertically adjusting a drill bitis achieved; a motor is installed at the end, away from the base, of the telescopic rod, a rotating rod is rotatably connected to an output shaft of the motor, and the drill bit is installed at the end, away from the motor, of the rotating rod; a positioning plate is fixedly connected to one side of the base through a connecting rod, a clamping plate is installed at the side, close to the drill bit, of the positioning plate, and a reinforcing plate is fixedly connected to the side, close to the clamping plate, of the positioning plate, so that the situation that the positioning plate is accidentally abraded when the drill bit punches holes is reduced; and a clamping device is mounted at the side, away from the connecting rod, of the clamping plate. The invention relates to the technical field of rubber product processing. According to the rubber product processing device, the purpose of adjusting the hole diameter when a rubber product is punched is achieved, then the applicability ofa punching device is improved, and the rubber product processing device is more economical and efficient.

Owner:南陵县巍曙新材料科技有限责任公司

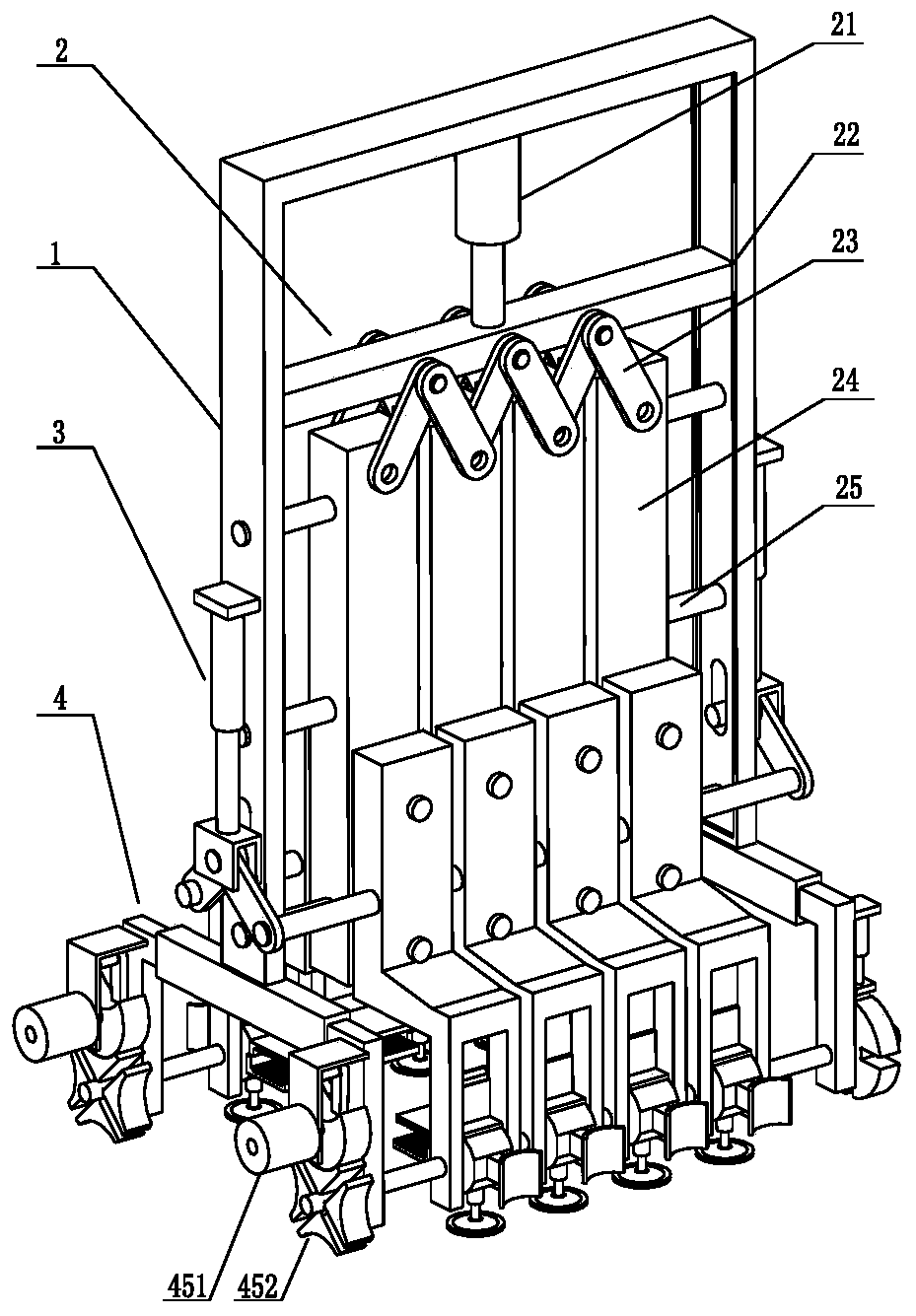

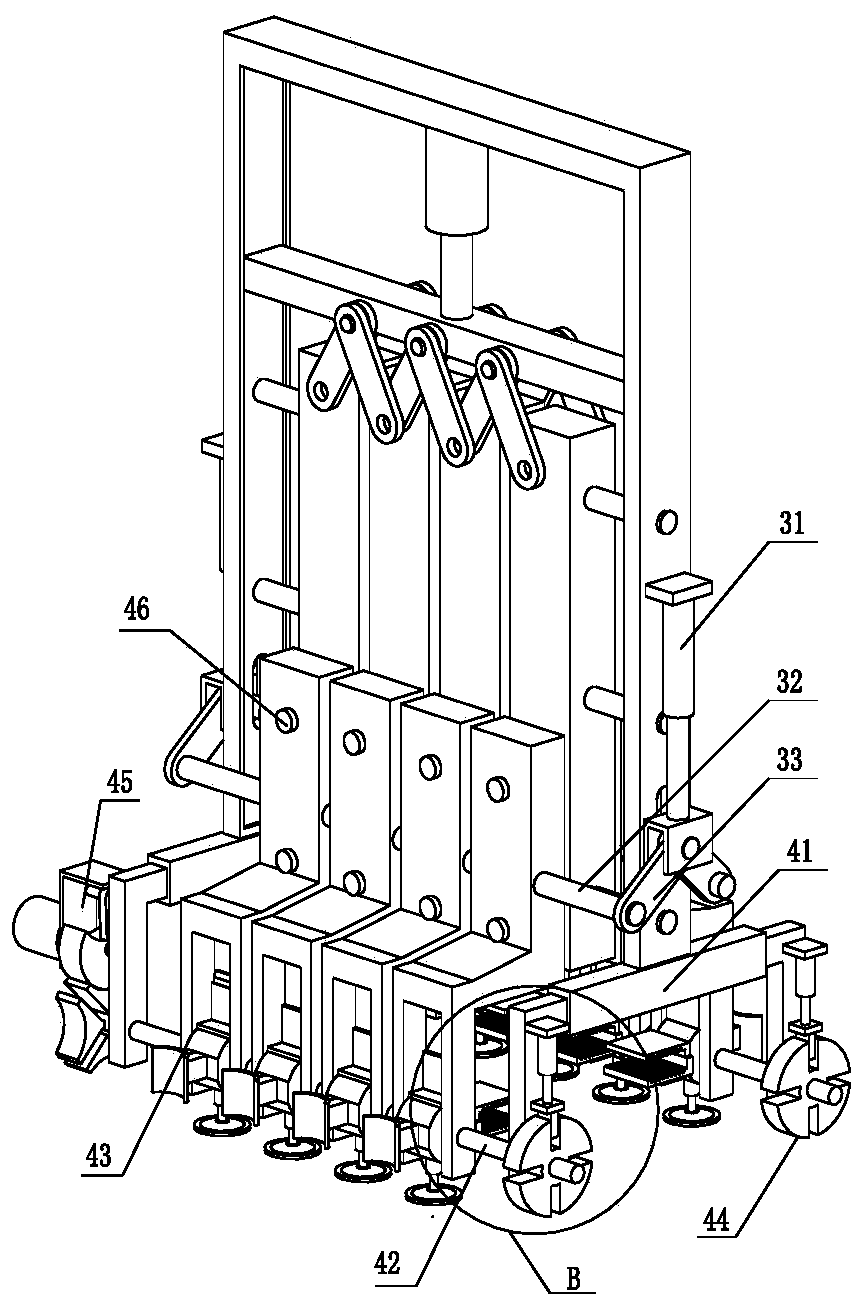

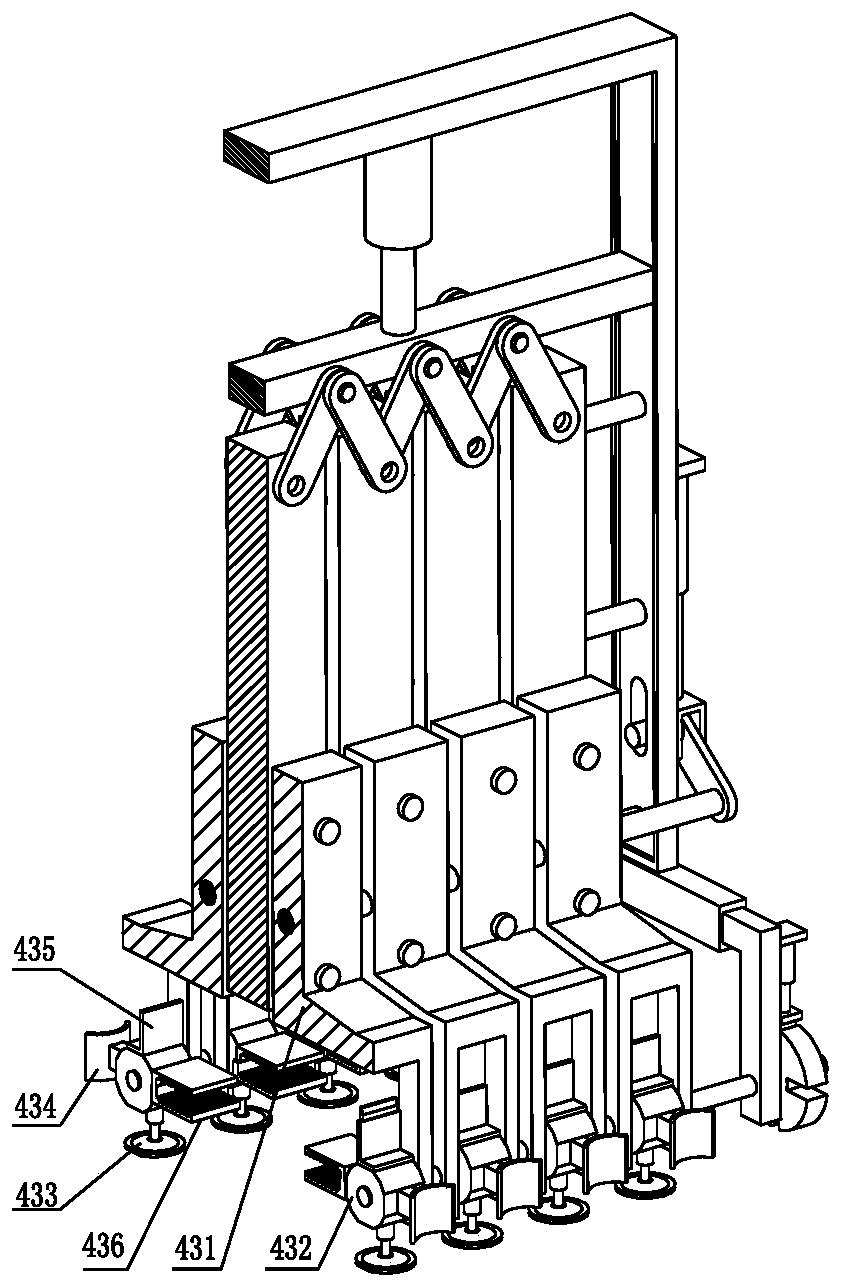

Warehouse logistics goods automatic clamping carrier

ActiveCN110921177ATo achieve the purpose of clampingNo damageStorage devicesConveyor partsLogistics managementMechanical engineering

Owner:深圳市靖洋集慧科技投资有限公司

Wire clamp clamping and fixing device

InactiveCN107649911ACompact structurePlay the role of clamping and fixingWork clamping meansPositioning apparatusPower cableEngineering

The invention belongs to the technical field of power cable clamping devices, and particularly relates to a wire clamp clamping and fixing device. The device comprises a base, an air cylinder, a leftclamping plate, a right clamping plate and a bottom plate, wherein the bottom plate is fixed on the base; the right clamping plate is fixed to the right side of the bottom plate through a right fixingseat; two left fixing seats are fixed on the left side of the bottom plate; two guide columns are connected between the left fixing seats and the right fixing seat; guide sleeves are arranged at thetwo ends of the left clamping plate; the left end of the left clamping plate is hinged to one end of a right connecting arm; a connecting seat is arranged on the bottom plate on the left side of a through hole; the connecting seat is hinged to one end of the left connecting arm; the other end of the left connecting arm and the other end of the right connecting arm penetrate through the through hole to be hinged to a piston rod of the air cylinder; and the bottom of the air cylinder is hinged to the base. The wire clamp clamping and fixing device is compact in structure and can be mounted at any position as a whole, so that the effect of clamping and fixing is achieved, the wire clamp can be clamped through the wire clamp clamping and fixing device, and the clamping is rapid and stable.

Owner:徐州宇飞电力科技有限公司

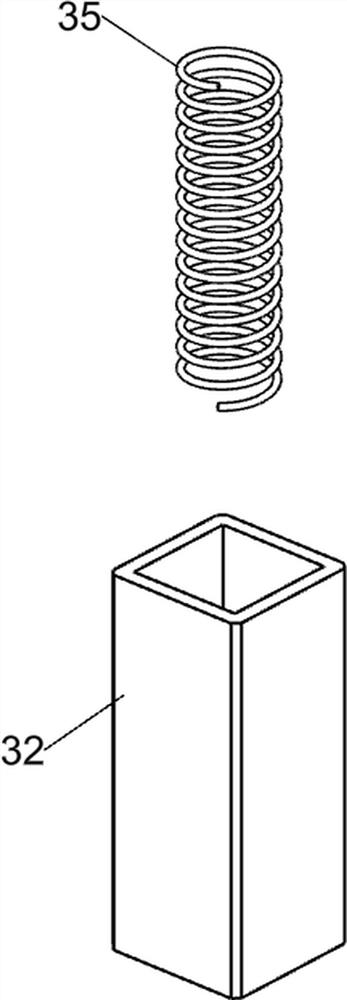

Plate-shaped pear syrup candy crushing equipment

ActiveCN112619750AAchieve the purpose of breakingTo achieve the purpose of automatic receivingGrain treatmentsConveyor partsEngineeringMechanical engineering

The invention relates to crushing equipment, in particular to plate-shaped pear syrup candy crushing equipment. The plate-shaped pear syrup candy crushing equipment is convenient for crushing plate-shaped pear syrup candies and is convenient for people to eat. According to the technical scheme, the plate-shaped pear syrup candy crushing equipment is characterized by comprising supporting columns, a crushing mechanism and limiting mechanisms, wherein the two sides of the top of a base are both connected with the supporting columns; the top side of the base is connected with the crushing mechanism; and the limiting mechanisms are connected to the two sides of the crushing mechanism, and the supporting columns are connected with the limiting mechanisms. Through cooperation of an air cylinder, a mounting square pipe, a crusher and a second spring, the purpose of crushing the plate-shaped pear syrup candies is achieved.

Owner:安徽龙润堂生物科技有限公司

Cutting device for wire and cable processing

ActiveCN111211516AEasy to fixShorten the timeApparatus for cutting/splicing cablesGear wheelElectric machinery

The invention discloses a cutting device for wire and cable processing. The device comprises a first transverse plate and a first base, a lower surface of the first transverse plate is fixedly connected with the first base, and a fixing device is installed in the middle of an upper surface of the first transverse plate. By using the cutting device for wire and cable processing, through cooperationof a handle, a helical gear rod, a fluted disc, a threaded rod, a first vertical plate and other structures, wires and cables can be conveniently and rapidly fixed, a labor and time are saved, and ausing effect is better; and through cooperation of structures such as a motor, a second threaded rod, a second gear, a second transverse plate, a third vertical plate, a cutting machine and the like,a traditional manual cutting method is changed, labor intensity is reduced, and safety guarantee of workers is improved.

Owner:河北春鸿电线电缆有限公司

Conveying device for electric heating pipe of water heater

The invention discloses a conveying device for an electric heating pipe of a water heater, and relates to the technical field of electric heating pipe machining. The conveying device for the electricheating pipe of the water heater comprises a bottom plate, one side of the top of the bottom plate is fixedly connected to a slide rail by mounting a support rod, the position, on the right side of the slide rail, of the bottom plate is fixedly connected to a support rack, the side, away from the slide rail, of the support rack is fixedly connected with a clamping device, the slide rail is sleevedwith a sliding block, the top of the sliding block is fixedly connected with a sliding mounting frame, the upper part of the sliding mounting frame is fixedly connected with a feeding pipe, and the middle of the slide rail is slidably connected with a sliding mounting plate.. The conveying device for the electric heating pipe of the water heater realizes clamping of the electric heating pipe, andensures that the electric heating pipe can be rapidly clamped and stopped from being conveyed in pause when being conveyed, stable conveying of the electric heating pipe and the clamping and conveying efficiency of the electric heating pipe are ensured, the working speed is improved, and the labor cost is reduced.

Owner:南通同江机电设备有限公司

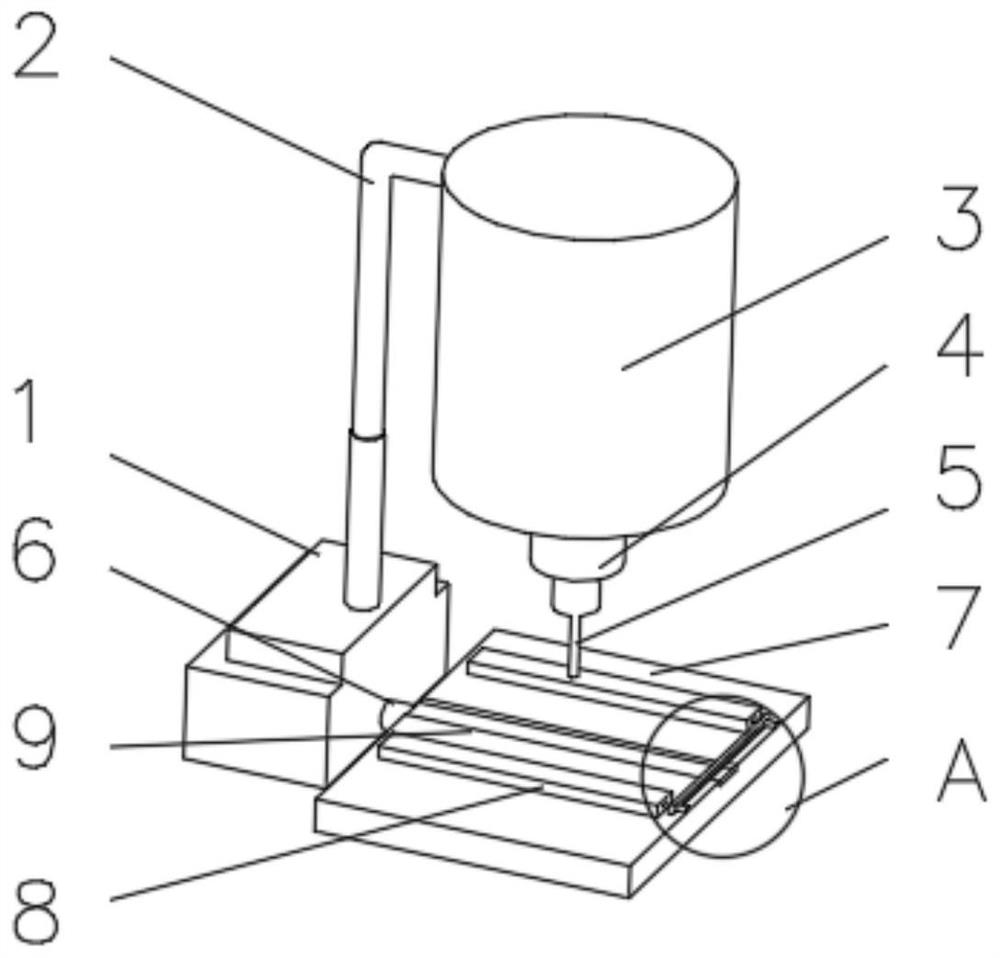

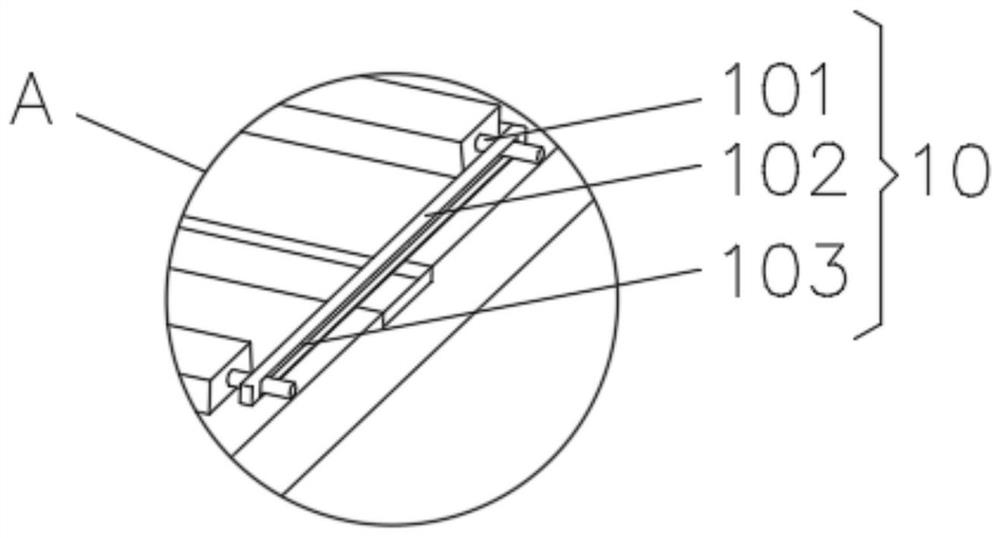

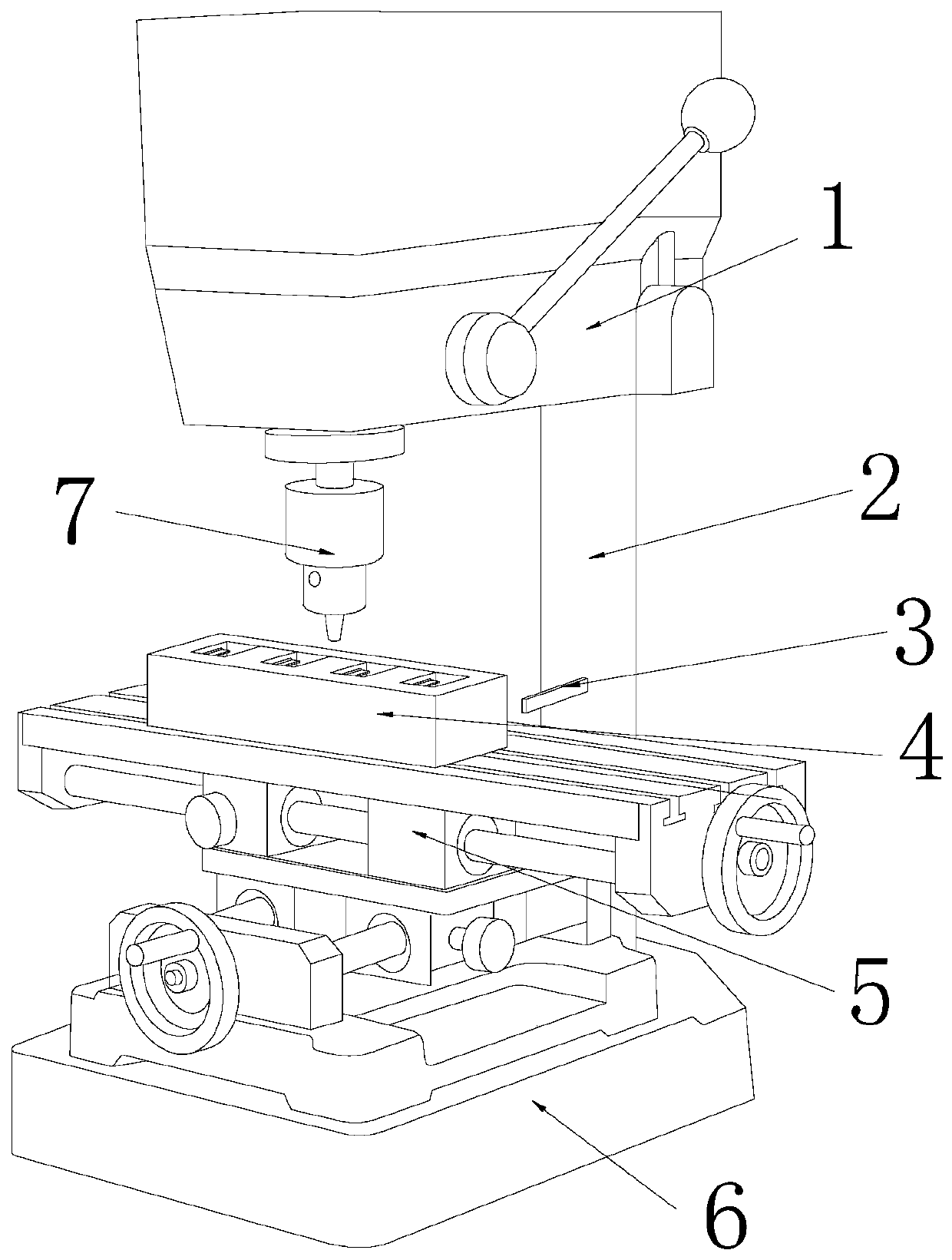

Milling machine sliding platform for placing machined part

InactiveCN110039322AEasy to take outAchieve clampingLarge fixed membersMachine partsIndustrial engineering

The invention discloses a milling machine sliding platform for placing a machined part. The milling machine sliding platform structurally comprises an upper fixing seat, a main supporting column, a fixed extending rod, a positioning processing device, a work table, a base and a machining head; and the upper fixing base and the base are arranged to be of upper and lower structures. The milling machine sliding platform has the beneficial effects that a control gear is driven by external mechanical force to rotate counterclockwise, as a gear is engaged with a toothed edge on a driving rod, the driving rod moves in the same direction accordingly, under the action of a reversing mechanism, the transmission direction of the force is changed, two clamping plates move in the opposite direction toclamp the part, and the aim of clamping the to-be-machined part is achieved; the part slides on the work table through slippage, when the part passes through the fixed extending rod, the fixed extending rod and a groove are embedded, a first rod is reset under traction of a rectangular block, clamping force of the part is lost, the part groove drive the part to upwards move under the effect of a third spring, the part can be conveniently taken out, and manual disassembling of the part from the work table is not needed.

Owner:南安市跃启机械制造有限公司

Electroplating spraying device for composite material automobile plate spring production

The invention discloses an electroplating spraying device for composite material automobile plate spring production, and belongs to the technical field of automobile plate spring processing. The device comprises a processing workbench, an adjusting assembly, a rotating assembly, fixing assemblies, lifting assemblies, a moving assembly, screw rod sliding tables and a spraying machine; the adjustingassembly is arranged at one end of the lower portion of the processing workbench; the rotating assembly is arranged at one end of the processing workbench; two groups of fixing assemblies are arranged, each group comprises two fixing assemblies, and the two groups of fixing assemblies are symmetrically arranged at the working end of the rotating assembly; twp lead screw sliding tables are arranged on the two sides of the processing workbench; two lifting assemblies are arranged at the working ends of the two lead screw sliding tables correspondingly; the moving assembly is fixedly arranged atthe working ends of the two lifting assemblies; and the spraying machine is fixedly arranged at the working end of the moving assembly. According to the device, full-automatic spraying can be conducted on plate springs through cooperation of the assemblies, the spraying efficiency is good, and surface spraying is uniform.

Owner:李登进

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com