Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Fastened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-draining vacuum breaker

A self-draining vacuum breaker includes a first valve having an inlet at its one end for connecting an outfall, a second valve having a coupling portion at its one end connected with the other end of the first valve, an outlet at its the other end for connecting a hose, and an annular fringe formed at an inner periphery thereof, a movable stopper having a stopping member and a plurality of claw hooks, which extends downwards from the stopping member and movably contacts against the inner periphery of the outlet of the second valve and each has a barb-like hook portion, and a spring having two ends respectively engaging the barb-like hook portions and lying against the annular fringe.

Owner:YANG YUNG FANG

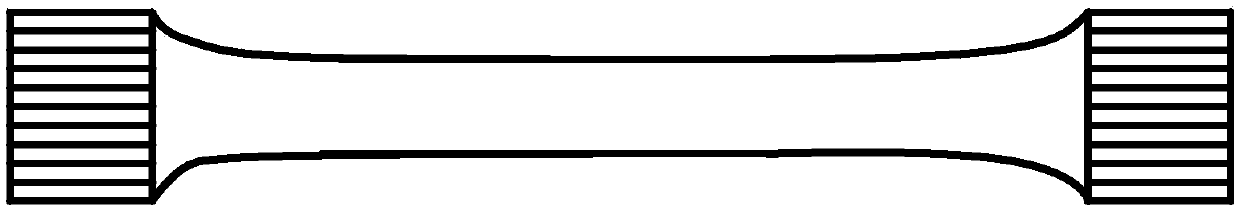

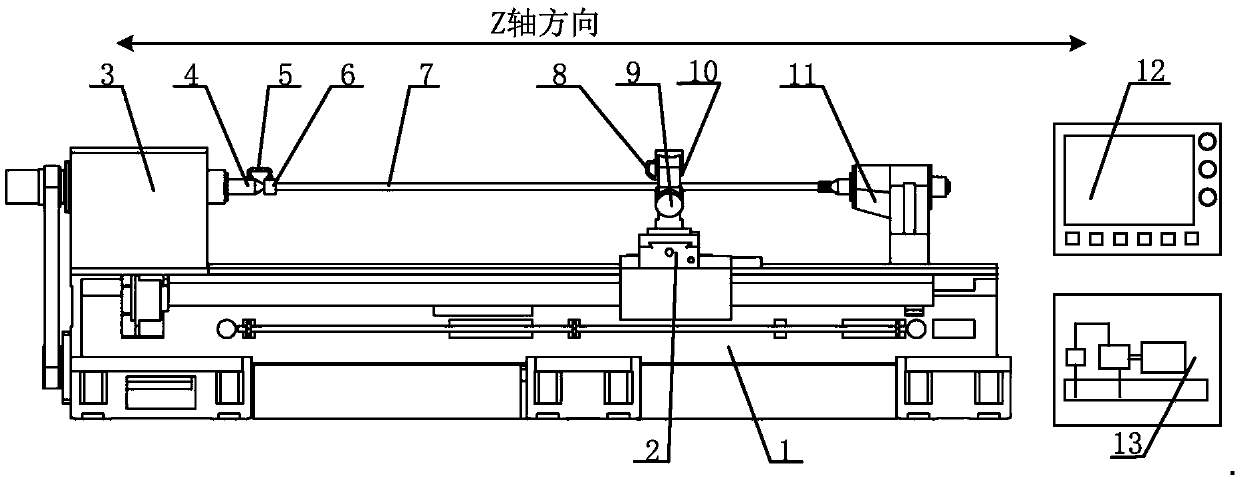

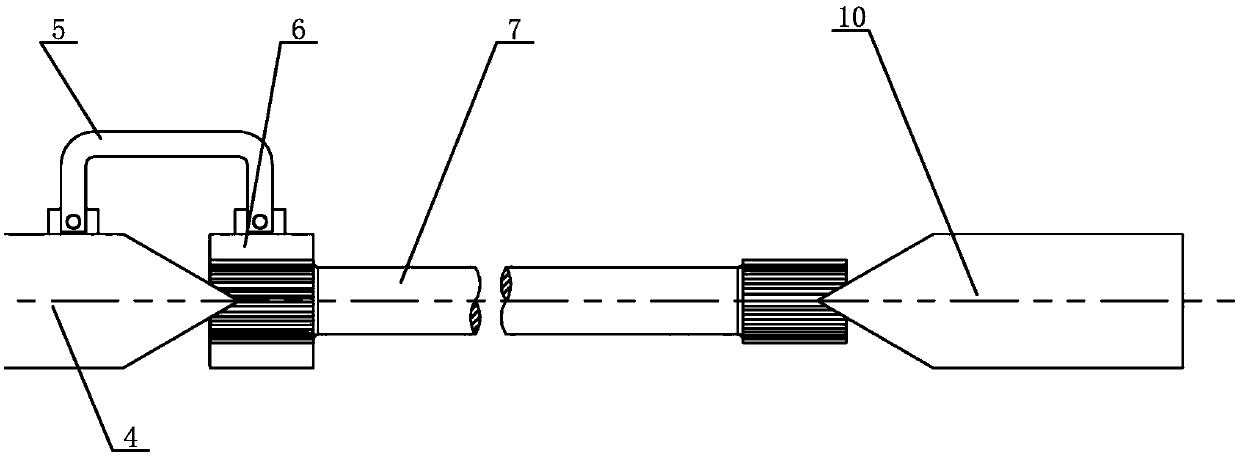

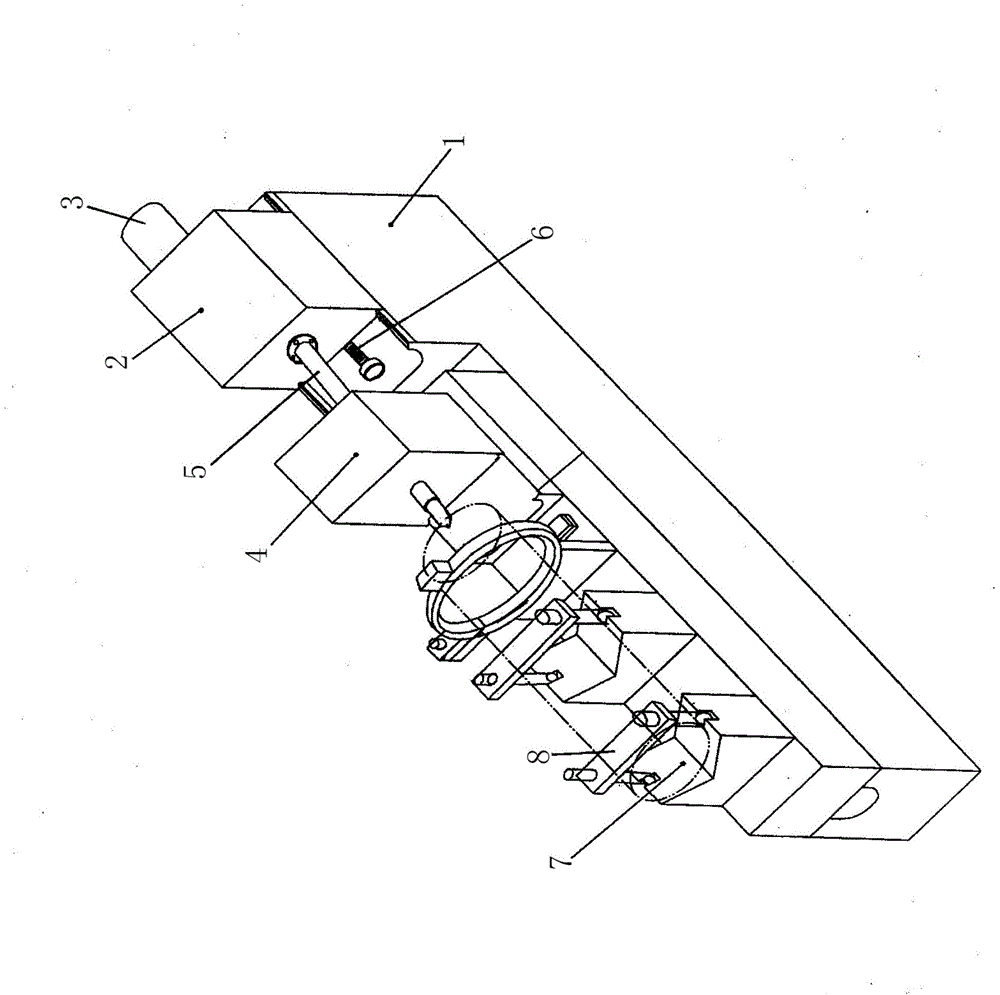

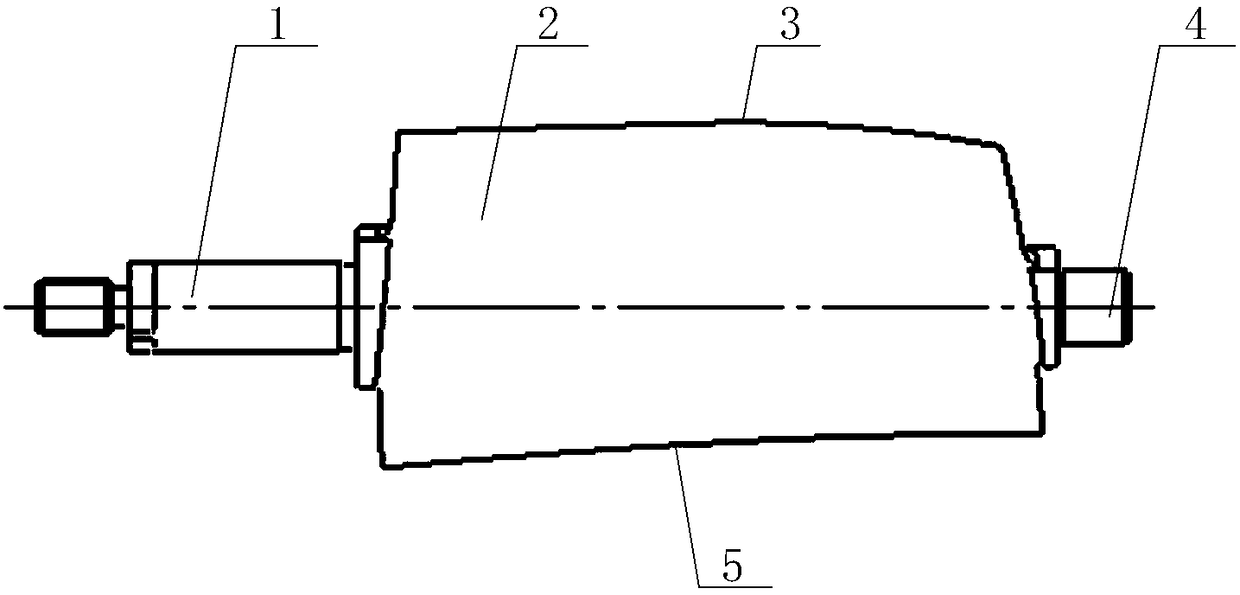

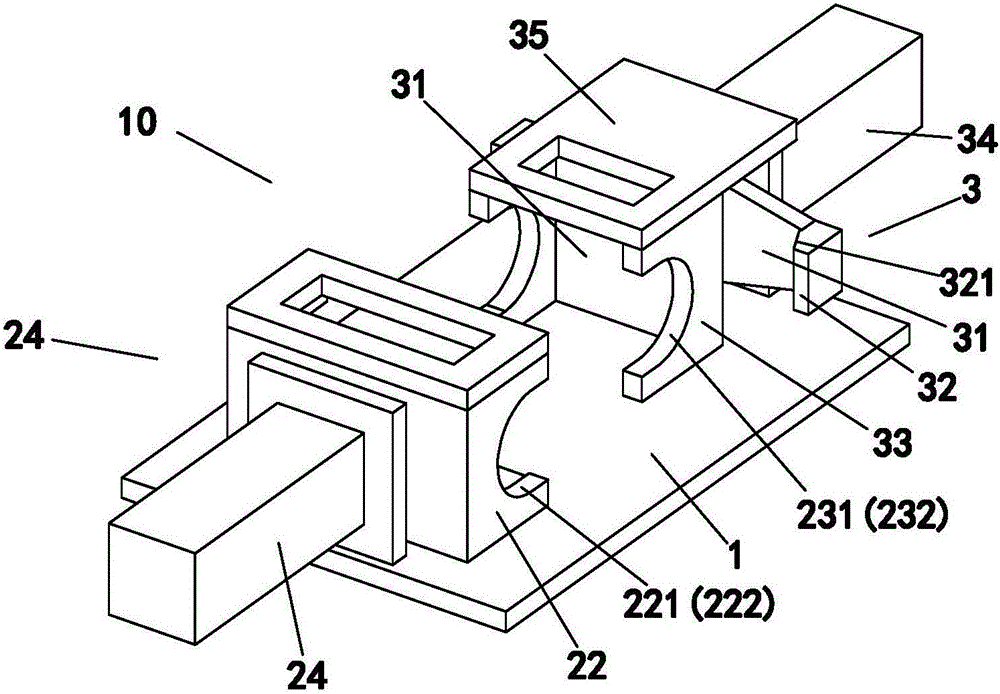

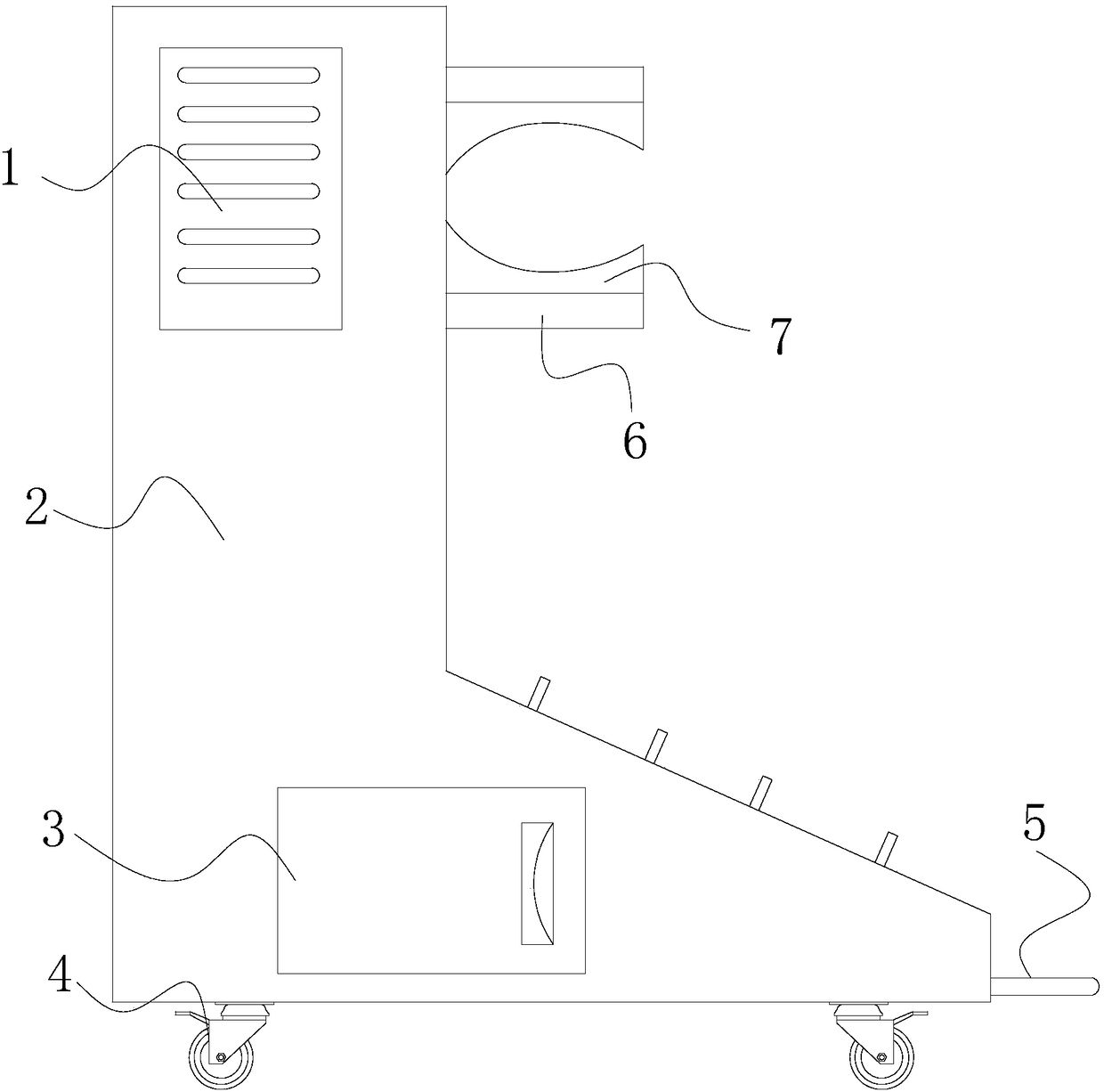

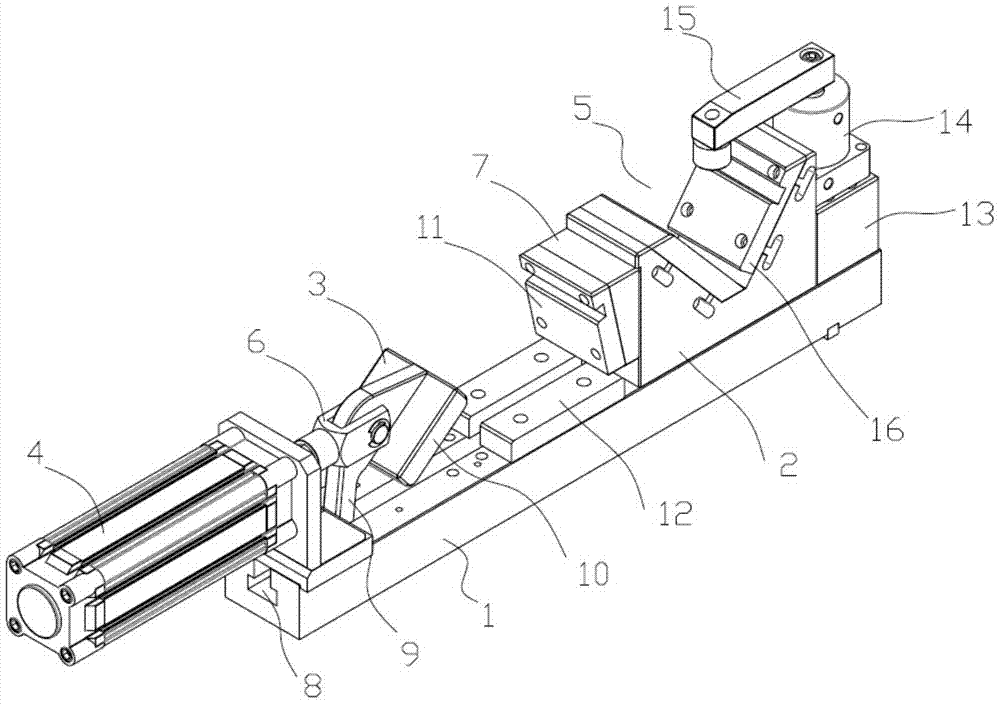

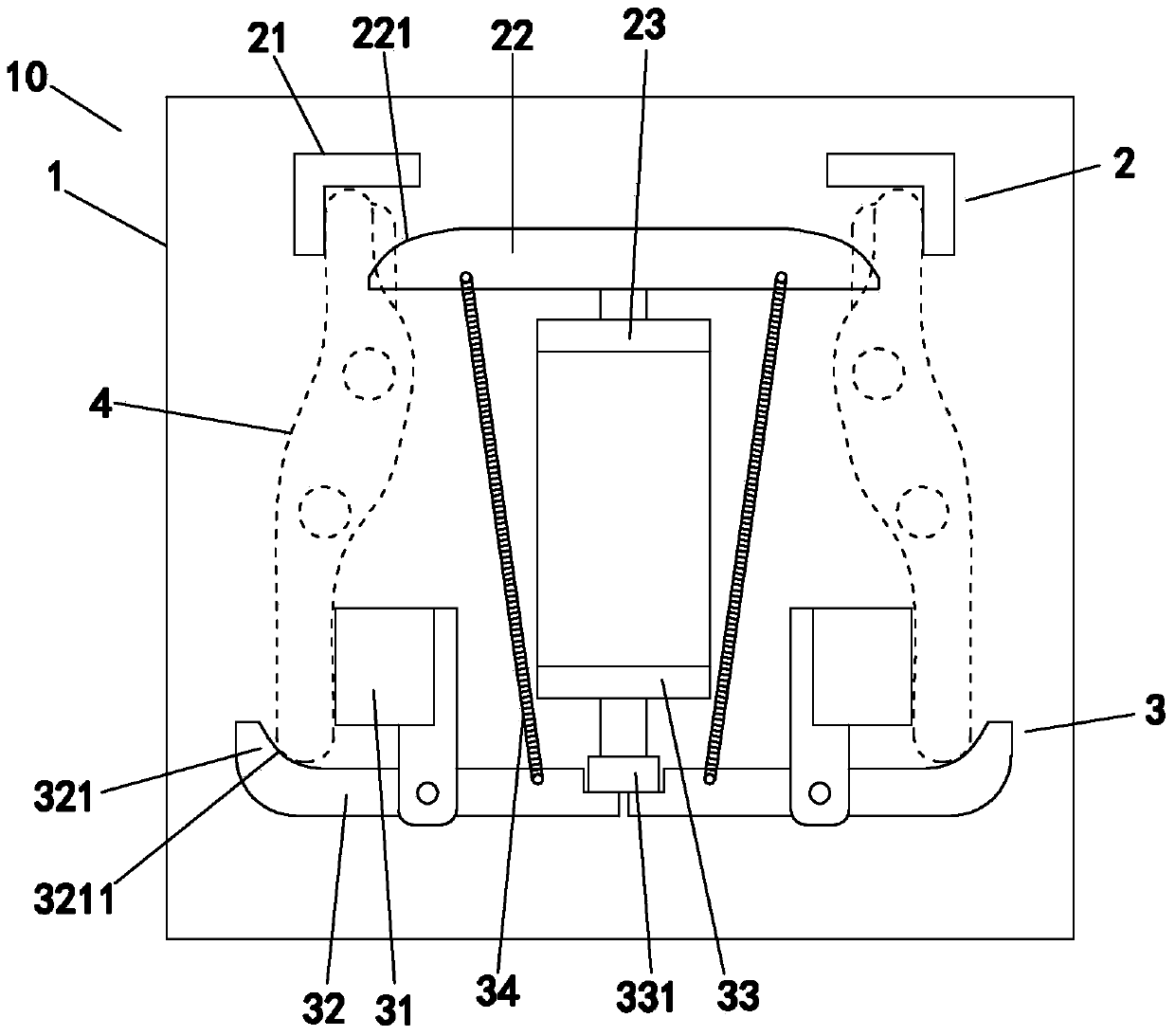

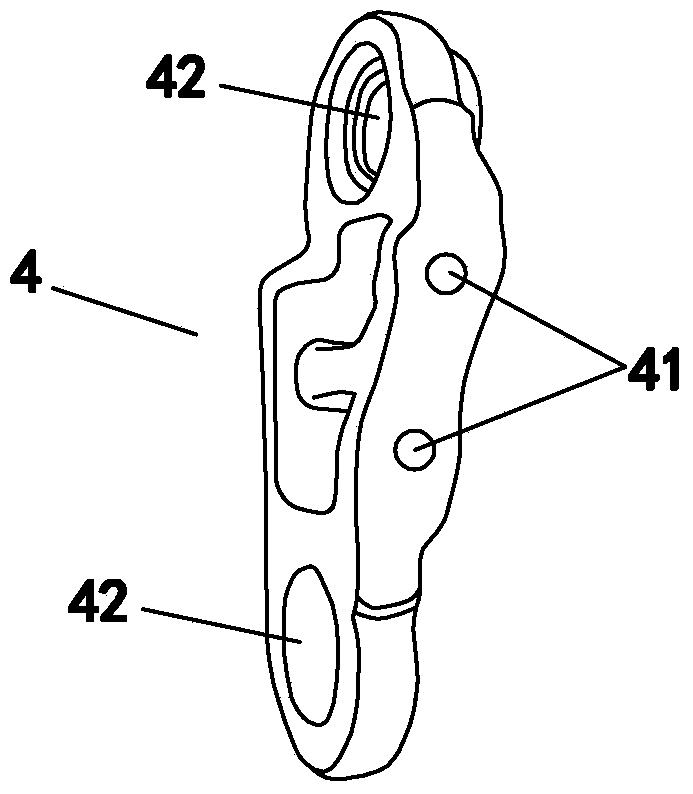

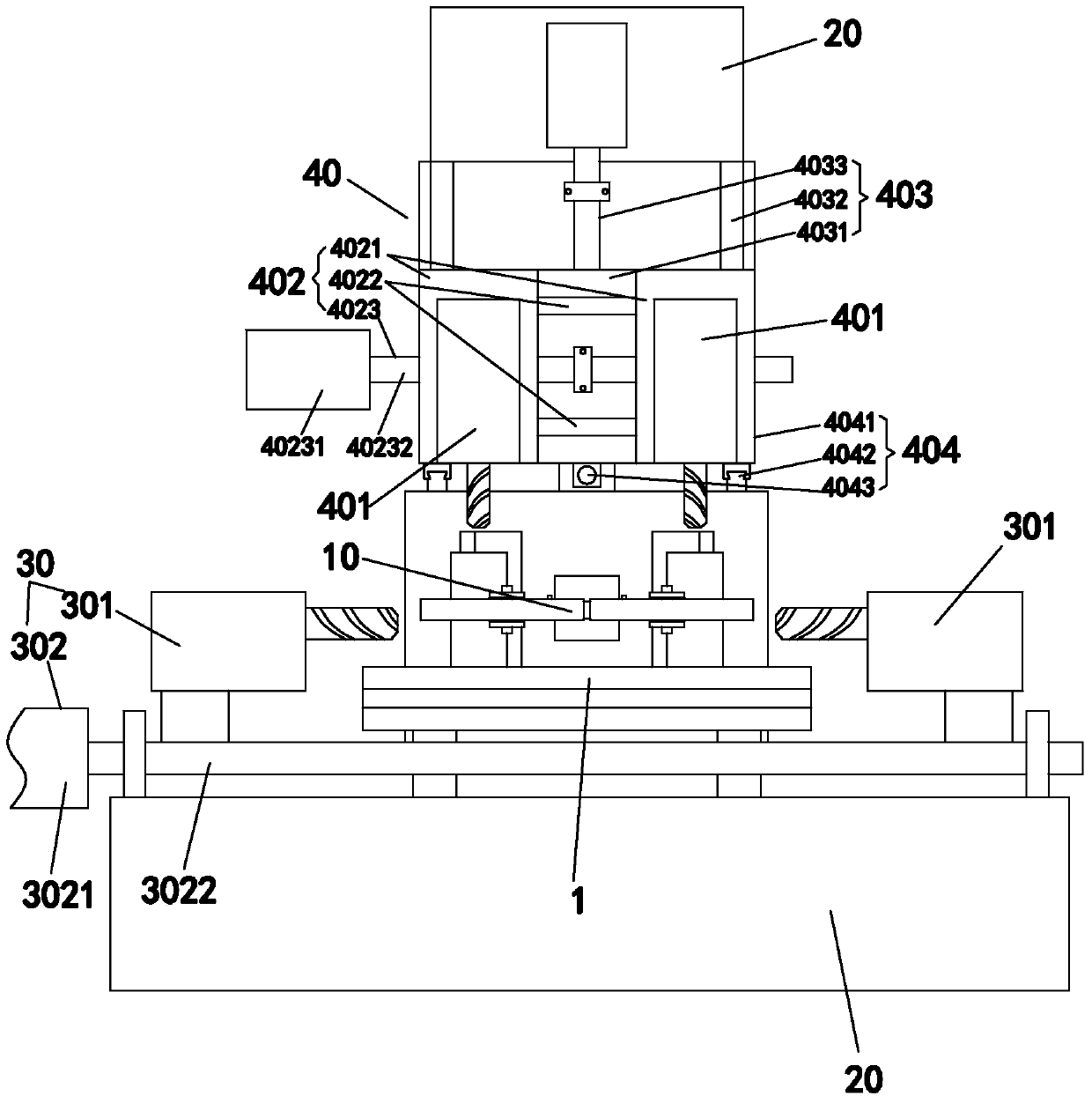

Numerical control rolling machine tool for outer circle rolling of torsion shaft

ActiveCN108673051AFastenedHigh speedWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention provides a numerical control rolling machine tool for outer circle rolling machining of a torsion shaft. The numerical control rolling machine tool comprises a machine tool body, an outer circle rolling head, a dual centre locating device, a shifting fork connecting part, an internal spline clamp sleeve, a full closed protection cover, a displacement measurement system, a precise oilmist cooling system, a numerical control system and a hydraulic system. The outer circle rolling head of the machine tool adopts a multi-rolling-wheel symmetric rolling device structure, and when outer circle rolling machining of the torsion shaft is carried out, a workpiece bears multiple equal pressures in the radiation direction; a displacement sensor is mounted in a hydraulic cylinder of theouter circle rolling head, the change value of the rolling diameter in the outer circle rolling process is worked out through the rolling cylinder displacement value fed back by the displacement sensor, and intelligent judgment on the limiting position of the outer circle rolling arc end can be achieved; and the shifting fork connecting part replaces a traditional chuck, a transmission structure is optimized, meanwhile, worker operation is more convenient, the machine tool is more suitable for streamlined production operation, and the rolling machining efficiency is higher.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

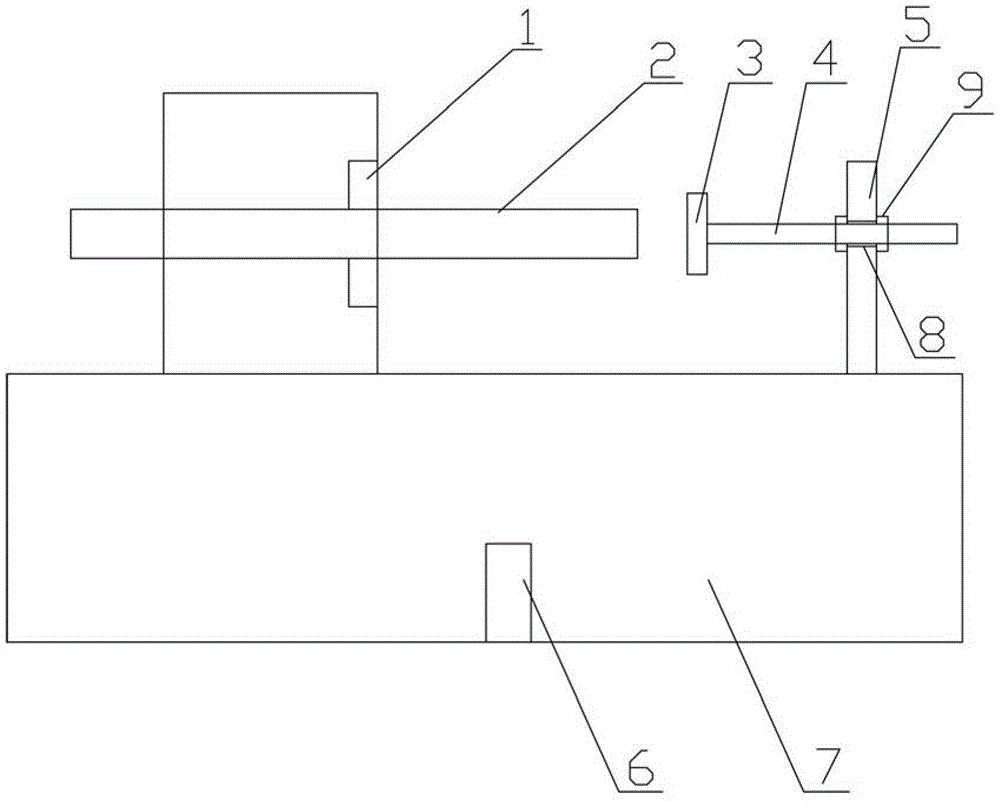

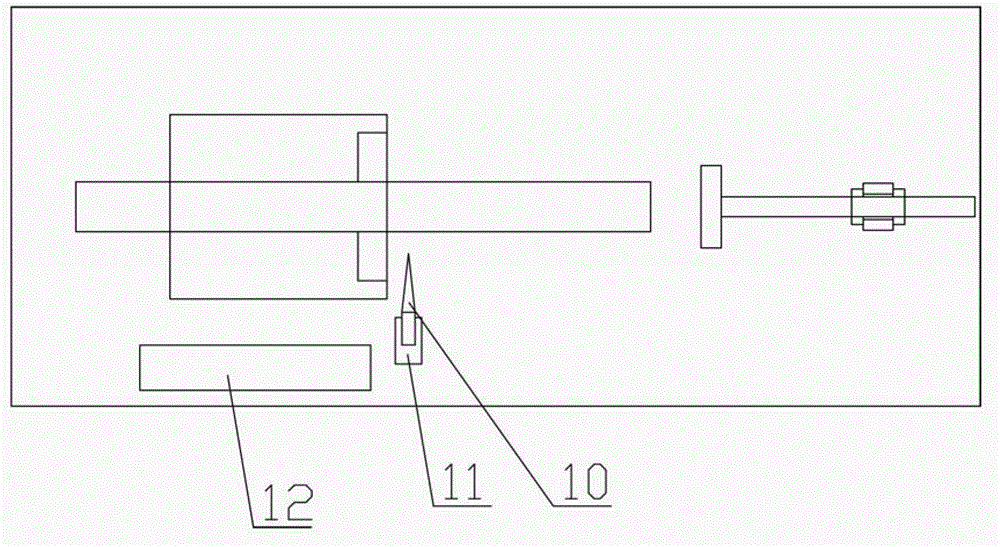

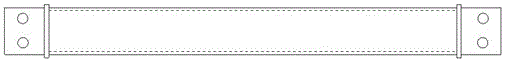

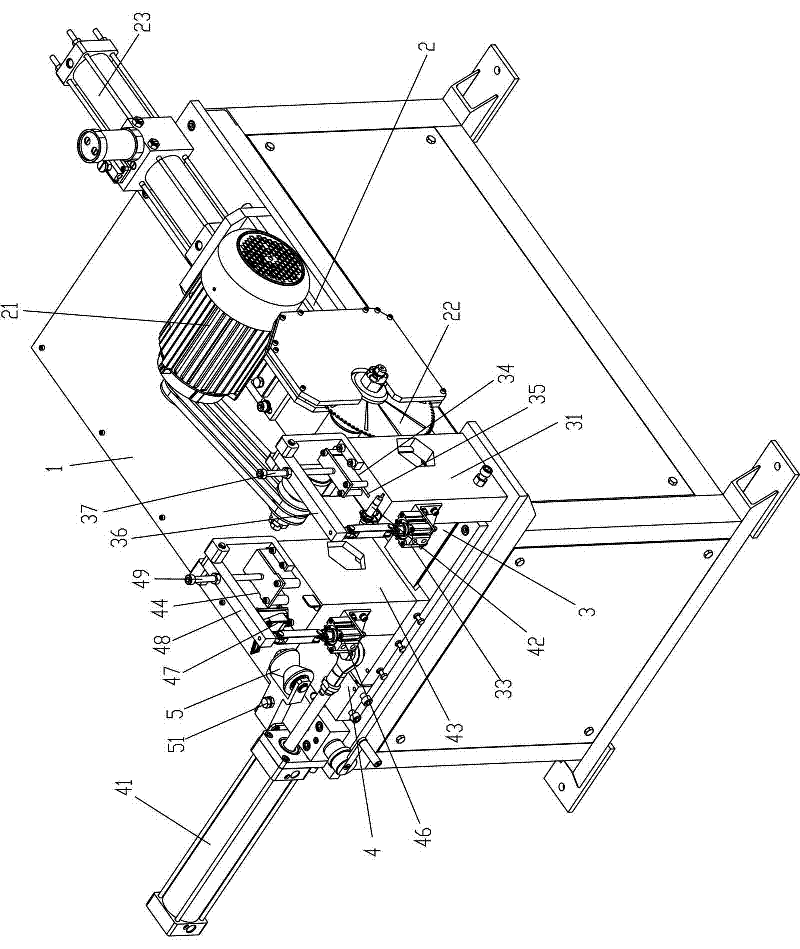

Drilling machine tool for round timber tip

InactiveCN104626280AFastenedThe processing position is accurateStationary drilling machinesFixed frameElectric machinery

The invention discloses a drilling machine tool for a round timber tip. The drilling machine tool for the round timber tip is characterized in that a main machine head is supported at one end of a machine tool body by a guide rail, a driving motor is arranged at the upper part of one side of the main machine head, a drilling rod supporting block is arranged at the inner side of the main machine head, a drilling rod connected with the main machine head is supported by the drilling rod supporting block, a propelling screw is arranged at the lower part of the main machine head, multiple clamp bases are arranged at the other side of the machine tool body, the center of a workpiece fixing frame on each clamp base and the center of the drilling rod are positioned on the same horizontal line; the drilling machine tool can be used for deeply processing the tip of a round timber due to the arrangement, the clamping effect is firm, and the processing position is accurate; and the drilling machine tool is economic and practical, can be operated conveniently and has high production efficiency.

Owner:陈红

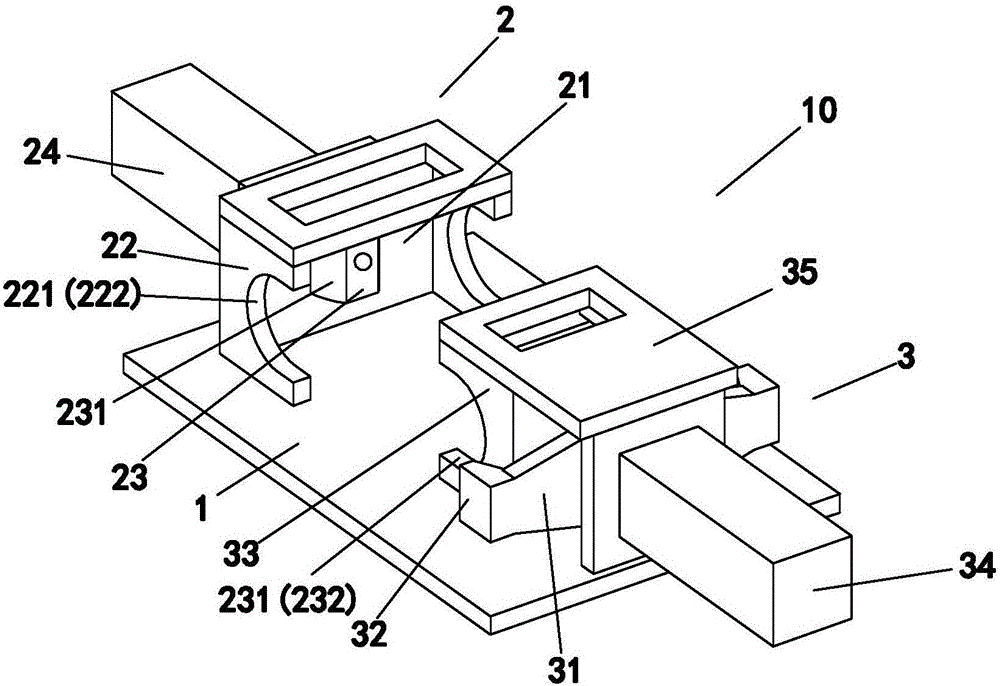

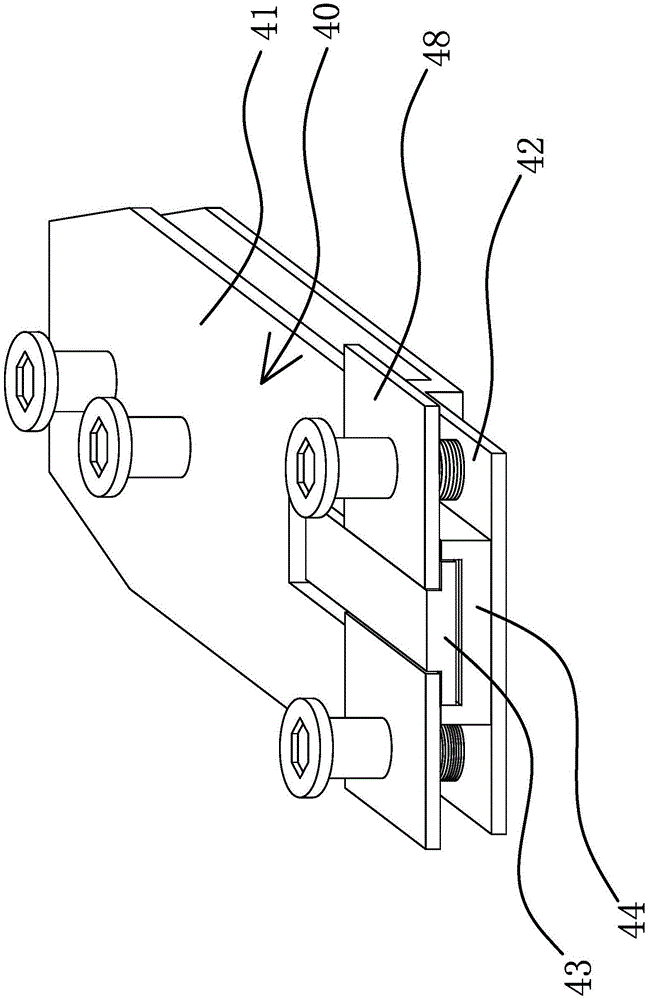

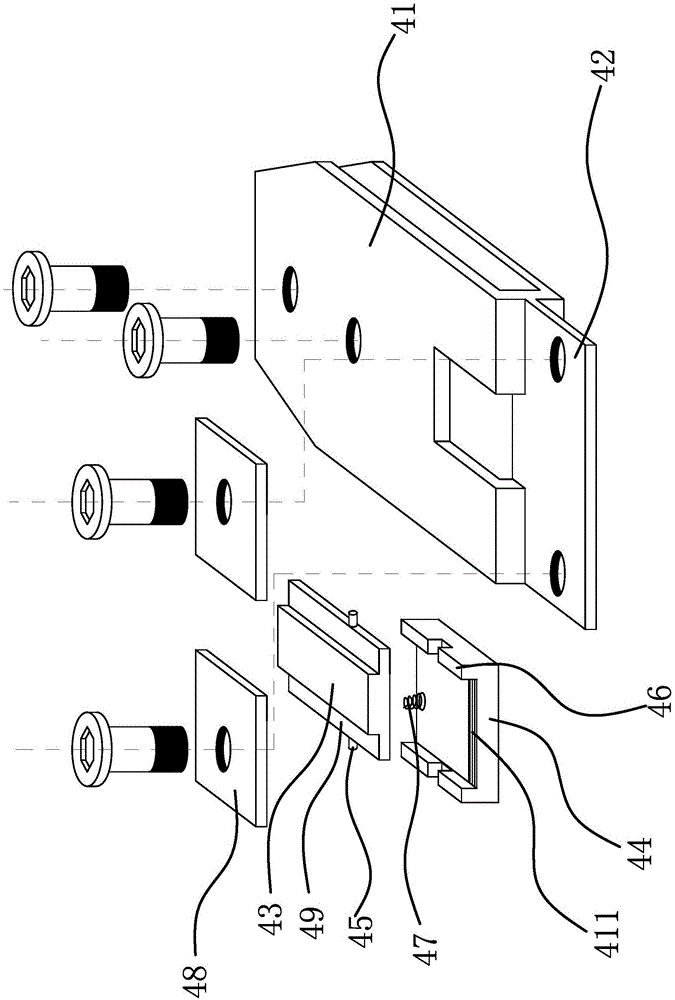

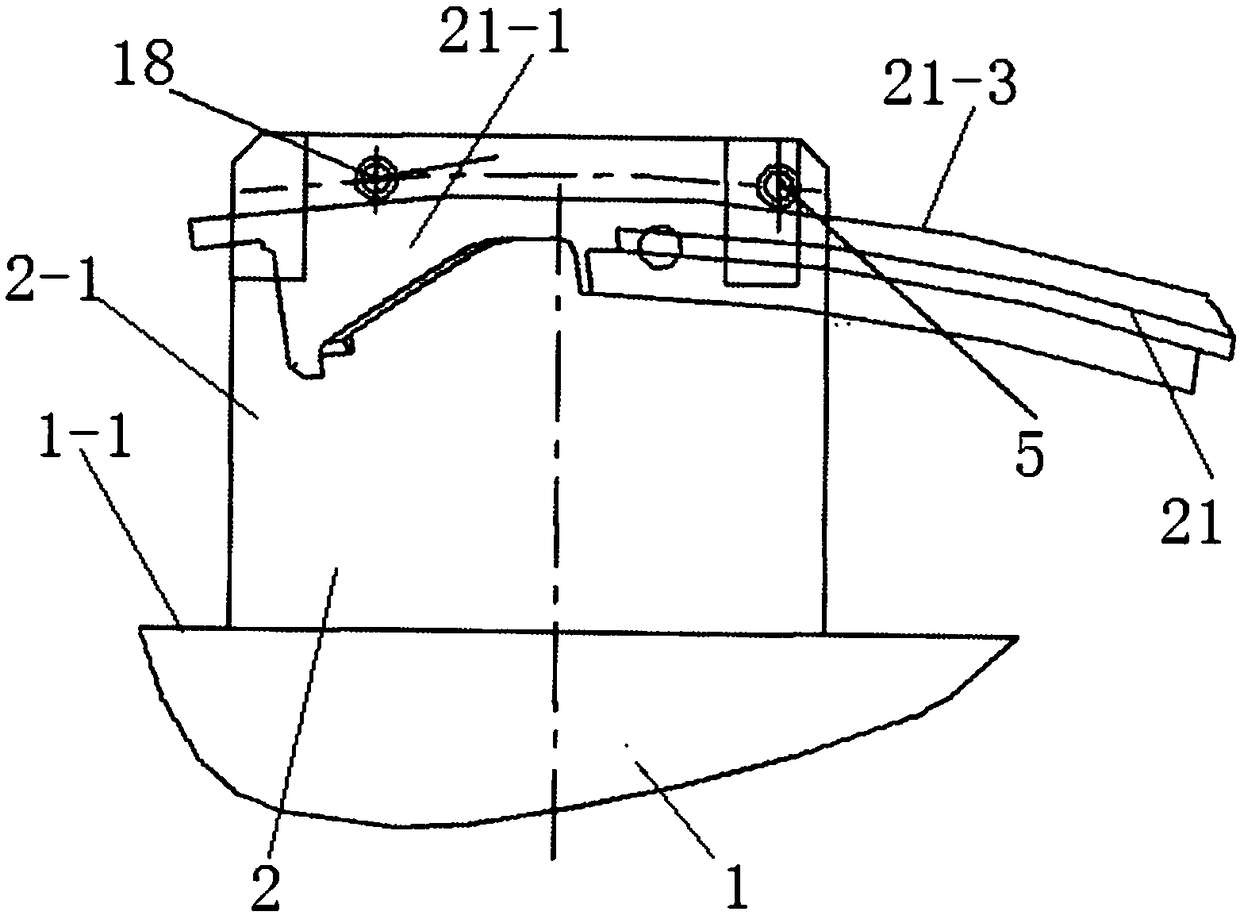

Guide blade edge plate dustpan hole machining rapid changing clamping device and method

ActiveCN106270859AUniform gapCompact structureElectrical-based auxillary apparatusEngineeringTurbine

The invention belongs to the field of machining of aero-engine turbine guide blades, and relates to a guide blade edge plate dustpan hole machining rapid changing clamping device and method. The clamping device is in a whole type, a positioning block and a supporting plate are arranged on the angular face of a clamping device body, the direction of a guide blade edge plate is positioned through a positioning face on the positioning block, through two positioning pins on the positioning block and one positioning pin on the supporting plate, positioning of the circular-arc top face of the guide blade edge plate in the vertical height direction is achieved, and the guide blade edge plate is jacked upwards from the lower portion of the guide blade edge plate through a jacking mechanism so that the guide blade edge plate is clamped; the exhaust side end face and the positioning face of the positioning block are attached, the guide blade edge plate is jacked upwards by adjusting the jacking mechanism, the circular-arc top face of the guide blade edge plate is tightly attached to the first positioning pin, the second positioning pin and the third positioning pin, a uniform gap is arranged between the exhaust side end face and the positioning face, and the beneficial effects of being compact in structure and rapid and convenient to operate are achieved.

Owner:AECC AVIATION POWER CO LTD

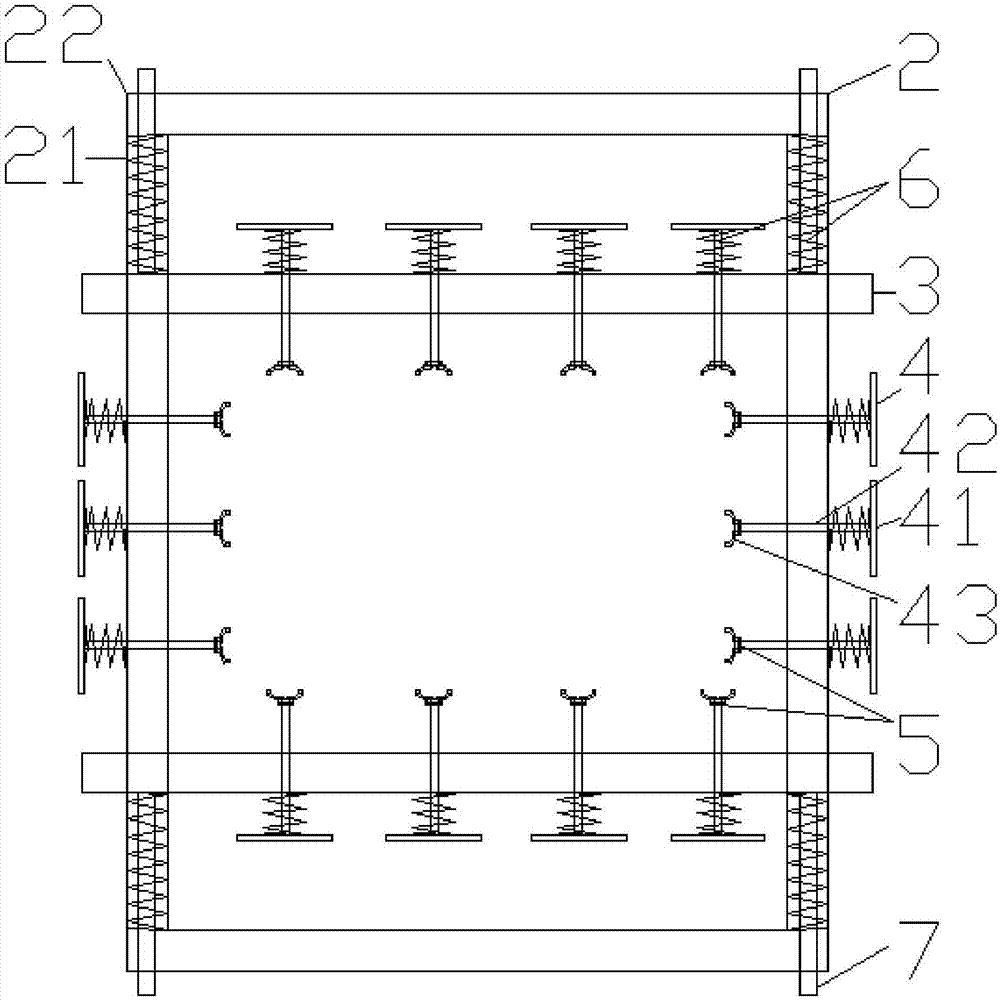

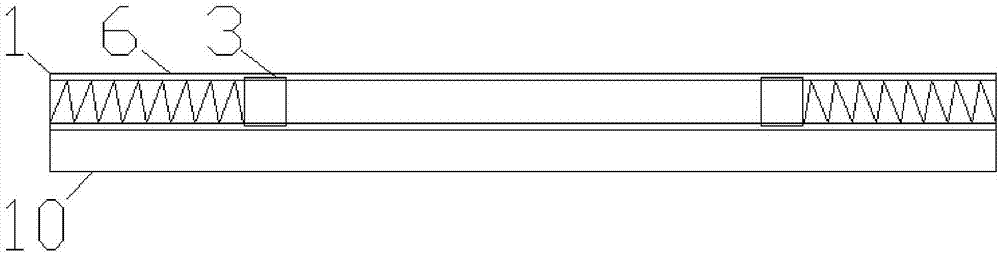

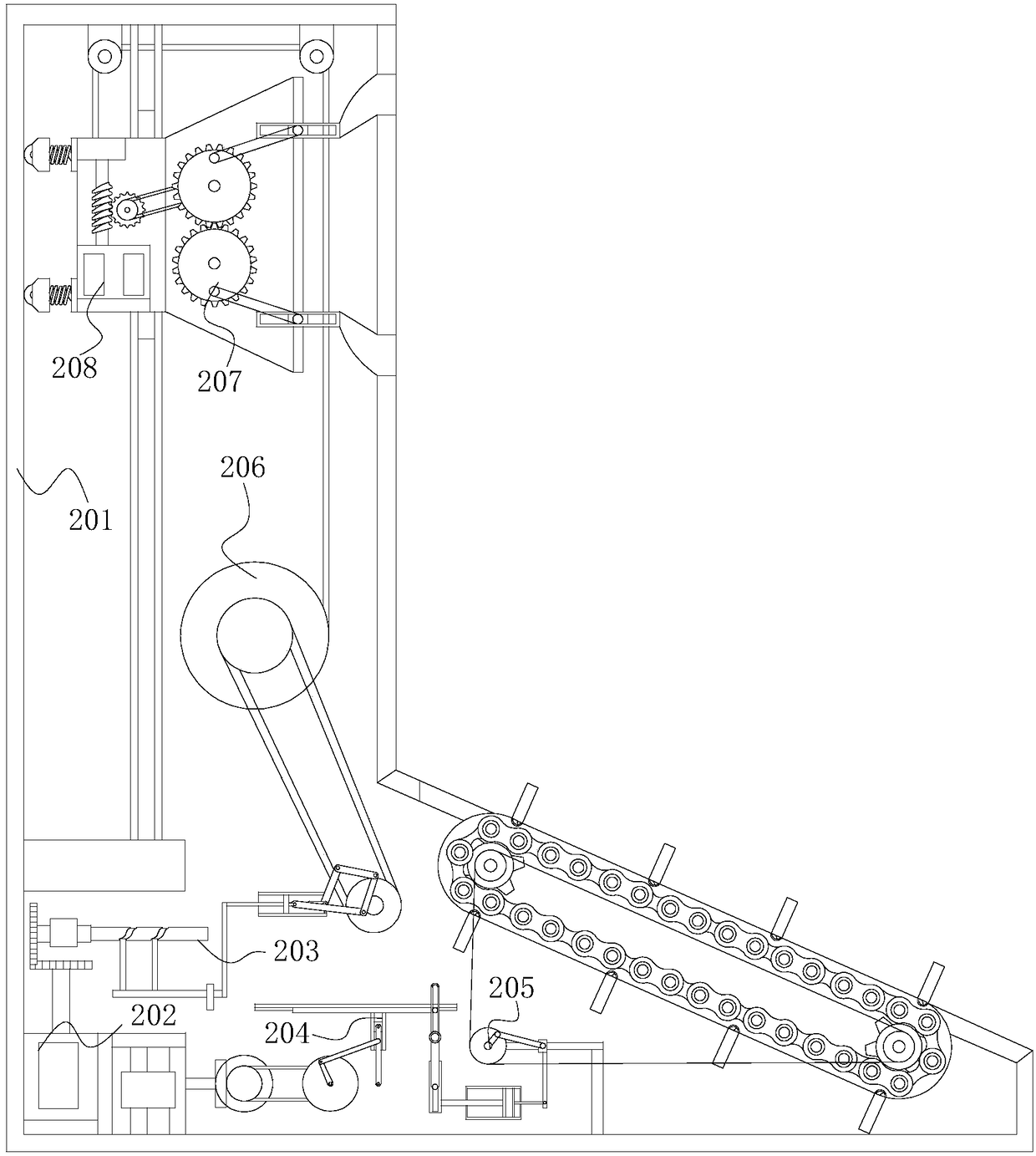

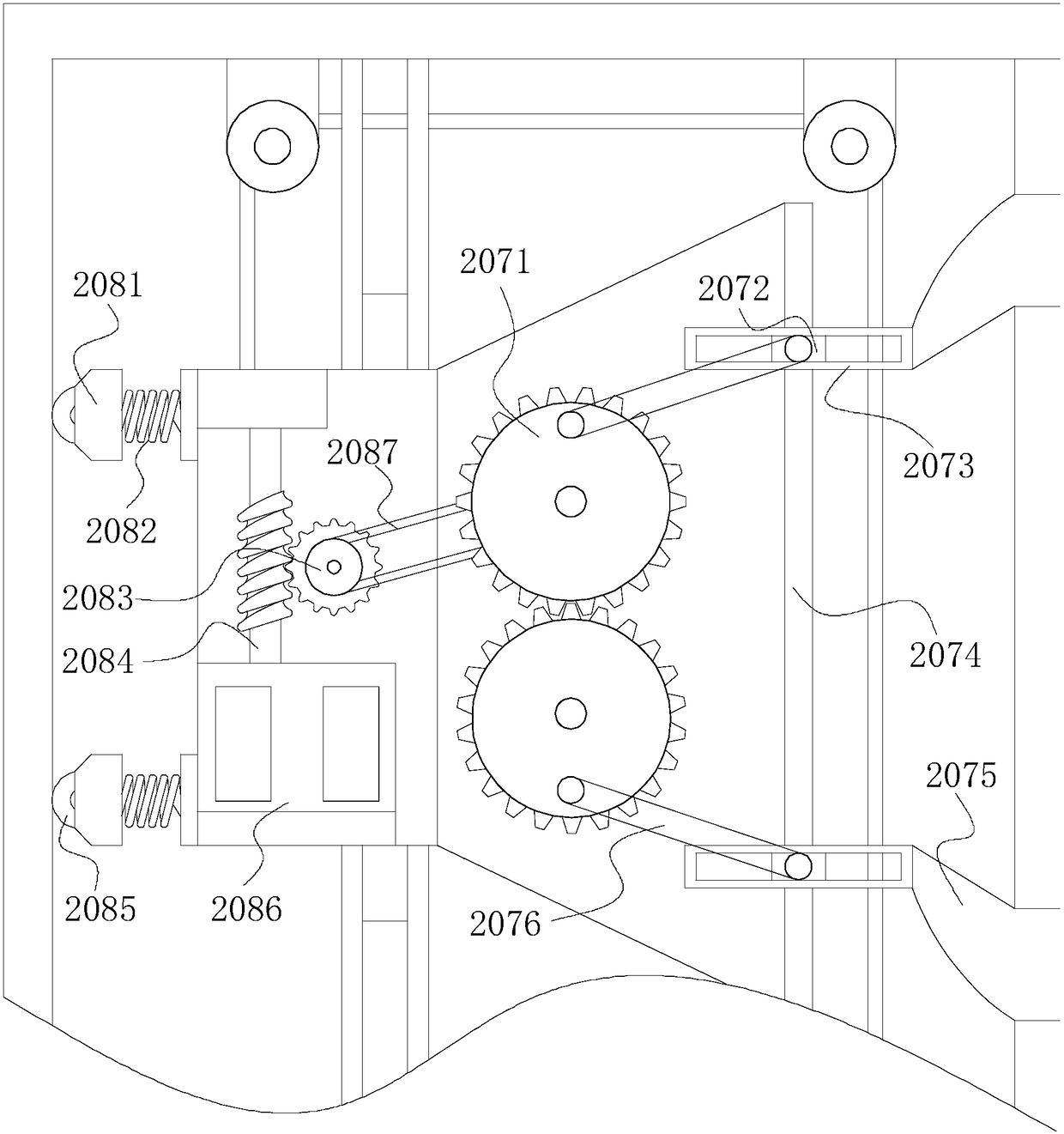

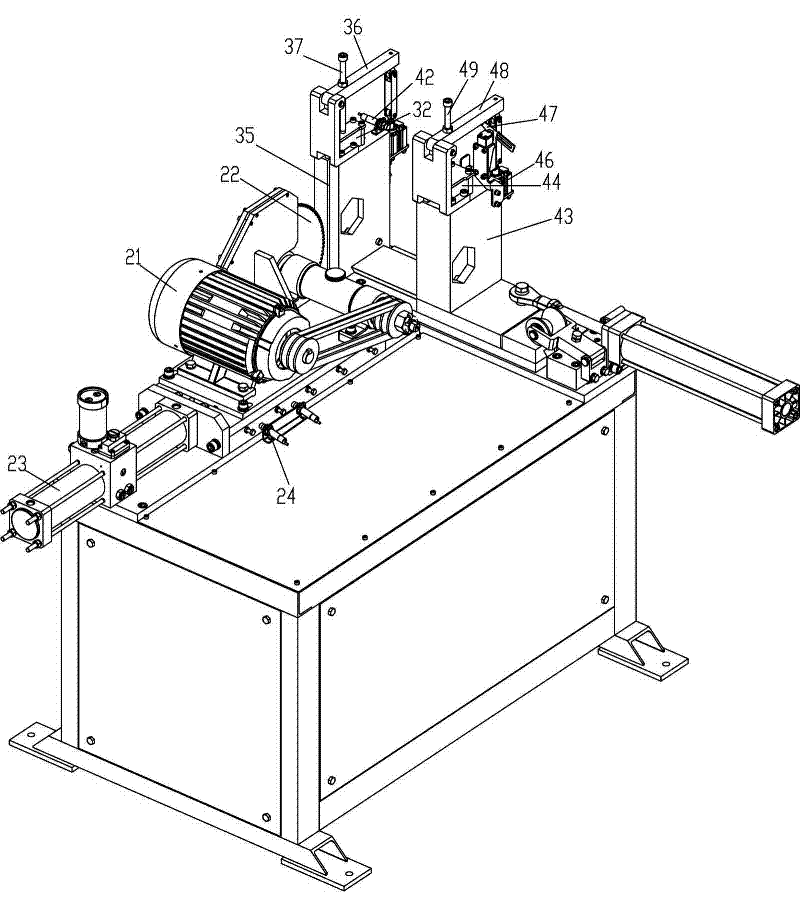

Semi-automatic pipe feeding machine

InactiveCN102909426ANot easy to stainSimple and fast operationTube shearing machinesPositioning apparatusSemi automaticEngineering

The invention discloses a semi-automatic pipe feeding machine which comprises a machine frame (7), a length positioning device and a clamping device, wherein the length positioning device and the clamping device are arranged on the machine frame (7), the clamping device is used for clamping pipes (2), the length positioning device is used for limiting the length of the pipes (2), and a cutting device used for cutting the pipes (2) is arranged in front of the clamping device. The semi-automatic pipe feeding machine is high in work efficiency, simple in device process and low in labor intensity.

Owner:宁波培源股份有限公司

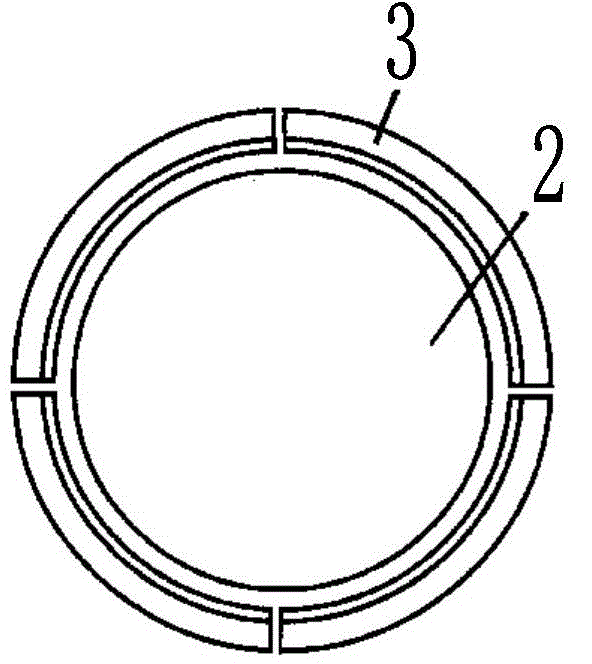

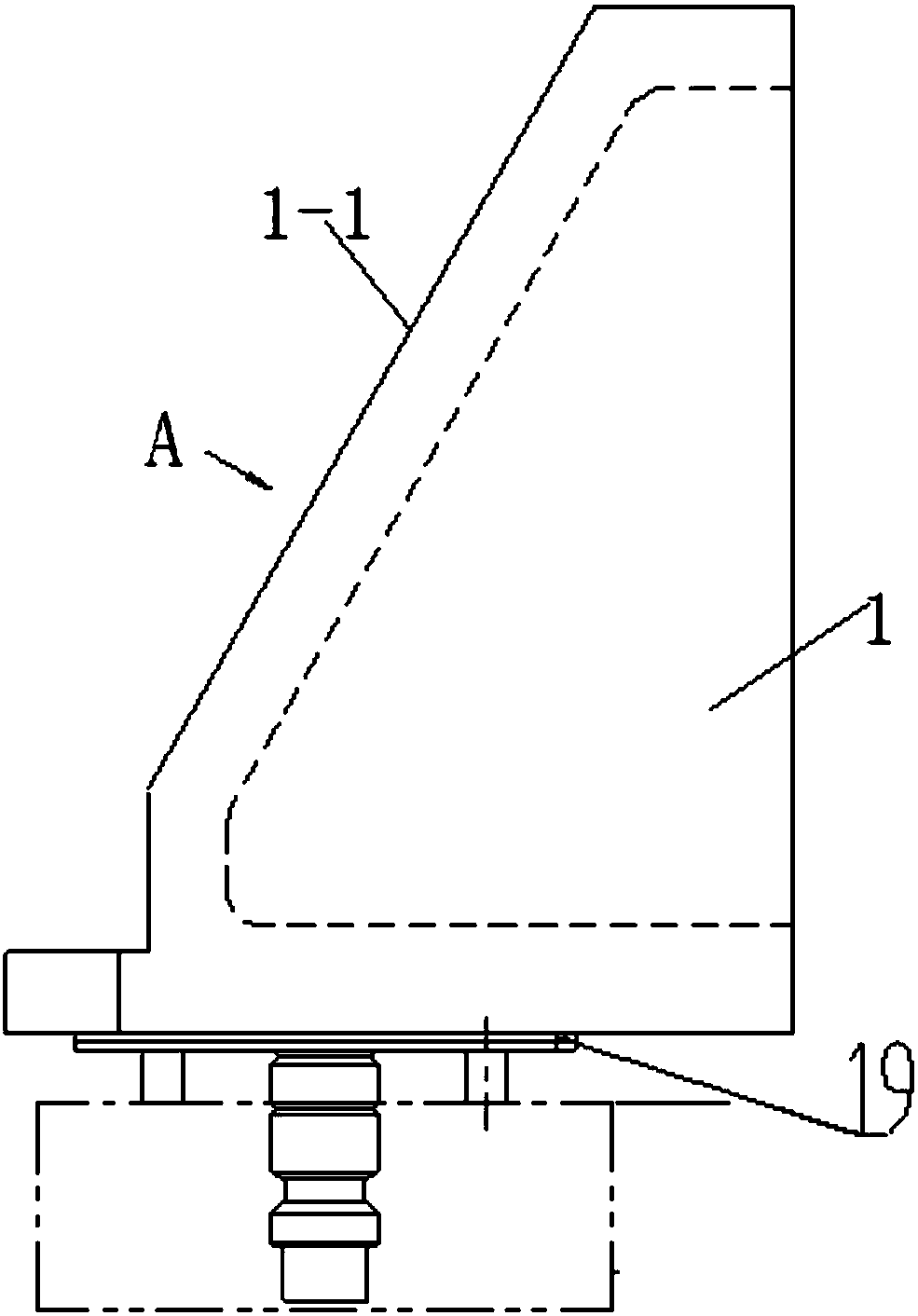

Clamp for lathing ventilation face of volute

InactiveCN102990443AAvoid offsetImprove processing qualityPositioning apparatusMetal-working holdersEngineeringBreathing

The invention discloses a clamp for lathing the ventilation face of a volute. The clamp effectively clamps and fixes the volute of a booster, locates the center of the ventilation face of the volute of the booster on the axis of the lathe, is convenient to use, and can improve the lathing precision of the ventilation face of the volute and improve the processing quality of the workpiece. The clamp comprises a chassis; the clamp is characterized by comprising a locating boss and a support ring, wherein the bottom of the locating boss is provided with a limiting face, a through hole is formed on the chassis in a manner of deviating from the circle center, the locating boss is inserted into the through hole of the chassis, the support ring is sleeved on the locating boss, a to-be-processed volute is located on the locating boss by a junction surface thereof and is attached to the support ring, and the to-be-processed volute is fastened with the support ring and the chassis by bolts through the junction surface connection hole thereof.

Owner:WUXI MINGZHU TURBOCHARGER MFG

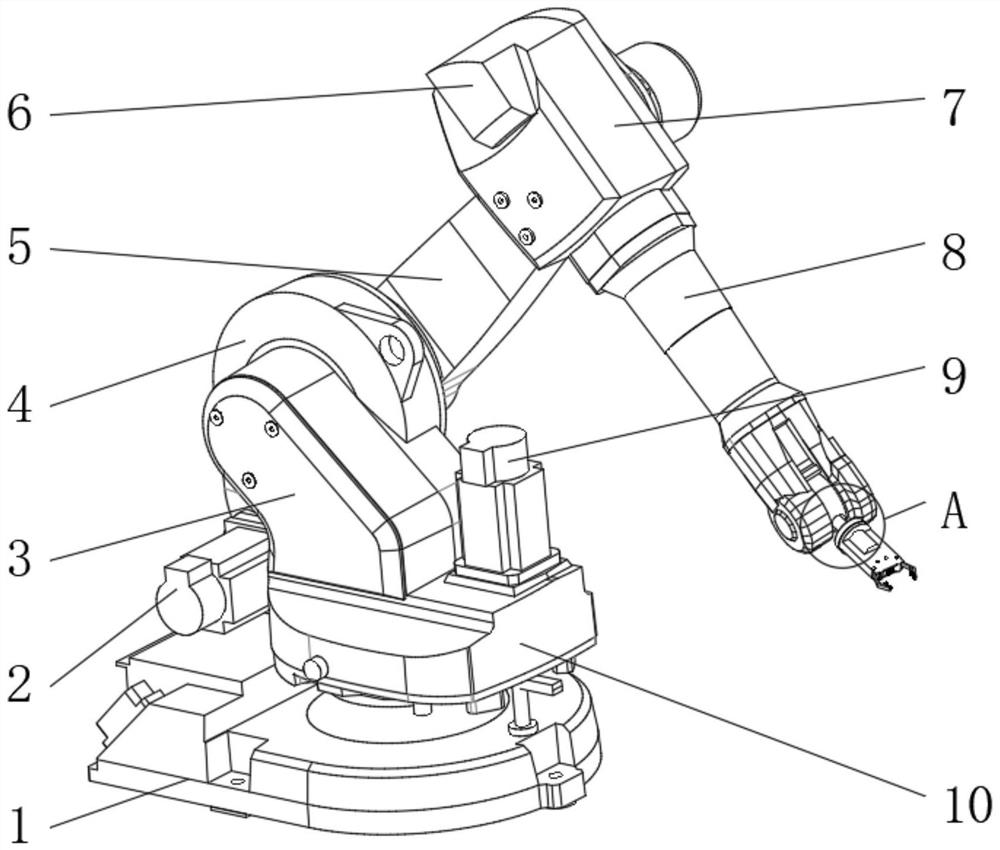

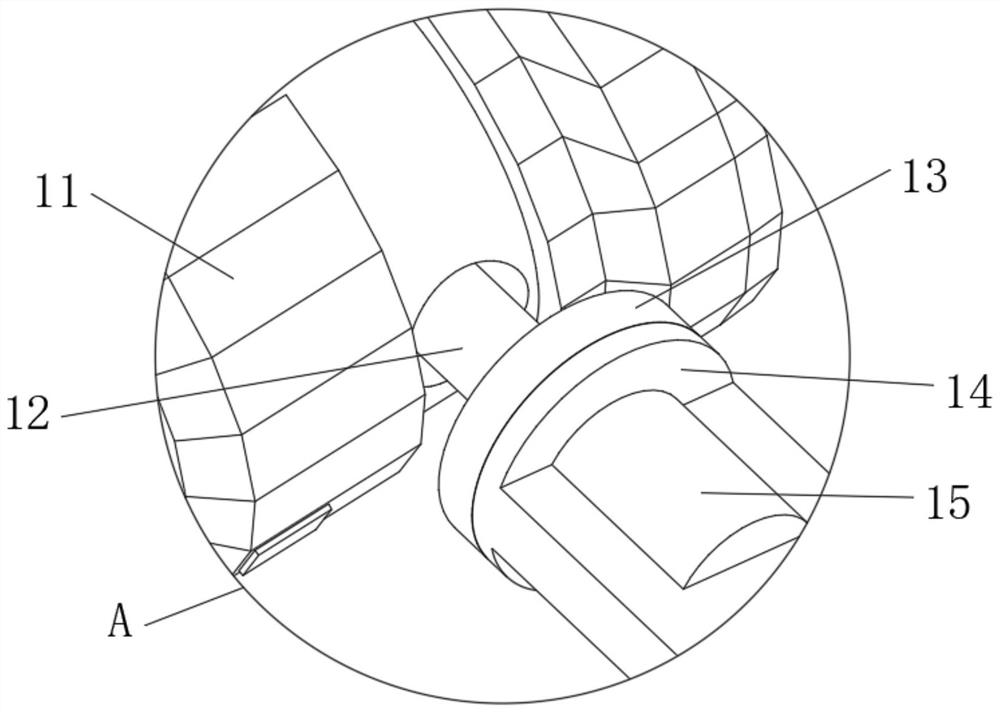

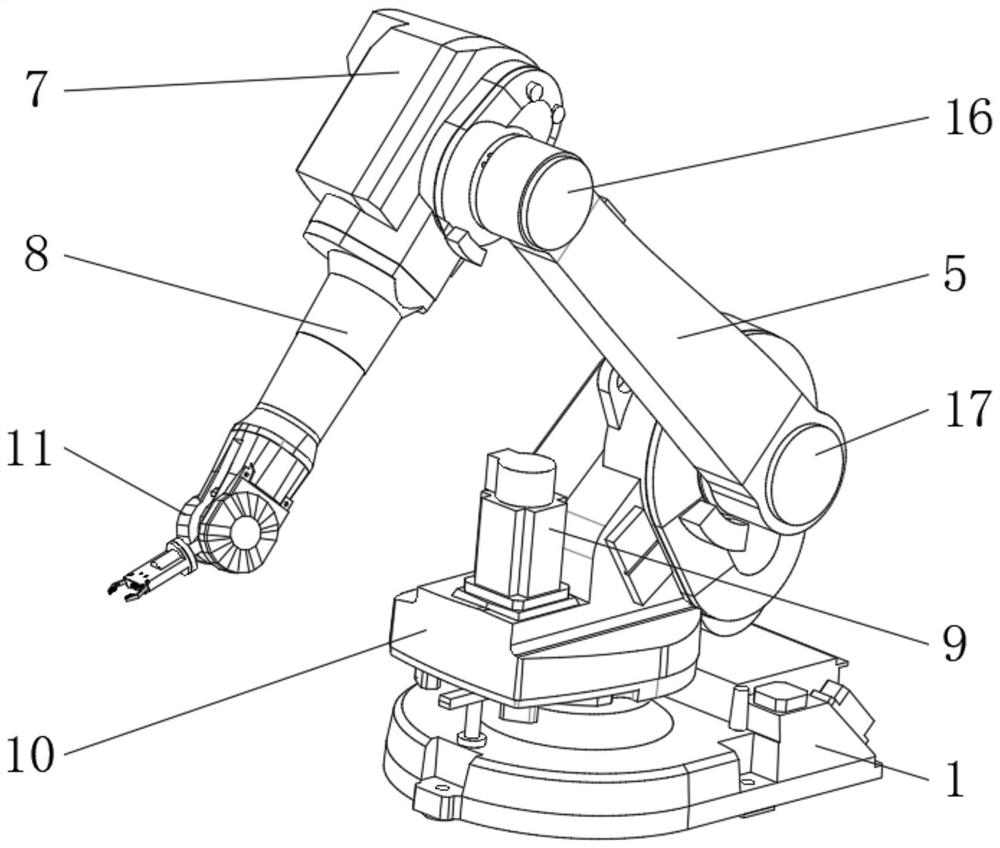

Work fixture for mechanical arm

PendingCN113070892AFastenedFit tightlyProgramme-controlled manipulatorGripping headsRobotic armEngineering

The invention discloses a work fixture for a mechanical arm, and relates to the technical field of industrial instruments. The work fixture comprises a mounting base and a connecting base; the front side face of the connecting base is fixedly connected with a fixture box; and the inner wall of the rear end of the fixture box is fixedly connected with an air cylinder. According to the work fixture, by arranging a spring barrel and side face clamping rods, a workpiece can be limited through three side faces; the workpiece is clamped more firmly by the stability capacity of a triangle; due to the fact that a large number of anti-skid discs can be tightly attached to the surface of the workpiece, the purpose of firm clamping can be better achieved; and by arranging a tensioning spring, a telescopic rod can stretch out and draw back in the spring barrel when being stressed, and accordingly, diameters among three arc-shaped clamping pieces are adjusted; meanwhile, due to the fact that jacking columns can stretch out and draw back in limiting barrels, the work fixture can well adapt to workpieces with different diameters when being used for clamping the workpieces with the different diameters, thereby achieving the purpose that the workpieces with different diameters can be clamped.

Owner:武汉熙锐自动化设备有限公司

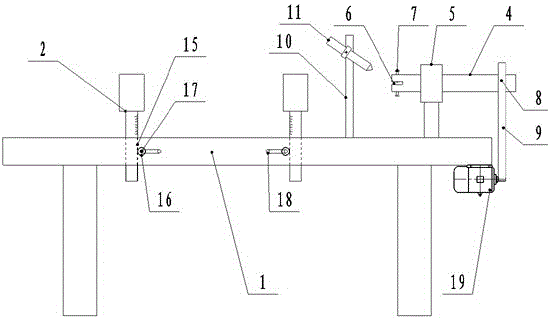

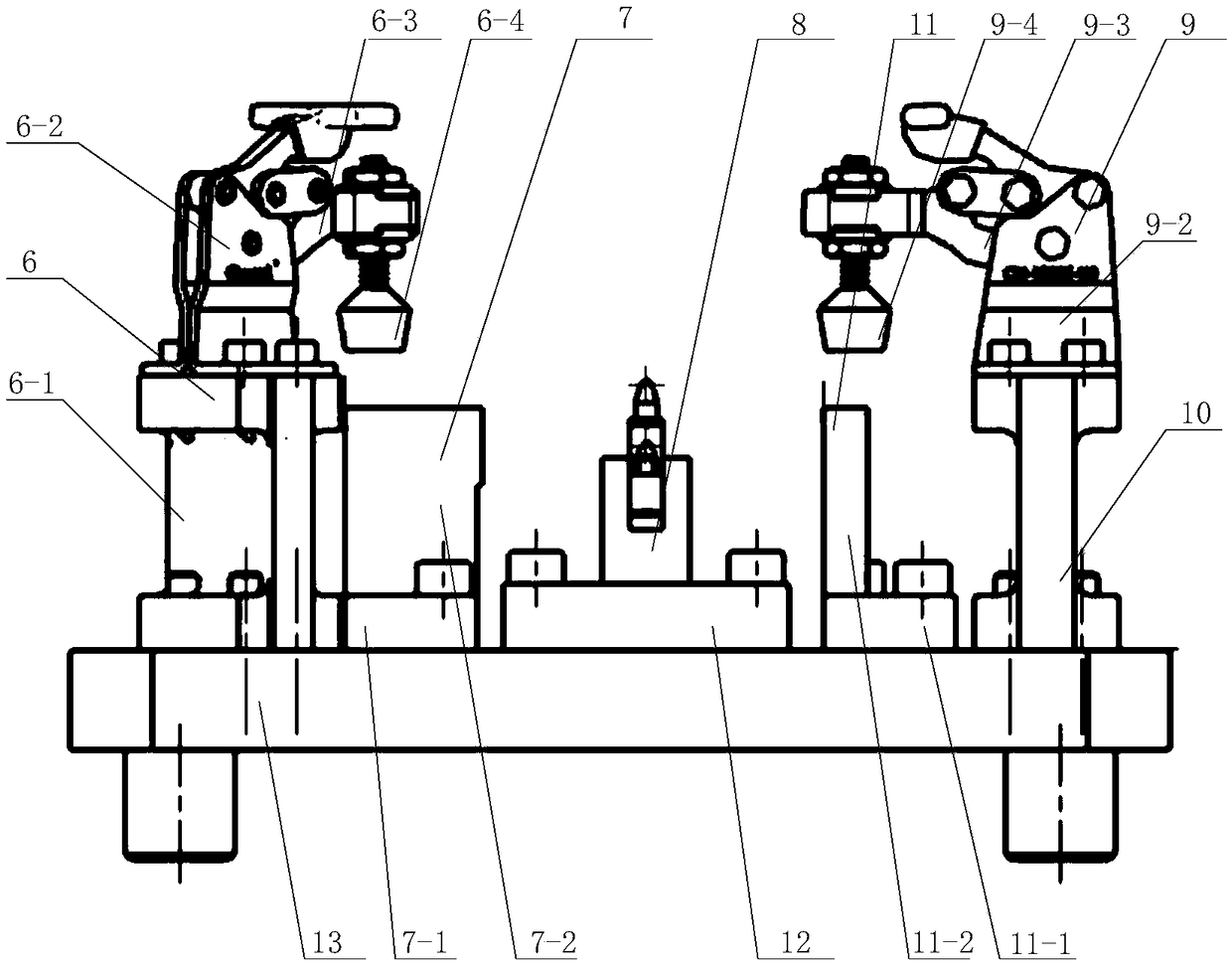

Device for manufacturing rigid tie bar structural member

InactiveCN105666019APrecise dockingPrevent deviationWelding/cutting auxillary devicesAuxillary welding devicesRotational axisEngineering

The invention discloses a manufacturing device for a rigid tie rod structure, which comprises a tie rod welding table, a steel pipe bracket and a T-shaped plate clamping rotating assembly. The tie rod welding table is provided with two sets of steel pipe brackets. The T-shaped clamping rotating assembly includes a rotating shaft, a rotating shaft bracket and a motor, the rotating shaft bracket is arranged on the tie rod welding table, the rotating shaft is arranged on the rotating shaft bracket to rotate, and the inner end of the rotating shaft There is a T-shaped plate clamping groove in the middle of the head, and the fastening bolts for clamping the T-shaped plate are arranged on the T-shaped plate clamping groove. The outer end of the rotating shaft is provided with a pulley, and the pulley corresponds to A motor is arranged on the tie rod welding table, and the motor drives the pulley to rotate through a belt.

Owner:CHINA MCC5 GROUP CORP

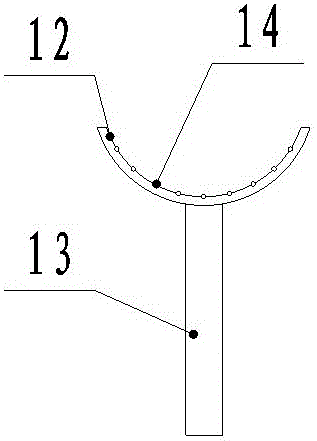

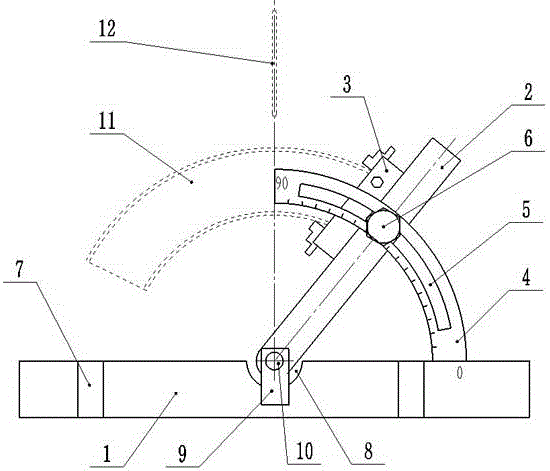

Adjustable cut plastic pipeline elbow clamping system

InactiveCN106272657AEasy to adjustEasy to fixMetal working apparatusPlastic pipeworkAgricultural engineering

The invention discloses an adjustable cut plastic pipeline elbow clamping system, which comprises a clamping platform, an angle adjustment block and a pipeline elbow chuck, wherein the bottom end of the angle adjustment block is connected with the middle part on the clamping platform, a 90-degree arc type angle measurement rack is respectively arranged on the front end and the rear end of the angle adjustment block, an arc type adjustment opening is formed in the middle of the 90-degree arc type angle measurement rack, the 0-degree side of the 90-degree arc type angle measurement rack is fixedly arranged on the clamping platform, the front end surface and the rear end surface of the angle adjustment block are respectively fixedly arranged in the arc type adjustment openings in the 90-degree arc type angle measurement racks through adjustment bolts after the angle adjustment block and the clamping platform is adjusted to predefined angle, and the pipeline elbow chuck is arranged on the angle adjustment block. By setting an adjustable foldable included angle structure between the angle adjustment block and the clamping platform, a needed angle can be cut according to the PVC pipe piece elbow, so as to adjust the included angle between the angle adjustment block and the clamping platform.

Owner:SICHUAN DUOLIAN IND LIMITED

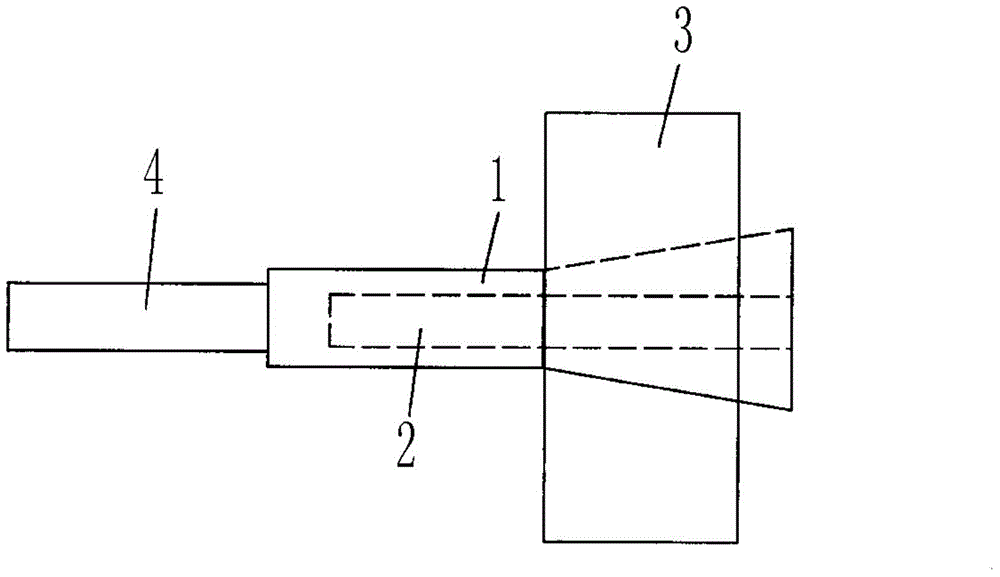

Bolt machining clamp for lathe

InactiveCN104589088AEasy to process and produceEasy to installThread cutting auxillary apparatusWork clamping meansMachiningEngineering

The invention discloses a bolt machining clamp for a lathe. The bolt machining clamp is characterized in that a clamping hole is drilled in the central position in a clamping sleeve; the clamping sleeve of which one end is of a conical structure is uniformly divided into four equal parts; an outer sleeve matched with the clamping sleeve is arranged on the clamping sleeve of the conical structure in a sleeving way; a pulling rod is connected to the other end of the clamping sleeve. In such a way, the bolt machining clamp is used for machining a lathe bolt and can conveniently clamp, time and labor are saved during clamping, a bolt is firmly clamped, the bolt is convenient to machine and produce, and the production efficiency is improved.

Owner:陈永臻

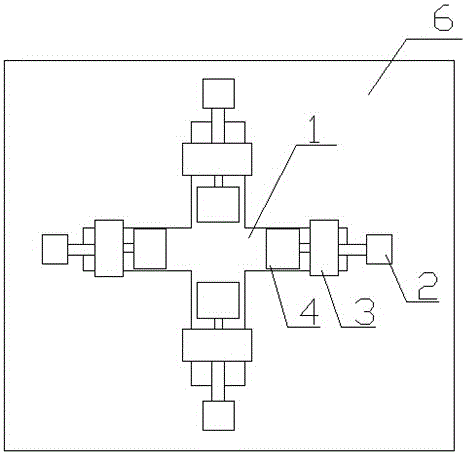

Clamping device of molds of engraving-milling machines

The invention discloses a clamping device of molds of engraving-milling machines. The clamping device comprises sliding rails, air cylinders, sliding blocks, clamping plates, butterfly-shaped screws and a machine tool, wherein the sliding rails are welded to the machine tool; the sliding rails are provided with four uniform clamping sets, each clamping set comprises one sliding rail, one air cylinder, one sliding block and one clamping plate, the air cylinders are arranged on the machine tool through bolts and are located at the right ends of the sliding rails, the sliding blocks are erected on the sliding rails in a sliding mode, are respectively of a U shape and are connected to piston rods of the air cylinders through bolts, the left end of each sliding block is connected to one clamping plate through one butterfly-shaped screw, and the clamping plates are arranged on the upper surfaces of the sliding rails. The clamping device has the advantages that time and labor are saved and clamping is stable and firm.

Owner:安徽龙锐模塑有限公司

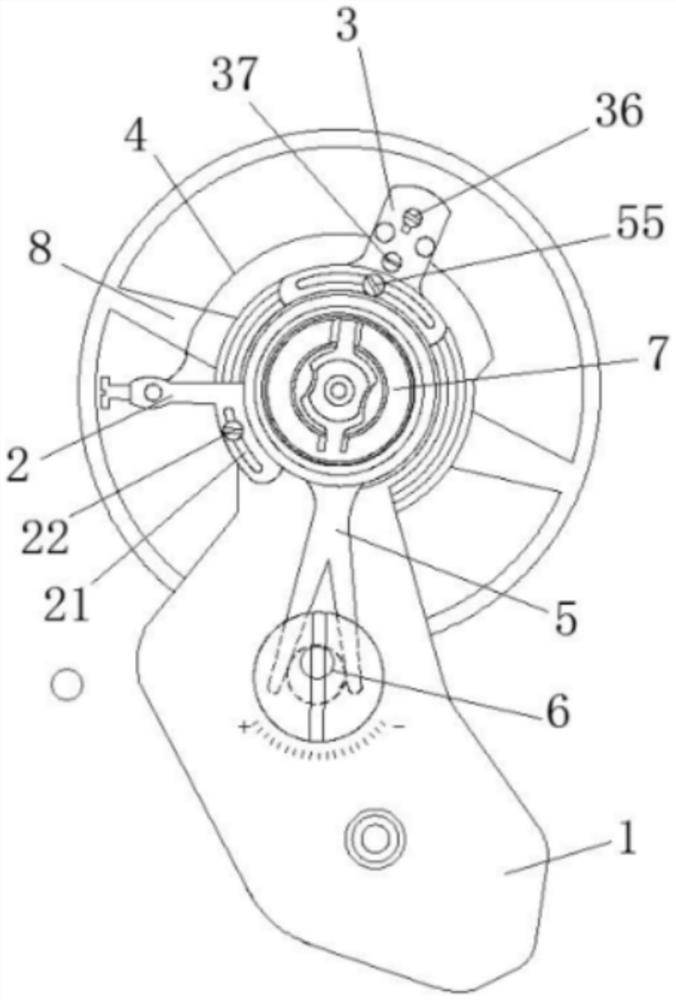

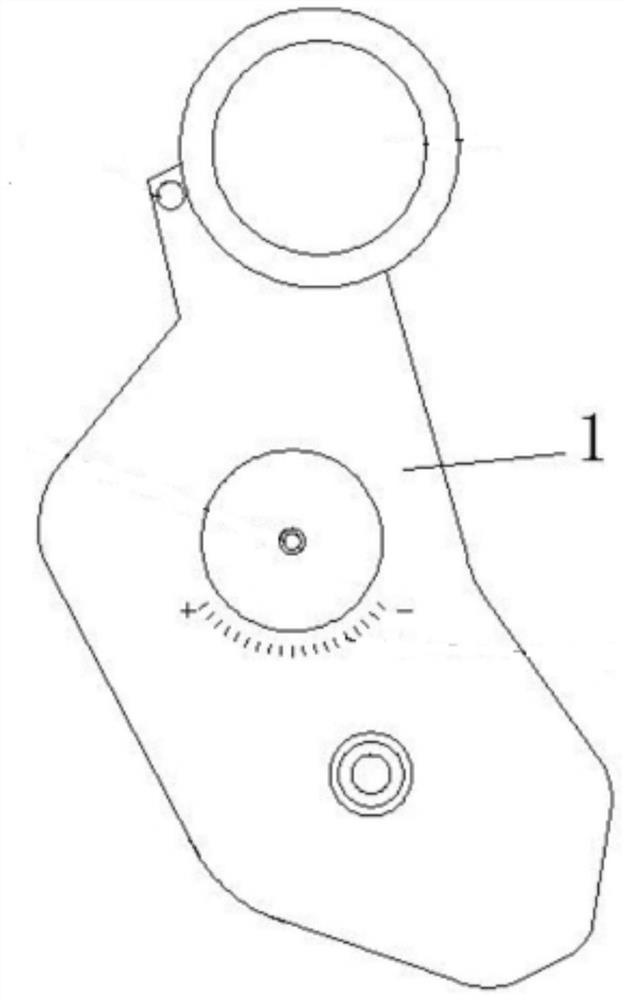

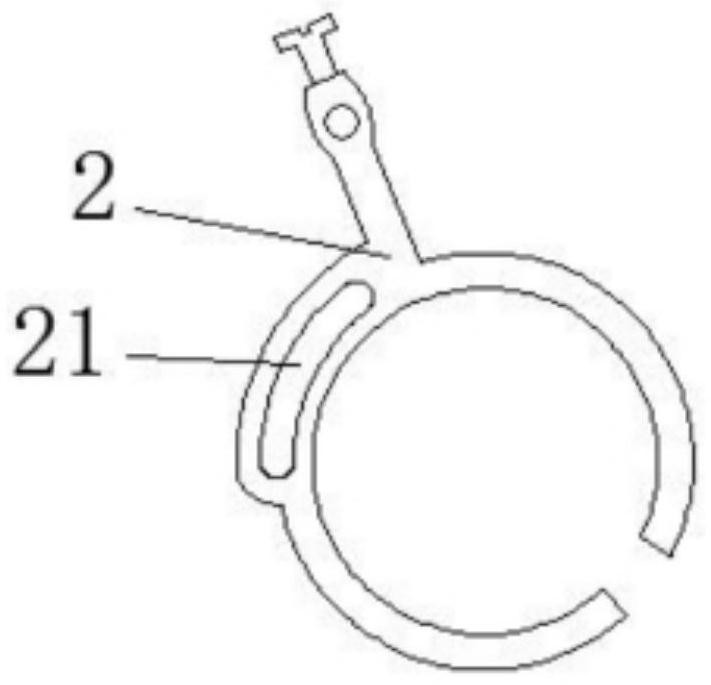

Clamping balance lockable regulator pin fine tuning mechanism

ActiveCN106950812AEasy to adjustEasy and fast coarse adjustmentFrequency setting mechanismEngineeringMechanical watch

The invention discloses a clamping balance lockable regulator pin fine tuning mechanism including a balance cock, a hairspring outer pile, a hairspring, an antivibrator, a balance, and an regulator pin mechanism, the balance cock is fixed on the movement of a mechanical watch, the inner end of the spring is connected at the balance shaft, the regulator pin mechanism includes an regulator pin body, a hairspring clamp, an regulator pin connecting rod, and a fine tuning screw with a big cap and a small eccentric shaft, the hairspring outer pile, the regulator pin body, and the regulator pin connecting rod sleeve the balance cock via the antivibrator, the hairspring penetrates into the hairspring clamp, the outer end of the hairspring is fixedly connected with the hairspring outer pile, and the hairspring clamp is composed of a hairspring fixed lock flap and a hairspring movable lock flap. The hairspring outer pile and the regulator pin can be fixed and also are convenient to adjust, the hairspring and the hairspring clamp are firmly clamped, so that the rapid coarse registration adjustment and fine registration adjustment of the regulator pin position can be facilitated, the structure is reasonable, and the efficiency for watch time-travelling accuracy adjustment and calibration is improved.

Owner:李国强

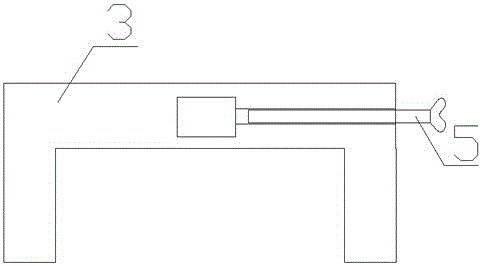

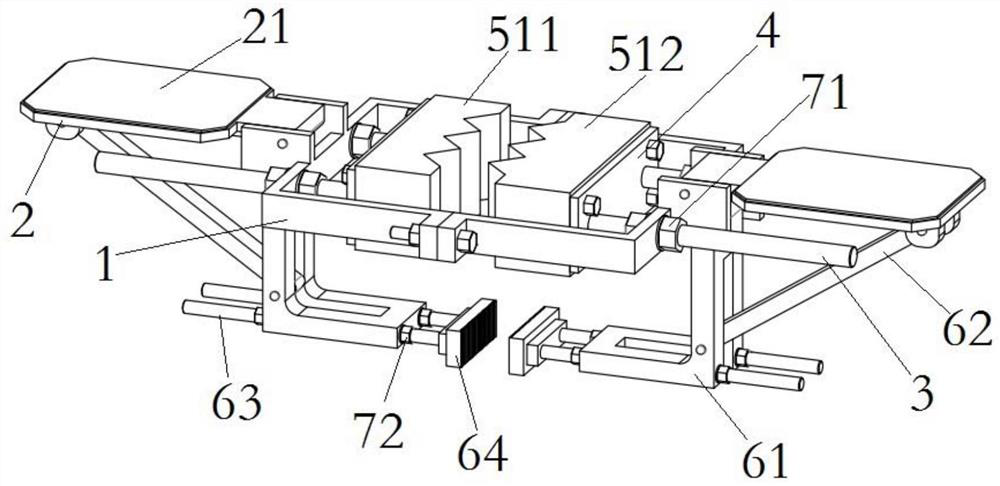

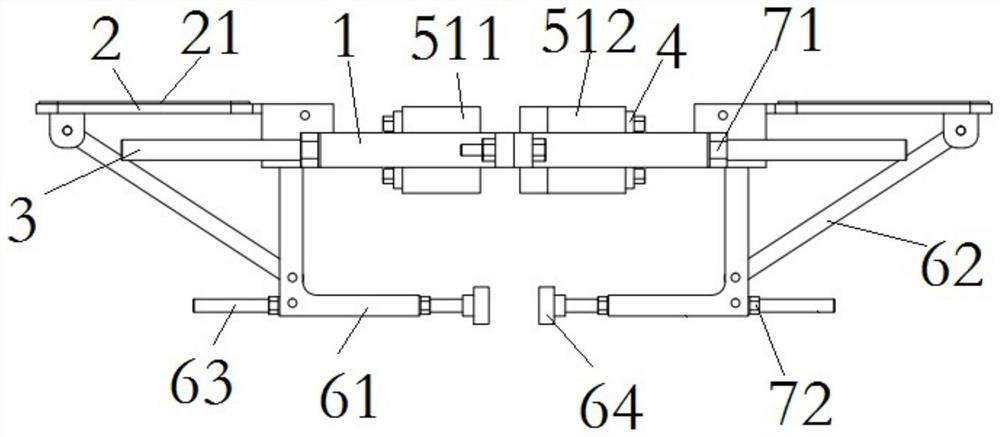

Measurement system for front and back edge positions of engine guide vane

InactiveCN108981525AEfficient full-section inspectionSimple structureMechanical measuring arrangementsSystems designEngineering

The invention discloses a measurement system for front and back edge positions of an engine guide vane. The system comprises a clamping device and a measuring device, the clamping device comprises a positioning mechanism and a compressing mechanism, the positioning mechanism and the compressing mechanism compress the two ends of the guide vane cooperatively, and a blade body positioning mechanismis positioned in an intermediate support blade in the guide vane. After that the clamping device clamps the guide vane, a measuring device measures the size in the front and back edge positions of a to-be-measured cross section. The measurement system designed aimed at the size in the front and back edge positions of the guide vane is simple in structure and convenient to operate and can detect the front and back edges of the vane in the whole cross section with high efficiency.

Owner:AECC AVIATION POWER CO LTD

Chain sheet clamping device and chain sheet machining equipment with same

ActiveCN106002267AEasy to put inImprove machining accuracyOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention discloses a chain sheet clamping device and chain sheet machining equipment with the chain sheet clamping device, and relates to the field of clamping devices for clamping chain sheets and chain sheet machining equipment. The chain sheet clamping device comprises an installation base, a first end jacking mechanism and a second end jacking mechanism. The first end jacking mechanism comprises a baffle, first side edge baffles arranged on the side faces of the baffle and a check block. The second end jacking mechanism comprises a movable baffle, second side edge baffles arranged on the side faces of the movable baffle and third side edge baffles. Different holes can be machined through one-time clamping of the chain sheet clamping device, and therefore machining precision and production efficiency are improved. The chain sheet machining equipment comprises a machine base, the chain sheet clamping device arranged on the machine base and a first machining cutter set, wherein the first machining cutter set is arranged on the machine base, and the chain sheet clamping device and the first machining cutter set are perpendicularly and correspondingly arranged. By means of the chain sheet machining equipment, multiple chain sheets can be simultaneously machined, clamping is stable, machining precision can be improved, and machining production efficiency can also be greatly improved.

Owner:QUANZHOU LIANTUO MACHINERY CO LTD

Novel inner diameter expanding clamping tool

InactiveCN104589089AEasy to process and produceEasy to installExpansion mandrelsPositioning apparatusMechanical engineeringEngineering

The invention discloses a novel inner diameter expanding clamping tool. The novel inner diameter expanding clamping tool is characterized in that a drawbar is inserted into an expanding sleeve in a penetration manner, wherein one end of a penetrating hole inside the expanding sleeve is tapered; an inclined boss is arranged on the outer wall of the expanding sleeve; the outer wall of the expanding sleeve with a tapered end is equally divided into four parts; one end of the drawbar is tapered; the tapered end of the drawbar is matched with the tapered penetrating hole inside the expanding sleeve. The novel inner diameter expanding and clamping tool is used for supporting an inner hole of a lathe processing workpiece, convenient to clamp, time-saving and labor-saving in clamping, firm in clamping and convenient for processing production of the workpiece, so that the production efficiency is improved.

Owner:陈永臻

Security monitoring terminal based on face recognition

ActiveCN111365574AEasy to fixEasy to assemble and disassembleTelevision system detailsColor television detailsStructural engineeringMonitor equipment

The invention relates to the technical filed of monitoring equipment, and discloses a security monitoring terminal based on face recognition. The security monitoring terminal comprises a camera body which is arranged in a shell, the shell comprises a lower bottom plate and an upper bottom plate which are arranged parallel to each other, and the lower bottom plate and the upper bottom plate are connected through a supporting plate located on the rear side; first sliding grooves are formed in the opposite side faces of the lower bottom plate and the upper bottom plate correspondingly in the left-right direction, and first guiding columns are arranged in the first sliding grooves in the left-right direction; and two moving plates are parallelly arranged between the lower bottom plate and theupper bottom plate, sliding blocks stretching into the corresponding first sliding grooves are arranged on the end faces of the moving plates, first through holes allowing the corresponding first guiding columns to penetrate through are formed in the sliding blocks, first springs used for pushing the moving plates to get close to each other are arranged on the positions, at the two ends, on the first guiding columns in a sleeving mode, and a clamping mechanism used for fixing the camera body is arranged between the moving plates. Through the structure, dismounting and mounting of the camera body in the shell are more convenient.

Owner:御智(厦门)科技有限公司

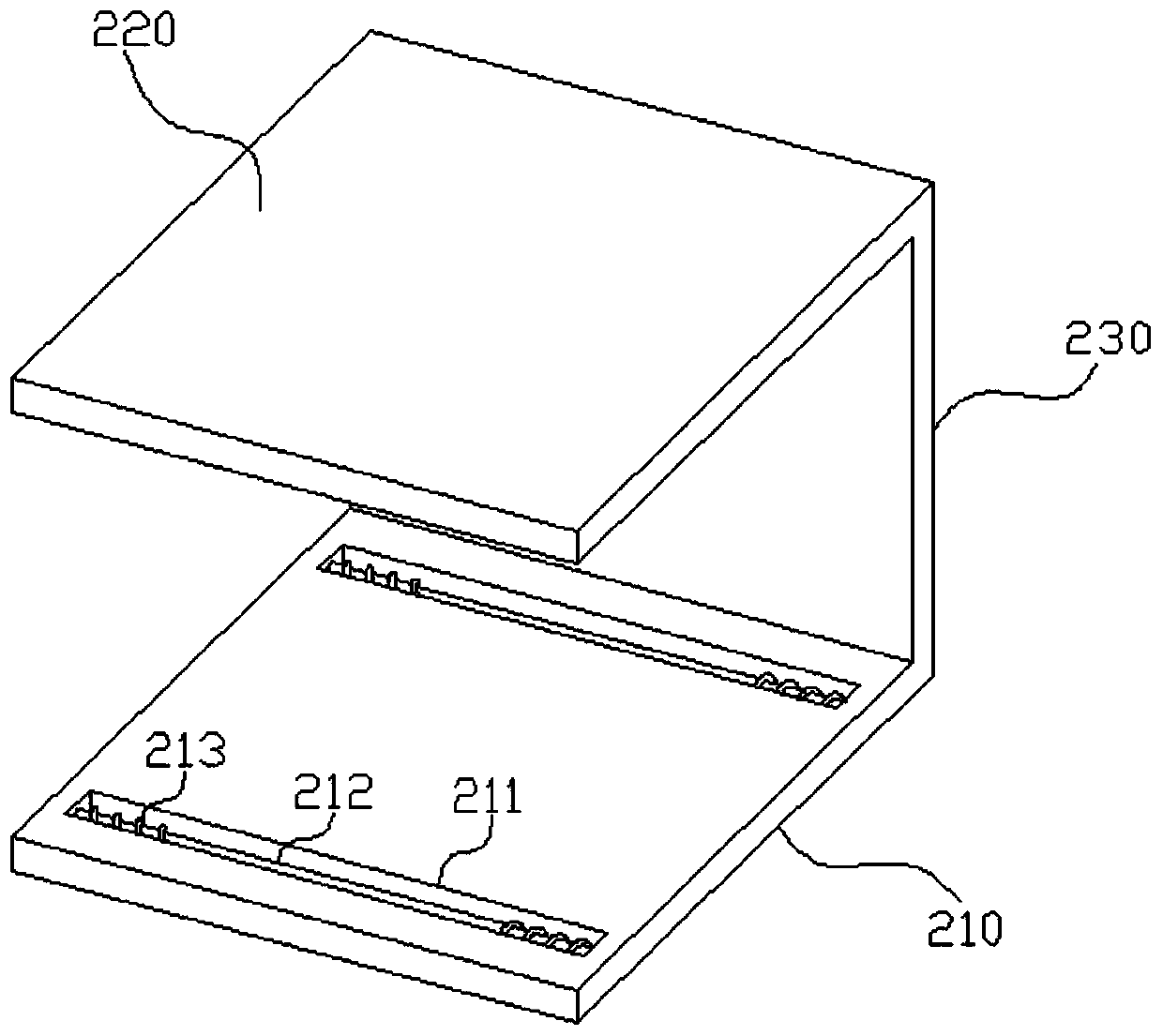

Auxiliary fixture for precision grinding machine

InactiveCN107363660ACooperate wellGood for magnetic fitGrinding work supportsPlane surface grinding machinesEngineeringMechanical engineering

The invention discloses an auxiliary fixture for a precision grinding machine, comprising an operation board and a bottom plate located under the operation board, the operation board comprises an outer frame and a movable board, and the outer frame is in the shape of a square hollow inside and has The two opposite side edges and the two opposite end edges have two movable plates, which are distributed parallel to the end edges. The movable plates are matched and connected to the opposite sides of the outer frame, and there are springs between the movable plates and the end edges. , the movable plate and the side are respectively connected with several clamping claws. The invention is further improved on the basis of the original grinding machine clamping fixture, greatly improves the process flexibility, applicability and reliability, and can conveniently realize efficient and stable grinding machine workpiece clamping.

Owner:苏州昌田机械设备制造有限公司

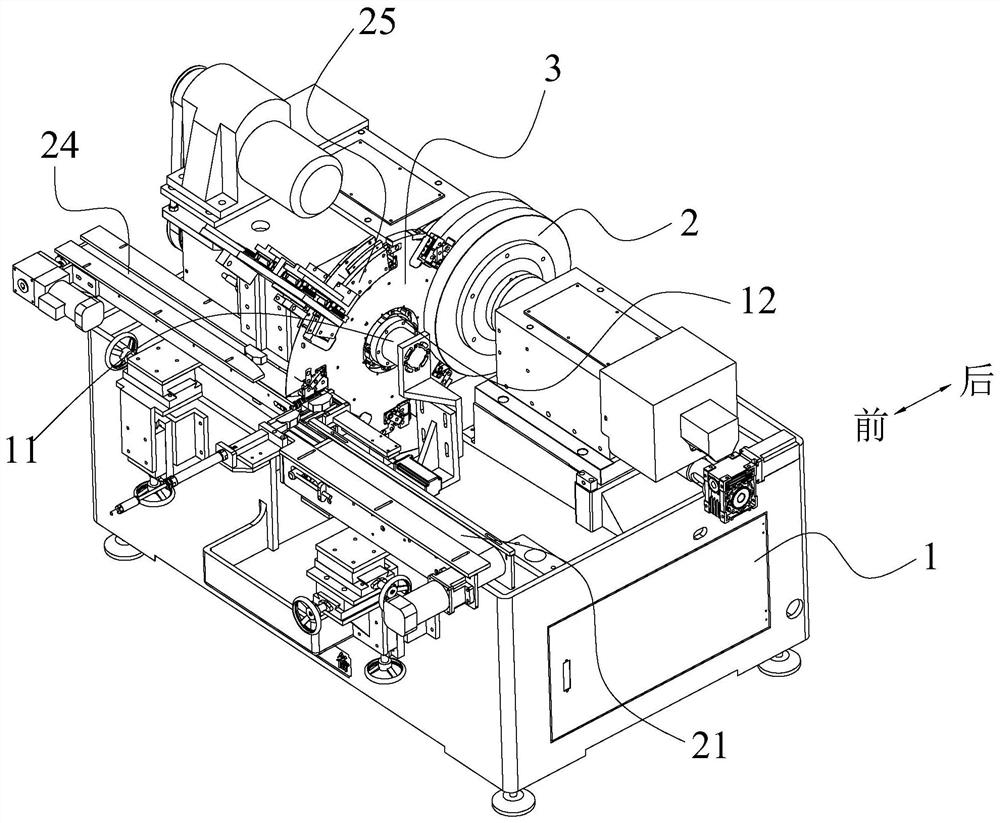

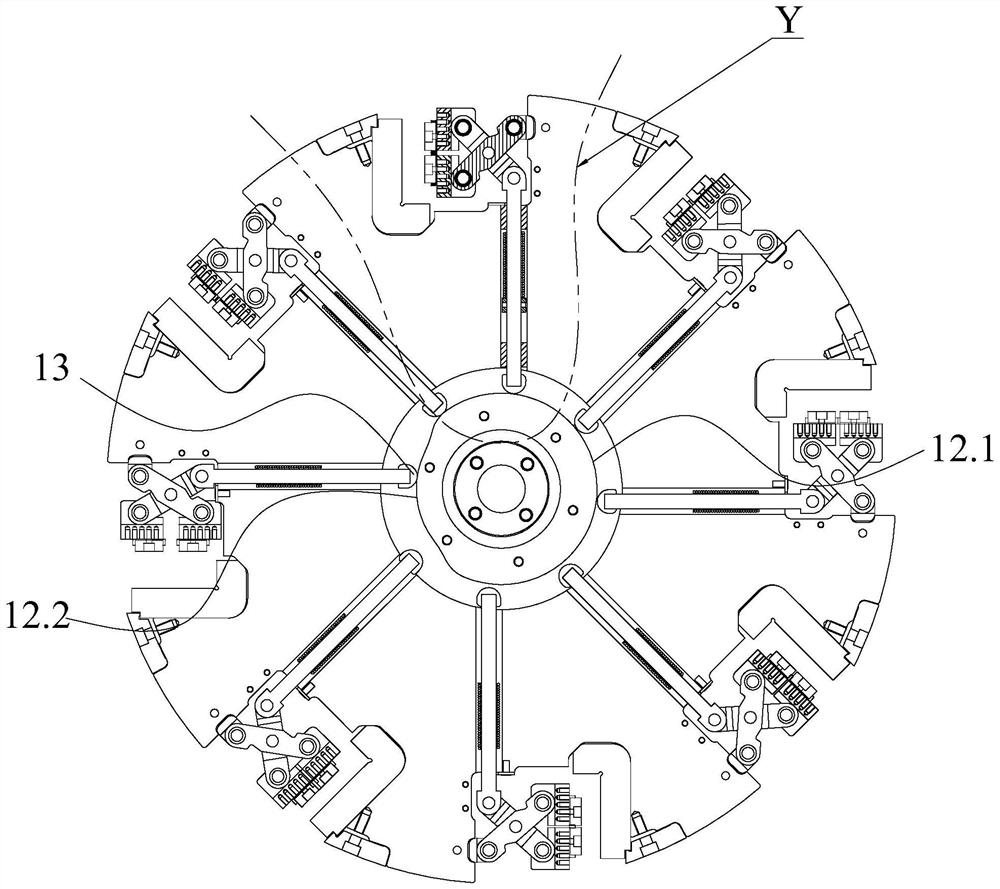

Improved filament welding machine

ActiveCN105033530ANot easy to looseFastenedResistance electrode holdersElectrical apparatusMotor driveEngineering

The invention provides a filament welding machine, and belongs to the technical field of machinery. The filament welding machine solves the technical problems of low automation degree, poor welding quality and the like of an existing filament welding machine. The filament welding machine comprises a base, a rotating disc is arranged on the base, a stepping motor driving the rotating disc to rotate is arranged between the rotating disc and the base, a plurality of clamping devices are uniformly and circumferentially distributed at the edge of the rotating disc, the base is provided with a molybdenum strip feeding device, a first weld-aid device, a tantalum strip welding device, a second weld-aid device, a tungsten filament welding device and a filament discharging device, and the molybdenum strip feeding device, the first weld-aid device, the tantalum strip welding device, the second weld-aid device, the tungsten filament welding device and the filament discharging device are sequentially distributed on the periphery of the rotating disc. The filament welding machine has the advantages of high automation degree and welding quality and the like.

Owner:邳州市鑫盛创业投资有限公司

Petroleum pipeline conveying device

The invention discloses a petroleum pipeline conveying device. The structure of the petroleum pipeline conveying device comprises a ventilating plate, a lifting conveying device and a friction material layer; the ventilating plate is fixedly connected to the front surface of the lifting conveying device in an embedded manner; a maintenance baffle plate mounted on the front surface of the lifting conveying device and simultaneously is connected with the lifting conveying device in the embedded manner; according to the petroleum pipeline conveying device disclosed by the invention, a clamping mechanism is driven to operate through the control of a micro motor braking device, so that a pipeline is clamped more stably and cannot fall off in a lifting conveying process; through the control of adual-motor braking device, the state of a lifting mechanism is influenced through a transmission rod mechanism, so that the lifting of a clamped pipeline can be controlled; a rotating conveying mechanism is controlled through a swinging mechanism, so that the pipeline can be placed better, the overall process is not required to be controlled manually, and the safety is improved; and the lifting conveying can be more stable because of mechanical control, and the subsequent conveying efficiency is improved.

Owner:刘志坤

Food cleaning device for organic food research and development

InactiveCN110420898ANot easy to distortClean and comprehensiveCleaning using toolsCleaning using liquidsBall bearingDrive shaft

The invention relates to the technical field of food wiping and cleaning auxiliary devices, in particular to a food cleaning device for organic food research and development. By means of the food cleaning device, foods do not need to be held by hands at any time during food cleaning, so that the practicability of the food cleaning device is improved; the food cleaning device comprises a top plate,a bottom plate, two side plates, a motor, a transmission shaft, a connecting plate, two fixing plates, two rotating shafts, two pulley blocks, two first sleeve spring groups, two first telescopic tube groups, two adjusting block groups, a gear, a driving shaft, a handle, a connecting frame and a connecting column, wherein a brush group is arranged at the bottom end of the connecting plate; bearing seats are symmetrically arranged on the inner sides of the two side plates; ball bearings and limiting pieces are arranged in the two bearing seats; blocking pieces are arranged on the inner sides of the two bearing seats; the connecting column comprises a second sleeve spring and a second telescopic pipe; the outer side wall of the fixing plate on the right side is provided with a tooth pattern; and the fixing plate on the right side is engaged with the gear.

Owner:盐城市新顺城市开发建设有限公司

Double-end-face grinding machine

ActiveCN114850995AAchieve clampingAchieve releaseGrinding carriagesGrinding feedersElectric machineryEngineering

The invention provides a double-end-face grinding machine which comprises a machine base. Two grinding discs, a feeding assembly, a feeding rotary disc and a motor for driving the feeding rotary disc to rotate are installed on the machine base. A plurality of mounting grooves are formed in the circumferential outer wall of the feeding rotary disc in an inward concave mode, and pressing assemblies are assembled on the sides, in the width direction, of the interiors of the mounting grooves and can stretch out and draw back in the width direction of the mounting grooves; a workpiece positioning channel with the adjustable width is formed between the pressing face of the pressing assembly and the other side of the installation groove in the width direction. The feeding rotary disc is further connected with a driving assembly, and when the motor drives the feeding rotary disc to rotate to different set positions in the circumferential direction, the driving assembly is used for driving the pressing assembly to stretch out or retract, so that the workpieces are clamped or loosened. According to the double-end-face grinding machine, the grinding channel used for conveying workpieces on the feeding mechanism to the position between the grinding discs one by one is additionally arranged between the two grinding discs, and clamping of the workpieces is stable and efficient.

Owner:宁波邦一机械科技有限公司

A Special Fixture for Triangular Workpieces

ActiveCN105058124BHigh positioning accuracyFastenedWork clamping meansPositioning apparatusEngineeringInverted triangle

The invention discloses a special fixture for triangular body workpieces. The fixture comprises a bottom plate, a base, a first pressing plate and a power cylinder. The base is arranged on the bottom plate. A first through groove with the cross section being an inverted triangle shape is dug in the base. The power cylinder is arranged on one side of the bottom plate and is connected with the first pressing plate through a Y joint. The first pressing plate is hinged to the Y joint and can rotate up and down around the hinged portion of the pressing plate and the Y joint. A second pressing plate is arranged on the outer surface of the side, close to the first pressing plate, of the base. The second pressing plate is not parallel to the first pressing plate. According to the disclosed special fixture for the triangular body workpiece, the Y joint and the base provided with the through groove are arranged so that different surfaces of the two triangular body workpieces can be clamped at the same time under cooperation of the two pressing plates through the fixture. Besides, the fixture has the characteristics of being high in positioning precision, stable in clamping and easy to operate.

Owner:FOSHAN PRATIC CNC SCI & TECH

Vehicular fixture for the air outlet surface of the volute

InactiveCN102990443BAvoid offsetImprove processing qualityPositioning apparatusMetal-working holdersEngineeringChassis

The invention discloses a clamp for lathing the ventilation face of a volute. The clamp effectively clamps and fixes the volute of a booster, locates the center of the ventilation face of the volute of the booster on the axis of the lathe, is convenient to use, and can improve the lathing precision of the ventilation face of the volute and improve the processing quality of the workpiece. The clamp comprises a chassis; the clamp is characterized by comprising a locating boss and a support ring, wherein the bottom of the locating boss is provided with a limiting face, a through hole is formed on the chassis in a manner of deviating from the circle center, the locating boss is inserted into the through hole of the chassis, the support ring is sleeved on the locating boss, a to-be-processed volute is located on the locating boss by a junction surface thereof and is attached to the support ring, and the to-be-processed volute is fastened with the support ring and the chassis by bolts through the junction surface connection hole thereof.

Owner:WUXI MINGZHU TURBOCHARGER MFG

Cutting off machine

InactiveCN101912998BStable positionImprove consistencyMetal sawing devicesEngineeringMechanical engineering

The invention relates to a cutting off machine. The machine comprises a frame, wherein the frame is provided with a feeding and clamping mechanism and a cutting power assembly; the feeding and clamping mechanism comprises a clamping device and a feeding device propelled in a translational way along a track; the feeding device clamps a blank and feeds the blank into the clamping device in a translational way; the cutting power assembly comprises a motor and a cutting disc which is driven by the motor to rotate at a high speed; in a horizontal direction, relative movement between the feeding and clamping mechanism and the cutting power assembly is restrained through the track; the cutting disc of the cutting power assembly is inserted into the blank clamped on the clamping device in a translational way along the direction of the track; and in a cutting process, the blank is pushed into the clamping device in a translational way along the track under the clamping action of the feeding device, clamped by the clamping device and cut by the cutting disc in another vertical direction. A product processed by the cutting off machine has the advantages of high accuracy, stable quality, correct blank location degrees (planeness and verticality) and high consistency.

Owner:黄大庆

Device and method for quick changeover and clamping of guide vane edge plate dustpan hole processing

The invention belongs to the field of machining of aero-engine turbine guide blades, and relates to a guide blade edge plate dustpan hole machining rapid changing clamping device and method. The clamping device is in a whole type, a positioning block and a supporting plate are arranged on the angular face of a clamping device body, the direction of a guide blade edge plate is positioned through a positioning face on the positioning block, through two positioning pins on the positioning block and one positioning pin on the supporting plate, positioning of the circular-arc top face of the guide blade edge plate in the vertical height direction is achieved, and the guide blade edge plate is jacked upwards from the lower portion of the guide blade edge plate through a jacking mechanism so that the guide blade edge plate is clamped; the exhaust side end face and the positioning face of the positioning block are attached, the guide blade edge plate is jacked upwards by adjusting the jacking mechanism, the circular-arc top face of the guide blade edge plate is tightly attached to the first positioning pin, the second positioning pin and the third positioning pin, a uniform gap is arranged between the exhaust side end face and the positioning face, and the beneficial effects of being compact in structure and rapid and convenient to operate are achieved.

Owner:AECC AVIATION POWER CO LTD

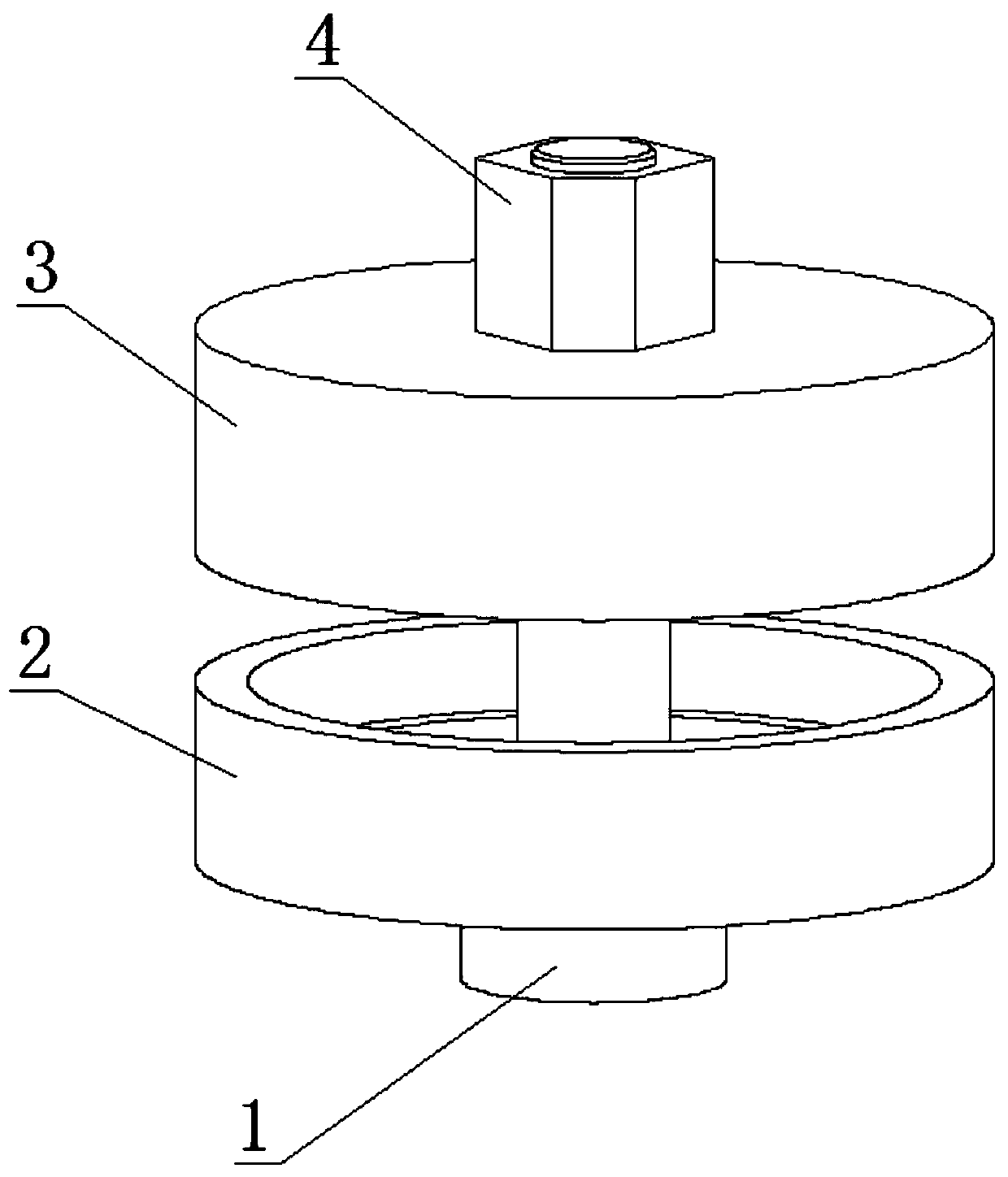

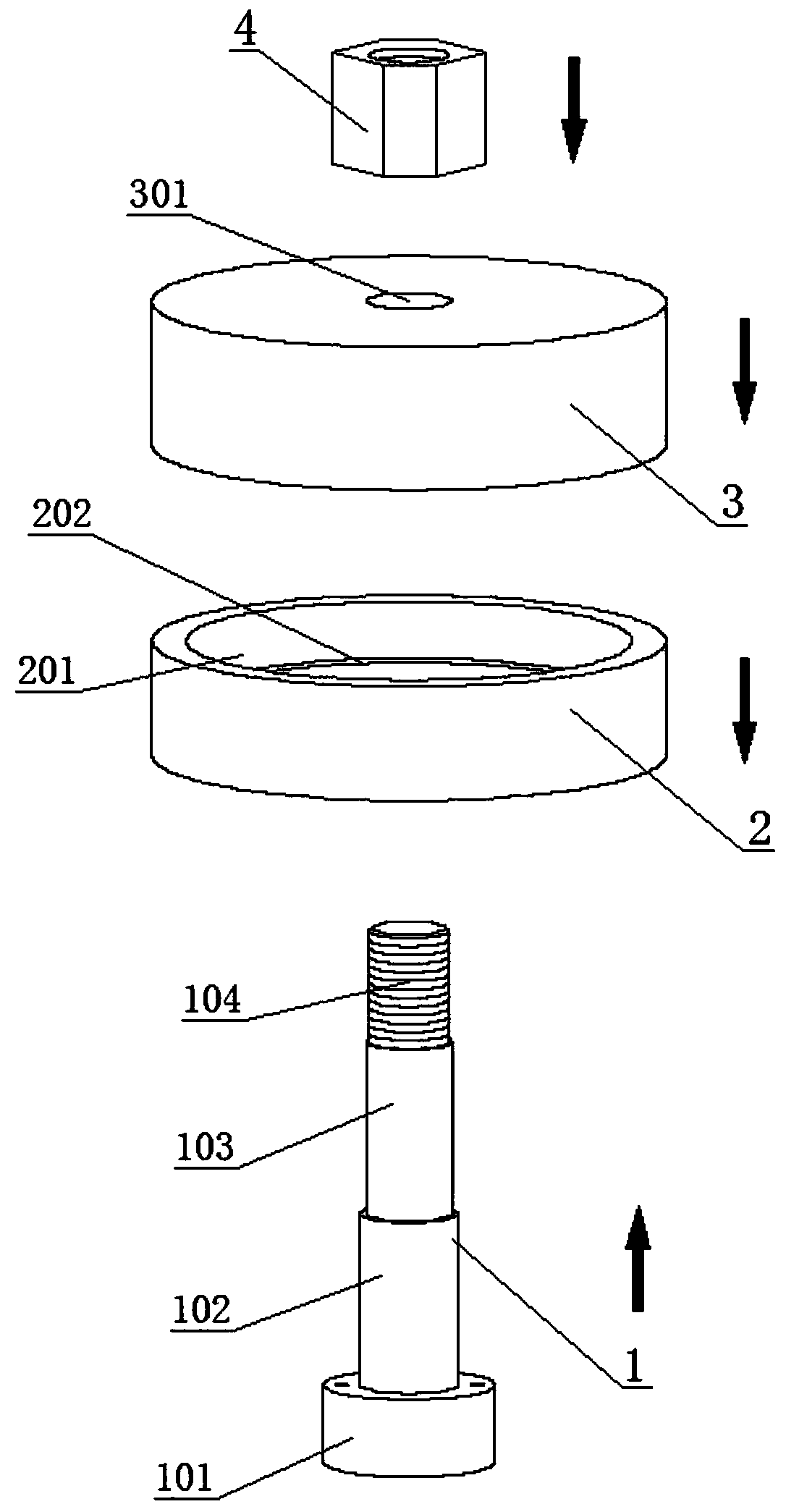

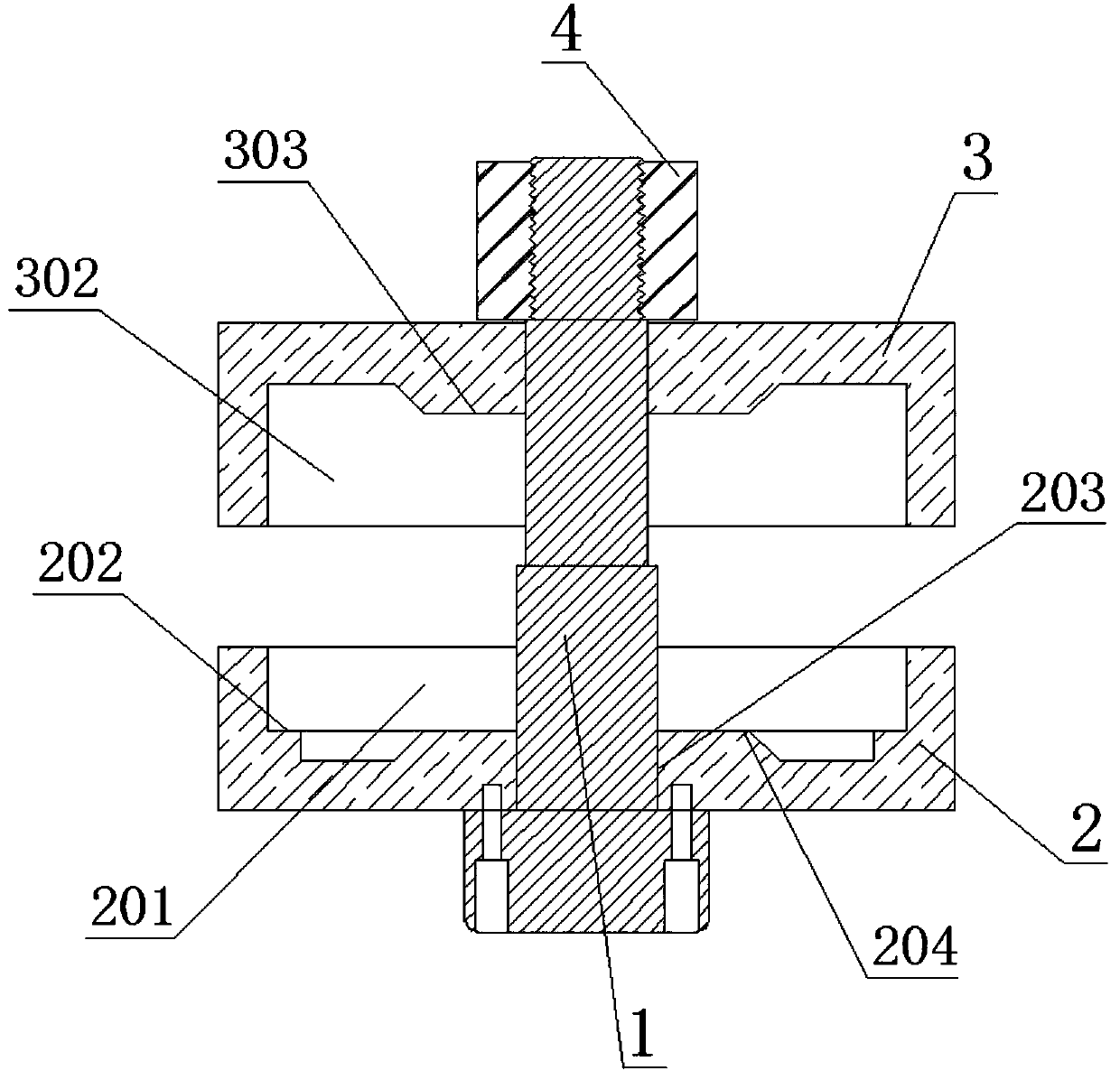

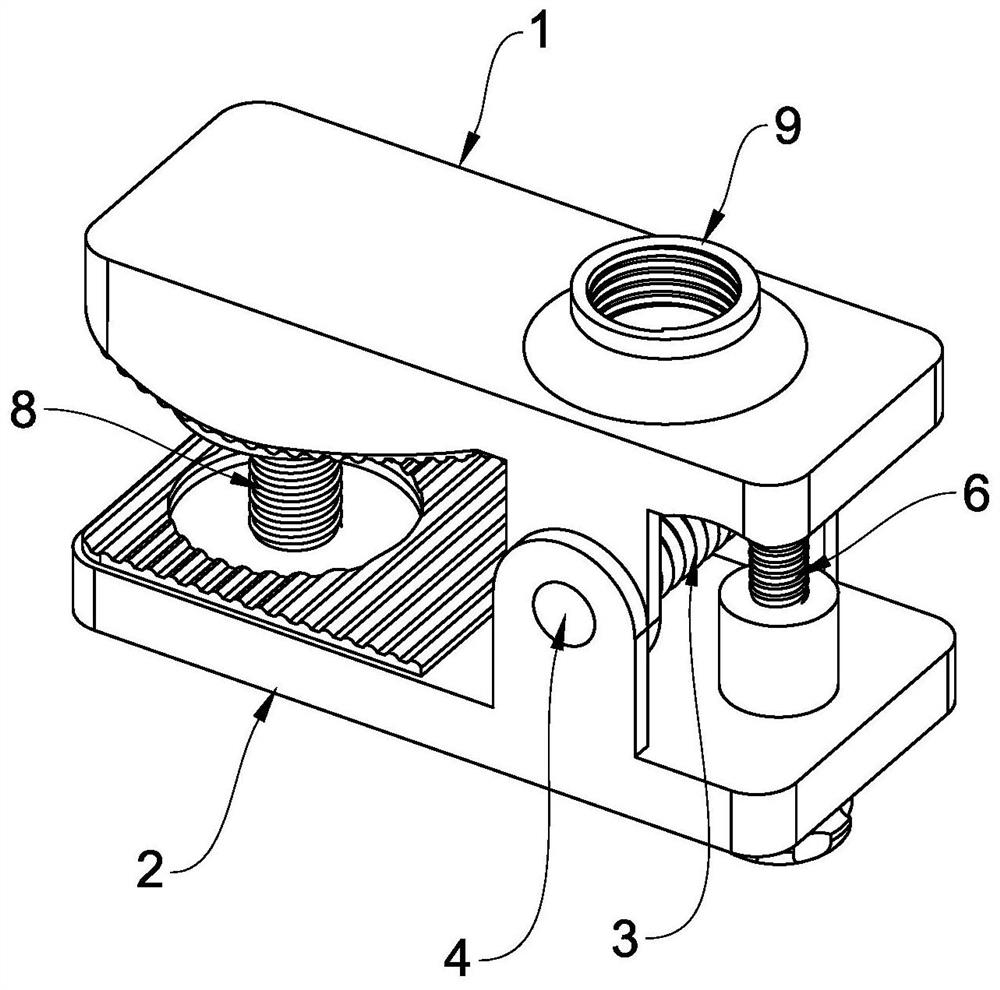

Circular seam welding tool of water pump cavity

PendingCN110893528AMake sure they are parallel to each otherSolve the poor parallelismWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention discloses a circular seam welding tool for a water pump cavity. The tool is characterized by comprising a positioning central shaft, a short sleeve positioning piece, a long sleeve positioning piece and a locking and unlocking nut, the short sleeve positioning piece and the long sleeve positioning piece both sleeve the positioning central shaft, the long sleeve positioning piece is positioned above the short sleeve positioning piece, the locking and unlocking nut is screwed in the upper portion of the positioning central shaft, and the positioning central shaft is provided with alimiting and fixing area, a short sleeve sleeving area, a long sleeve sleeving area and a threaded area. The welding tool is simple in structure and concentrically installed, a large hole body, a flow deflector, an inner shell and a small hole body can be installed in the inner sides of short and long cavity sleeves at the same time, positioning is accurate, the parallelism degree is high, clamping is firm, and circular seams of a connecting area of the short and long cavity sleeves can be welded conveniently.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

A fine-tuning mechanism with a lockable balance wheel and fast and slow needles

ActiveCN106950812BEasy to adjustEasy and fast coarse adjustmentFrequency setting mechanismEngineeringMechanical watch

The invention discloses a fine-tuning mechanism for a fast and slow needle that can be locked by a balance wheel with a card, comprising a balance splint, a hairspring outer post, a hairspring, a shock absorber, a balance wheel and a speed and slow needle mechanism. The balance splint is fixed on the movement of a mechanical watch. Above, the inner end of the hairspring is connected to the balance wheel shaft, and the speed needle mechanism is composed of a speed needle body, a hairspring clamp, a speed needle connecting rod and a fine-tuning screw of a large cap and a small eccentric shaft. The body and the speed needle connecting rod are set on the pendulum cleat through the shock absorber, the hairspring is arranged in the hairspring clamp, and the outer end of the hairspring is fixedly connected with the outer pile of the hairspring, and the hairspring clamp is composed of a hairspring locking flap and a hairspring It consists of moving lock flaps. The hairspring outer post and the speed needle of the present invention can be fixed and easy to adjust, the hairspring and the hairspring clip are firmly attached, which is convenient for the rapid coarse and fine adjustment of the position of the speed and slow needle body, and the structure is reasonable, and the accuracy of the watch is improved. s efficiency.

Owner:李国强

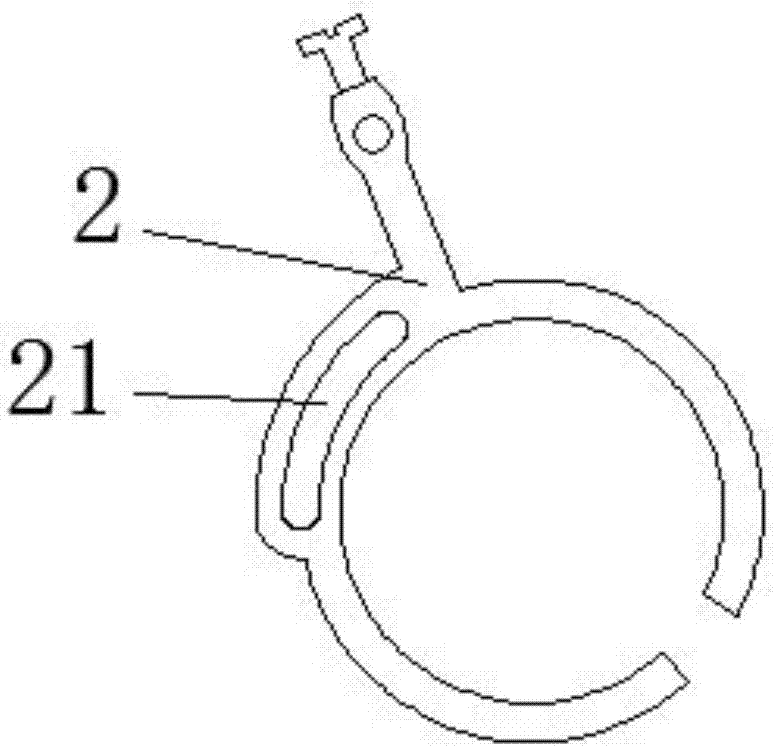

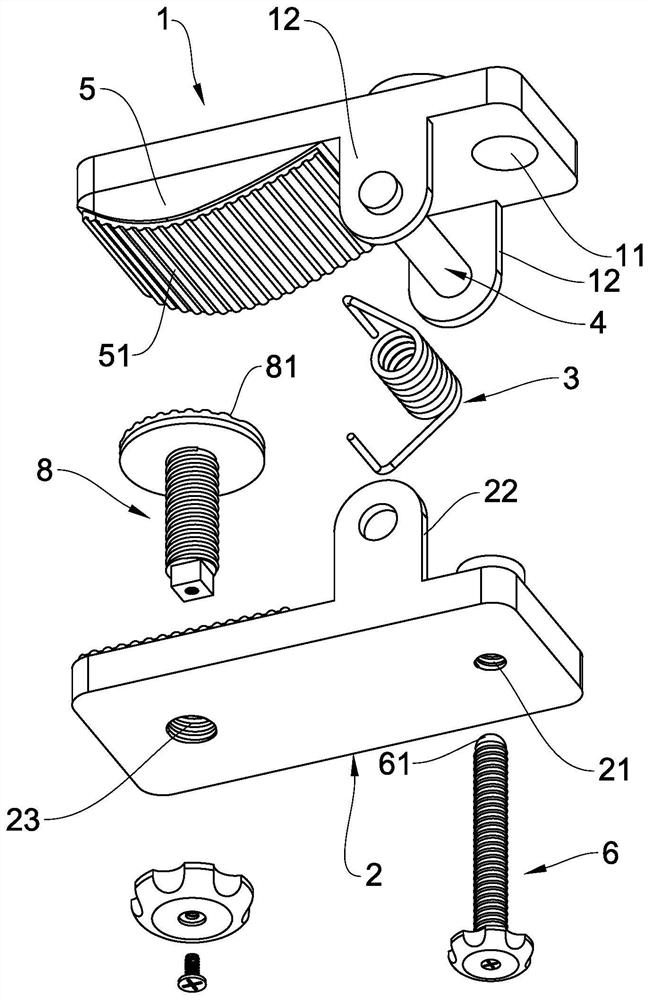

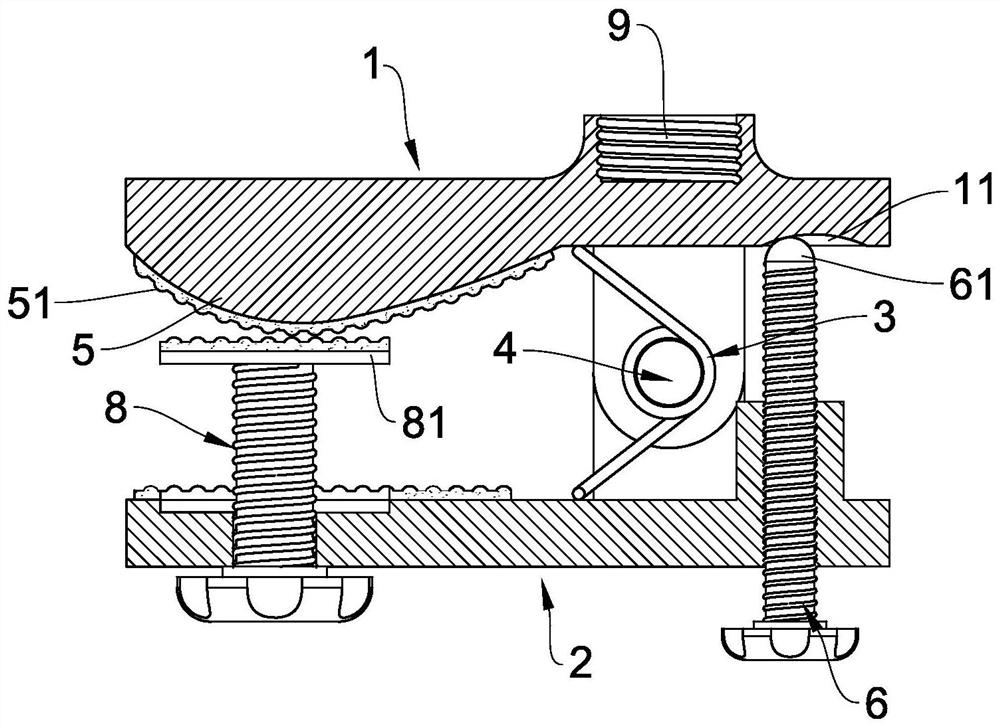

Firmly-clamping lever-type clamping device

PendingCN112438560AFastenedLock firmlyKitchen equipmentDomestic articlesElastic componentClassical mechanics

The invention relates to a firmly-clamping lever-type clamping device which comprises a first clamping component, a second clamping component, an elastic component, a pin shaft and a puller bolt. Thefirst clamping component and the second clamping component are assembled in a hinged mode, and the elastic component is arranged between the first clamping component and the second clamping component.One end of the second clamping component is provided with a screw hole for screwing the puller bolt, and the puller bolt is screwed in the screw hole. The inner side face of one end of the first clamping component is further correspondingly provided with a concave position for the puller bolt to abut against, the inner side face of the other end of the first clamping component is further providedwith an arc-shaped protruding part, the surface of the arc-shaped protruding part is further provided with insection, and the puller bolt abuts against the concave position. The clamping device is firm and reliable in clamping, does not loosen, is very safe in clamping and locking, and can carry out clamping and does not loosen even if the clamping device clamps a moving or vibrating object.

Owner:彭志军

A kind of multifunctional climbing device for distribution network of power supply company and its assembling method and using method

ActiveCN112274878BImprove versatilityLarge clamping rangeClimbingControl engineeringDistribution networks

Owner:STATE GRID SHANDONG ELECTRIC POWER CO BOXING POWER SUPPLY CO

A chain piece clamping device and chain piece processing equipment with the device

ActiveCN105945613BEasy to put inClamp fasteningPositioning apparatusMetal-working holdersMachiningIndustrial engineering

The invention discloses a chain sheet clamping device and a chain sheet machining equipment provided with the same and relates to the field of a clamping device for clamping a chain sheet and a chain sheet machining equipment. The chain sheet clamping device comprises a mounting pedestal which is mounted on the chain sheet machining equipment, and a first end propping-up mechanism and a second end propping-up mechanism which are relatively arranged on the mounting pedestal at an interval for propping up two ends of the chain sheet; the first end propping-up mechanism comprises right-angled baffle plates and a first baffle plate; the second end propping-up mechanism comprises second baffle plates and clamping arms. The chain sheet clamping device can clamp the chain sheet at one time to machine different holes, so that the machining precision and production efficiency are improved. The chain sheet machining equipment comprises a base, the chain sheet clamping device which is arranged on the base and a first machining knife tackle which is arranged on the base and is arranged correspondingly perpendicular to the chain sheet clamping device. The equipment can process a plurality of chain sheets simultaneously, is stable to clamp, can enhance the machining precision, and further can greatly enhance the machining and production efficiency.

Owner:QUANZHOU LIANTUO MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com